Furnace stay fixing device used for replacing coke oven cross brace

A fixing device and horizontal bracing technology, applied in the direction of the furnace foundation and other directions, can solve the problems affecting the normal production of coke ovens, the fixing effect of the furnace column is not good, and there are potential safety hazards, so as to achieve a good fixing effect, shorten the replacement time and operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

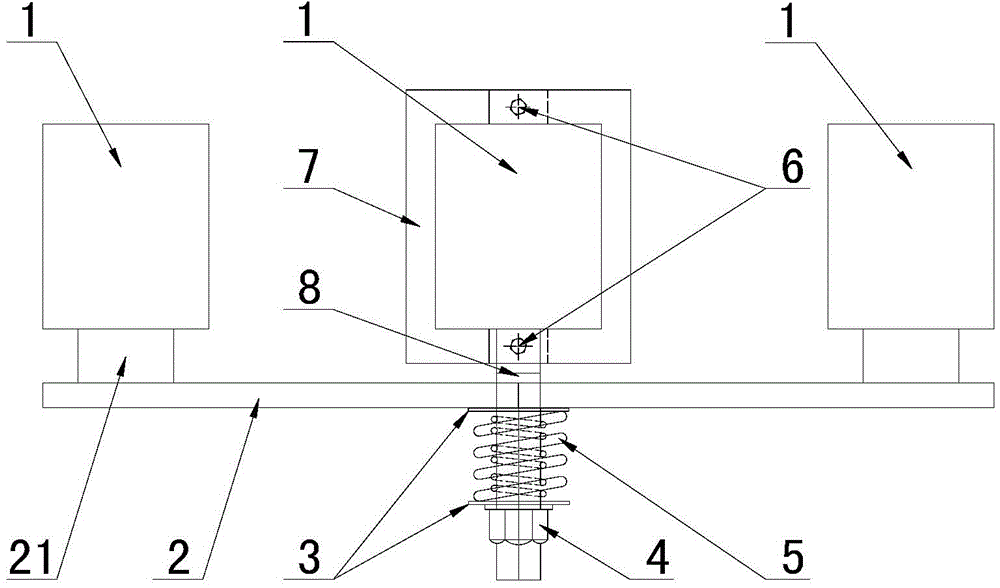

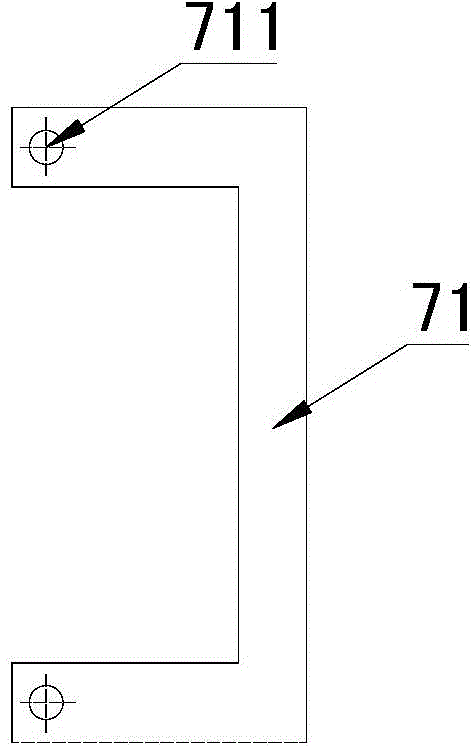

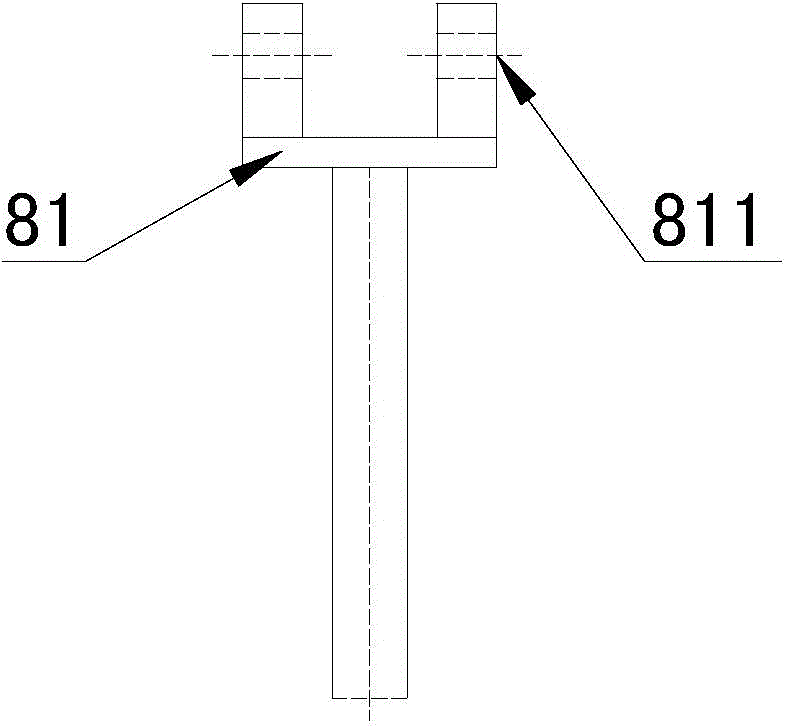

[0028] see Figure 1 ~ Figure 3 , figure 1 It is a schematic diagram of the layout of the furnace column fixing device for replacing the coke oven horizontal brace provided by the present invention, figure 2 yes figure 1 Schematic diagram of middleware 7, image 3 yes figure 1 Schematic diagram of middleware 8.

[0029] A furnace column fixing device for replacing a coke oven horizontal brace provided by the present invention includes a beam 2 , a nut 4 , a compression spring 5 , a connecting piece 7 and a tie rod 8 .

[0030] Wherein, the length of the crossbeam 2 is not less than twice the distance between two adjacent furnace pillars 1, a through hole (not shown) is provided in the middle of the crossbeam 2, and a foot portion perpendicular to the long direction of the crossbeam 2 is provided near the two ends of the crossbeam 2 21....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com