Method for dismantling coke oven column and protection plate

A technology for protection boards and columns, which is applied in coke ovens, coke oven heating, coke oven components, etc., can solve the problems of inconvenient removal of coke oven columns and protection panels, high safety risks in demolition construction, and complex coke oven structures and other issues, to achieve the effect of shortening the construction period, reducing engineering costs, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The construction process of the coke oven column and protective plate removal method of the present invention:

[0035] Remove the coke oven door and door frame → spring pressure relief on the upper and lower horizontal braces of the coke oven machine and coke side furnace columns → welding steel plates near the furnace pillars on the upper and lower horizontal braces of the coke oven machine and coke side → assembly of protection plates and setting of lifting points →The crane is in place→Fix the furnace column and protective plate with steel wire rope, and the lifting force is applied→Flame cutting of the upper horizontal brace→Removal of the lower horizontal brace nut and spring baffle→Lifting off the furnace column→Lifting off the protective plate.

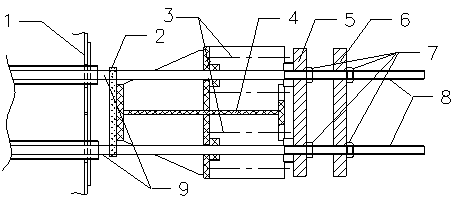

[0036] see now figure 1 , figure 1 It is a schematic diagram of technical measures for removing coke oven columns and protective panels in an embodiment of the present invention. Coke oven column of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com