Thermal-exchange construction method of coke oven column

A construction method and furnace column technology, which is applied in the field of coke oven column thermal replacement construction, to achieve high economic benefits, reduce maintenance costs, and reduce impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

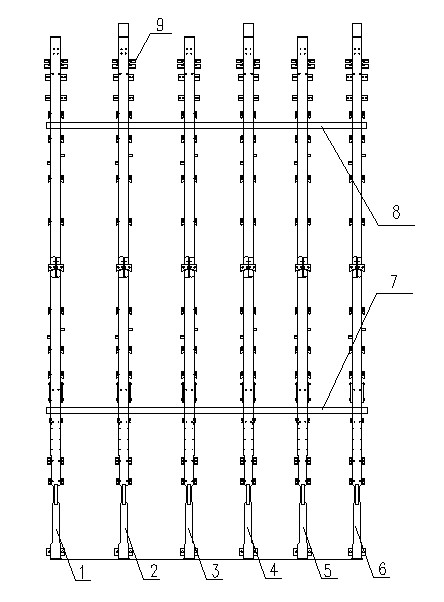

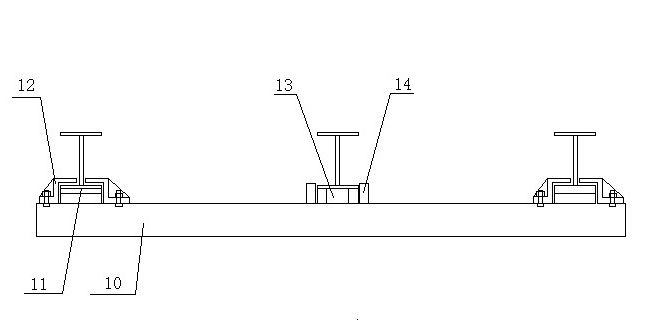

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

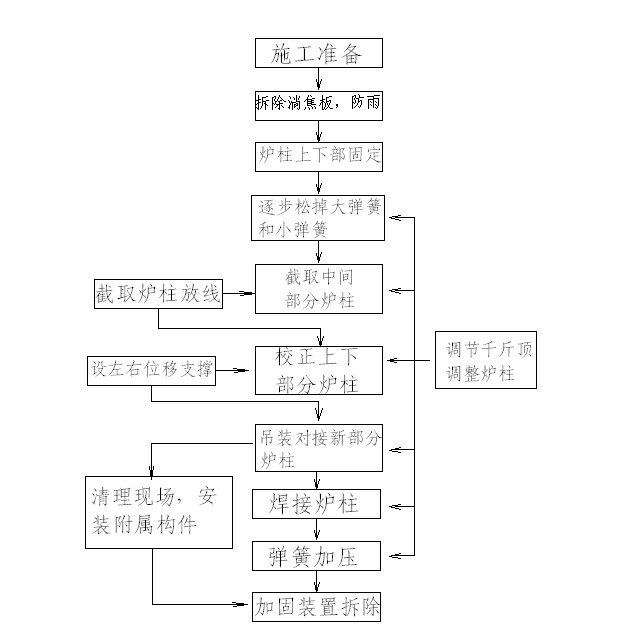

[0032] The coke oven column heat replacement construction method described in the present invention is carried out without affecting the coke oven production. Due to the short construction time and complicated construction location, any possible situation may occur during the construction process, so the construction The preparation work is very important, and the specific preparation work includes:

[0033] Site preparation:

[0034] ①Remove the auxiliary components such as coke-flowing plates and rain-proof plates on both sides of the maintenance furnace column on the coke side of the corresponding machine.

[0035] ②Make the beam of the temporary fixing frame of the furnace column and transport it to the site.

[0036] Materials and equipment preparation:

[0037] ① Part of the furnace column after production needs to be transported to the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com