Installing method for oven protecting iron component for coke oven

An installation method and coke oven technology, applied in the field of construction technology, can solve the problems of imprecise position control, inconvenient installation of iron parts, and long installation period, so as to reduce installation strength and installation safety risks, improve installation efficiency and Accuracy and construction cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

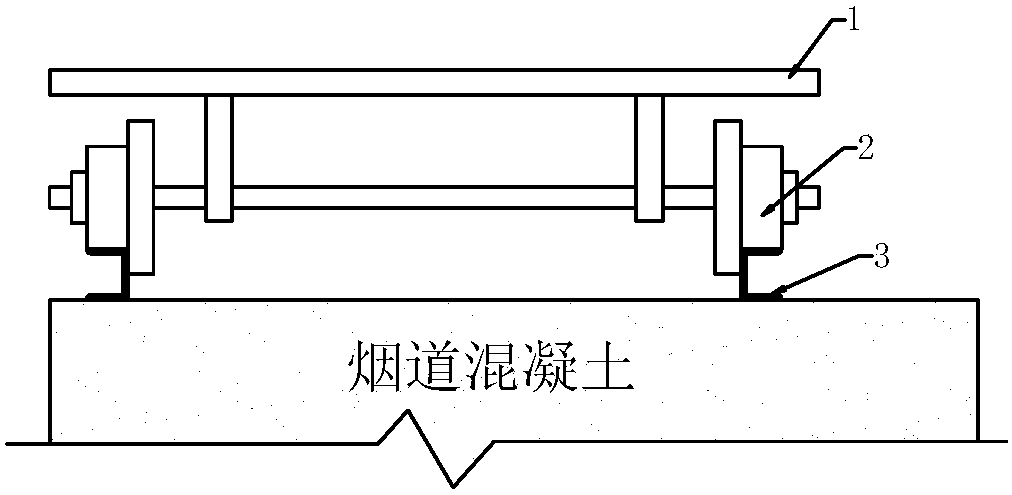

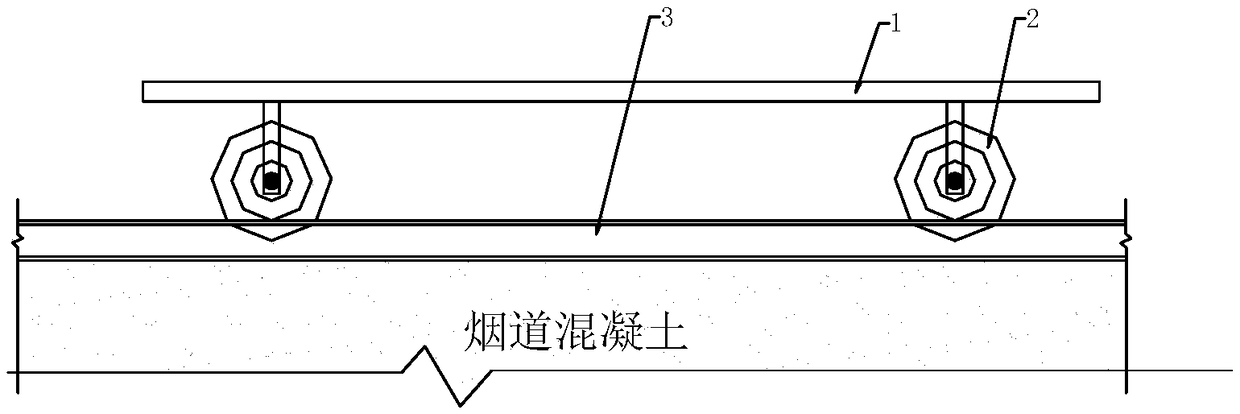

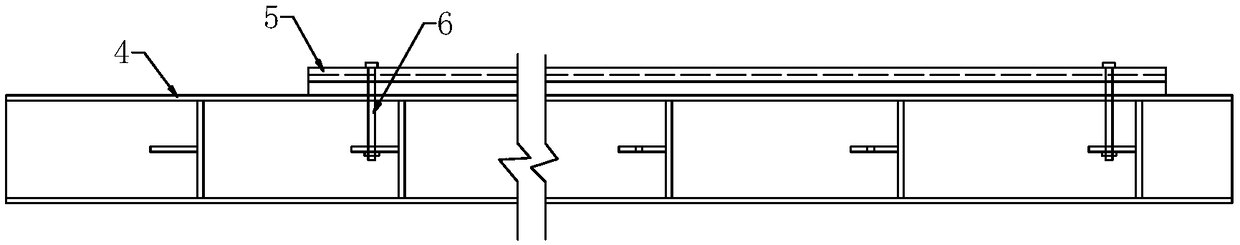

[0038] The invention relates to a method for installing and constructing various equipment parts of iron parts for protecting a new coke oven body. The overall idea of the construction method of the present invention is to assemble the installation modules on the ground workbench through a set of new installation process, special assembly tools and control means, and then install each module in place in sequence.

[0039] Overall process flow:

[0040] Furnace pillar and protective plate transportation→furnace pillar and protective plate assembly→furnace pillar and protective plate overall hoisting→furnace door frame transportation

[0041] → Furnace door frame hoisting → Furnace door transportation → Furnace door hoisting.

[0042] Specific construction:

[0043] Since the coke oven shed has not been dismantled during the installation of the iron parts for the furnace protection, the coke oven materials mainly enter from the reserved entrance on the machine side of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com