Local-slippage construction method of furnace column

A construction method and furnace column technology are applied in the field of local slippage construction of the furnace column, which can solve the problems of affecting the construction period, increasing the construction cost, and many hidden dangers, and achieving the effect of saving the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

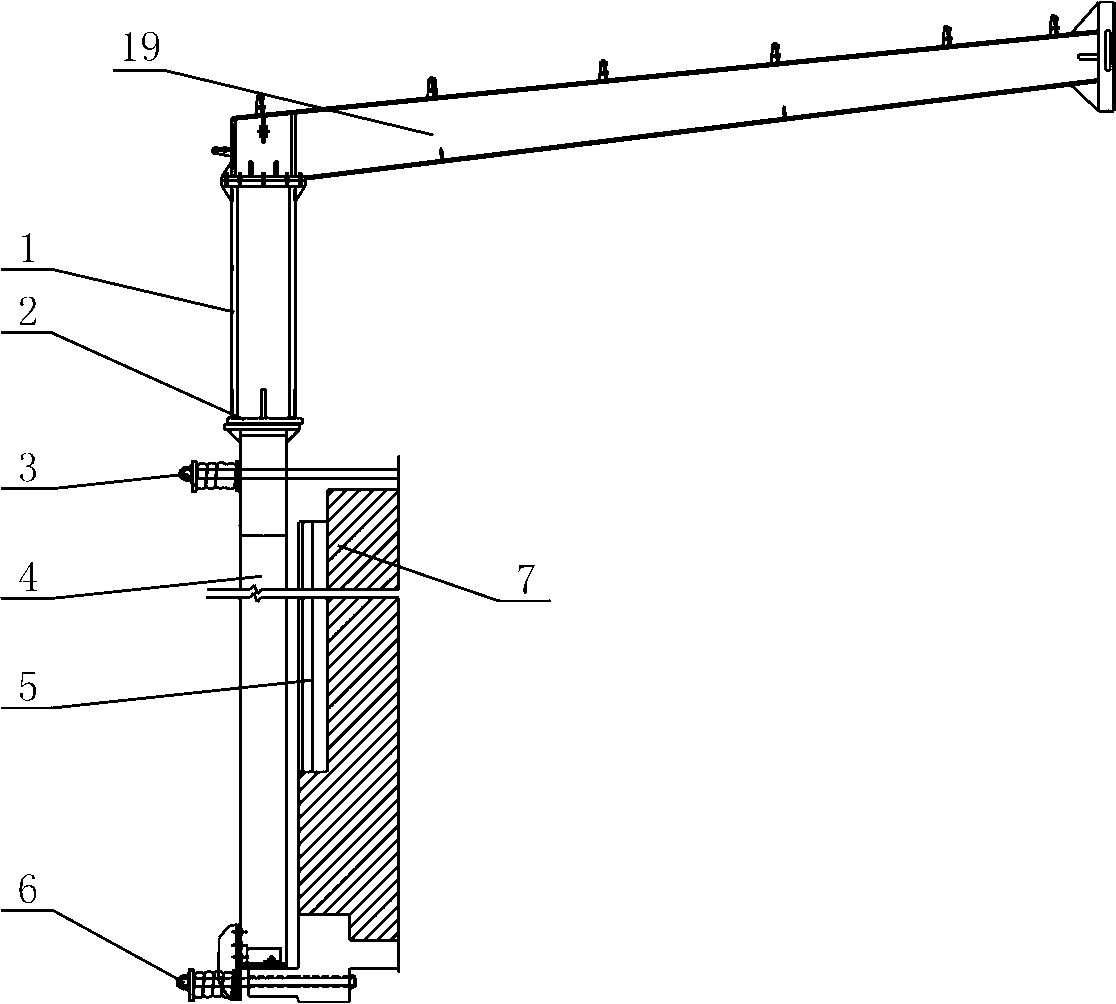

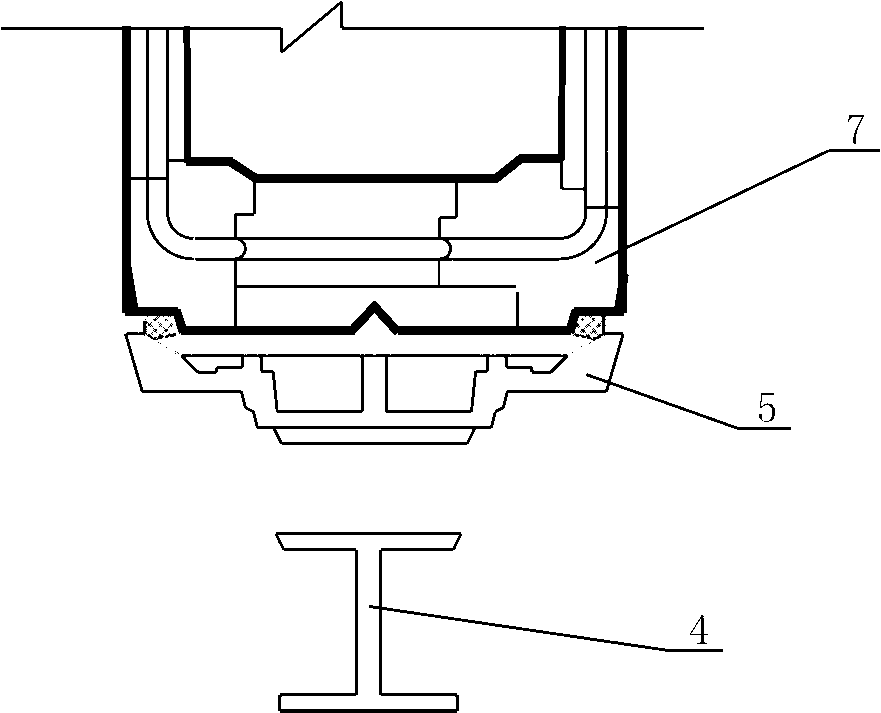

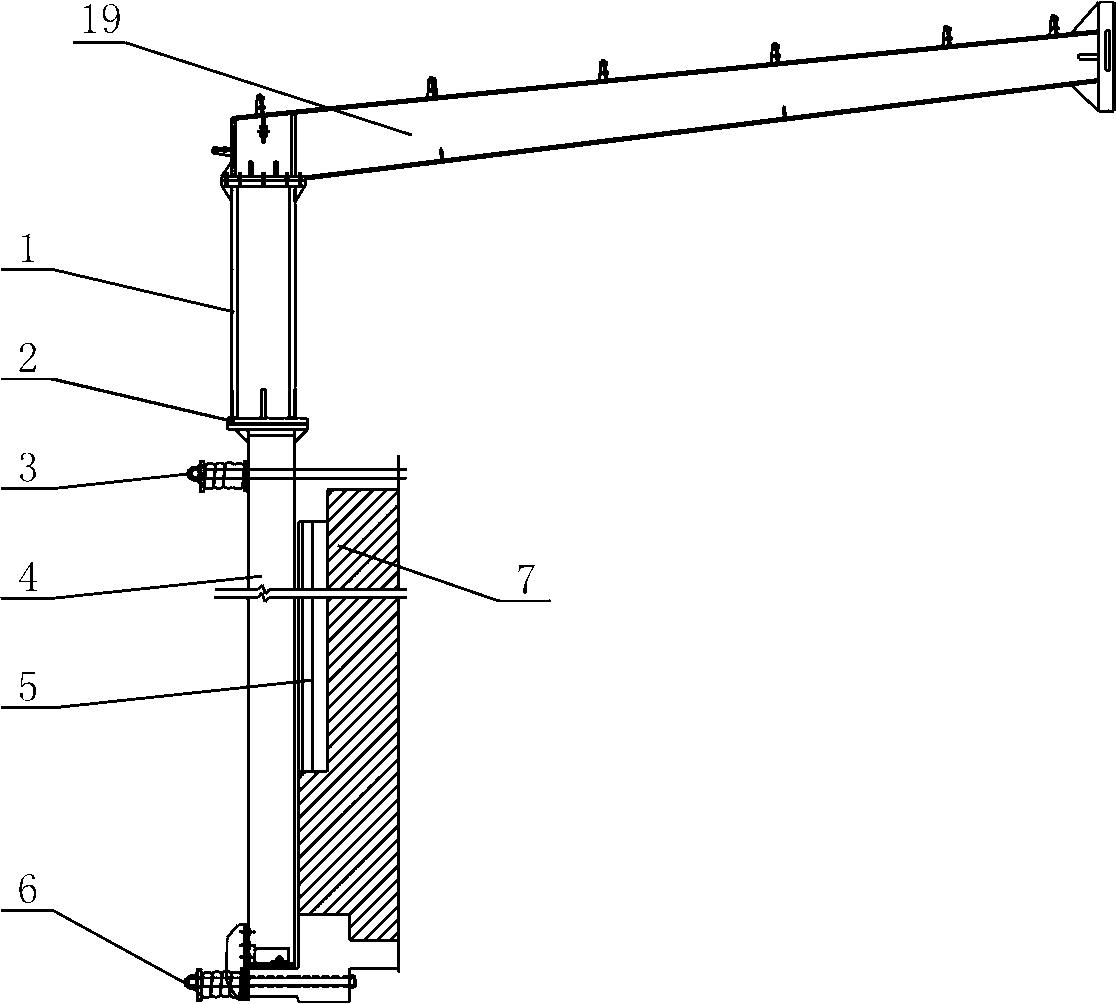

[0023] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with implementation examples and accompanying drawings. Among them, such as figure 1 As shown, the outer side of the coke oven head 7 is provided with a protective plate 5 . A furnace pillar 4 is arranged on the outer side of the protective plate 5 . After the furnace column 4 moves to the outside for a certain distance, the protective plate 5 and the furnace column 4 are spaced apart. Such as image 3 As shown, when the furnace pillar 4 moved to the normal position inwardly, the furnace pillar 4 withstood the protective plate 5, and the protective plate 5 was close to the refractory brick on the burner head 7 of the coke oven. The upper part of the furnace column 4 is provided with an upper horizontal bracing bar 3 , and the lower part of the furnace column 4 is provided with a lower part bracing bar 6 . As in the prio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com