Crane girder and roof supporting structure with span greater than or equal to 100m

A technology for supporting structures and crane girders, applied to truss structures, joists, girders, etc., can solve the problem that the height and width of box crane girders cannot meet the design requirements, and achieve novel structural systems, novel structures, and clear stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

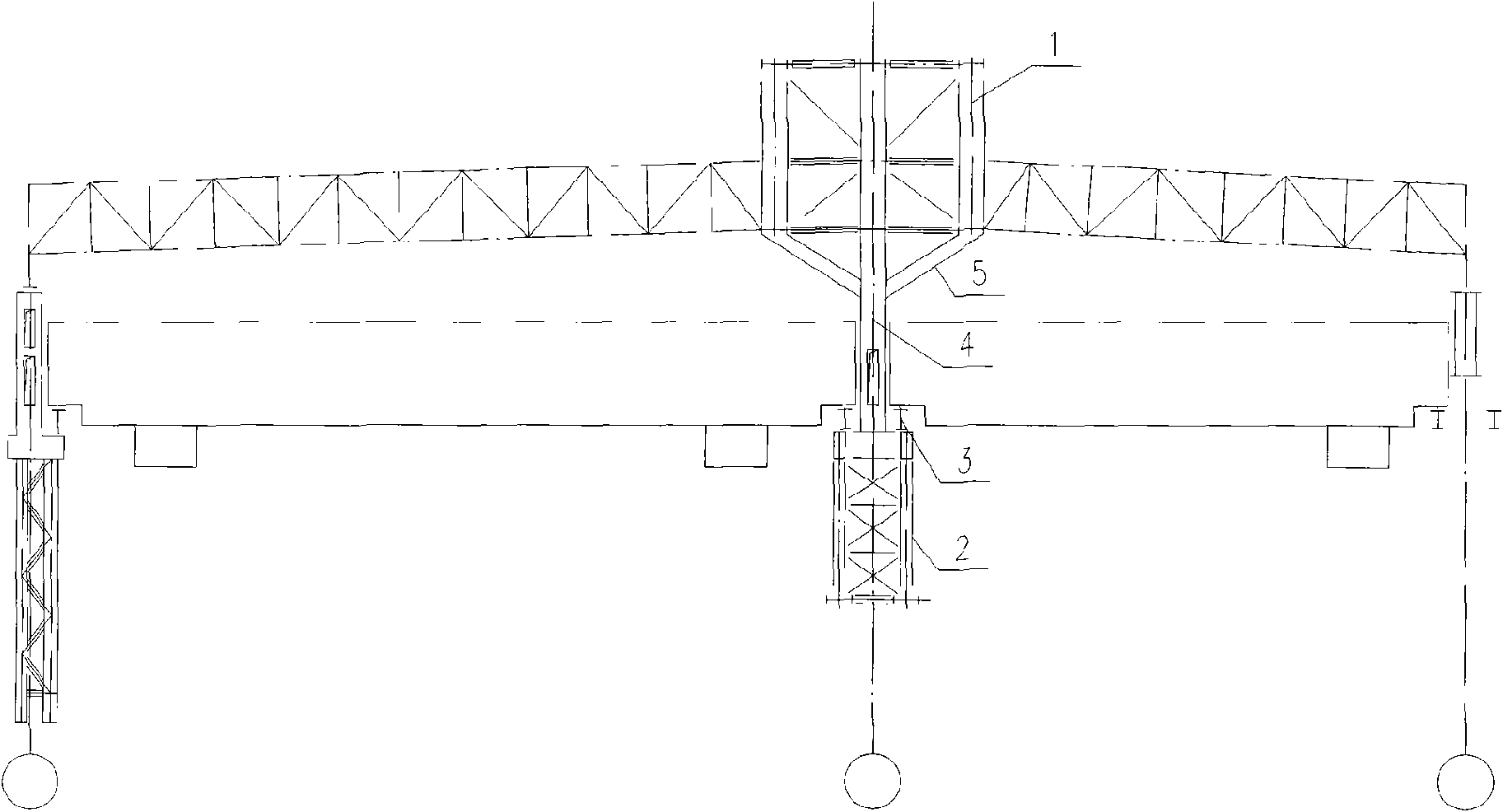

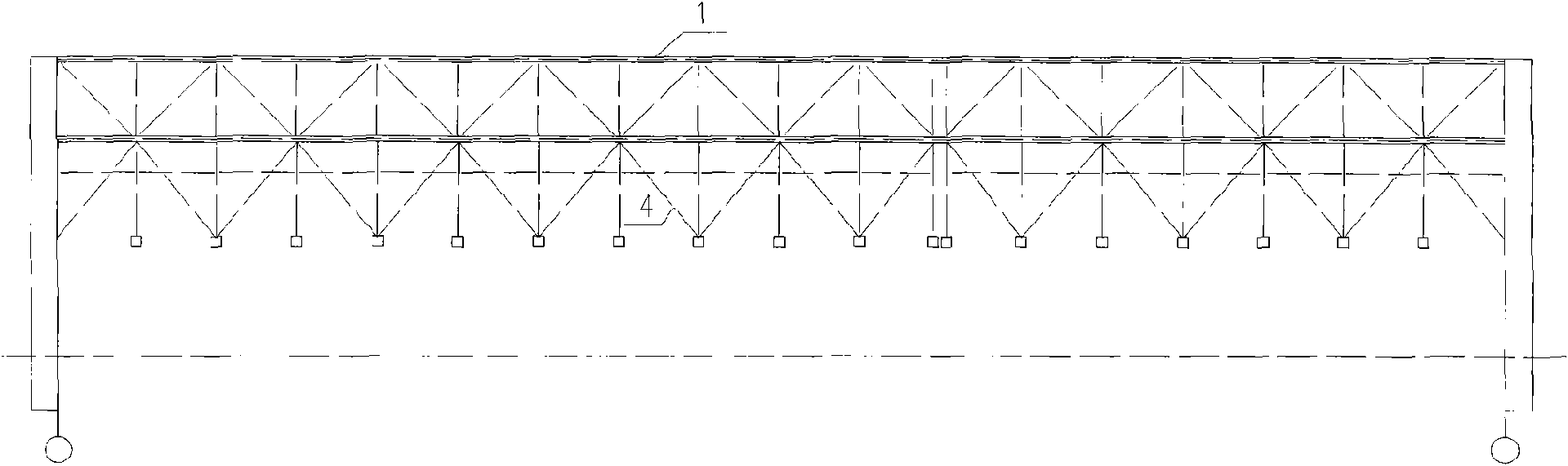

[0016] The large roof truss 1 is a cage system composed of 3 vertical trusses and 2 horizontal trusses, supported on two factory building columns (column spacing ≥ 100m), connected with the lower truss 2 through crane truss 4 and diagonal brace 5, The lower truss 2 is a cage system composed of 2 vertical trusses and 2 horizontal trusses, and both ends of the lower truss 2 are also supported on the factory building columns. The crane beam 3 is supported on the top of the lower truss 2 .

[0017] The span of the crane girder can be determined according to the 2 sections of the lower truss, and the span is relatively small. This kind of workshop structure transmits the load of the crane to the large roof truss 1 through the crane beam 3 and the crane truss 4. The space of the large roof truss 1 is relatively small, and when the span is large, the height and width of the truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com