Base structure of coke oven

A basic structure and coke oven technology, applied in the field of coke oven basic structure, can solve the problems of increasing the complexity of furnace body design and furnace structure, achieve the effect of improving construction speed and construction quality, novel structural system, and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

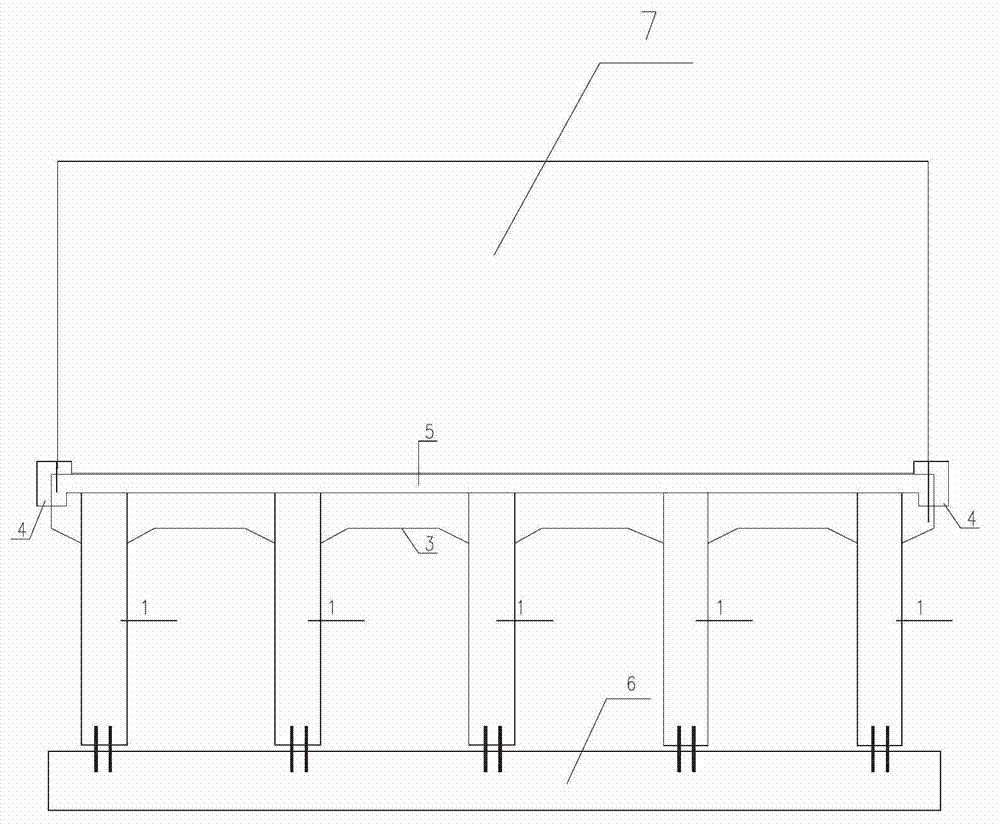

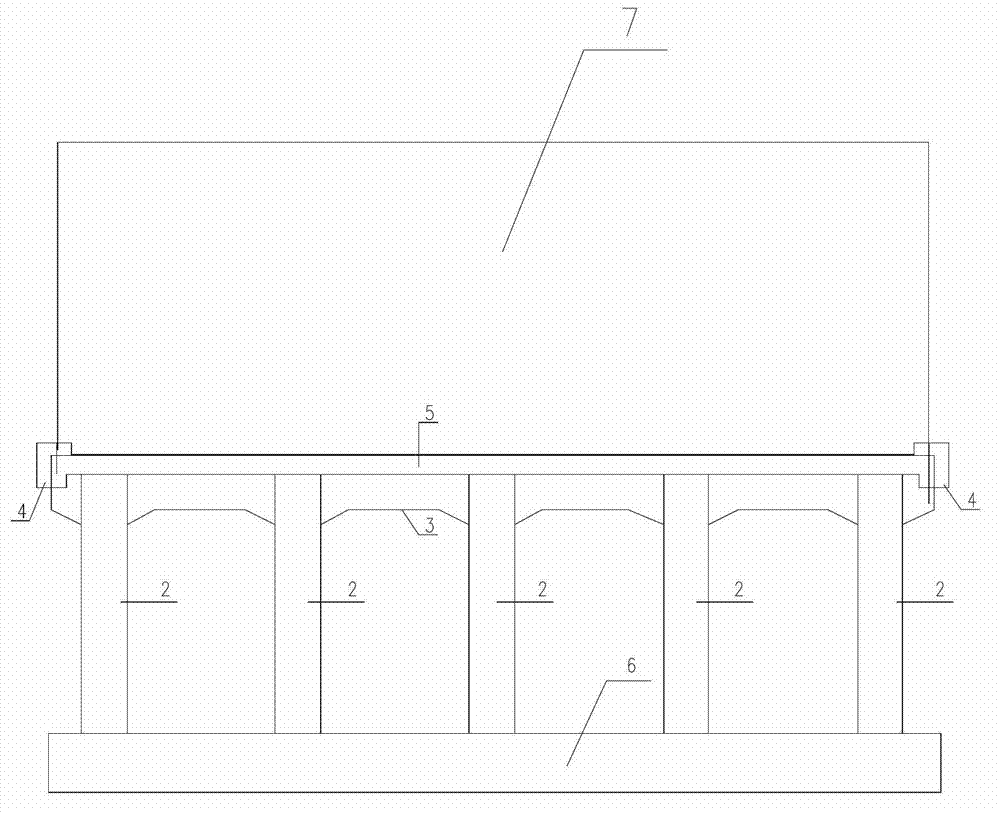

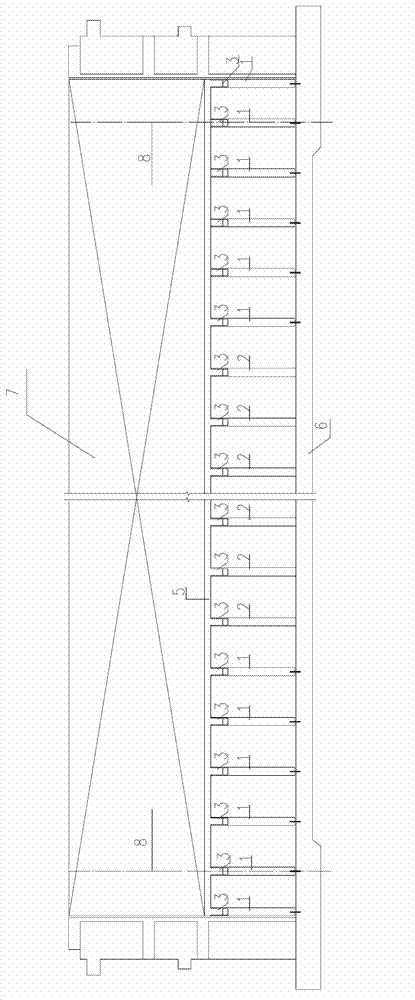

[0023] Concrete embodiment: 7m coke oven foundation structure, see figure 1 , figure 2 , is a frame system composed of 35 rows of frames, 2 side beams 4 and 1 roof 5. It is divided into four horizontal spans, and the frame columns of each span have the same column spacing, and the centerline of the frame column in the middle coincides with the centerline of the coke oven; in the longitudinal direction, 6 rows of frame columns 1 counted from both ends and the bottom plate 6 are connected by hinges. , and the frame beam 3 adopts a consolidated connection method of reinforced concrete pouring. The 23 rows of frame columns 2 in the middle, the bottom plate 6 and the frame beams 3 are all connected by reinforced concrete pouring. The frame beam 3, the side beam 4 and the roof 5 are all connected by reinforced concrete pouring.

[0024] The present invention can solve the effects of temperature stress and earthquake stress at the same time for super-long concrete structures over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com