Patents

Literature

142results about How to "Reduce installation risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

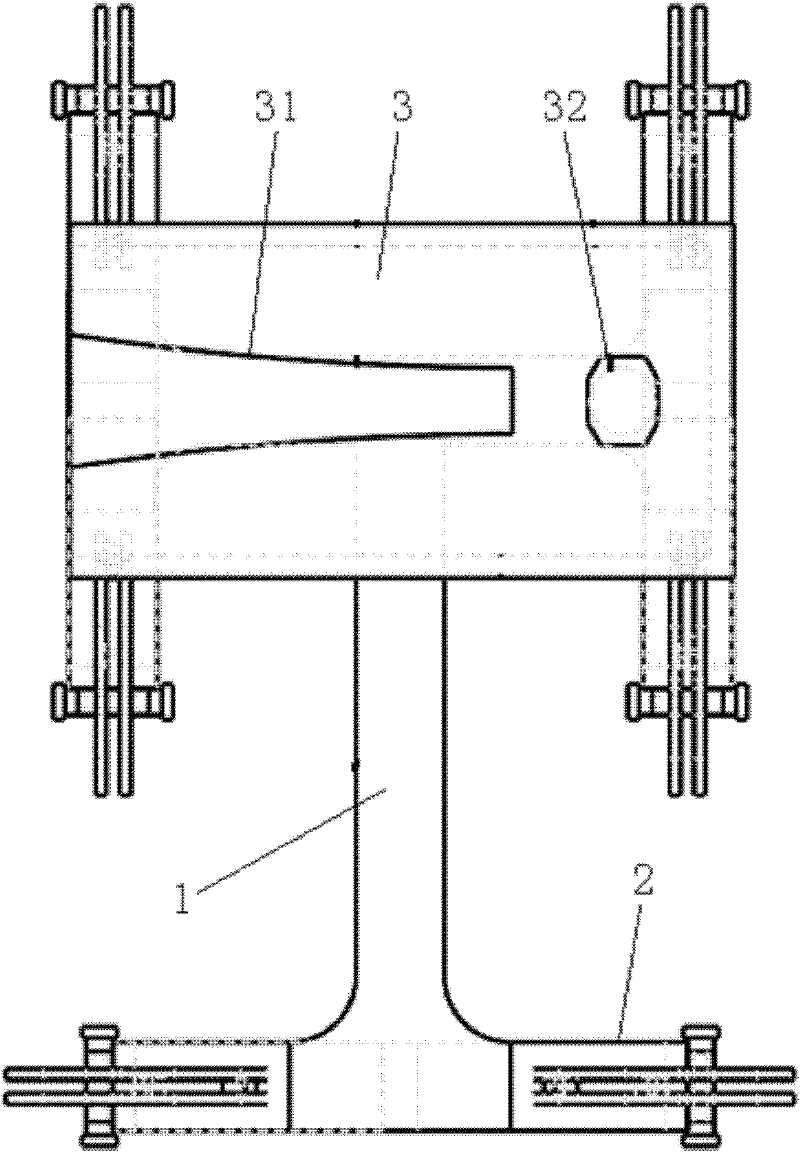

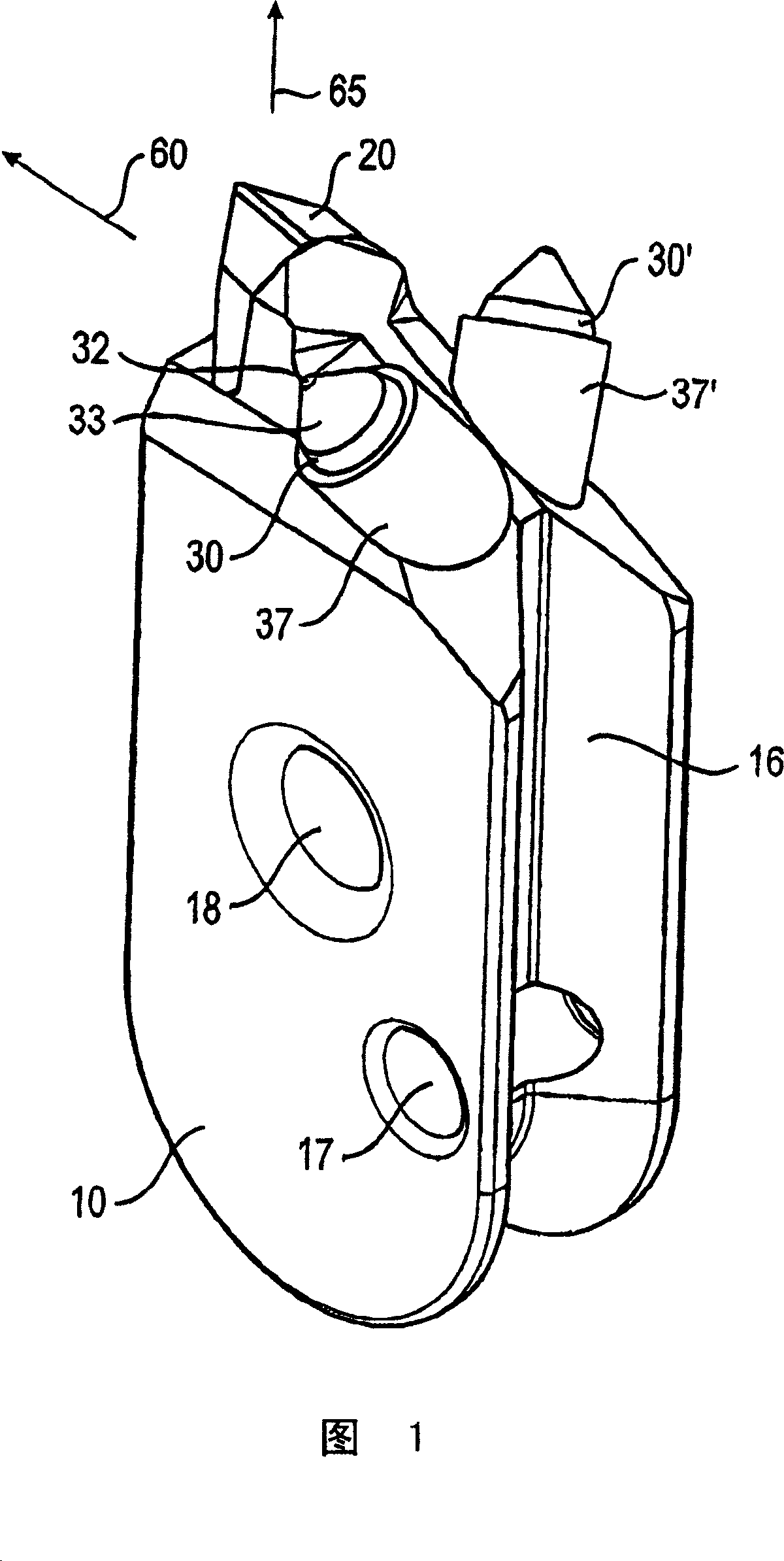

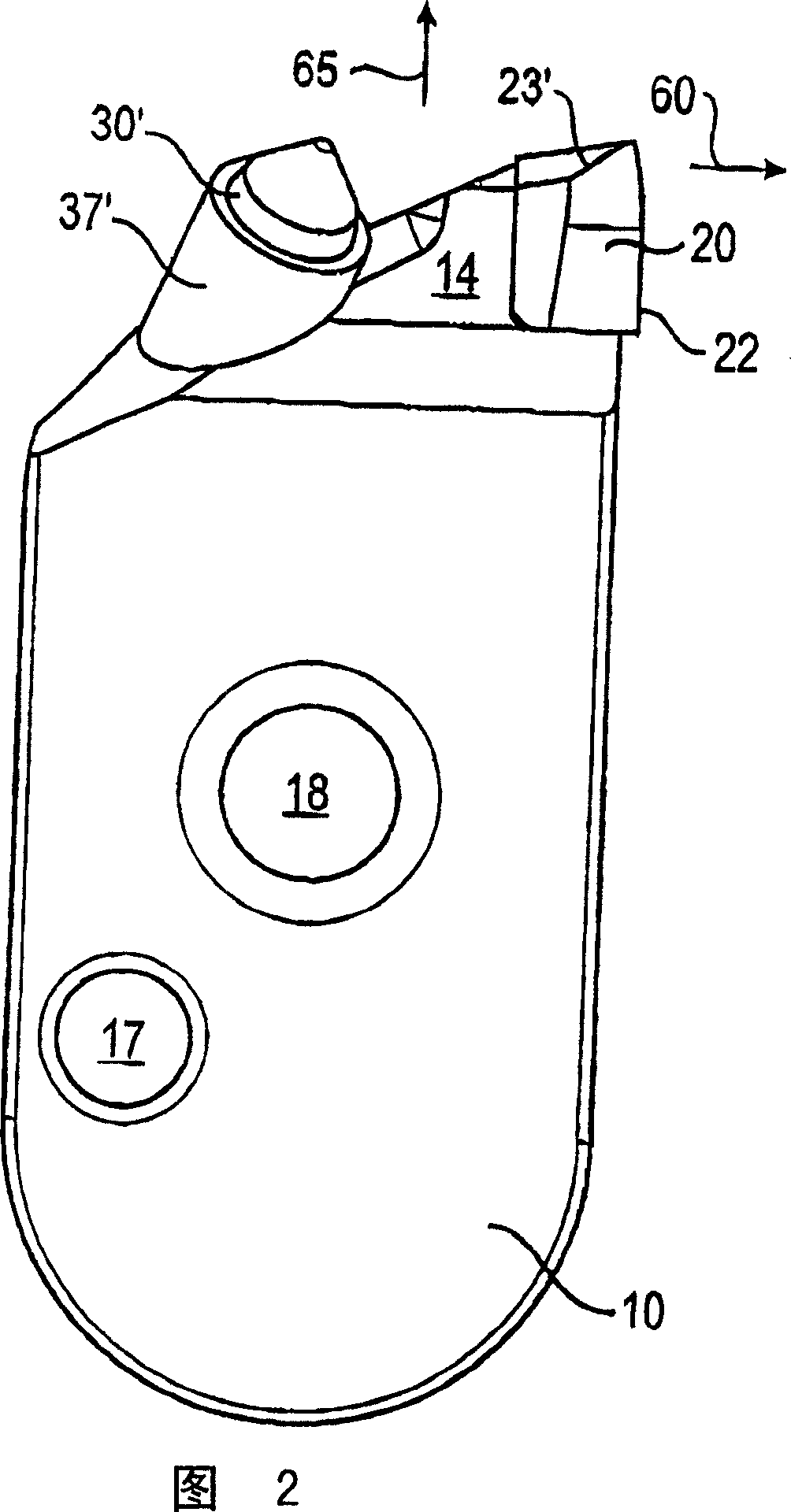

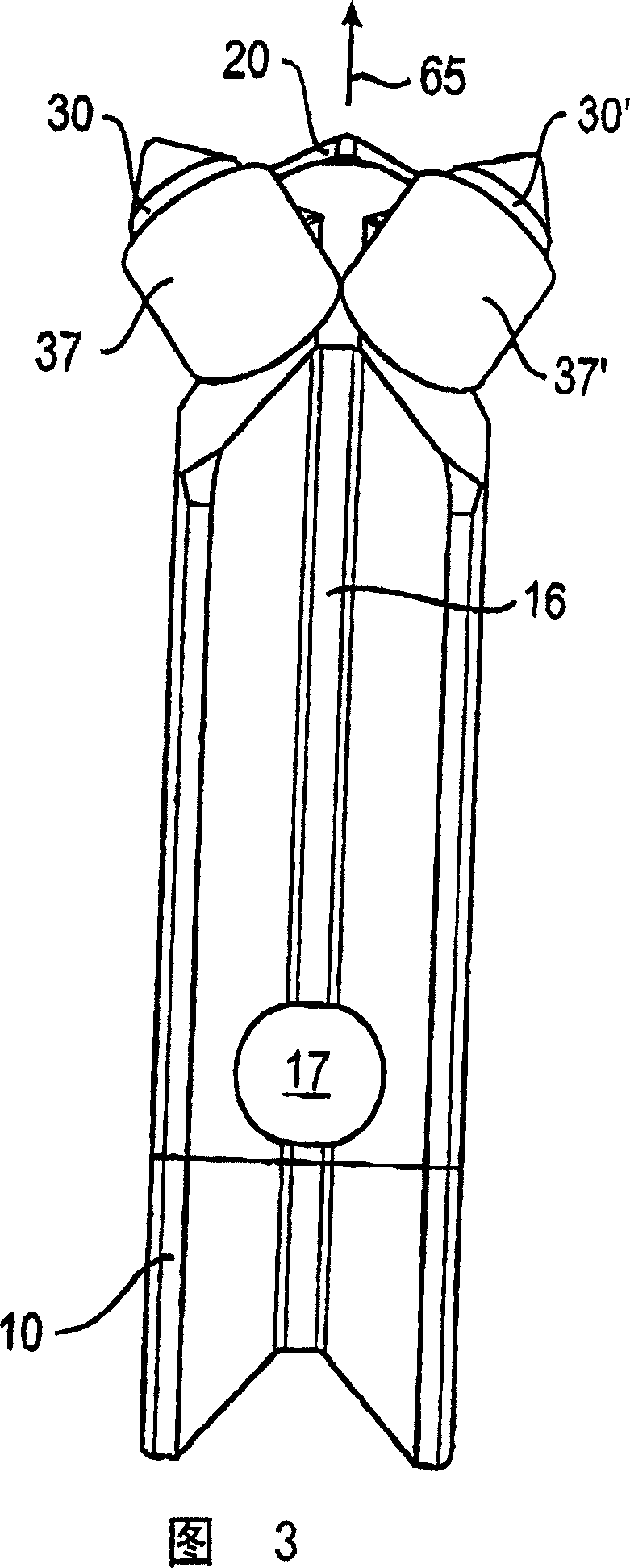

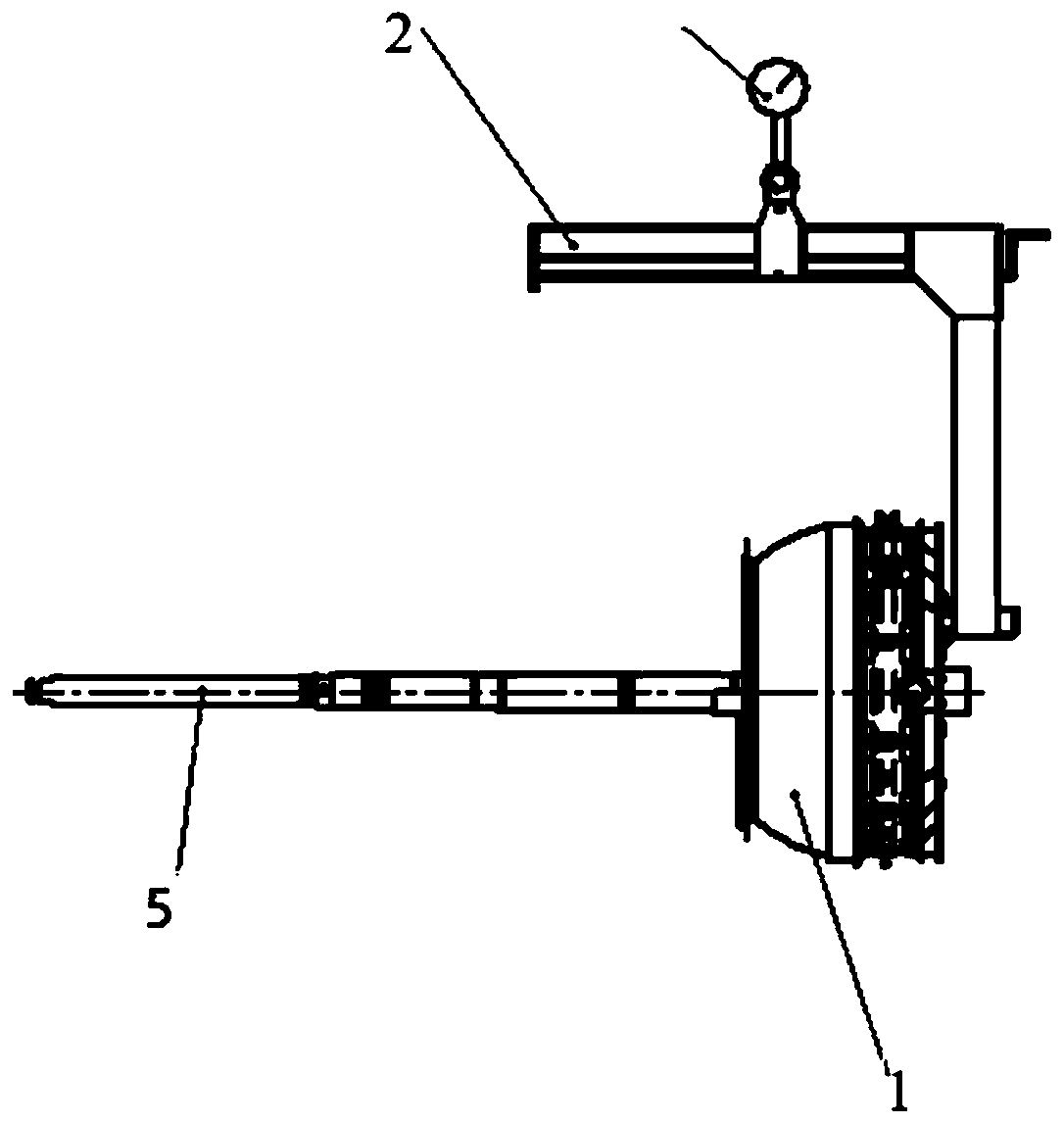

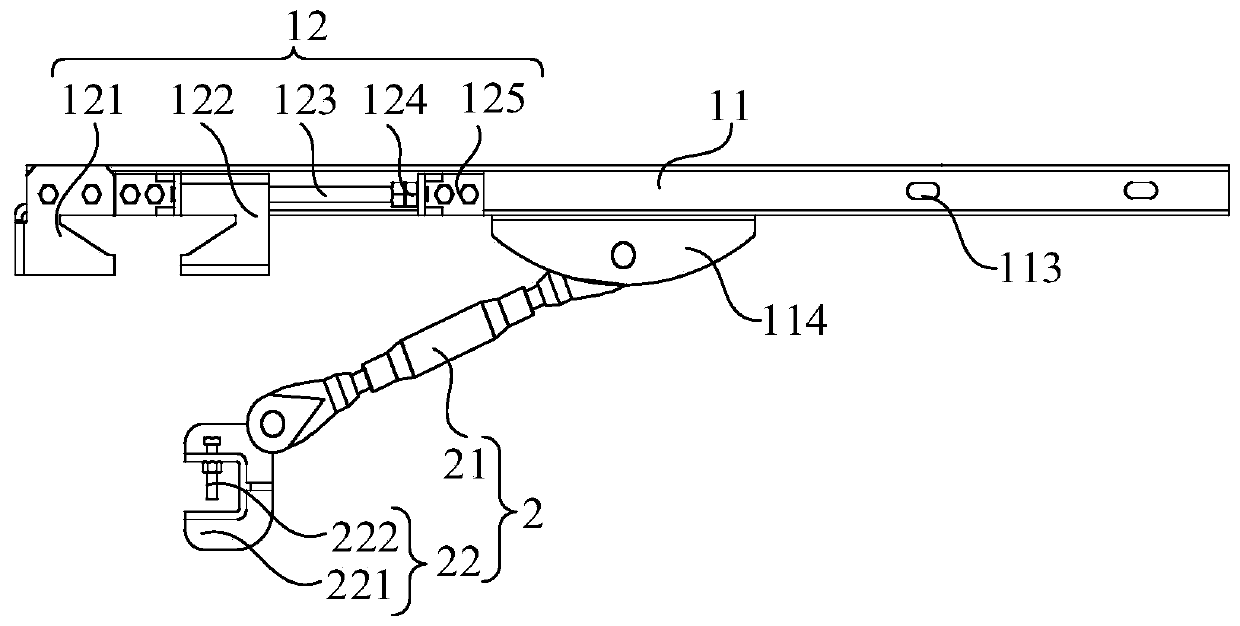

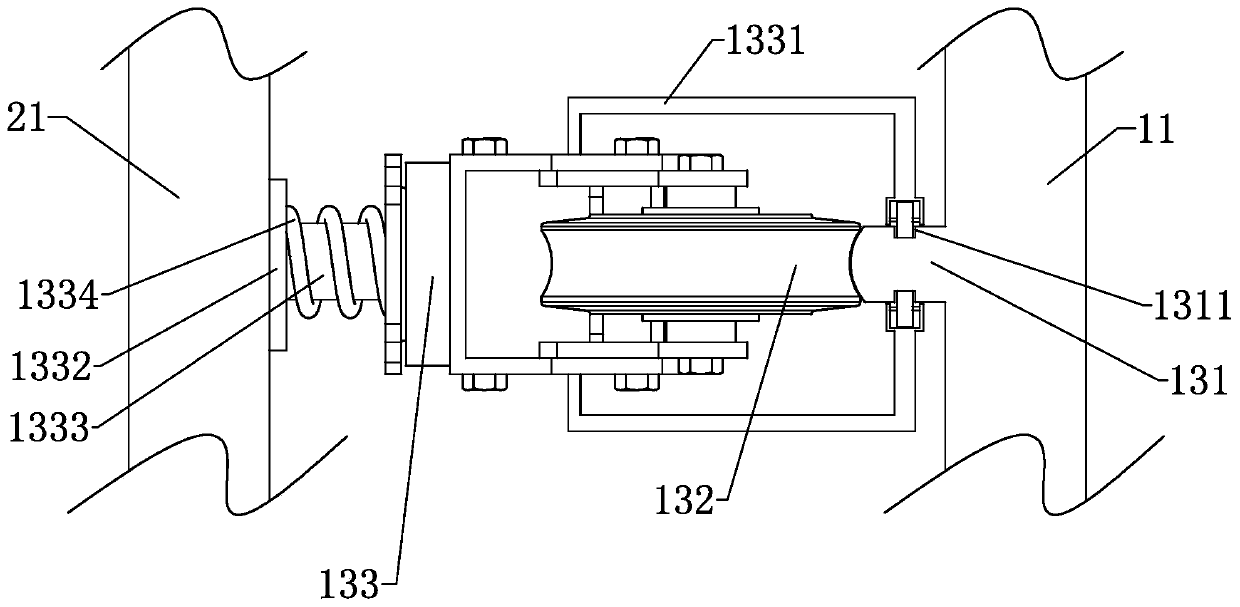

A fixture device for a ribbed anchor chain sensor on a deep-water floating platform

ActiveCN102288212APrevent rotationPrevent slidingMeasurement apparatus componentsEngineeringSelf locking

The invention relates to a fixture device of a deepwater floating platform rib anchor chain sensor. The device is characterized by comprising a T-shaped fixture body, self-locking devices and a sensor bearing cylinder; three ends of the T-shaped fixture body are respectively provided with one self-locking device; and the sensor bearing cylinder is horizontally fixed on the wing plate of the T-shaped fixture body. The device disclosed by the invention is not only used for effectively preventing the installed sensor from sliding along a chain ring but also used for preventing the sensor from rotating relative to the chain ring and ensuring the good in-place working state of the sensor. Simultaneously, a diver serves as an installation carrier; the diver can sufficiently play subjective initiative; more complex works can be completed; and installation risks resulted from reasons, such as improper operation, ocean current disturbance and the like, can be reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

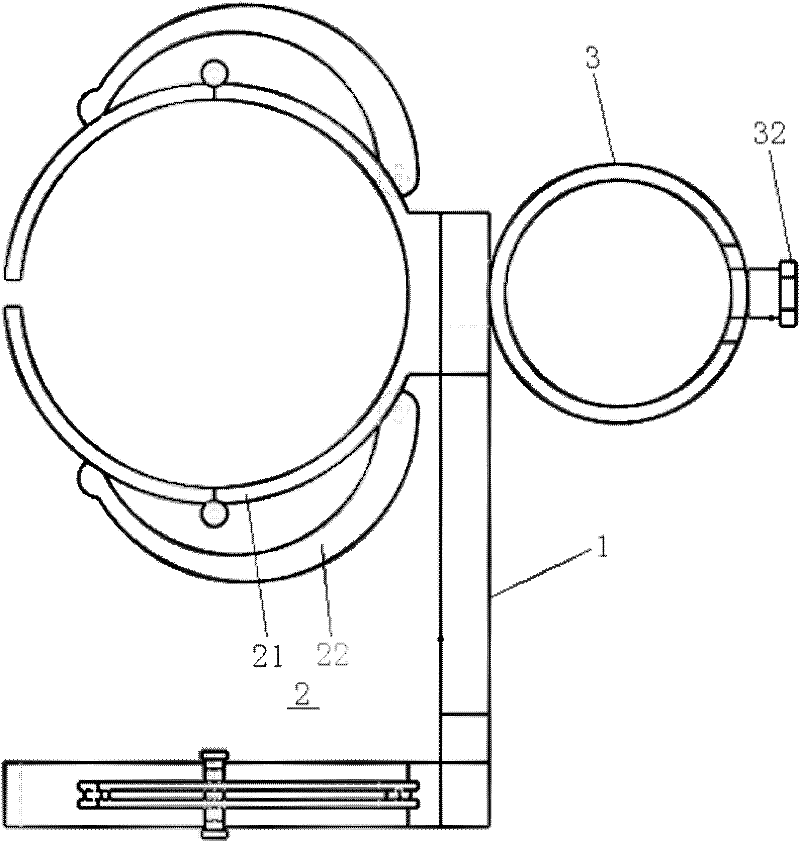

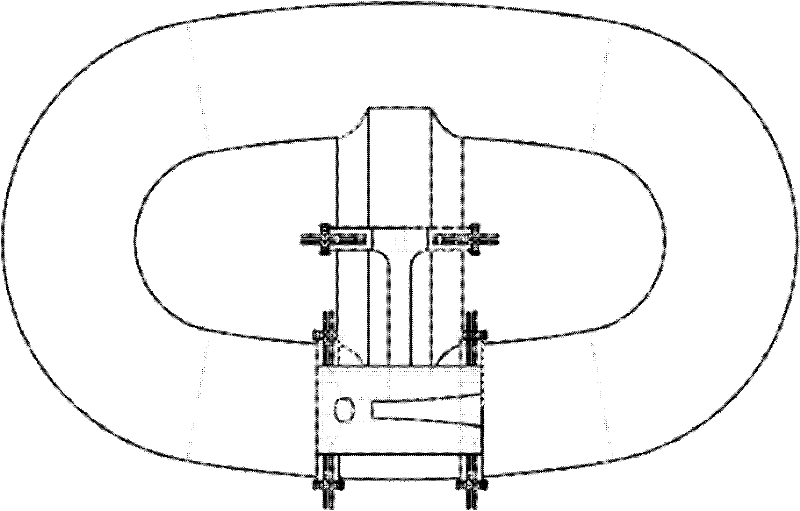

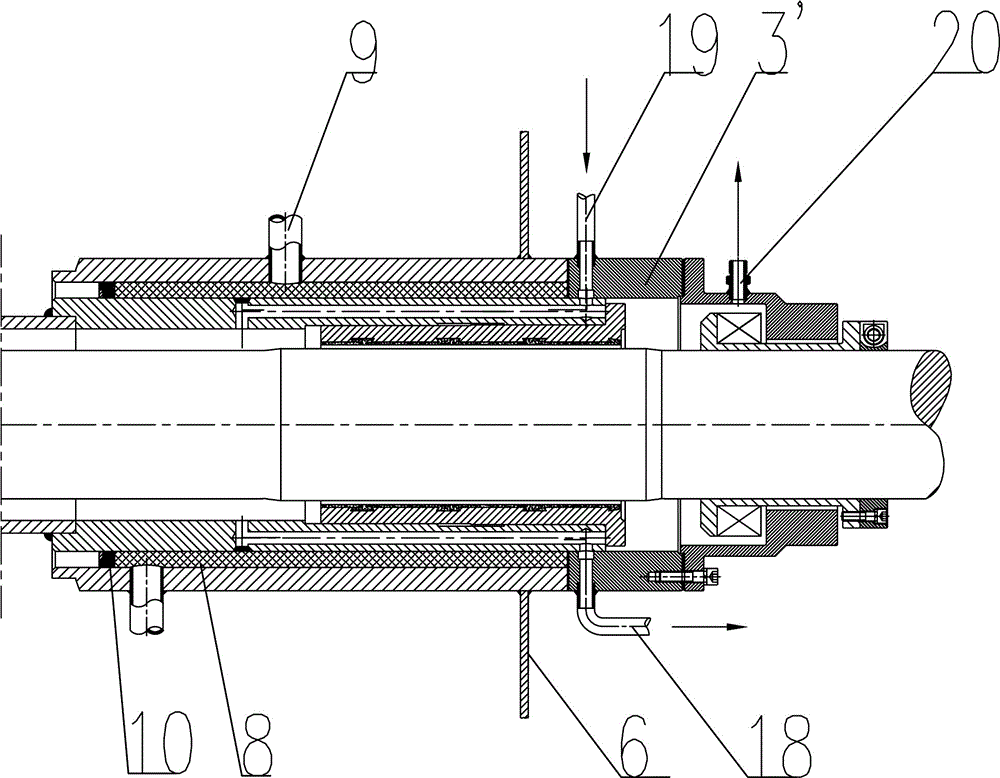

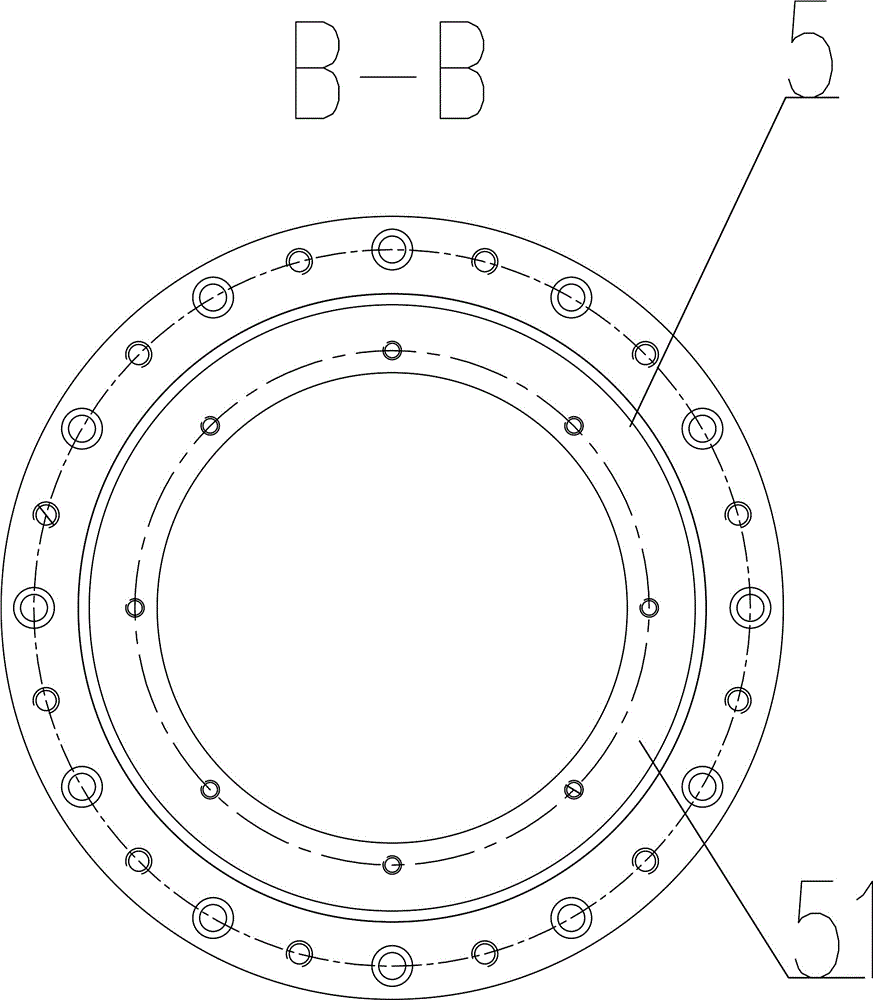

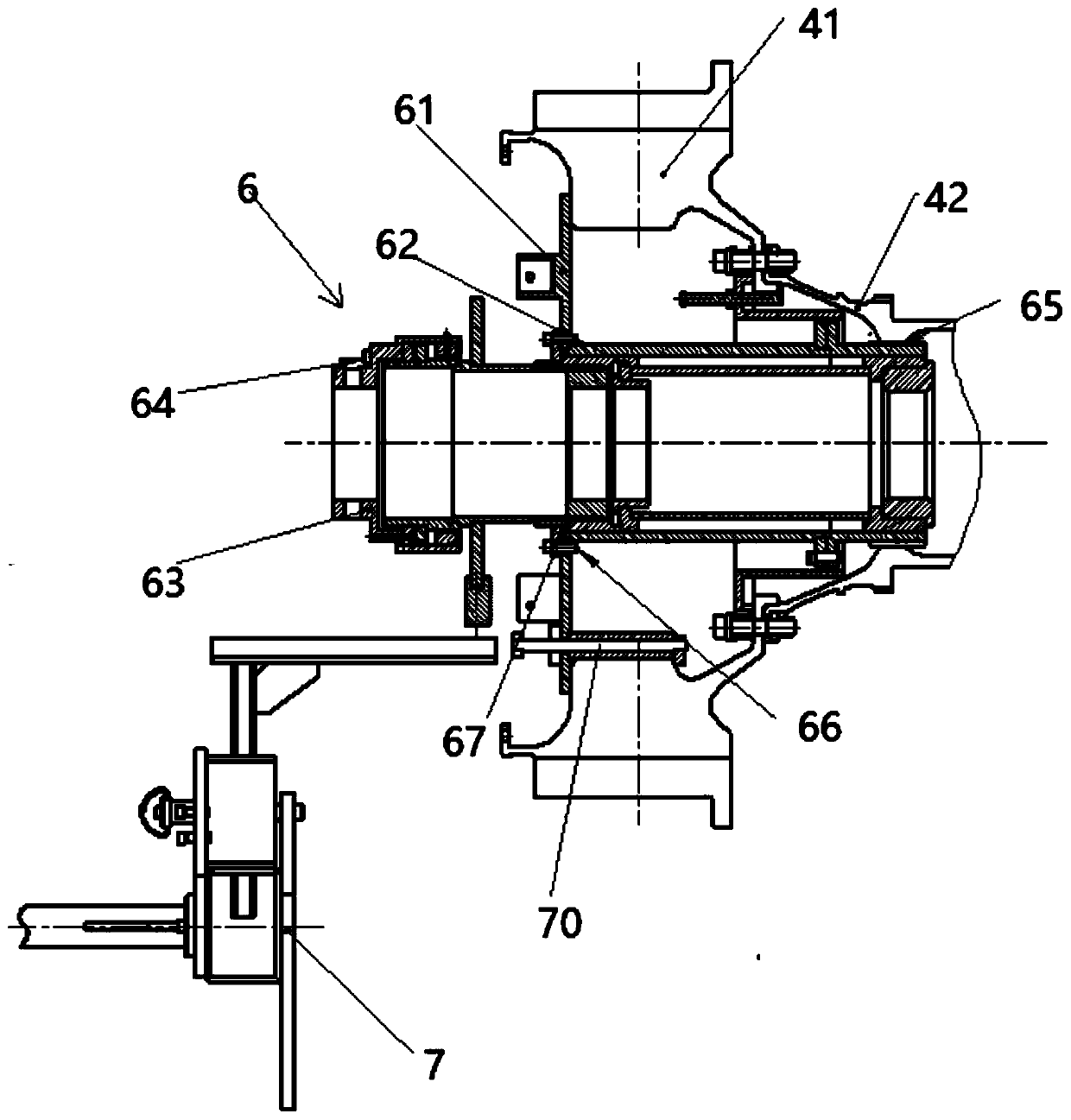

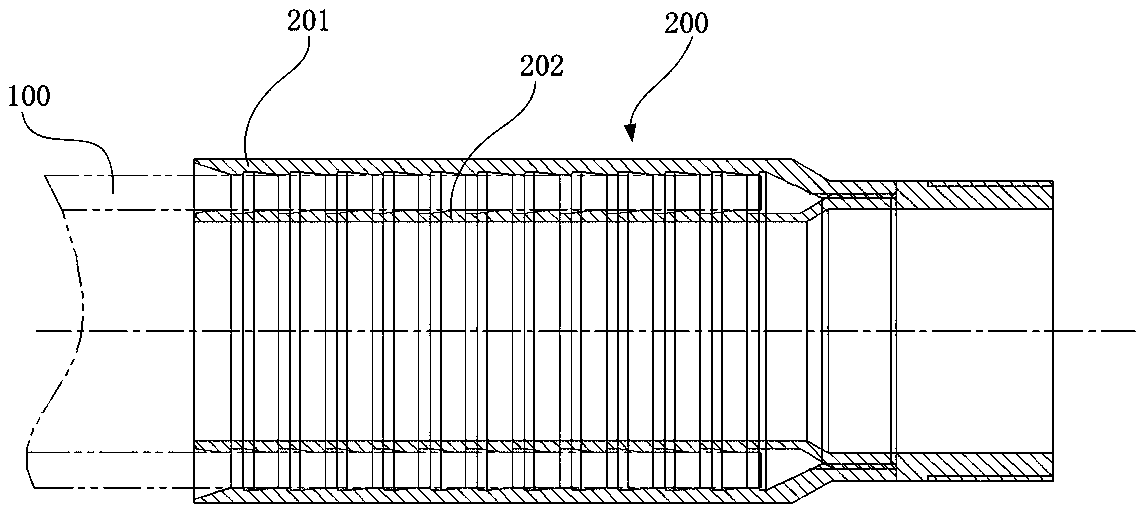

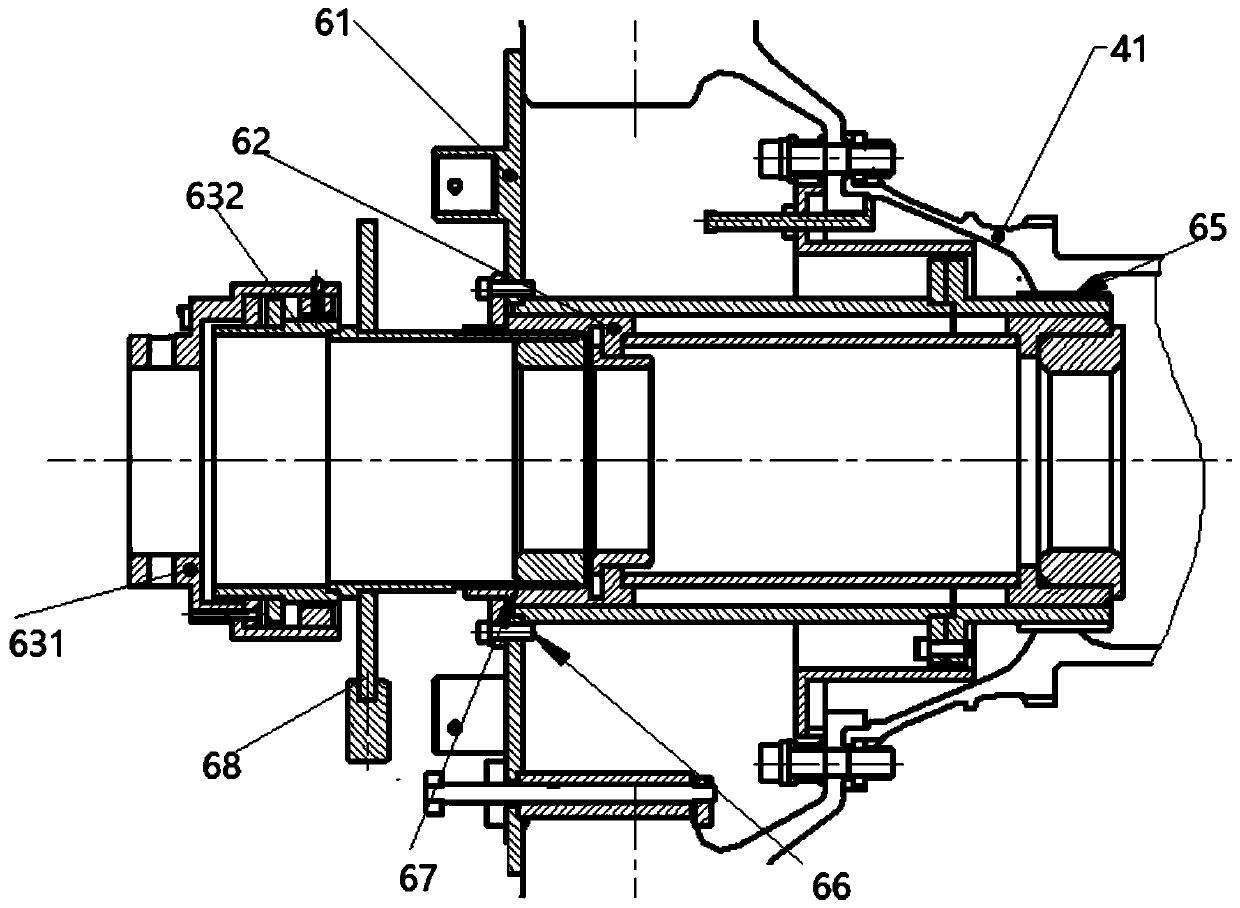

Stern shaft tail tube device for ship and method for mounting stern shaft tail tube device

ActiveCN106741799AEasy to install and disassembleFair usePropulsive elementsPropulsive transmissionInterference fitEngineering

The invention discloses a stern shaft tail tube device for a ship and a method for mounting the stern shaft tail tube device. A head-end sealing device and a tail-end sealing device are respectively arranged at two ends of a tail tube of the stern shaft tail tube device. The stern shaft tail tube device is characterized in that the tail tube is structured in such a manner that an outer tail tube is in sleeve connection with an inner tail tube, the inner wall of the inner tail tube is connected with bearings at two ends of the inner tail tube in an interference fit manner, and a fixing connecting layer is arranged between the outer tail tube and the inner tail tube. The method includes steps of manufacturing the inner tail tube and the outer tail tube in workshops, and carrying out press-fitting on front and rear bearings in place to obtain an inner tail tube assembly; completely mounting the outer tail tube, then mounting the inner tail tube assembly into the outer tail tube from the tail of the outer tail tube and adjusting the inner tail tube until central lines of shaft systems are concentric; pouring the fixing connecting layer. The stern shaft tail tube device for the ship can be mounted by the aid of the steps. The stern shaft tail tube device and the method have the advantages that mounting processes can simplified, the stern shaft tail tube device can be high in positioning accuracy in mounting procedures, and hole boring can be omitted.

Owner:YICHANG DONGJIANG SHIPBUILDING CO LTD

Mounting process of offshore oil single-leg jacket-type platform

InactiveCN101850829AImprove securityImprove reliabilityVessel partsFloating buildingsOil fieldGuide tube

The invention provides a mounting process of an offshore oil single-leg jacket-type platform, which comprises the following steps of: arranging a main operation ship in place; arranging a barge in place; constructing a lower part structure of the jacket-type platform; mounting an upper part structure; mounting a barge platform; mounting a submarine anode; mounting a conductor tube clip; and cleaning and checking the platform. The mounting of the upper part structure comprises the following steps of: mounting the platform, a walkway and railings, sandblasting and repairing paint. The mounting process of the offshore oil single-leg jacket-type platform is improved in that the construction of the lower part structure sequentially comprises the following steps of: constructing a main pile; mounting a guide sleeve; mounting a crown plate; constructing inclined piles; and mounting a gap plate. The invention has the advantages of scientific and reasonable process line design, can improve working efficiency, lower mounting danger, save steel for building the platform, reduce loading, mounting and transportation cost, enhance use safety and reliability of the platform, and comprehensively and effectively decrease exploration cost of a marginal oil field. And therefore, the invention provide necessary guarantee for a healthy, safe, environment-friendly construction environment and accords with the strategic requirement for sustainable development.

Owner:CHINA NAT OFFSHORE OIL CORP +1

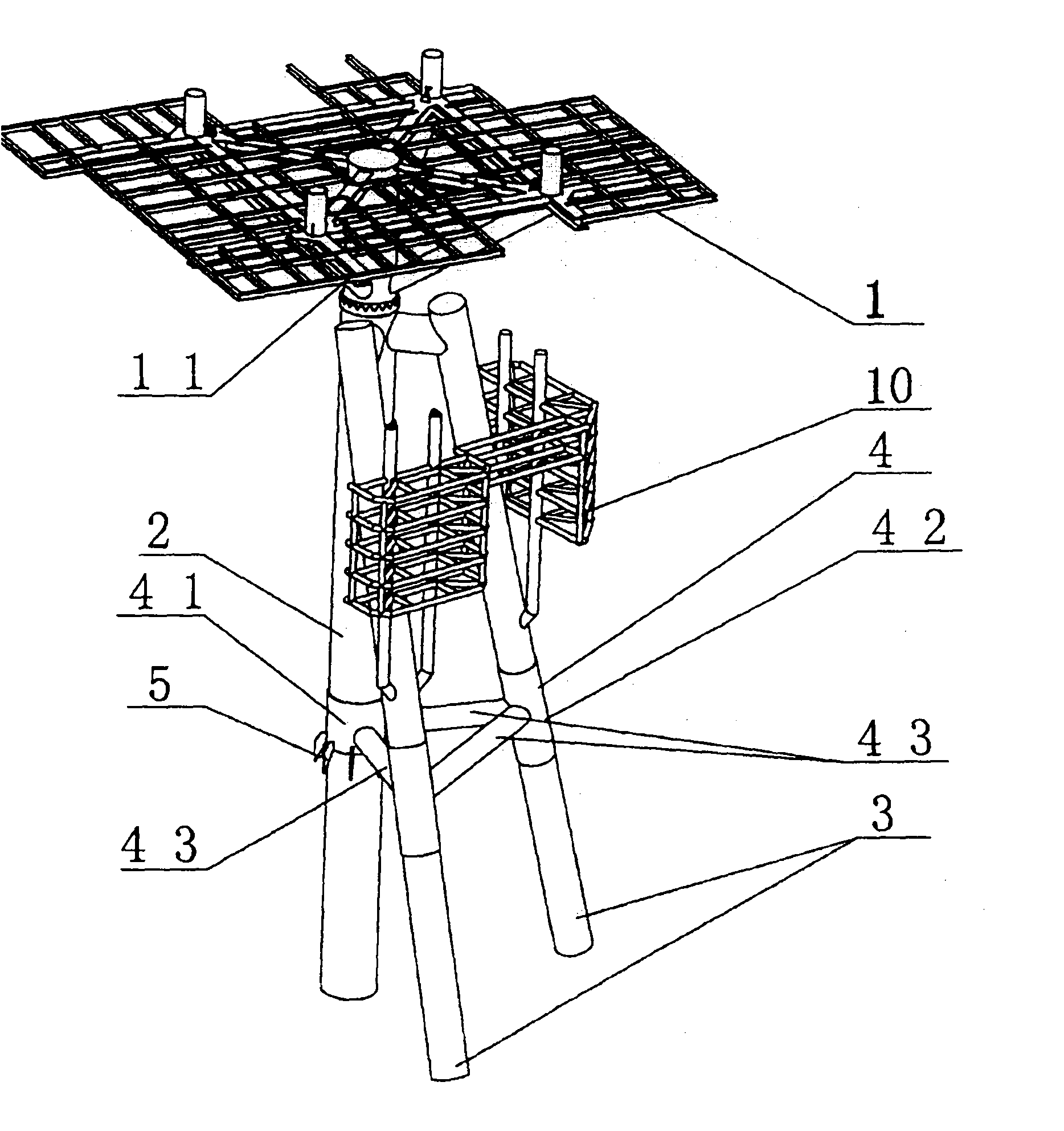

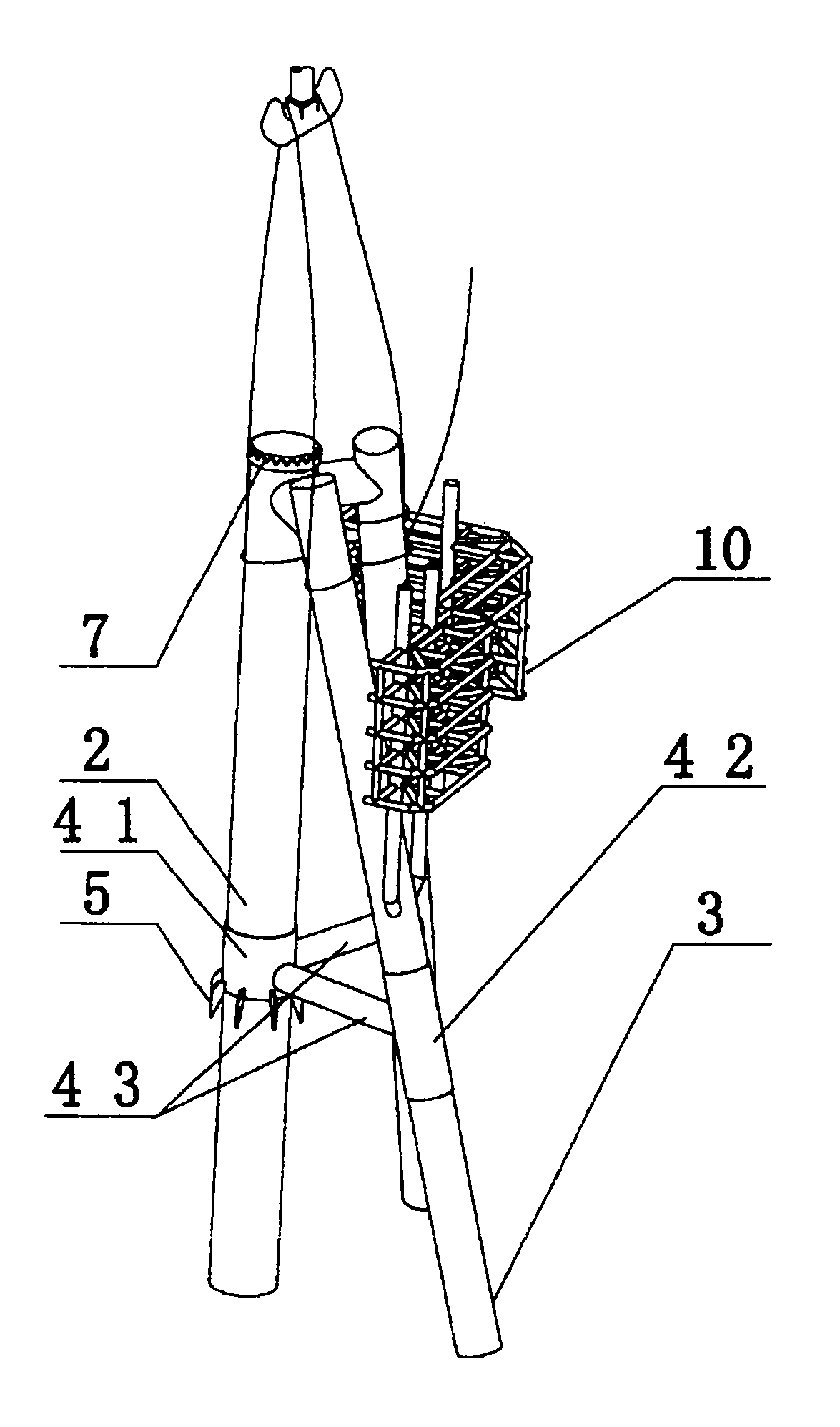

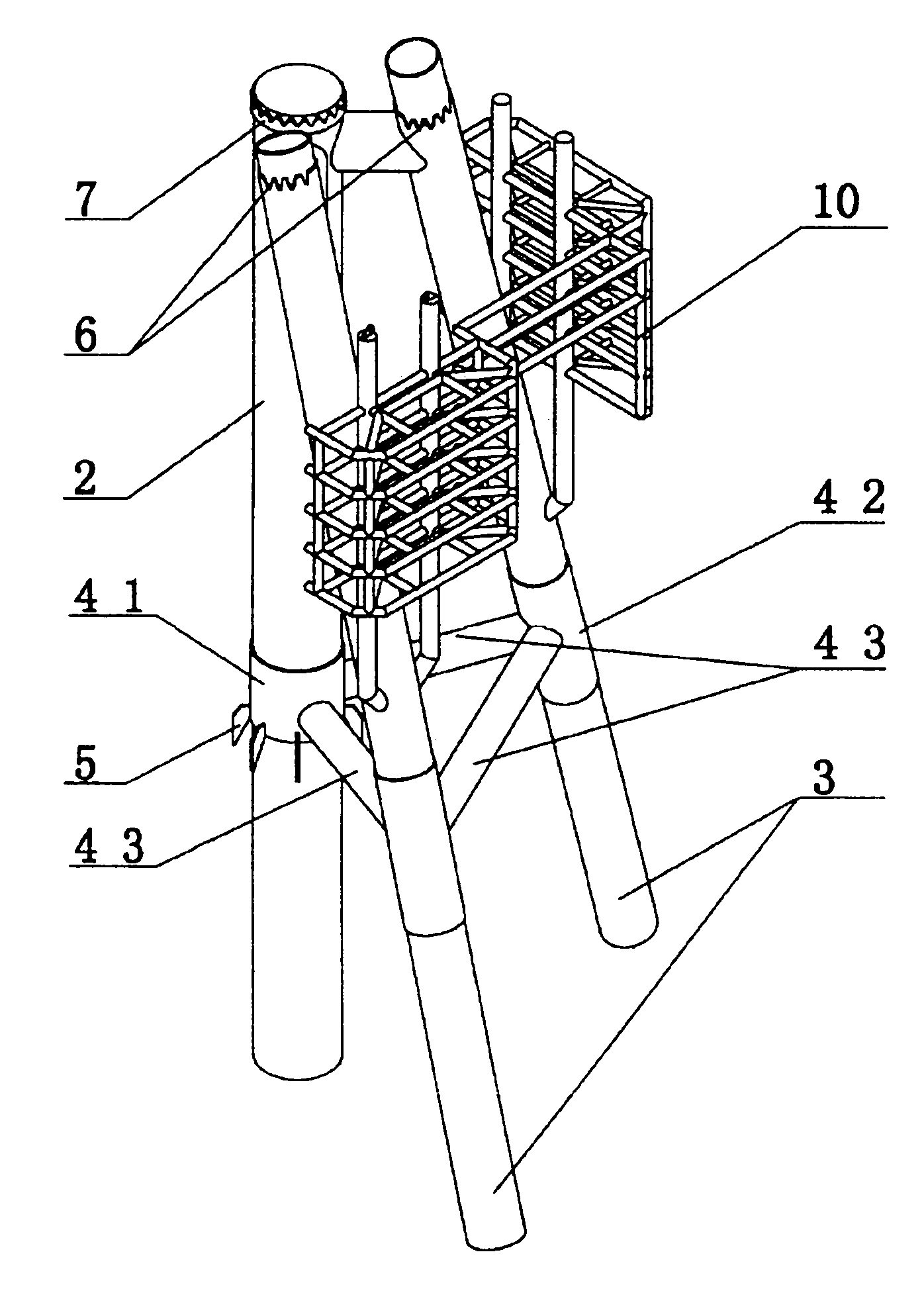

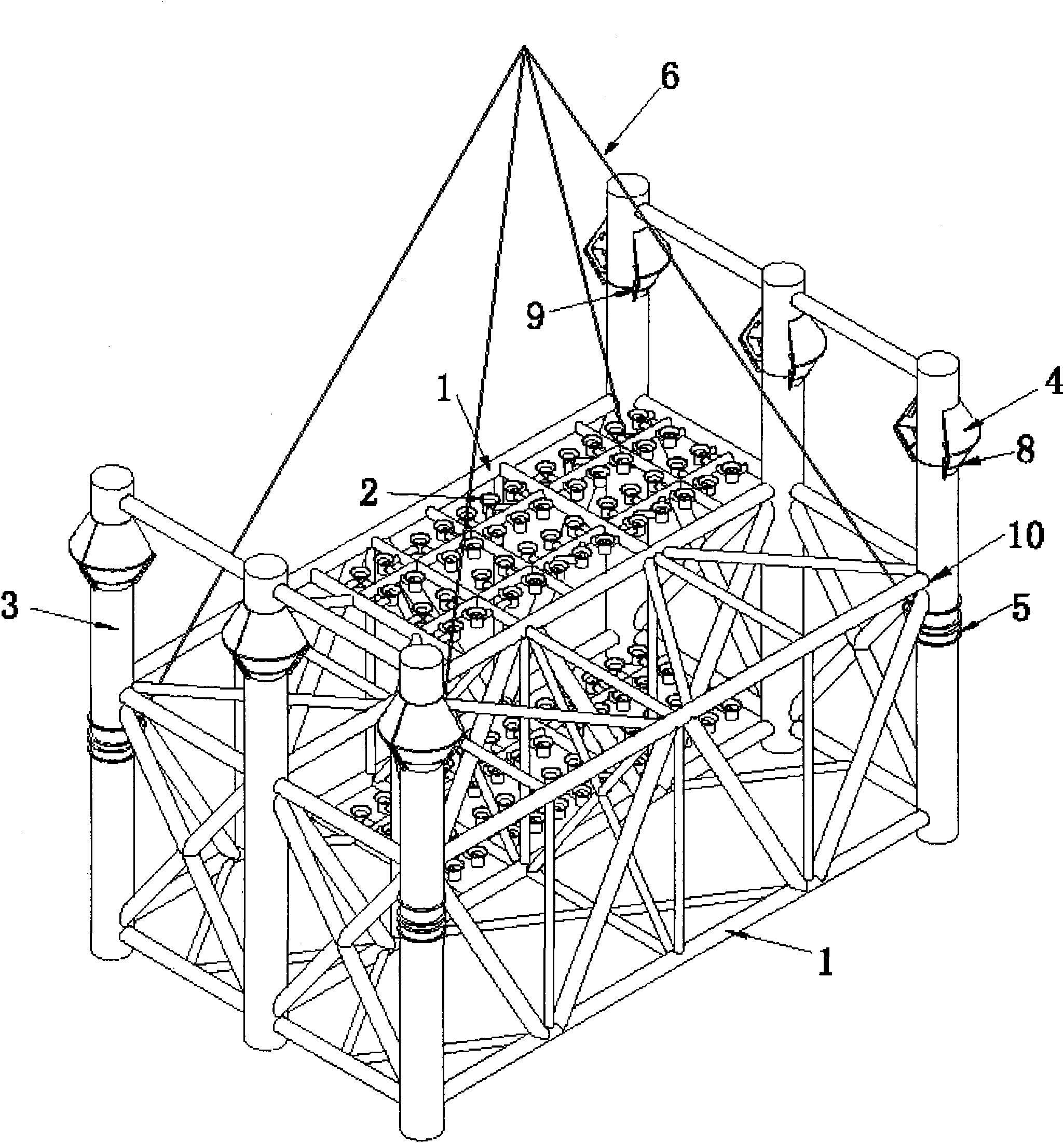

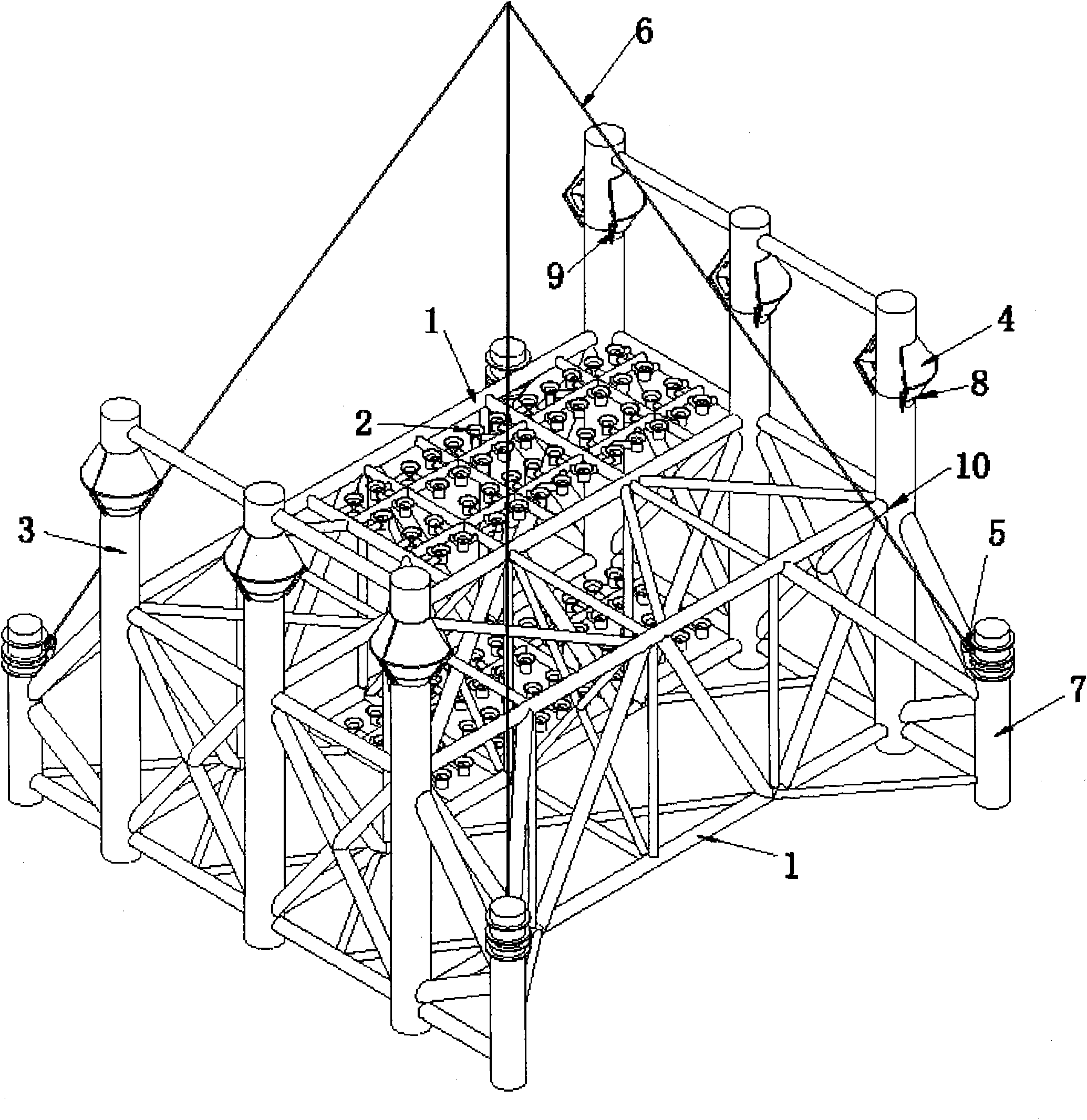

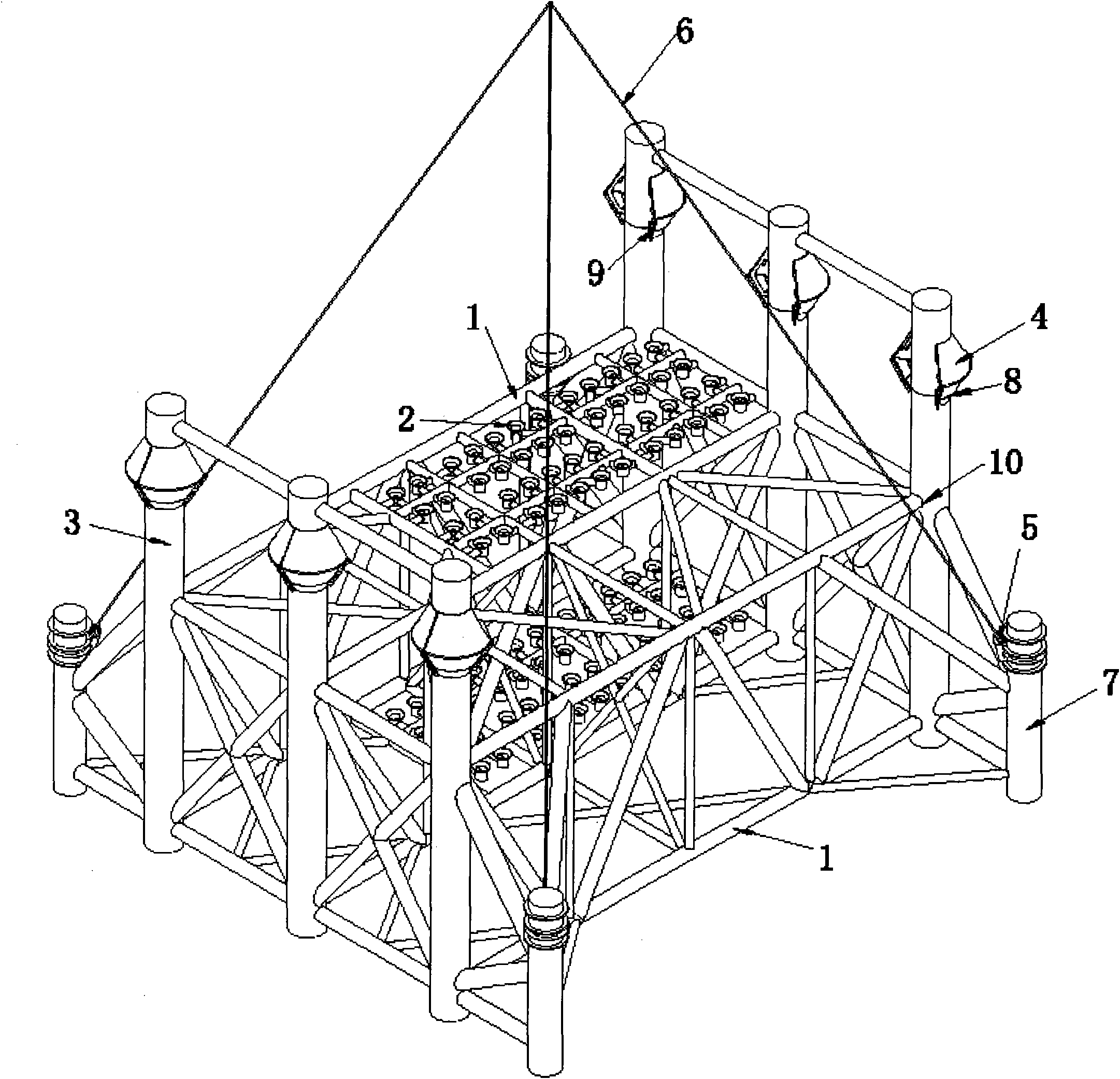

Method for arranging hoisting points and floating-supported conduit frame with skirt pile sleeves

InactiveCN101962946ASimplify the offshore installation processReduce mud entry depthArtificial islandsUnderwater structuresMarine engineeringPenetration depth

The invention relates to a method for arranging a hoisting point and a floating-supported conduit frame with skirt pile sleeves. The floating-supported conduit frame comprises a conduit frame main body, wherein the bottom of the conduit frame main body is provided with an underwater framework, a plurality of horizontal layers are arranged on the underwater framework, and a plurality of water-isolating sleeve guides are arranged on the horizontal layers; both sides of the underwater framework are provided with a plurality of main upright leg pipe columns, and ice cones are arranged on the main upright leg pipe columns; and a skirt pile sleeves are arranged on the plane of the conduit frame main body beyond the four corners, and the skirt pile sleeves are connected with the main upright leg pipe columns into a whole through a plurality of support rods to form an open type straight leg conduit frame structure with the skirt pile sleeves. The hoisting points are arranged on the top of the skirt pile sleeves. The method structurally increases the loading capacity of the supporting conduit frame, and the conduit frame is applicable to loading larger upper blocks; the penetration depth of piles driven into the bottom of the sea and pile driving refusal risk caused by marine pile driving work can be reduced, and hoisting can not be influenced by well mouth guides and the ice cones arranged on conduit frame pile legs; and the marine installation process of the conduit frame is furthest simplified, and marine installation cost and risk are also reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Cutting tooth for earth working equipment

ActiveCN1955383AReduce storage costsReduce installation riskSoil-shifting machines/dredgersRooted toothEngineering

Cutting tooth has foot to sit in a seat on the ground treatment appliance and at least one main cutting part is located on the cutting foot on the head side to treat the ground material. To enlarge the treatment area of the main cutting piece situated on the foot, a further post cutting piece is provided. It has a different cutting design compared to the main cutting piece. The post cutting piece has a pin blade. The main cutting piece has at least one wedge-shaped blade.

Owner:BAUER MASCH GMBH

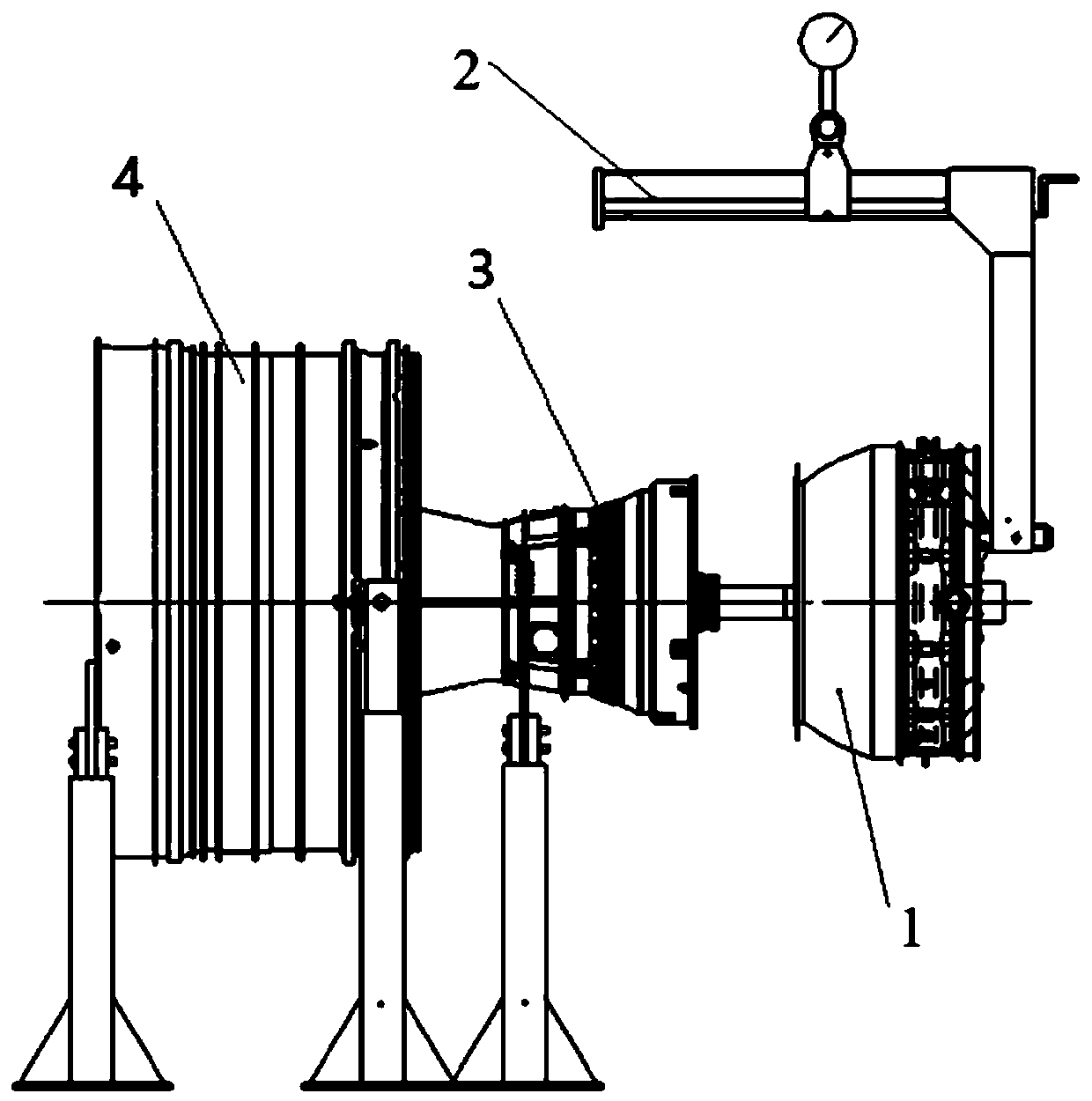

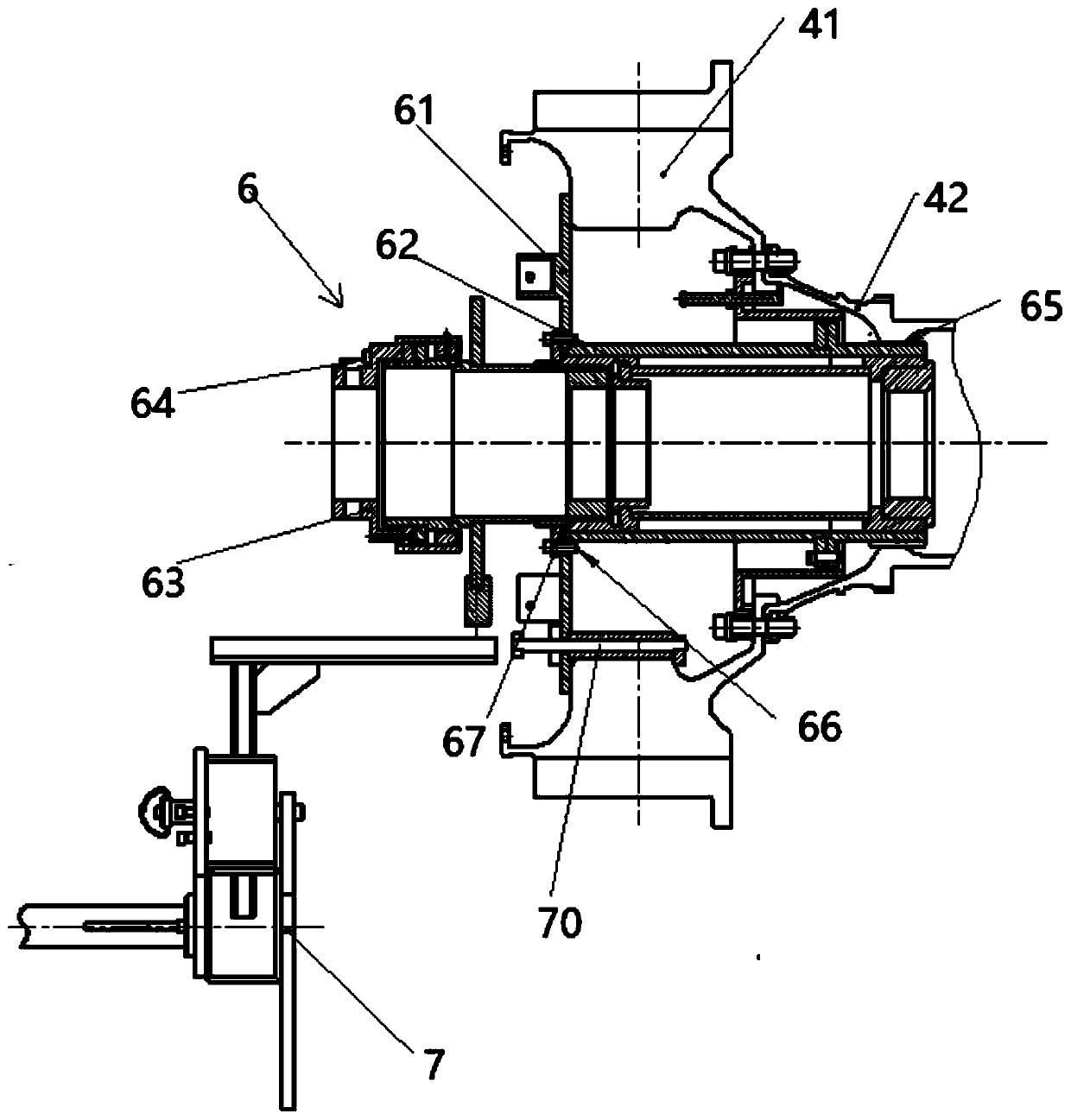

Assembly tool for low-pressure turbine of engine

ActiveCN111266861AHigh positioning accuracyEasy to install and disassembleAssembly machinesPhysicsEngineering

Owner:AECC AVIATION POWER CO LTD

Method for measuring inclination of ship stern bearing through laser

InactiveCN106705938AReduce installation riskSimple structureActive open surveying meansIncline measurementLaser transmitterMeasurement device

The invention provides a method for measuring inclination of a ship stern bearing through laser. Bluetooth, a laser receiver and a measuring unit are mounted on an emitter bracket, a laser emitter is mounted on one side of the emitter bracket, and a measuring device is connected with a display. The inclination of the ship stern bearing is measured by mounting and using a laser measuring system. The structure is simple, the method is high in measurement accuracy and high in operability, measured data are real and reliable, the mounting risk of the stern bearing is reduced, and labor force for construction is saved. The method is suitable for being used for measuring the inclination of the ship stern bearing.

Owner:中国船舶集团渤海造船有限公司

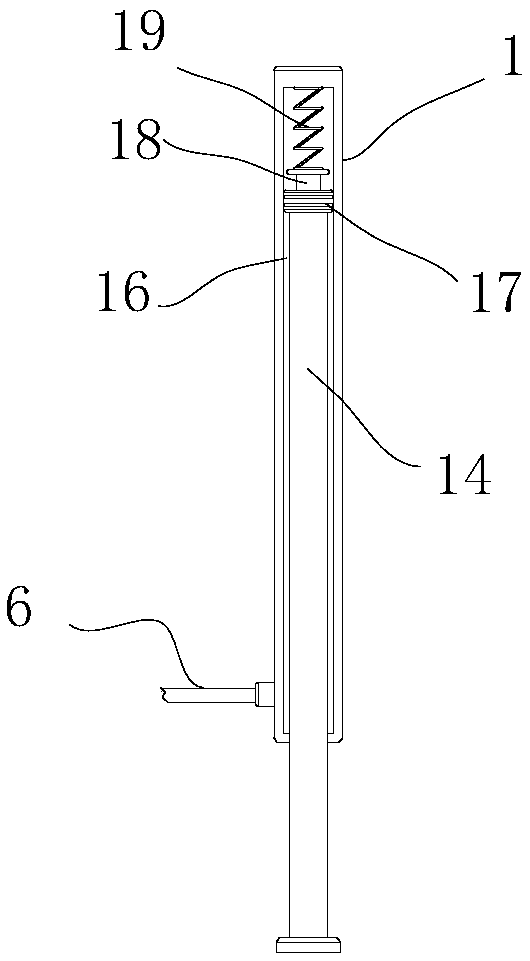

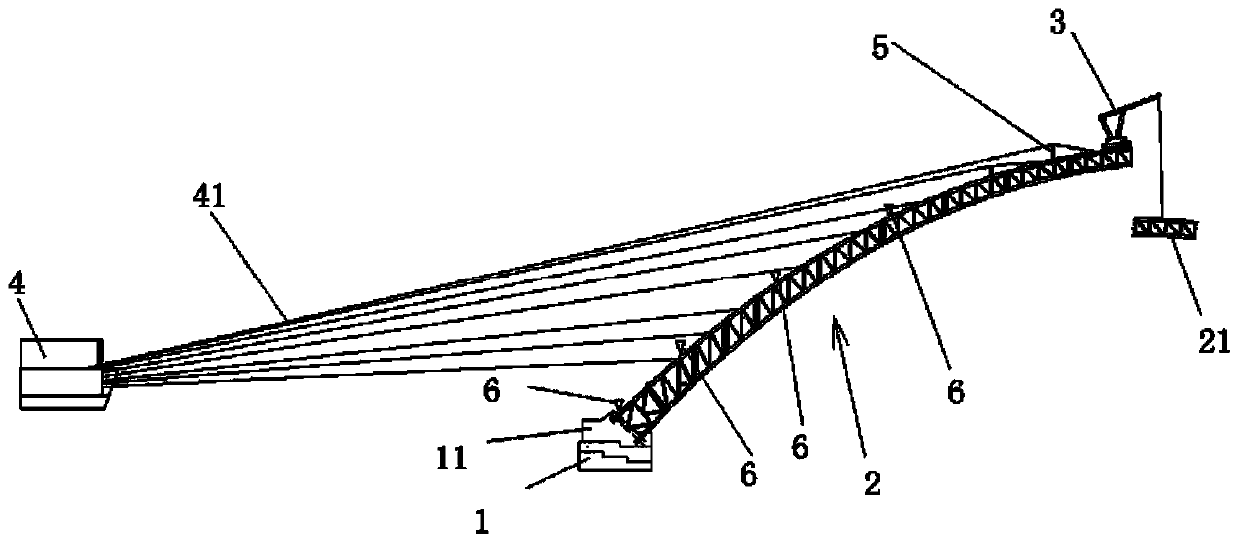

Installation method of overlength mast with large inclination angle of space structure

ActiveCN103850515AControl precisionGuaranteed stitching qualityTowersBuilding material handlingSpatial structureAnchor point

The invention relates to an installation method of an overlength mast with a large inclination angle of a space structure, which belongs to the technical field of architectural engineering construction. The installation method comprises the following steps: mast shaping and manufacturing in subsections, field splicing, anchor point and base arranging, integral hoisting, cable rope arranging, mast inclination implementing, process monitoring, cable rope checking, fastening, and installing the overlength mast with the large inclination angle with the length being more than 40m and the inclination angle being 65 degrees on the space structure. According to the method, floor subsection splicing and integral hoisting in situ are adopted, and a cable rope is released slowly through a chain block to control the angle of the mast, so that the mast in the space structure is inclined slowly so as to be positioned accurately; the requirement of the installation accuracy of a space structure system is met; the problems of how to control the dimensional accuracy of the mast, and large deviation of the spatial position, angle and relative position of mast installation in the space structure are solved; and meanwhile, the stability and the safety of a structure stress system are ensured, the installation quality of the mast is improved, and the risk of installation construction of the overlength mast with the large inclination angle is reduced.

Owner:杭州建工集团有限责任公司

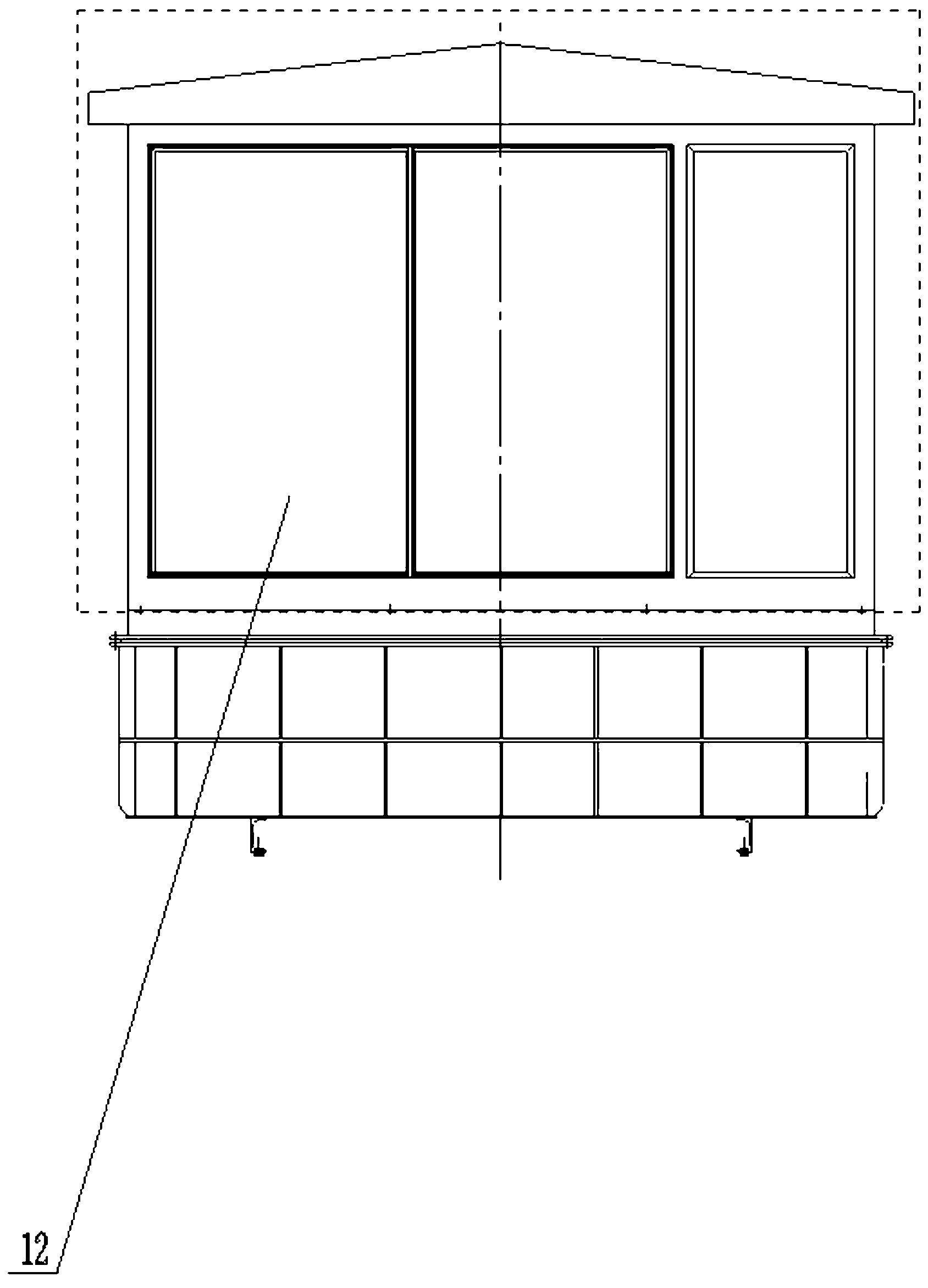

Air conditioner external unit bracket

InactiveCN108954795AReduce installation riskRapid coolingLighting and heating apparatusSpace heating and ventilation detailsEngineeringPower loss

The utility model discloses an air conditioner external unit bracket. The air conditioner external unit bracket comprises two fixing cylinders. The upper ends of the fixing cylinders are each providedwith a fixing bracket. The fixing cylinders are fixed to a building outer wall through the fixing brackets. Each fixing cylinder is internally provided with a water storage cavity. A sealing piston is arranged in each water storage cavity. Each sealing piston seals the whole corresponding water storage cavity. The bottom of each sealing piston is connected with a piston rod. The piston rods penetrate through piston holes in the bottoms of the water storage cavities to extend out of the fixing cylinders. A supporting bottom plate is welded and fixed to the outer extension ends of the piston rods. An inclined supporting plate is arranged at the bottom of the supporting bottom plate. An air conditioner external unit is fixedly mounted on the supporting bottom plate through screws. Through the air conditioner external unit bracket, convenient mounting can be achieved, the safety of the bracket during mounting is improved, the effect that the air conditioner external unit has good heat dissipation performance during application can be ensured, power losses of the external unit are reduced, and application of the air conditioner external unit bracket is more environmentally friendly.

Owner:王满姣

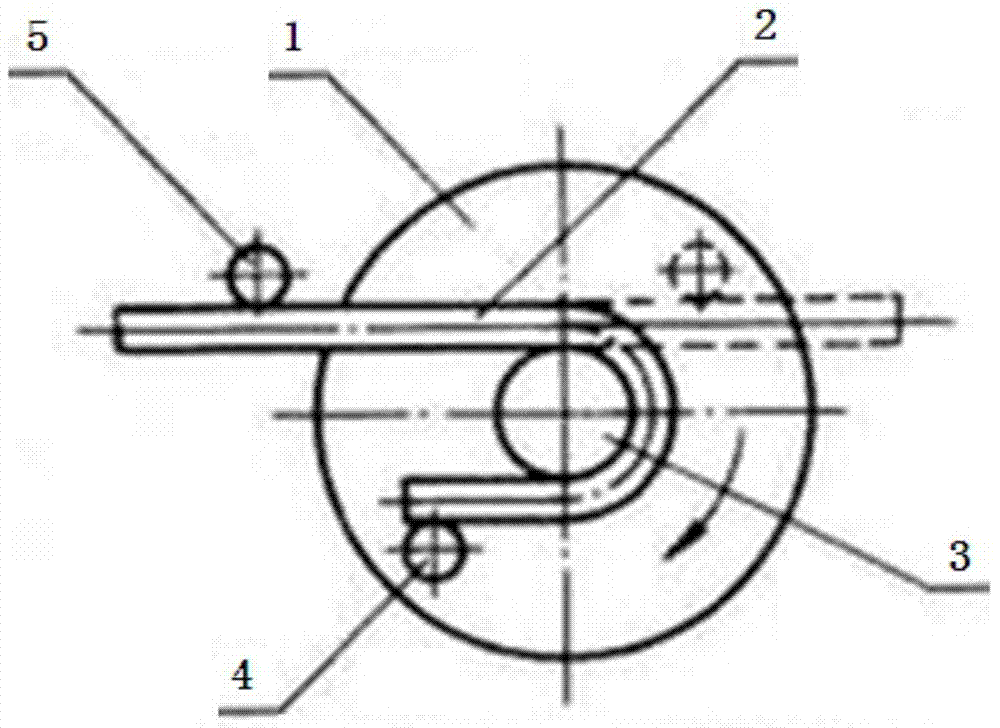

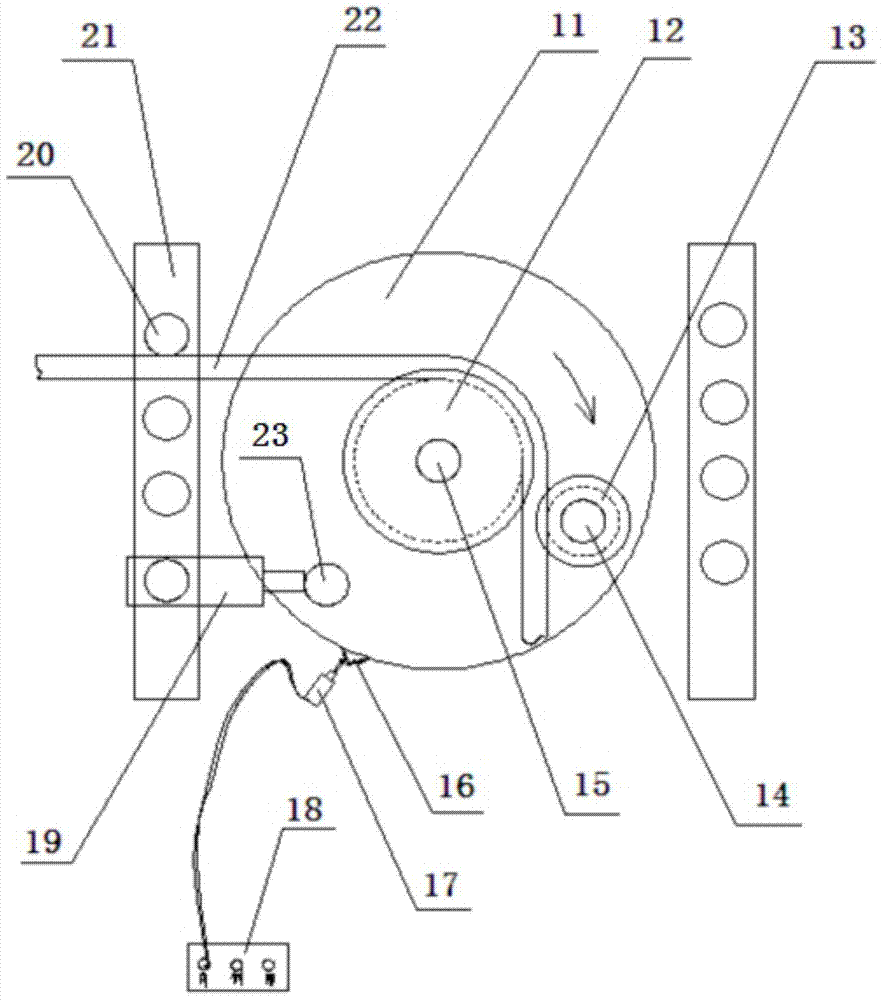

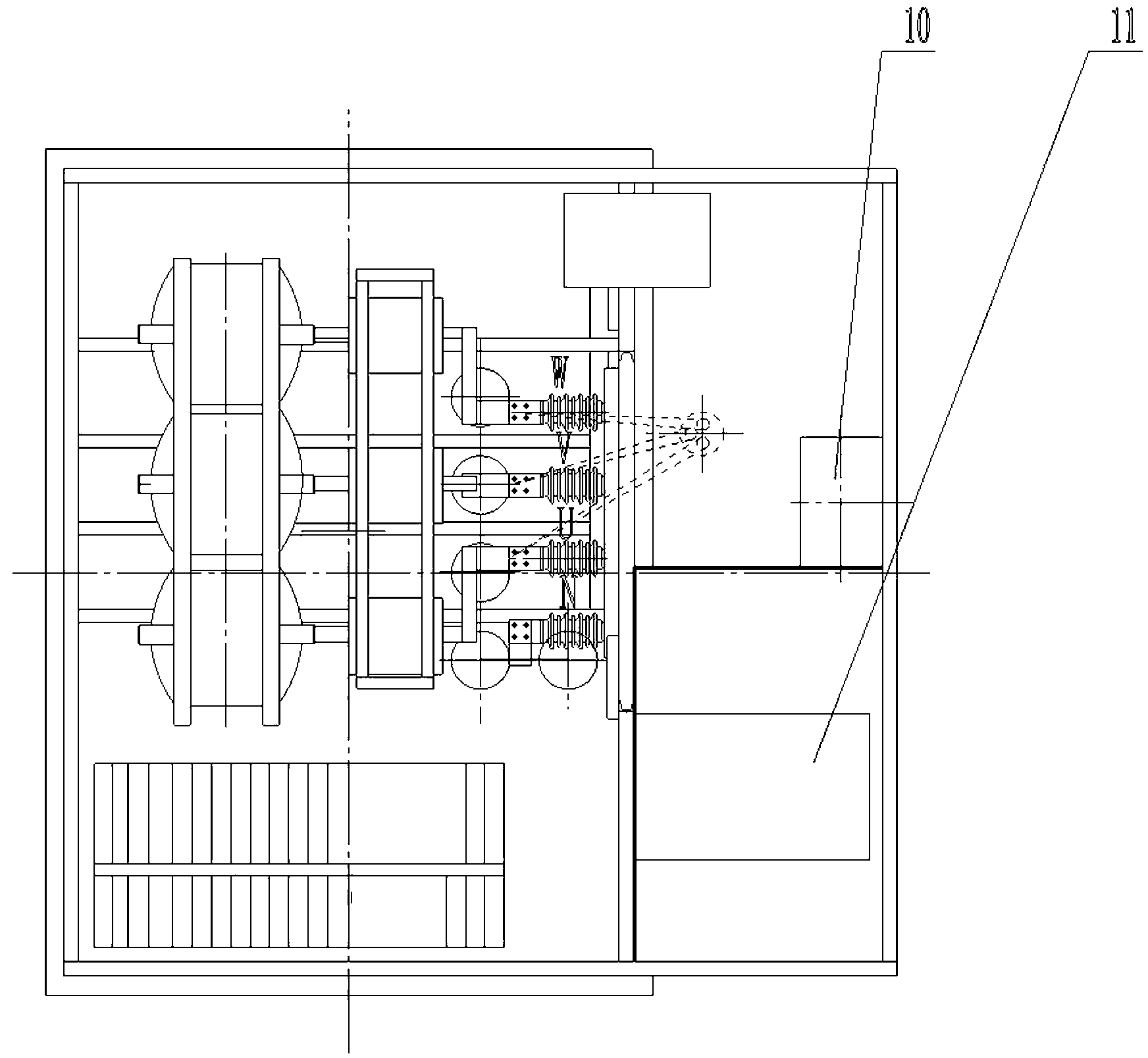

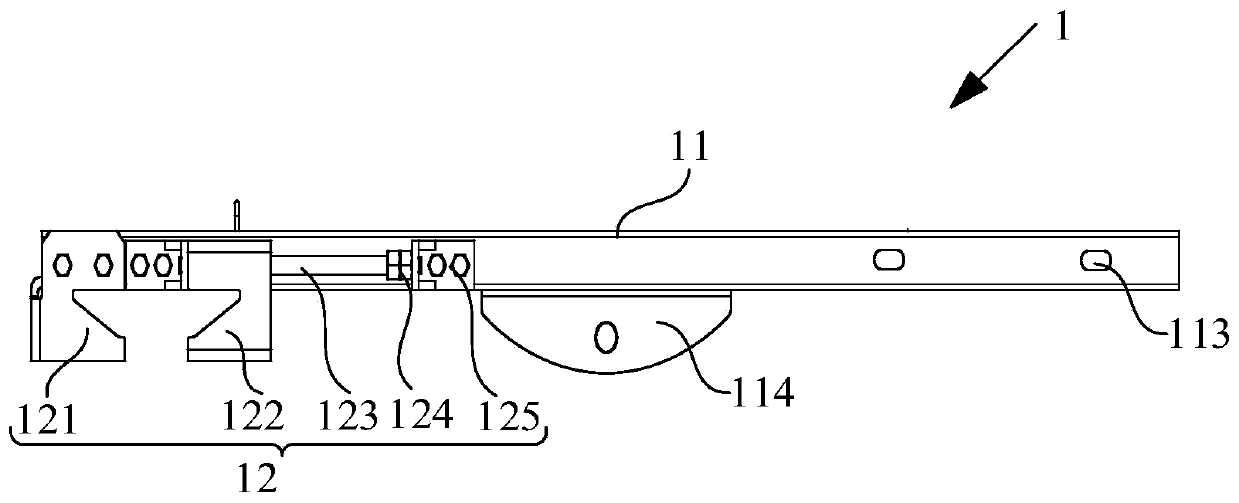

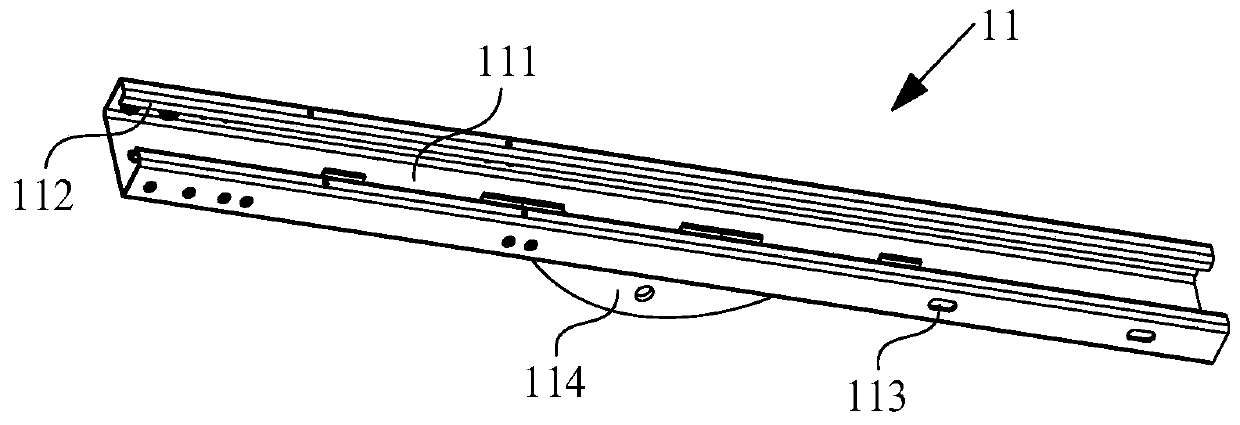

Bending machine for small-bore medium pipelines and using method of bending machine

The invention discloses a bending machine for small-bore medium pipelines and a using method of the bending machine. The bending machine comprises a working plate which is arranged on a working panel of a transmission case and is connected with a transmission chain of the transmission case, the working plate is provided with a center wheel installed on a center pin shaft and a bending wheel installed on a bending pin shaft, the wheel edge of the center wheel and the wheel edge of the bending wheel are respectively provided with a wheel groove of which the section is in a semi-circle shape, the semi-circle diameter of each wheel groove is matched with the diameter of a bent pipeline, the two sides of the working plate are respectively provided with a piece of stop iron used for installation of stop pin shafts, each piece of stop iron is provided with mechanical limiting positions which are used in cooperation with a limiting pin shaft on the working plate, and the edge of the working plate is provided with a steel angle contact which is used in cooperation with a travel switch which is connected with a switch box and synchronizes with a switch button. By means of the bending machine, the problem that differences exist between angles obtained by an existing bending method and angles used on spot is solved, secondary hand finishing is not needed, labor intensity is relieved, and working efficiency is improved.

Owner:TIANJIN 20 CONSTR

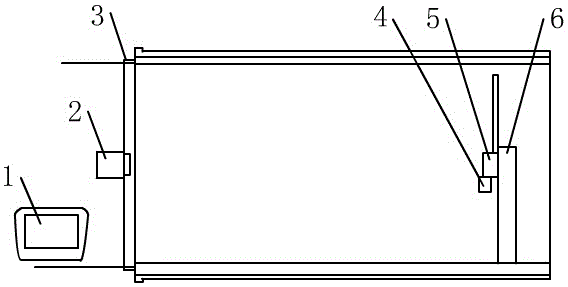

Suspended ceiling keel sheet assembling and hoisting method

InactiveCN102022003AReduce riskAssembly positioning is accurateBuilding material handlingEngineeringLifting equipment

The invention relates to the field of installation of steel structures, in particular to a suspended ceiling keel sheet assembling and hoisting method. The suspended ceiling keel sheet assembling and hoisting method comprises two steps of assembling on ground and hoisting to elevation, and is characterized in that: in the process of assembling on the ground, primary and secondary suspended ceiling keels under a high-altitude net rack are vertically projected to a horizontal plane and then are assembled; and in the process of hoisting to elevation, lifting equipment is started to lift the suspended ceiling keels to the elevation, and then connecting rods for the suspended ceiling keels are fixedly connected with the net rack. The method reduces the risk in the process of mounting a high-altitude scaffold, and is accurate in positioning and higher in mounting speed.

Owner:MCC5 GROUP CORP SHANGHAI

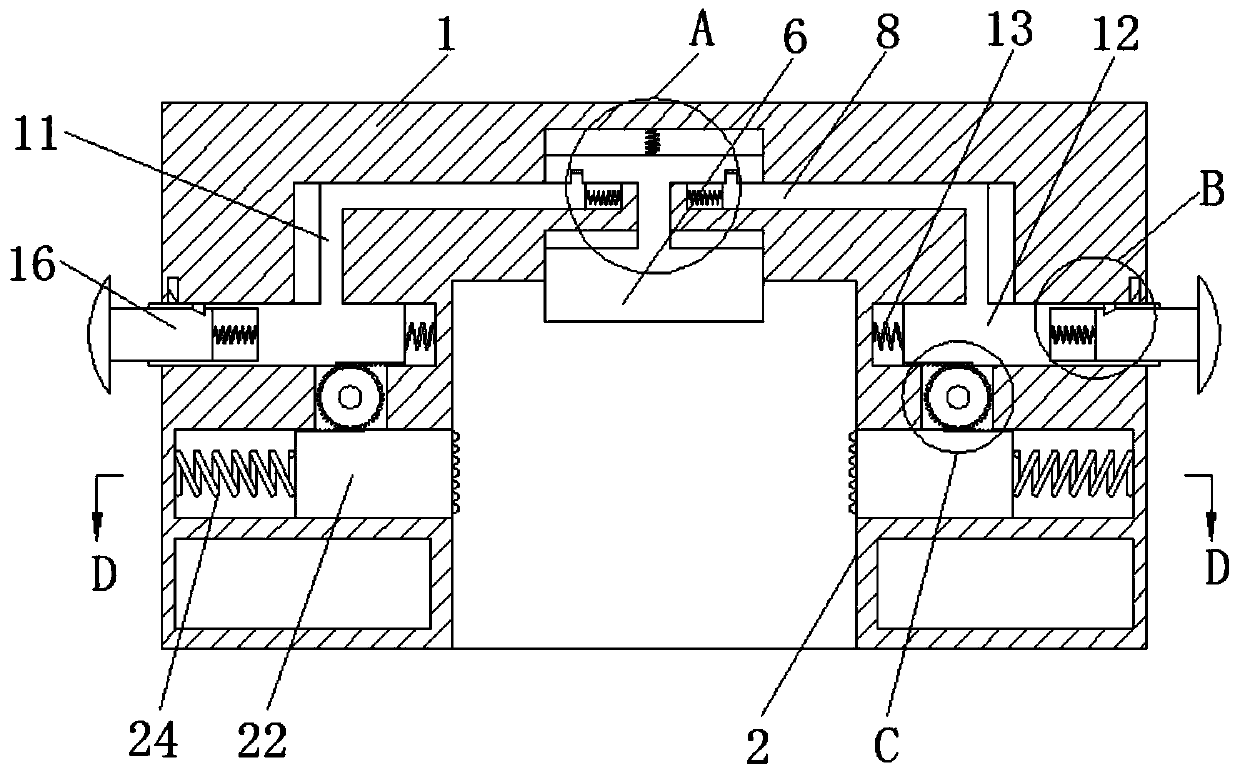

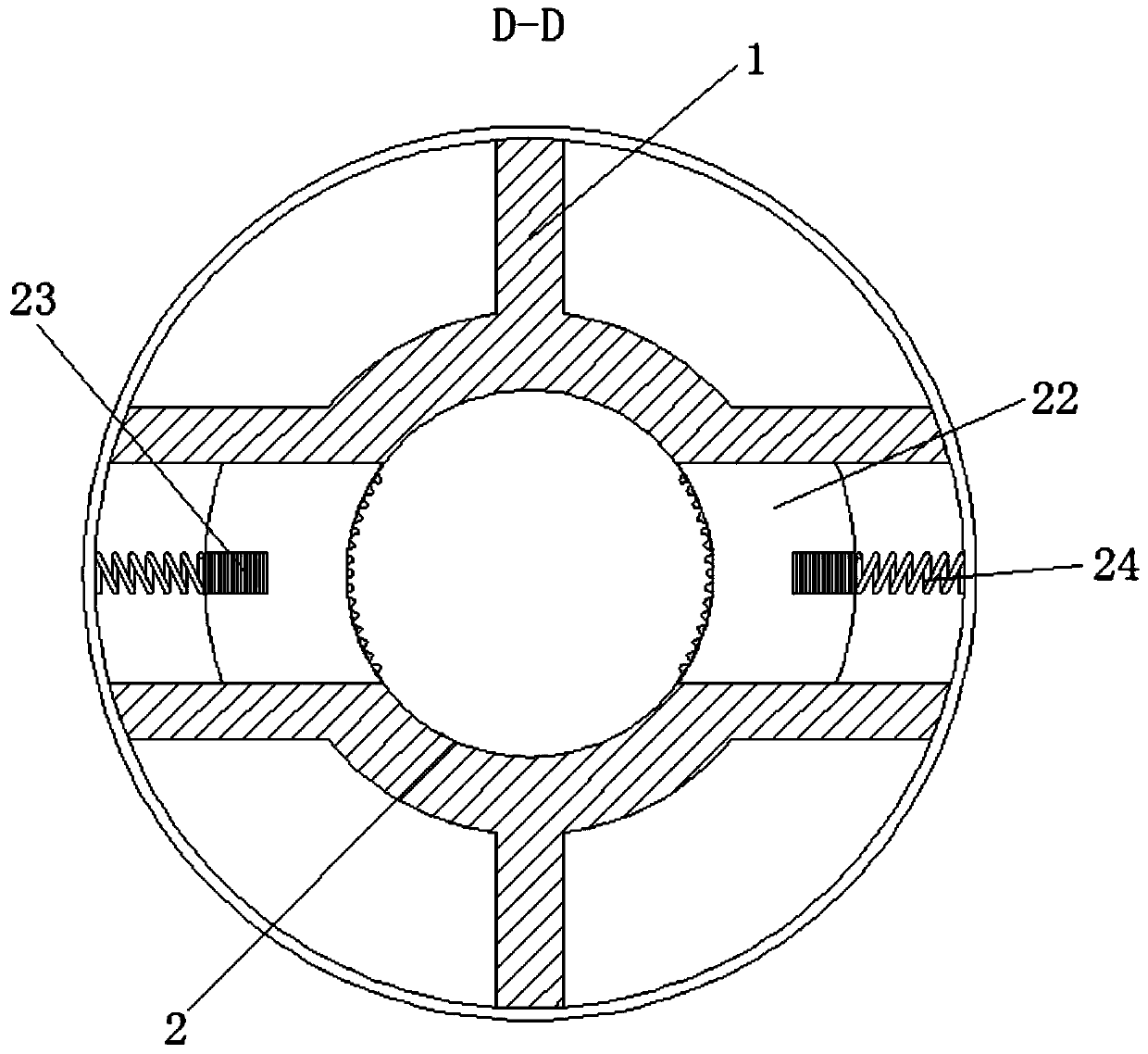

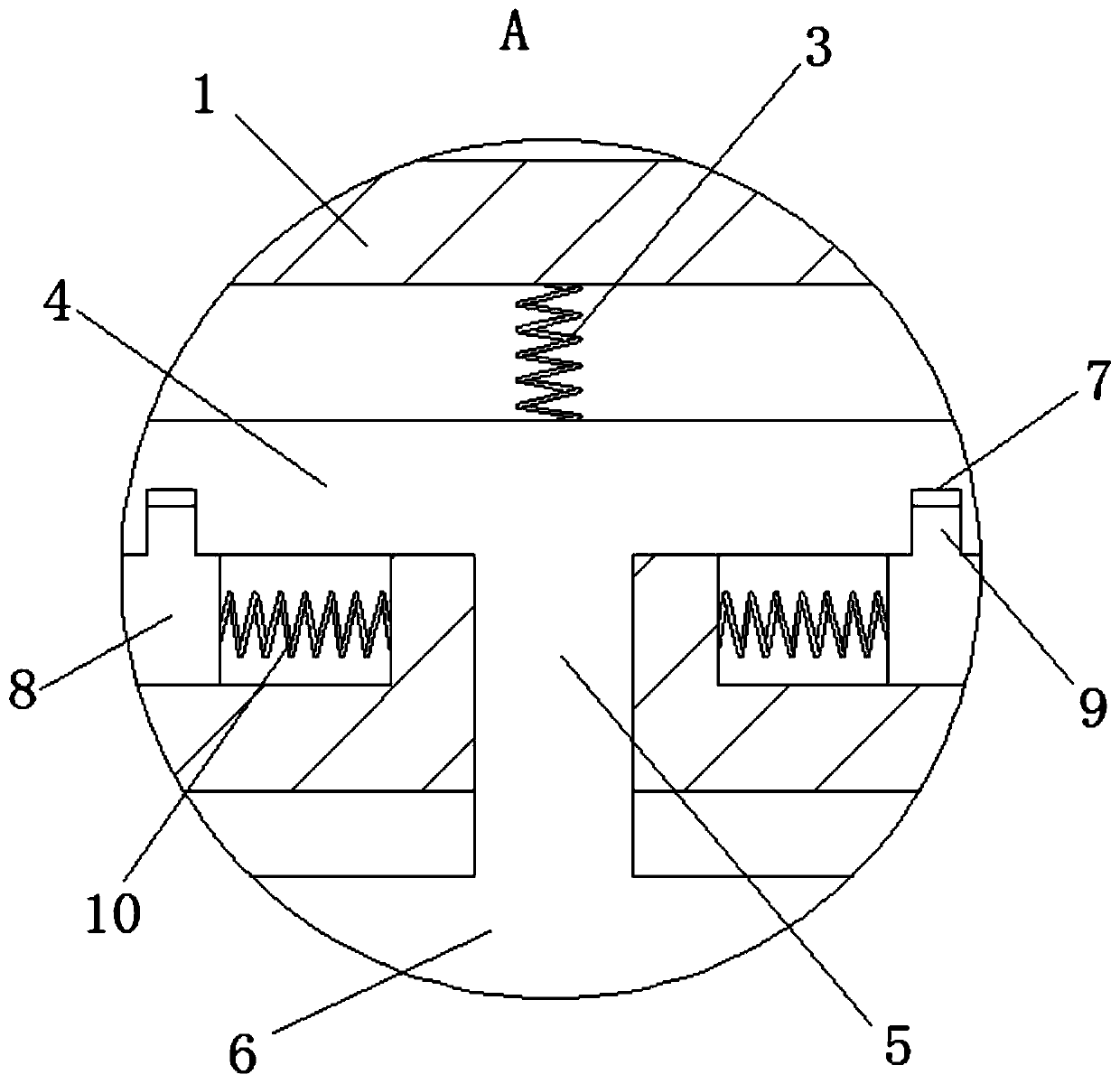

Lam pholder with automatic clamping function based on gear drive principle

InactiveCN110645551ASave installation timeReduce installation riskCoupling device connectionsElectric discharge tubesGear driveGear wheel

The invention relates to the technical field of lamps, and discloses a lamp holder with an automatic clamping function based on the gear drive principle. The lamp holder comprises a housing, wherein alamp installation groove is formed in the housing, a first spring is fixedly connected to the interior of the housing, and a clamping plate is fixedly connected to the bottom of the first spring; a first connecting rod is fixedly connected to the bottom of the clamping plate, a jacking plate is fixedly connected to the bottom of the first connecting rod, clamping grooves are formed in the bottomof the clamping plate, clamping rods are movably connected to the bottom of the clamping plate, and clamping blocks are fixedly connected to the exteriors of the clamping rods. Through the cooperativeuse of the jacking plate and the clamping blocks, when a lamp cap jacks up the jacking plate, the clamping blocks automatically clamp the lamp cap under the actions of first push rods and fifth springs. Therefore, the lamp is convenient to install, the installation speed is high, the installation time is shortened for installation personnel, the situation that the installation personnel fall froma high place when installing the lamp for a long time is avoided, the efficiency of installing the lamp is improved, and the installation risk brought to the installation personnel is also reduced.

Owner:浦江功琪机械有限责任公司

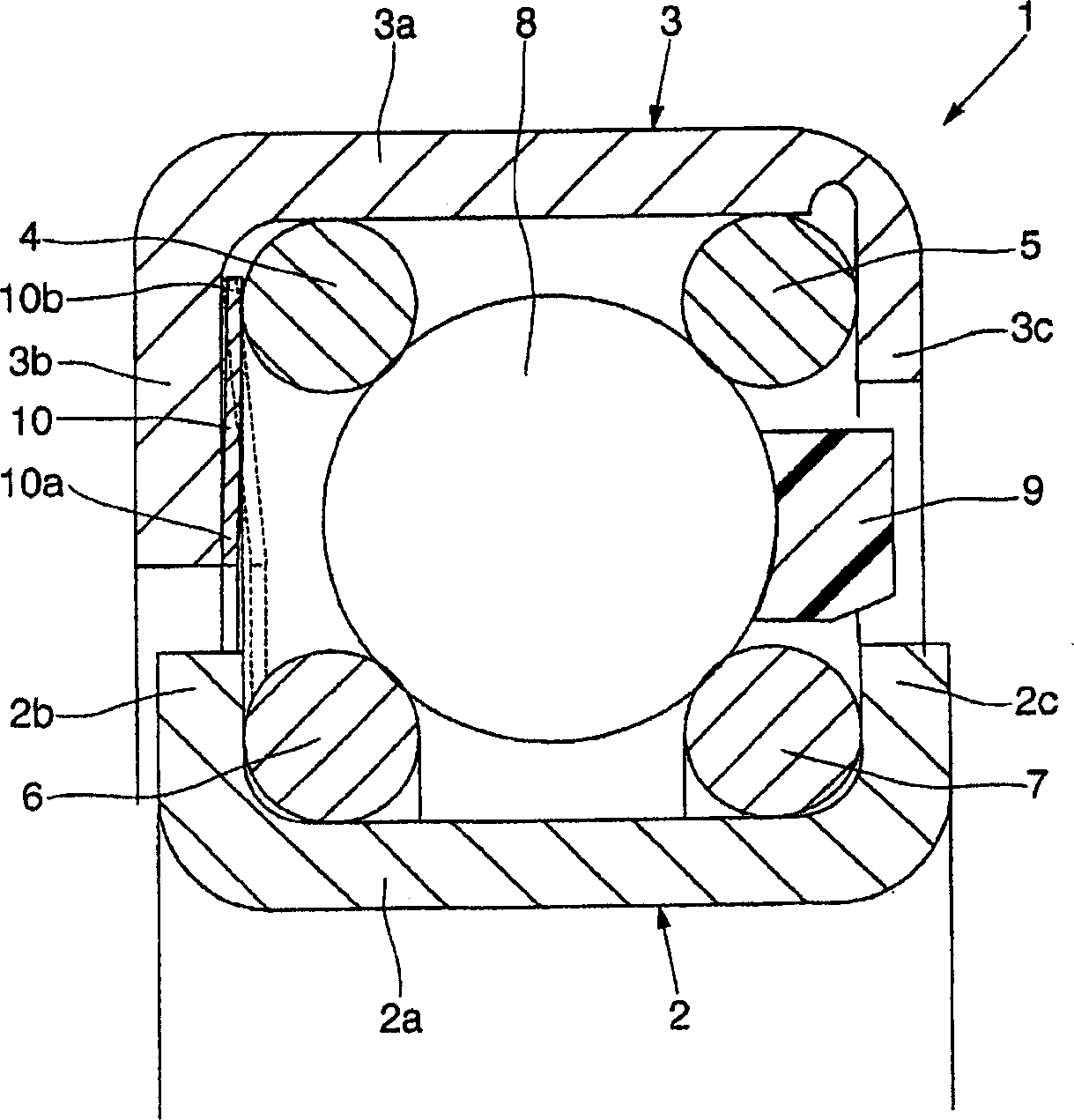

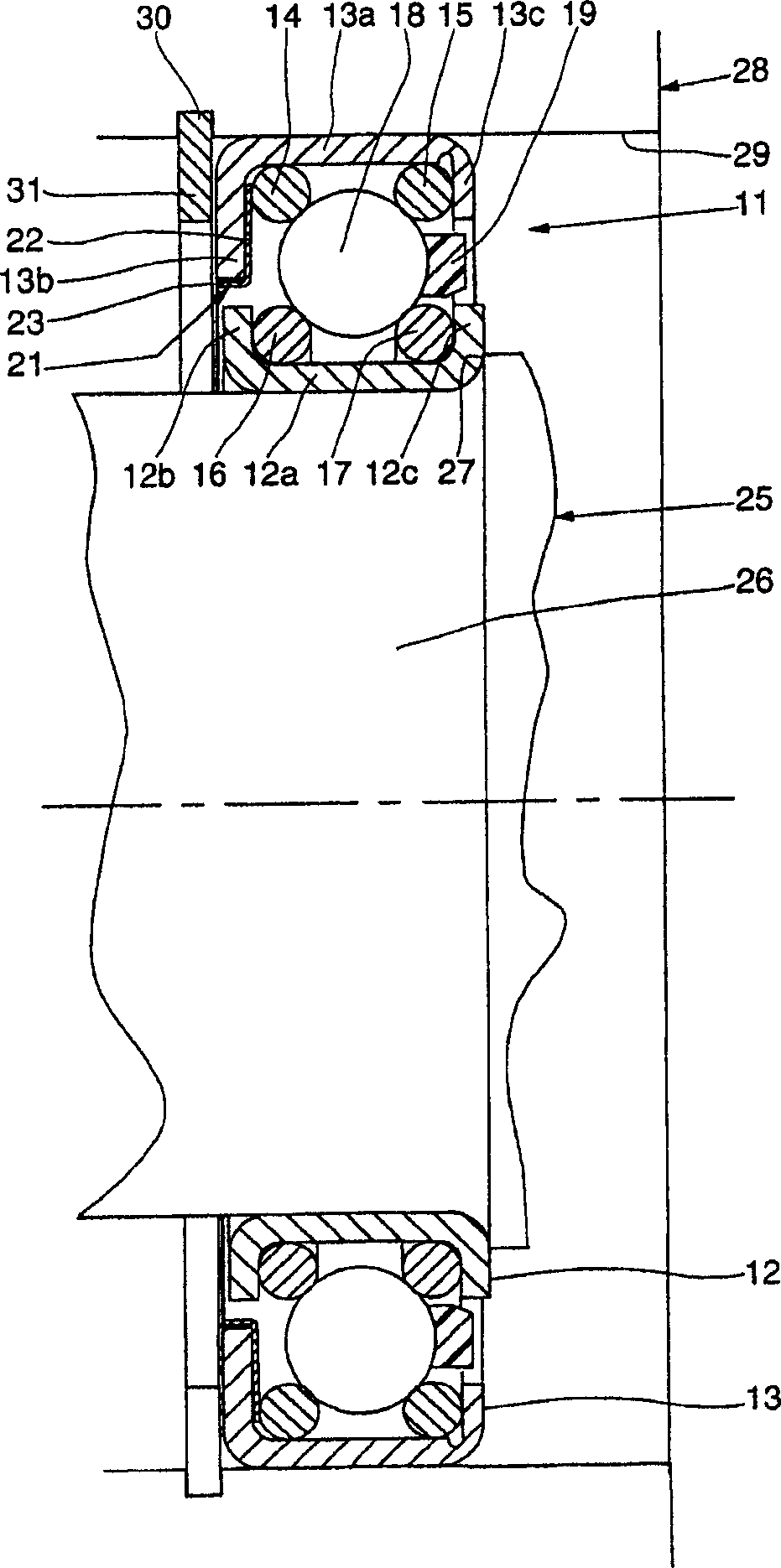

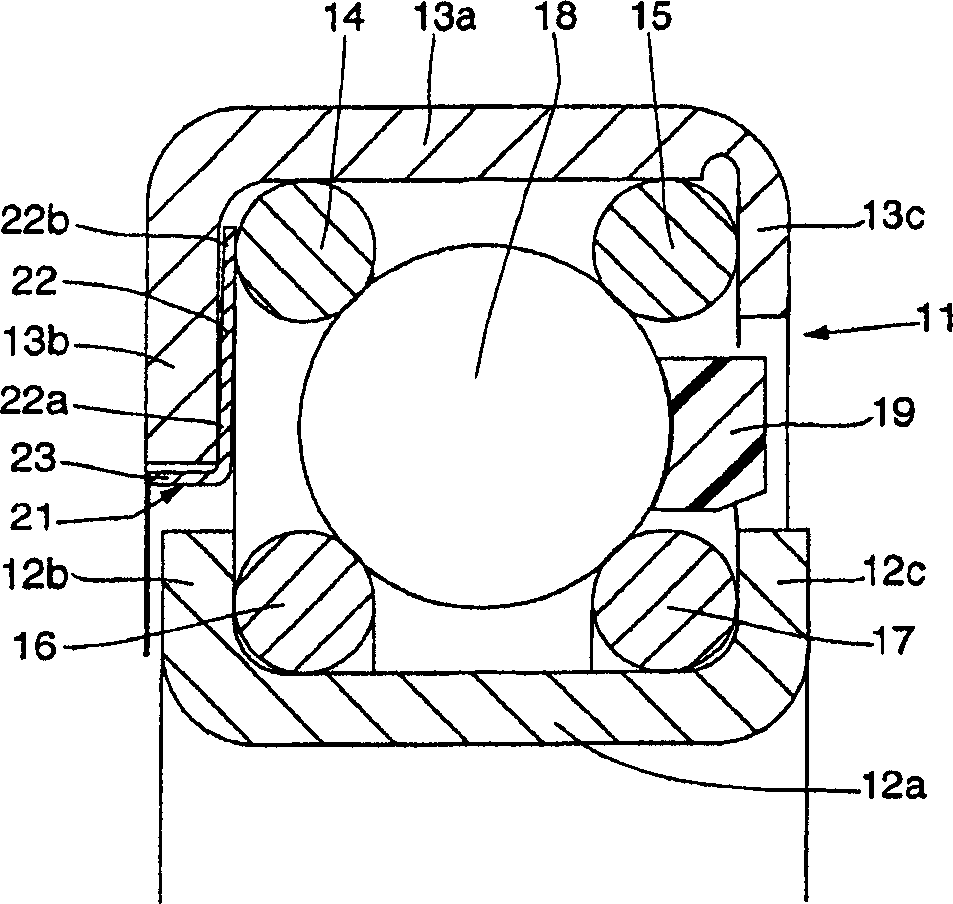

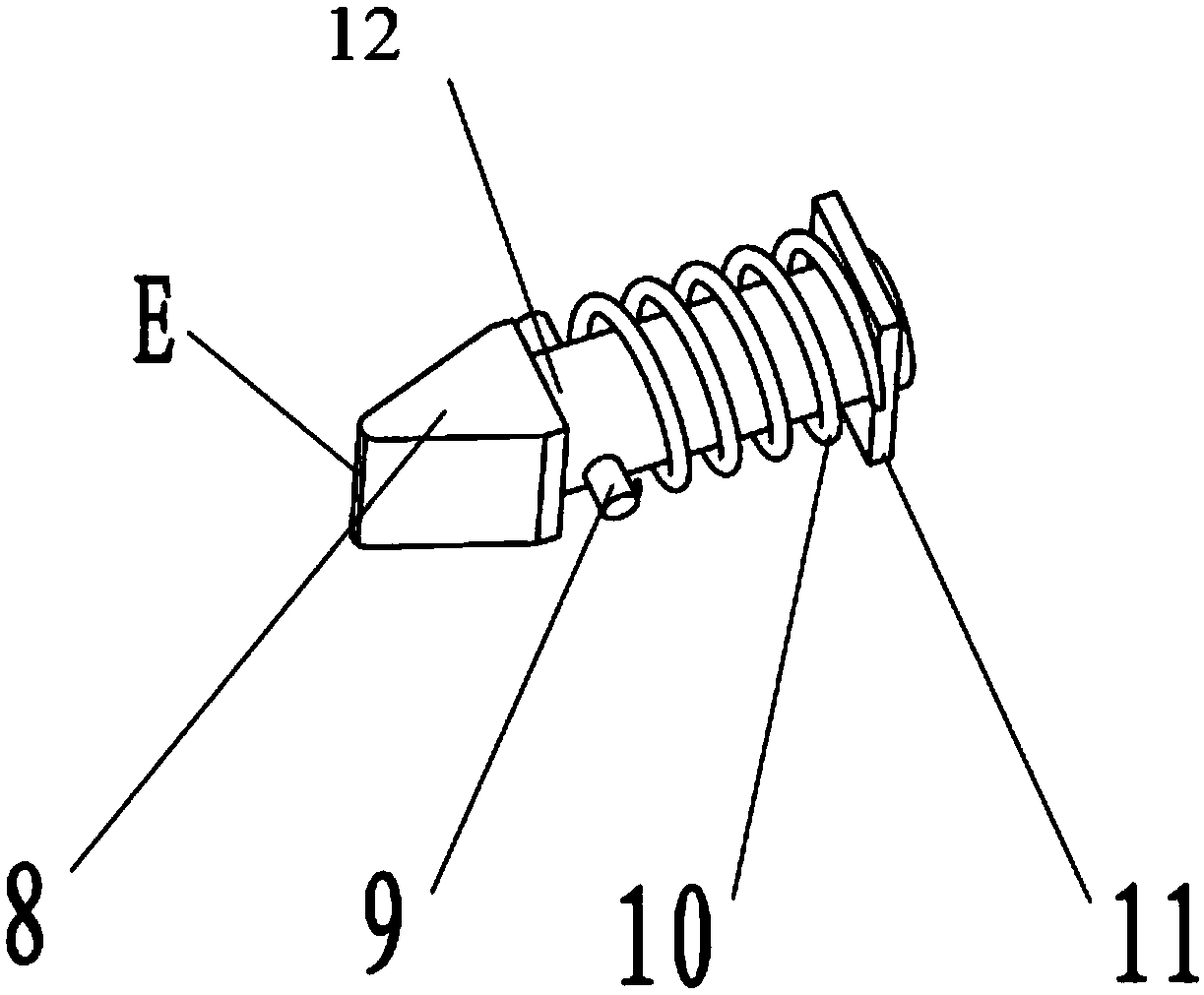

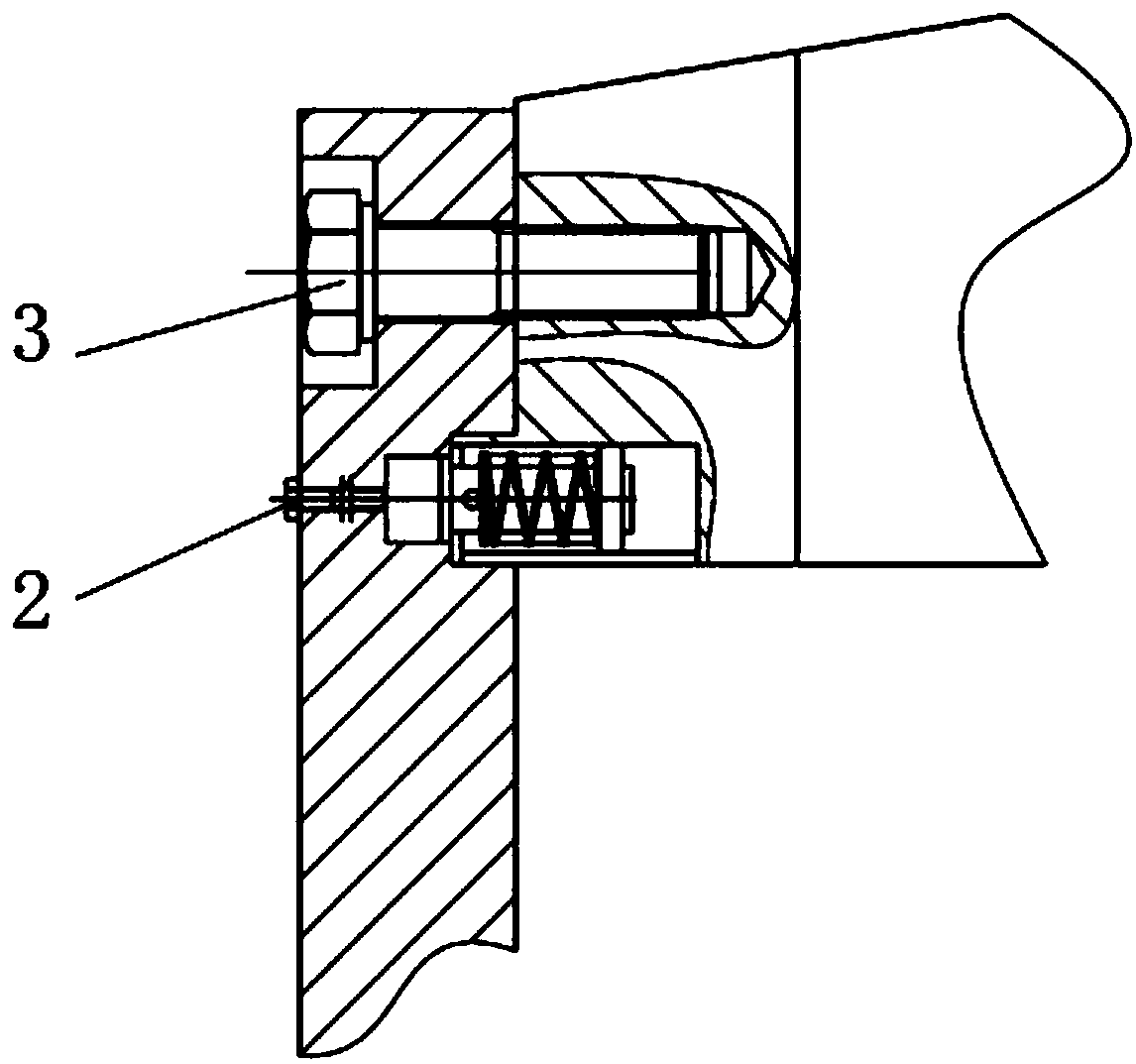

Antifriction bearing for a steering column

InactiveCN1551953ACompactness injuryReduce the risk of wrong method installationBall bearingsBearing componentsSteering columnEngineering

The invention relates to an antifriction bearing for a steering column. The inventive device comprises an outer ring and an inner ring, each of said rings being fitted with a raceway for rolling elements (8) which are in contact with said raceways. At least one of the rings comprises an annular casing (3) to which two wires (4, 5) are mounted which form a raceway for the rolling elements (8). Moreover, said device comprises a preload washer (10) which is mounted axially between a radial portion of the casing (3) and one of the wires. The aforementioned wire is in contact with the bore of an axial portion of the casing (3) and another wire is also in contact with the bore of said axial portion of the casing (3).

Owner:AB SKF

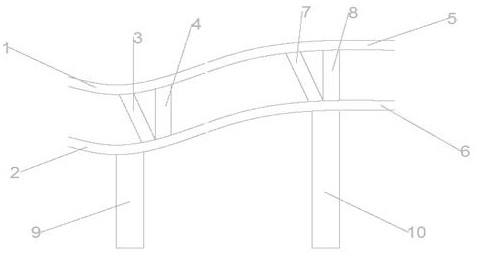

Non-bracket arch ring mounting method of concrete-filled steel tubes arch bridge

ActiveCN110685232AEasy to liftImprove splicing efficiencyBridge erection/assemblyArch-type bridgeArchitectural engineeringSteel tube

The invention relates to the technical field of bridge construction, in particular to a non-bracket arch ring mounting method of a concrete-filled steel tubes arch bridge. The non-bracket arch ring mounting method of the concrete-filled steel tubes arch bridge comprises the following steps of S1, construction of an arch seat; S2, mounting of a track; S3, erection of a transporting platform; and S4, splicing of arch ribs, wherein after the first section of arch rib is mounted to each arch seat, a crane is transported to the first section of arch rib; by controlling the crane to creep on the track, the crane can hoist the next section of arch rib on the previous section of arch rib; the two adjacent arch ribs in the riverway width direction are spliced with each other through a flange plateto splice an arch ring whose interior is through; and the two opposite arch ribs on the same bottom plate are connected through a cross brace after being spliced with each other; S5, mounting of a buckle cable; and S6, pouring of concrete. According to the non-bracket arch ring mounting method of the concrete-filled steel tubes arch bridge, by enabling the crane to creep on the arch ring and splicing the arch ribs by using a mode of hoisting the arch ribs, the arch ring can be mounted without using a bracket.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

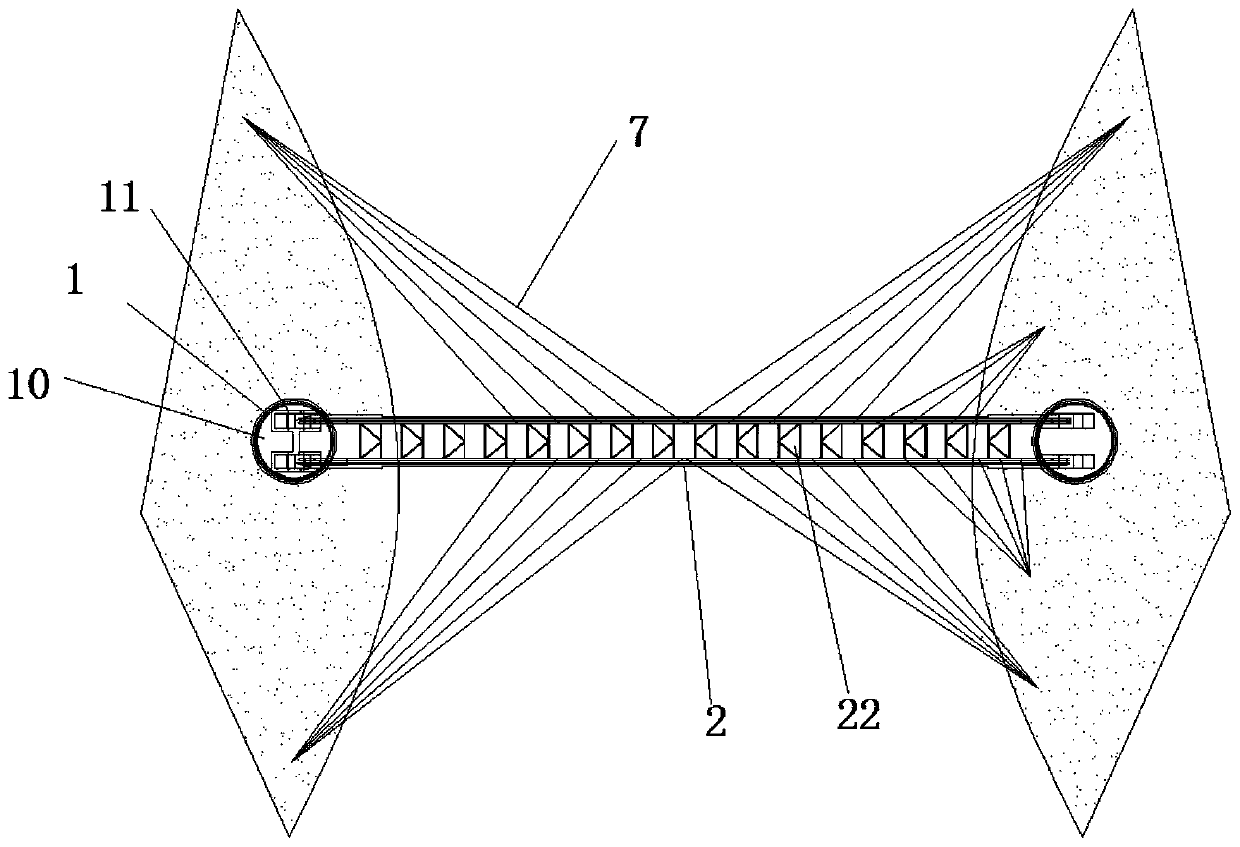

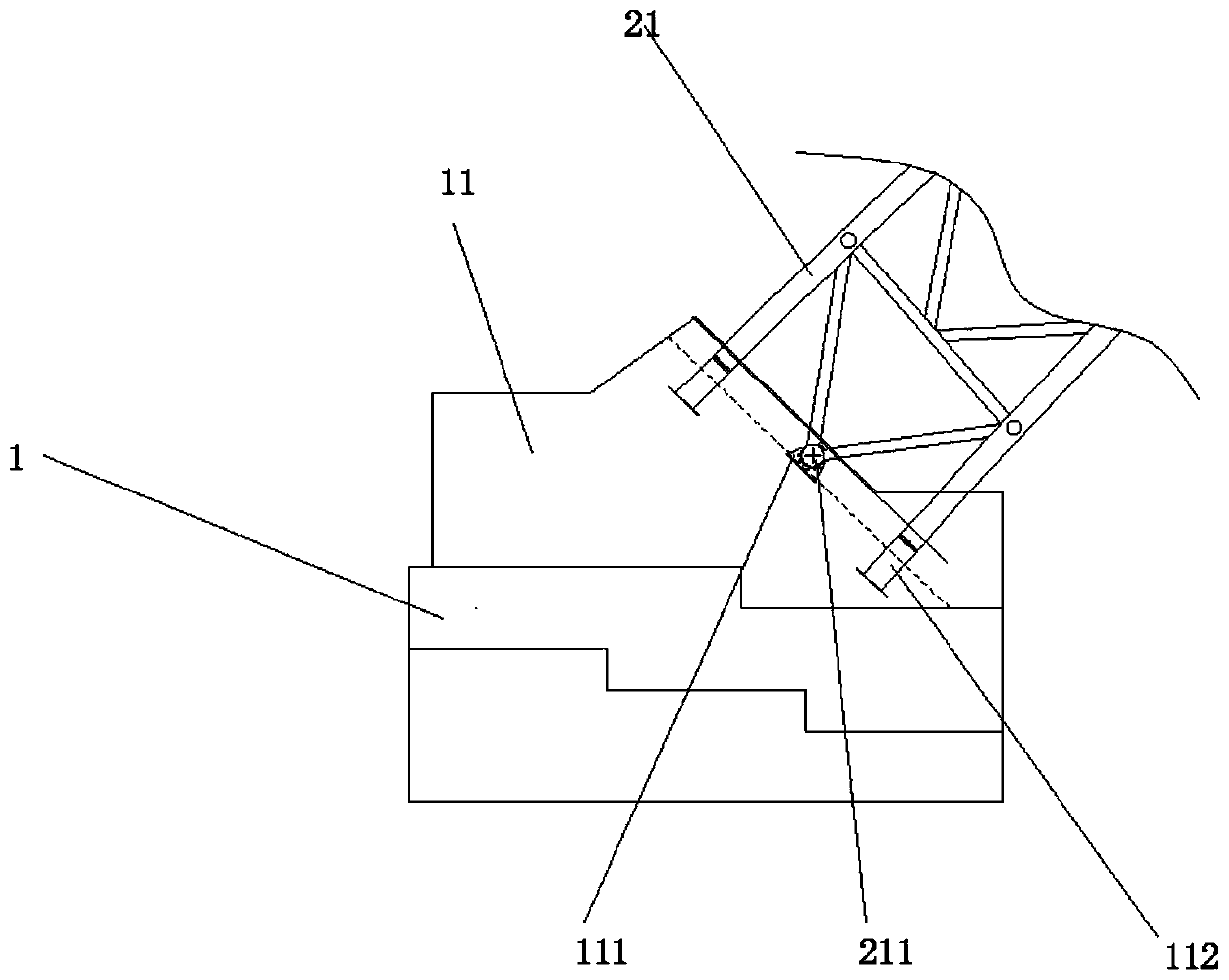

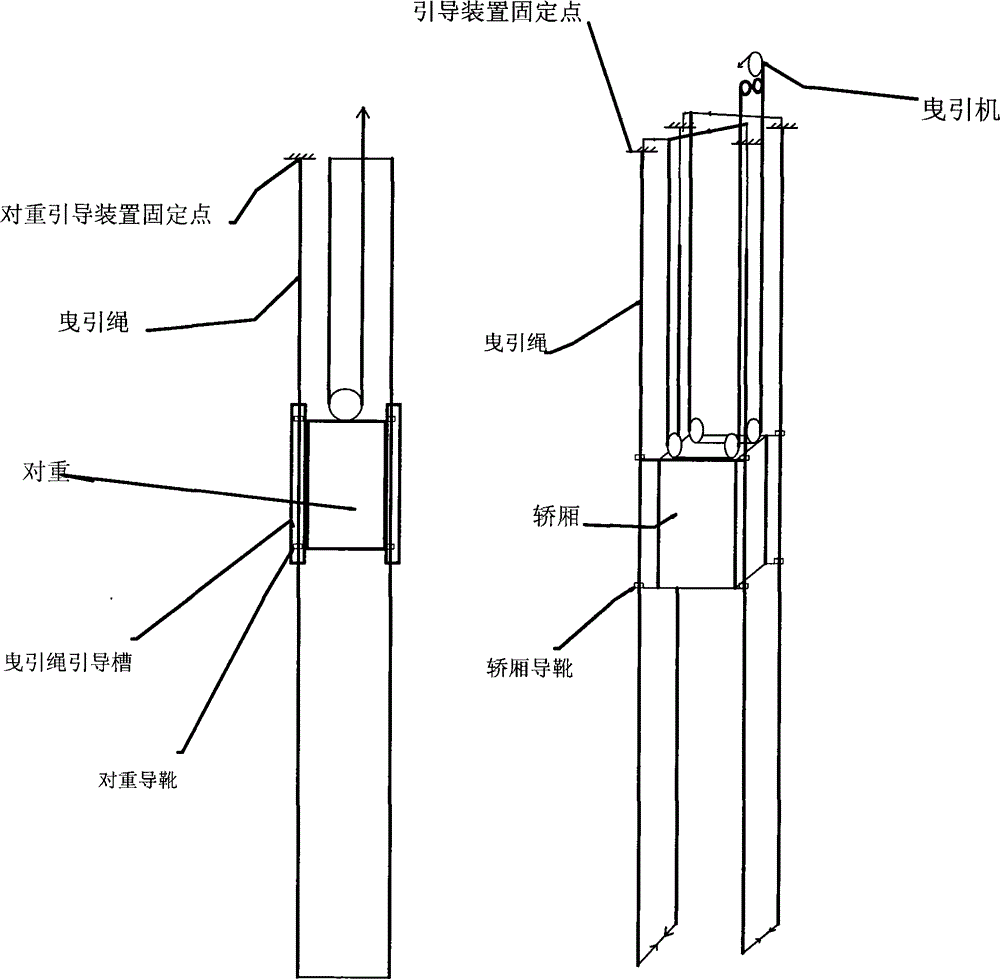

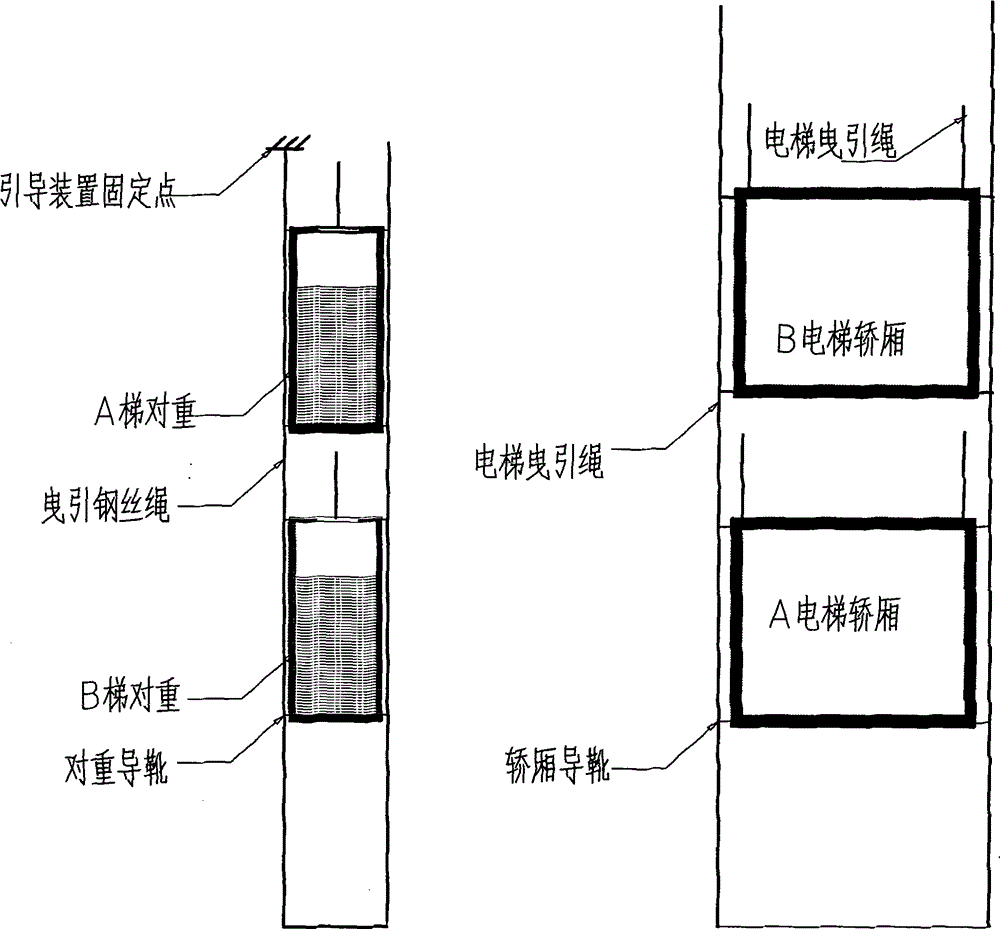

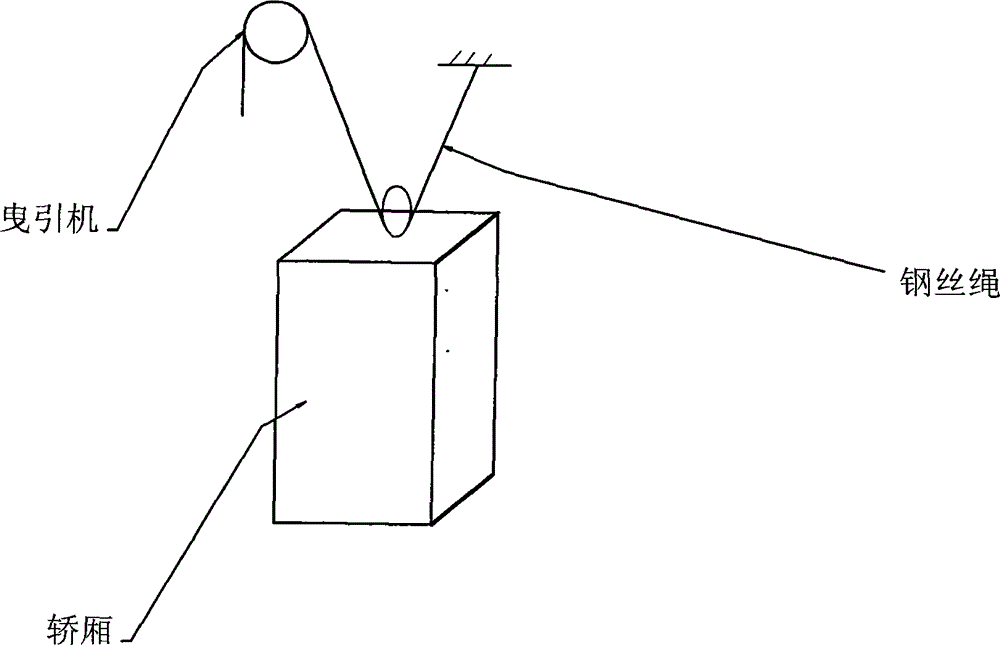

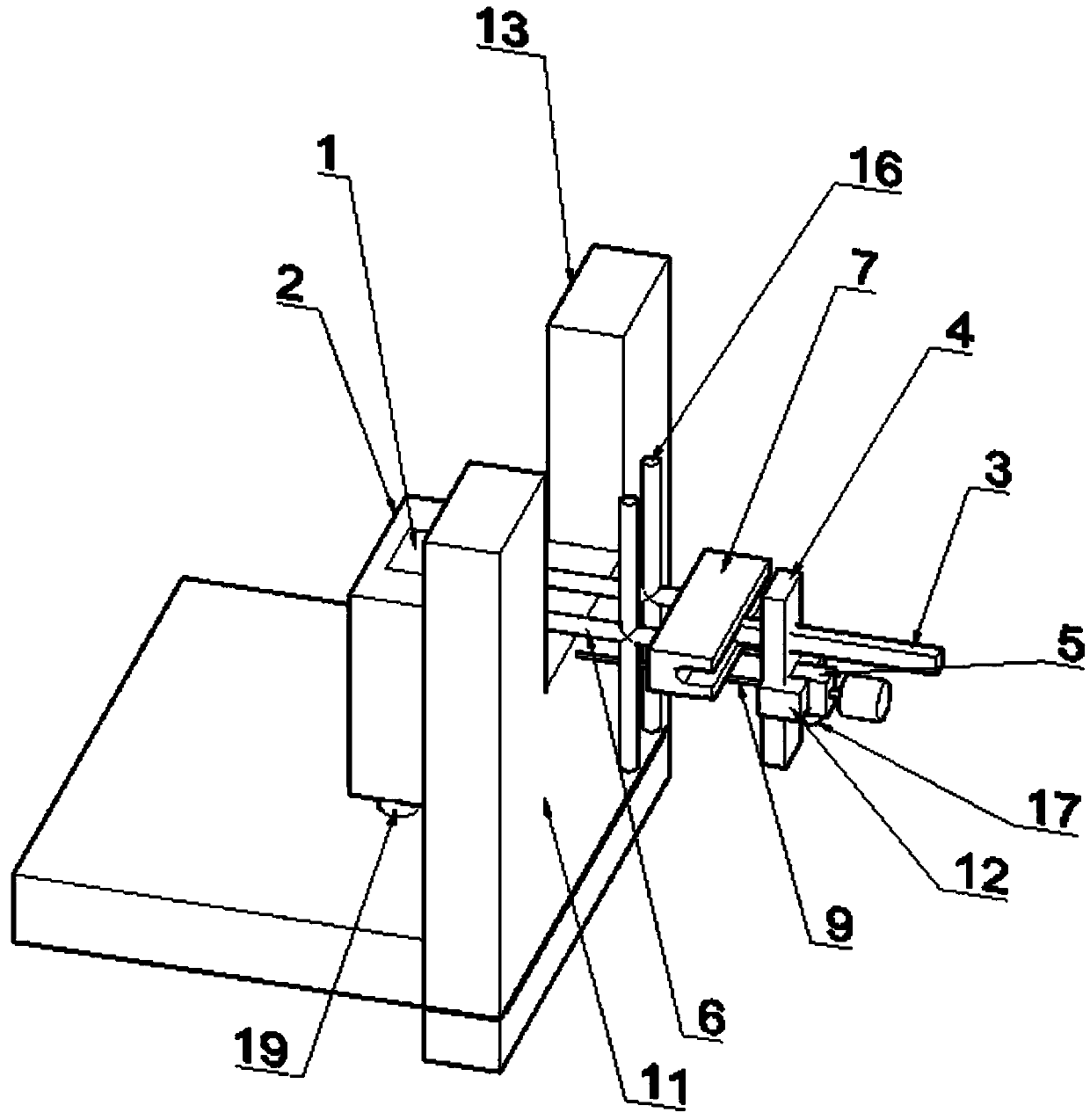

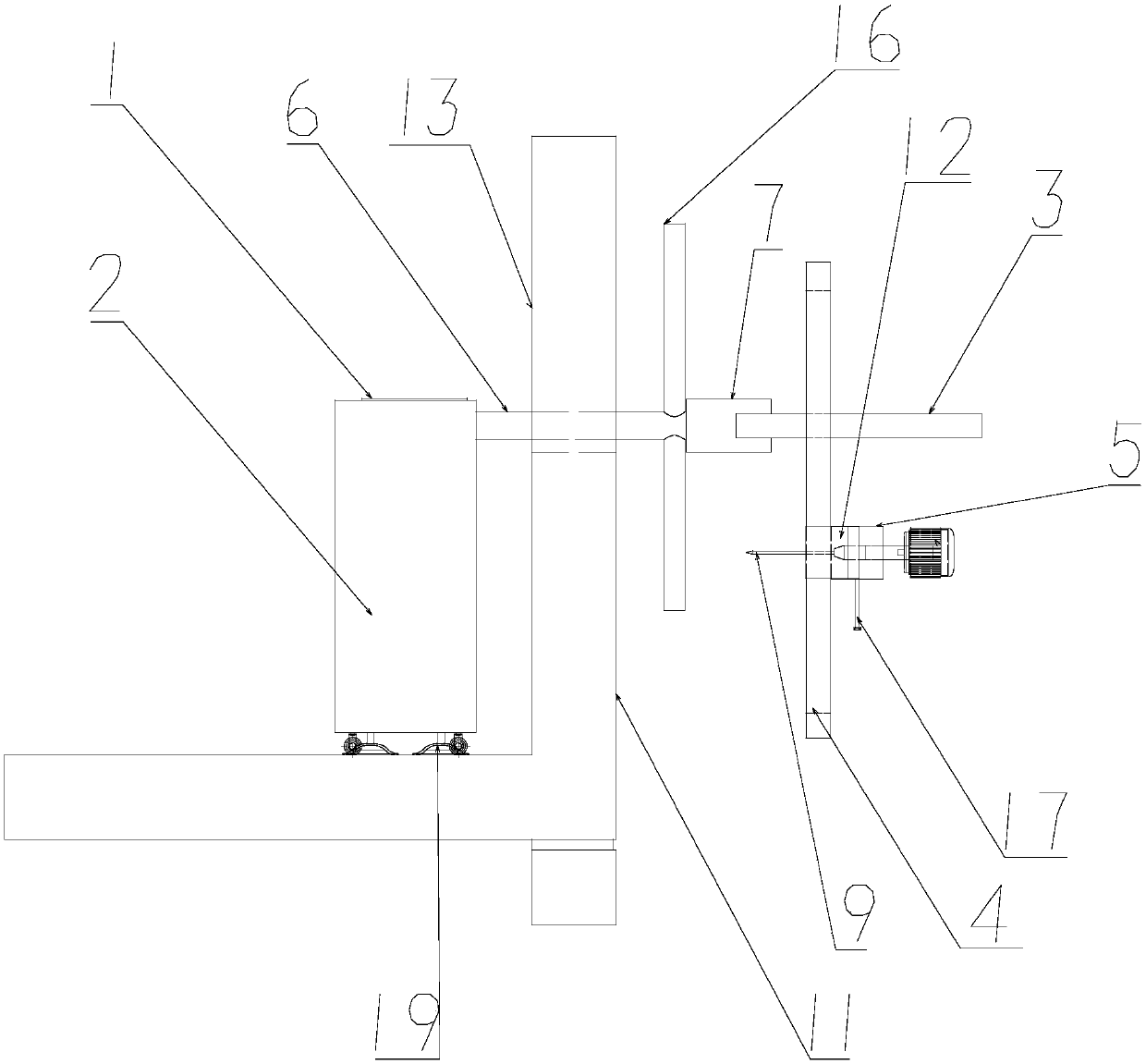

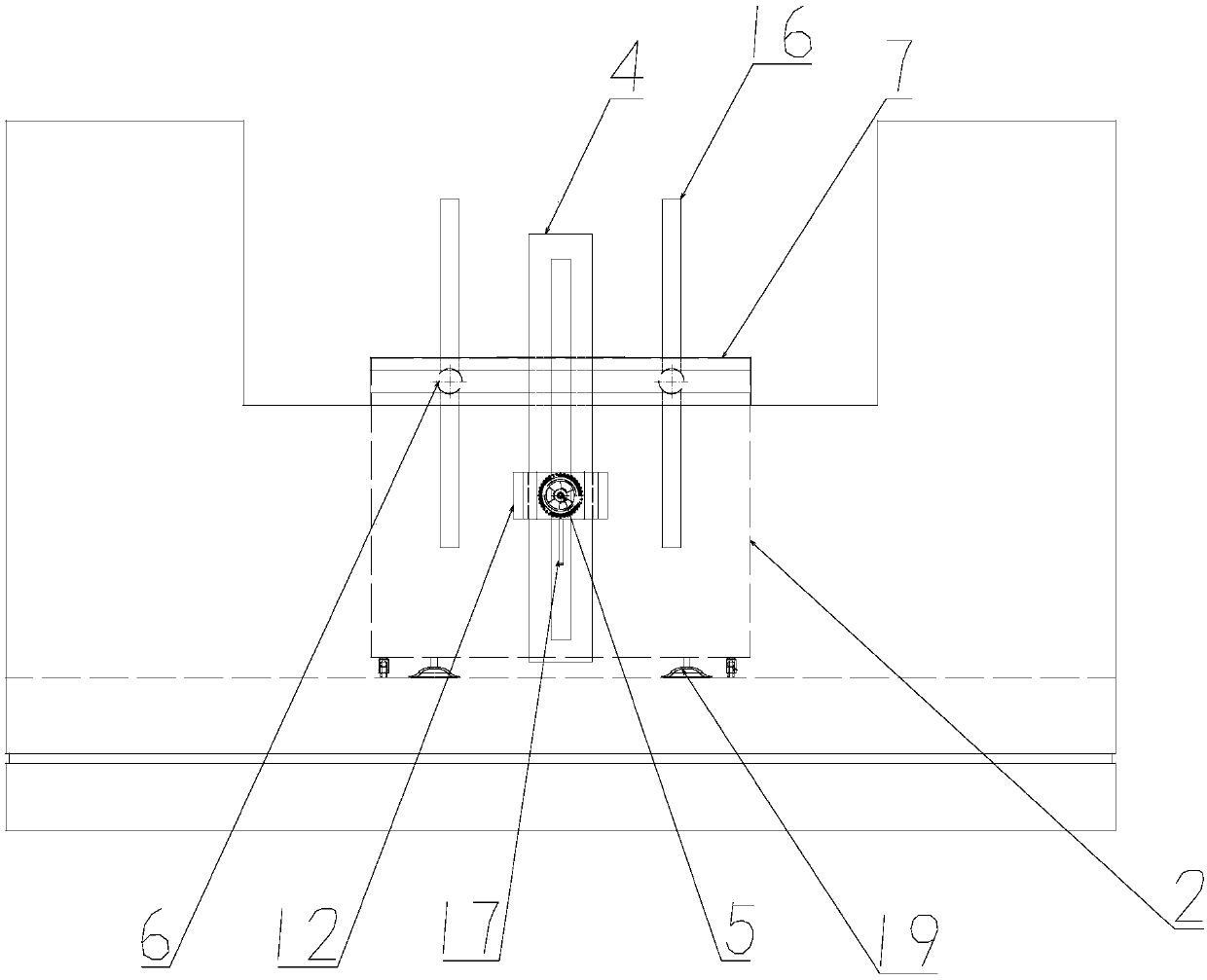

elevator

InactiveCN102887415BReduce manufacturing costReduce installation costsElevatorsBuilding liftsAcousto-opticsAlarm device

The invention provides a brand-new elevator aiming at the situations of high manufacturing cost, high civil engineering construction cost, high installation risk and the like of the conventional elevator. An elevator operation guide device is vertically hung at the upper end of an elevator shaft or a machine room and is used for guiding an elevator cage or a counterpoise to operate; and elevator hoisting ropes are respectively arranged at the positions of four corners of the cage vertically or are hoisted in the form of a hoisting surface. A hoistway door adopts a clamping way; wires of a control cabinet are integrated into a circuit board; a safety fence of a switch is arranged above a cage door machine; pr-buried foundation bolts are arranged at the corresponding positions of the wall of the elevator shaft; a guide rail can be directly arranged on the bolts; a blocking rope is arranged at the lower end or the upper end of the elevator shaft so that the elevator is retarded in a forced way; and an acousto-optic alarm device for an elevator maintenance state is arranged. By the elevator provided by the invention, the manufacturing cost, the civil engineering construction cost and construction accident risks can be greatly reduced; and a plurality of elevators can be operated on the same guide rail.

Owner:保定申菱机电有限公司

Cooperative control air-conditioner outdoor unit installing equipment and method

ActiveCN109668222AImprove installation qualityGuaranteed installation efficiencyLighting and heating apparatusAir conditioning systemsEngineeringCo operative

Owner:CHANGZHOU UNIV

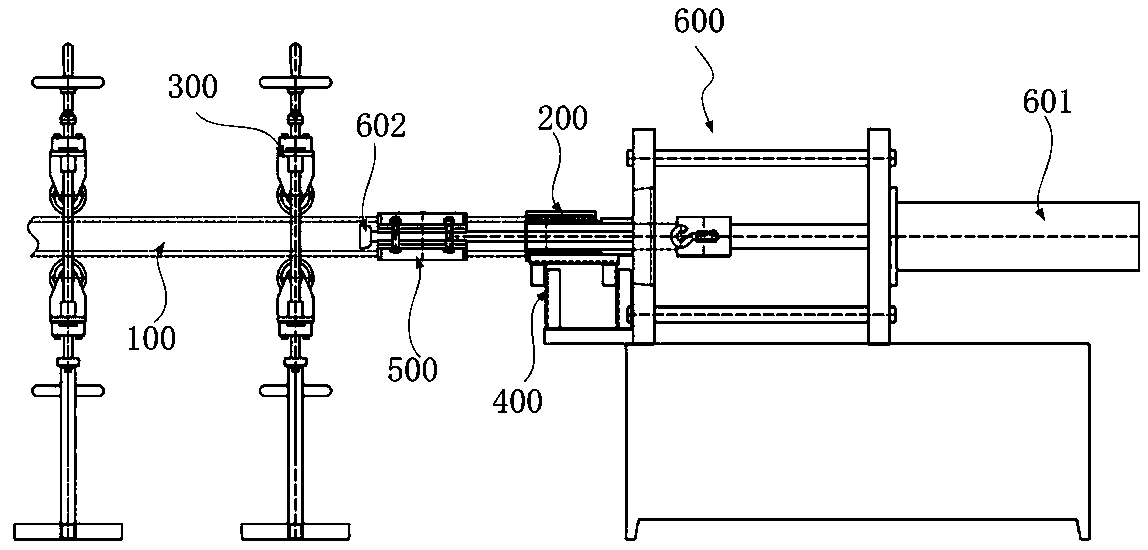

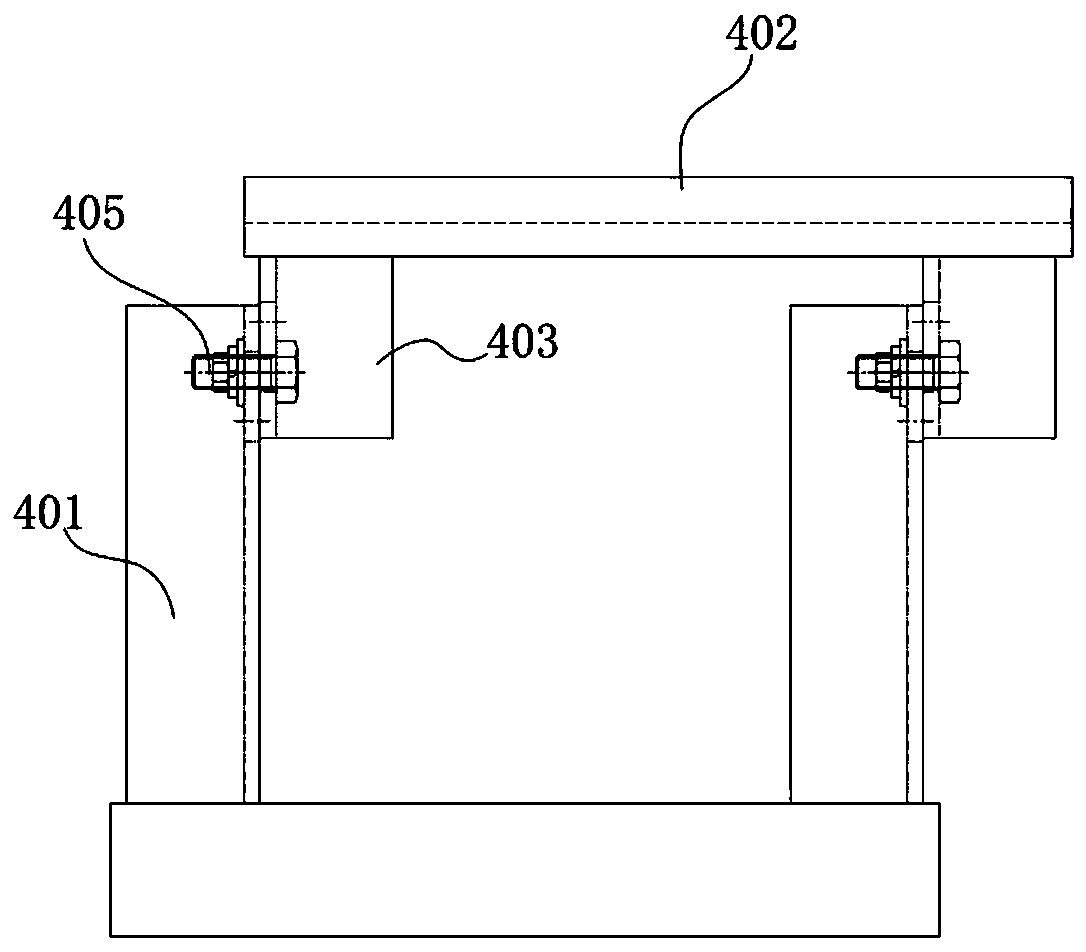

Joint mounting equipment and connecting method of flexible pipe and joint

ActiveCN110843221AReduce installation riskImprove installation accuracyTubular articlesEngineeringStructural engineering

The invention provides joint mounting equipment and a connecting method of a flexible pipe and a joint. The joint mounting equipment comprises a joint supporting mechanism for placing a joint, a pipemounting dragging mechanism and a joint pressing mechanism, wherein the joint supporting mechanism is used for supporting the flexible pipe and aligning the flexible pipe and a flexible pipe aligned to the joint to a bracket; the pipe mounting dragging mechanism is sleeved on the flexible pipe for pulling the flexible pipe to move toward the joint and inserting the flexible pipe into the joint; and the joint pressing mechanism is used for compacting the flexible pipe and the joint and comprises a joint outer pressing die, a joint inner swelling die, a baffle plate and a driving mechanism. Whenthe joint is pressed, the driving mechanism enables the joint inner swelling die and the joint to move relatively along the axial direction of the joint and the joint outer pressing die and the jointto move relatively along the axial direction of the joint; and the baffle plate is used for limiting axial movement of the joint when the flexible pipe is inserted into the joint. The joint mountingequipment is high in pressing efficiency, the quantity of operators for mounting the joint of the flexible pipe is reduced greatly, and meanwhile, the risk of mounting the joint of the flexible pipe is reduced, the mounting precision and the pressing efficiency are improved greatly, and the safety is improved.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

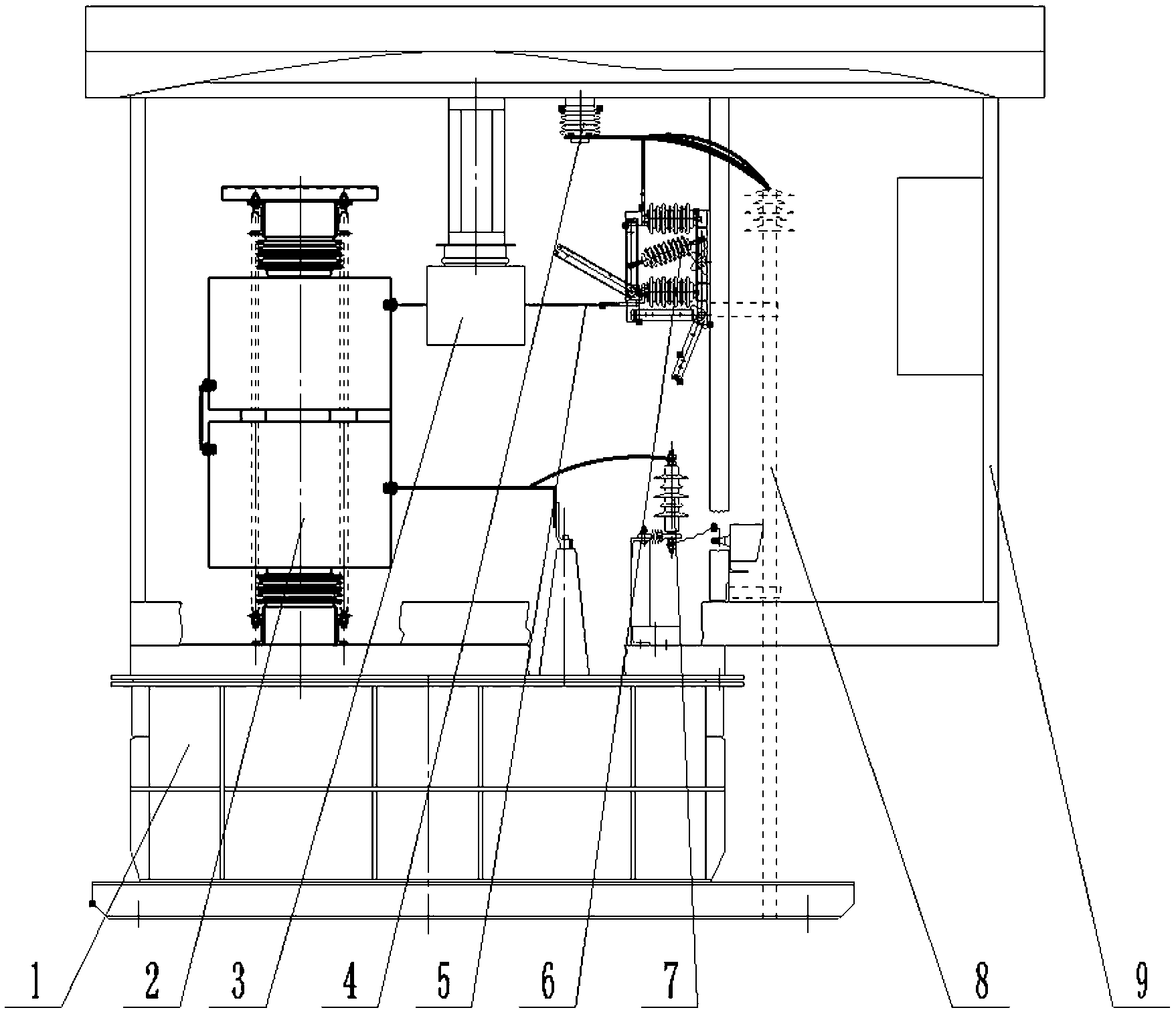

Compact integration high voltage power capacitor device

ActiveCN103311931ASmall footprintLayout specificationReactive power adjustment/elimination/compensationReactive power compensationForeign matterTransformer

The invention discloses a compact integration high voltage power capacitor device, mainly consisting of an integration capacitor module and a box transformer substation module, wherein the box transformer substation module is arranged above the integration capacitor module. The internal mounting and assembling work of the power capacitor device is finished before leaving a factory, so that the power capacitor device can be wholly dispatched. The field installation workload is reduced to minimum, and basically, the whole device needs to be in position, a primary cable connector and a secondary cable connector need to be mounted for work. The integration level is high, the device has the obvious characteristics that the mounting is instant and the use is instant, and the mounting cost of the device and the corresponding mounting risk are reduced at the same time. A platform above the integration capacitor module is taken as a mounting platform, the box transformer substation module is arranged above the integration capacitor module, the layout space in the vertical direction is fully utilized, the structure is fully-closed, the occupied area and size can be effectively reduced, the hazard brought by rain and snow weather, birds trouble, foreign matters and the like can be effectively prevented, and the reliability when the device operates is improved.

Owner:GUILIN POWER CAPACITOR

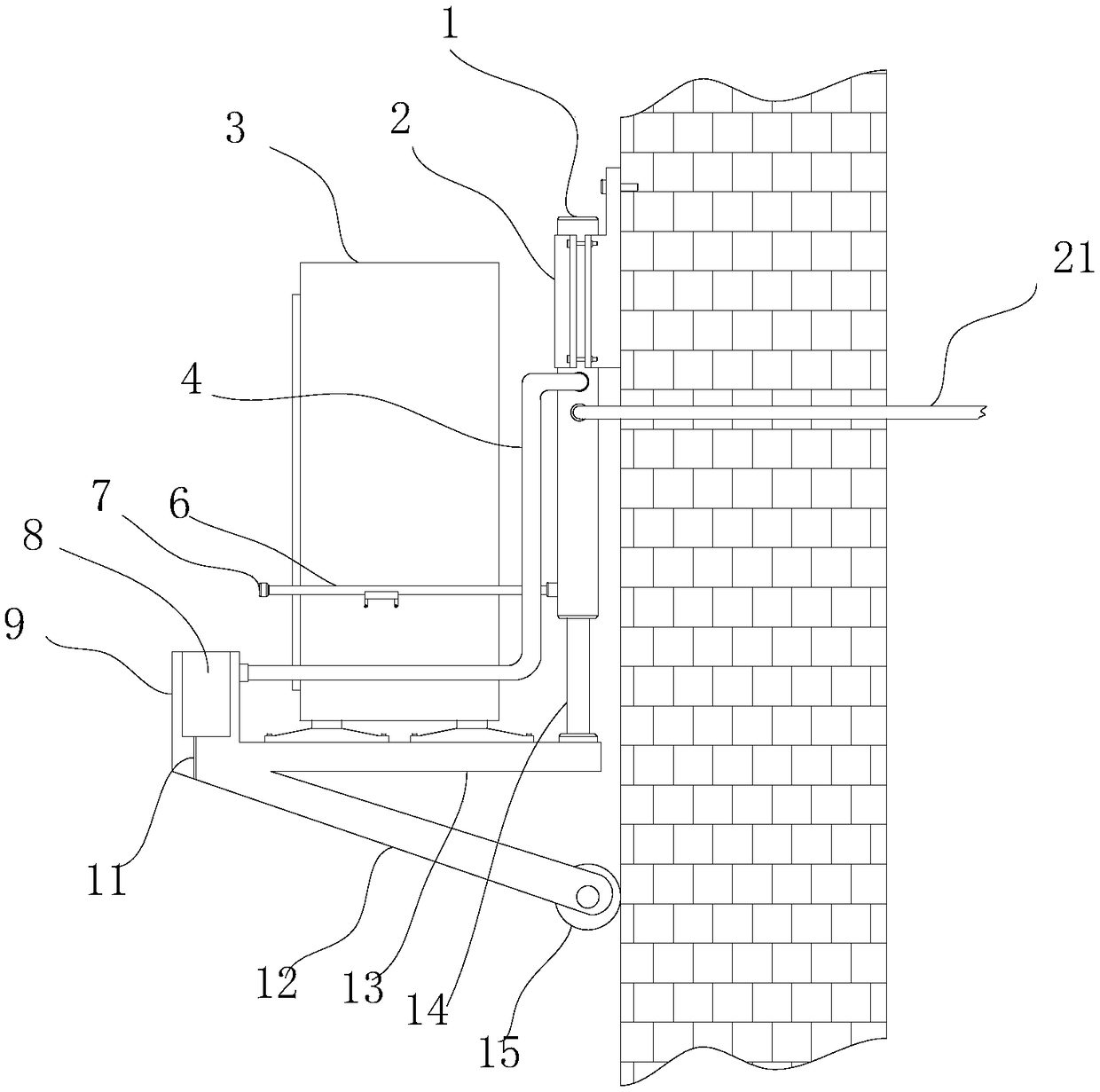

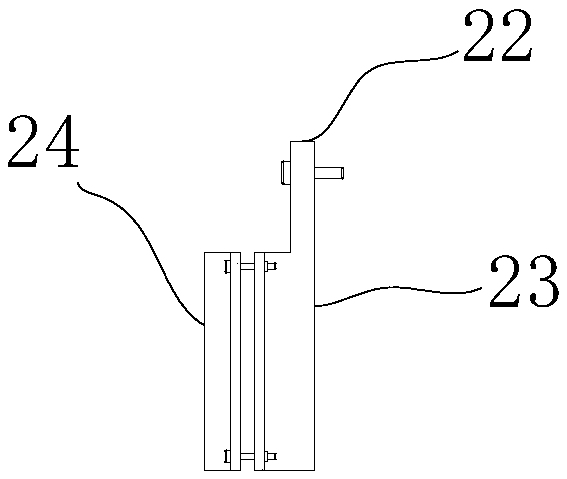

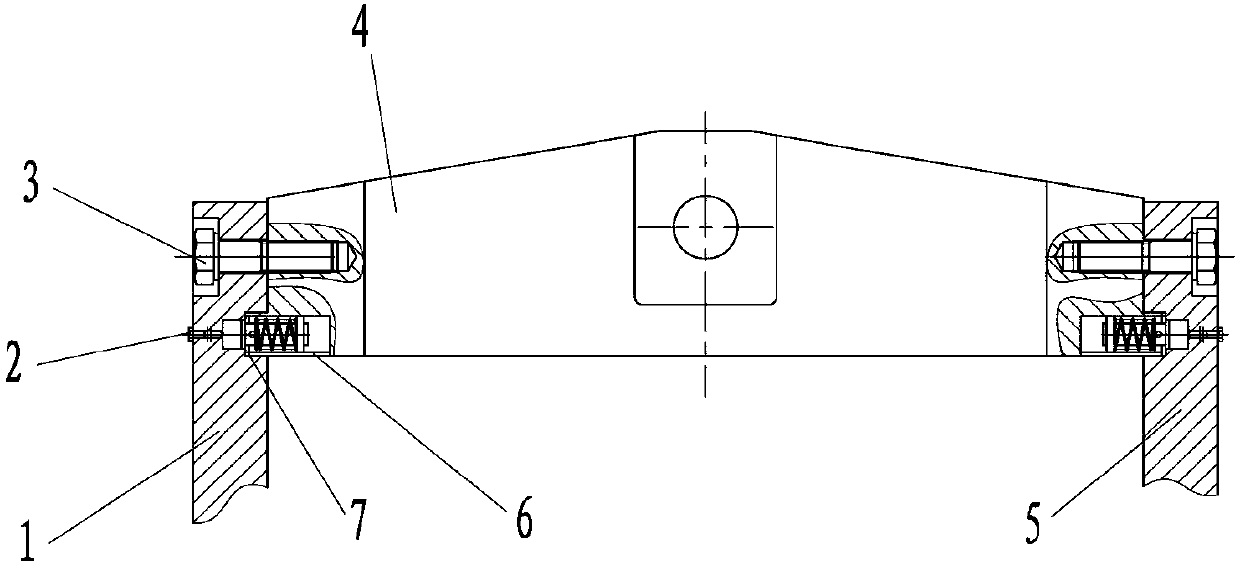

Self-locking cantilever beam, bearing device and operation platform

PendingCN110273537AImprove stabilityEasy to installScaffold accessoriesBuilding support scaffoldsEngineeringSelf locking

The invention provides a self-locking cantilever beam, a bearing device and an operation platform and relates to the technical field of construction tools. The self-locking cantilever beam comprises a cross beam and a clamping assembly arranged at one end of the cross beam. The clamping assembly can achieve the self-locking function. The clamping assembly comprises a first clamping part, a second clamping part, a connecting rod and a locking part. The first clamping part is arranged at one end of the cross beam. The two ends of the connecting rod are connected to the cross beam. The second clamping part is arranged on the connecting rod in a penetrated mode. The second clamping part can move close to or far away from the first clamping part to form a range adjustable clamping space between the first clamping part and the second clamping part. When the second clamping part moves to a preset position, the locking part can lock and limit displacement of the second clamping part so as to complete mounting of the self-locking cantilever beam. The self-locking cantilever beam is easy and convenient to mount and demount and can reduce the mounting risk of the personnel when personnel work at heights.

Owner:广州中石科技有限公司 +1

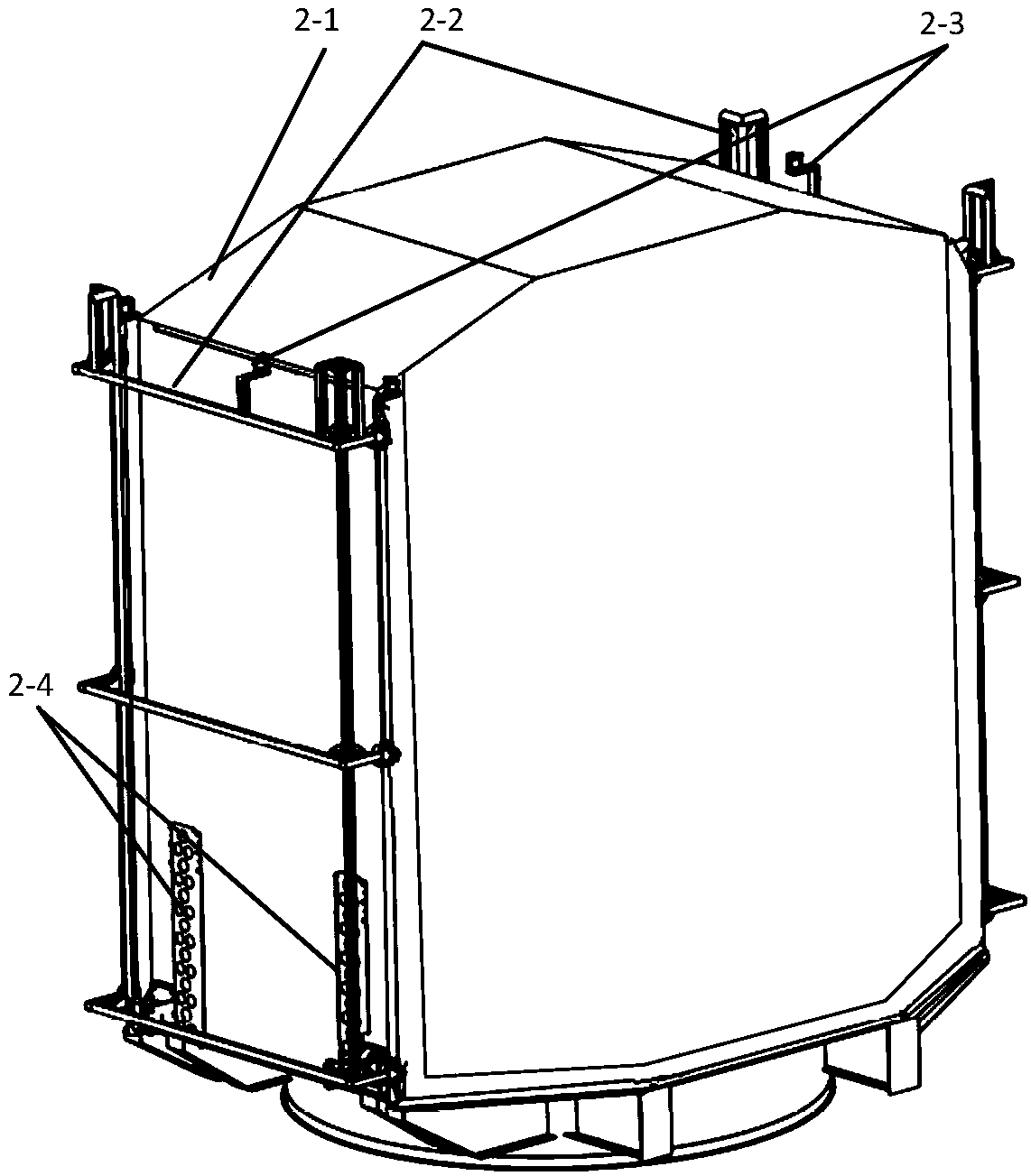

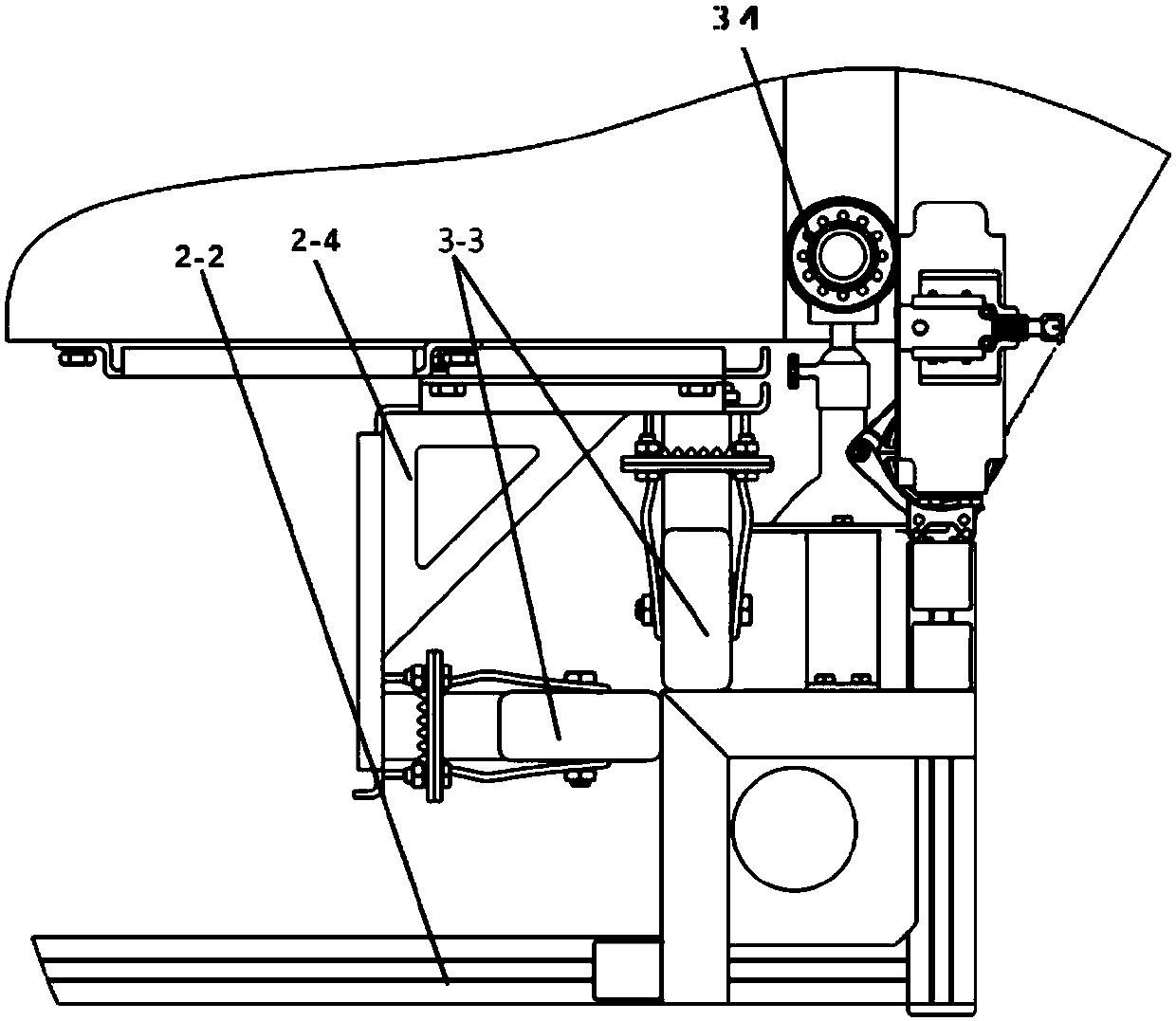

Auxiliary system for mounting optical camera in deep-embedded mode

ActiveCN107554822ASafe distance active monitoringReduce operating intensityCosmonautic vehiclesCosmonautic partsMonitoring systemEngineering

The invention discloses an auxiliary system for mounting an optical camera in a deep-embedded mode. The auxiliary system comprises two parts of a mechanical guiding device and a real-time monitoring system which are arranged inside a cabin body of a load cabin. The mechanical guiding device is in fastened connection with the load cabin through a load cabin hole position and guides the camera to beslowly embedded in the cabin body of the load cabin through a guiding roller set. The real-time monitoring system comprises a position and pose positioning part and a position and pose monitoring part for monitoring the safe distance between the camera and a satellite body by 360 degrees. Through an active and passive combination mounting process, the operation intensity of manual holding and gapobserving difficulty can be lowered, mounting risks are reduced, and the mounting time is saved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

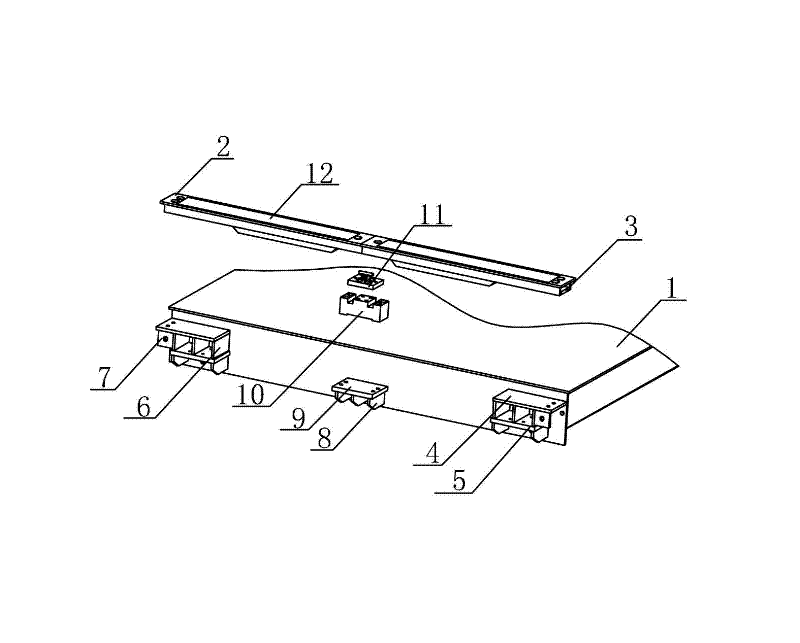

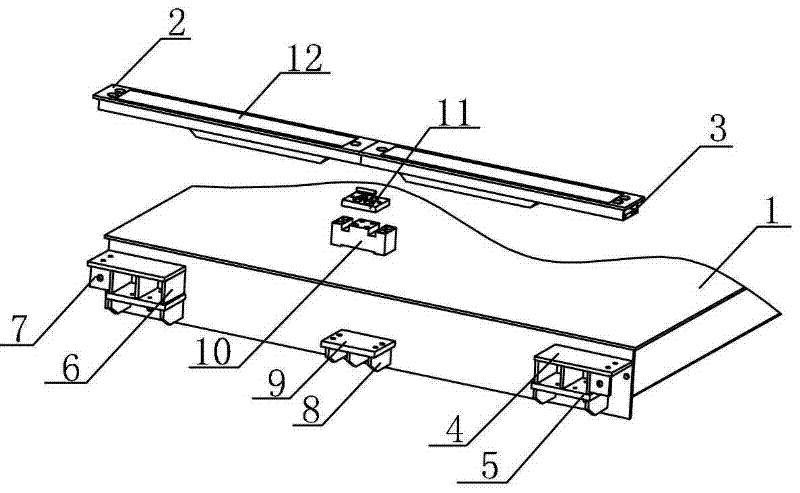

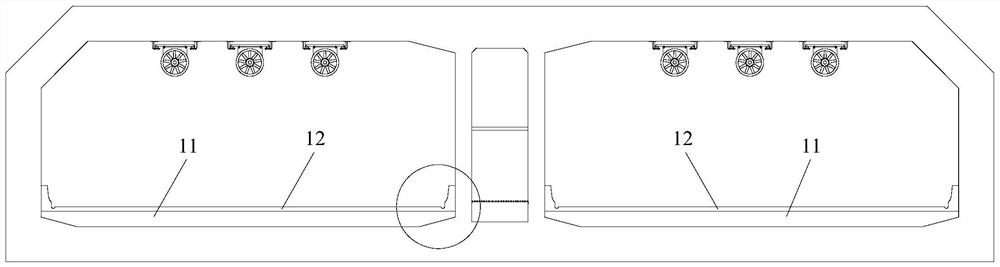

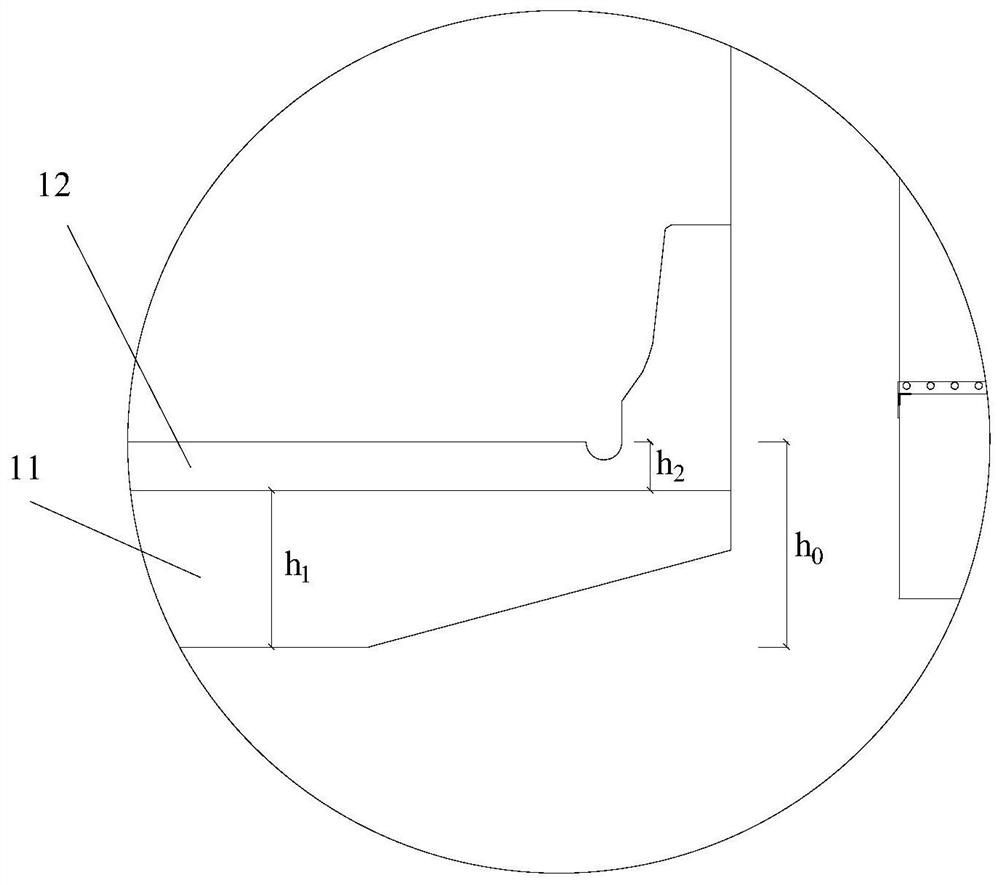

Whole-vehicle type weighing and axle number identifying device

InactiveCN102654415AReduce installation errorsReduce installation riskWeighing apparatus detailsSpecial purpose weighing apparatusIdentification deviceLoad cell

The invention discloses a whole-vehicle type weighing and axle number identifying device, comprising an electronic automobile weigher, wherein an axle number identification weighing platform is arranged at the end of the electronic automobile weigher and comprises a panel, a supporting beam, a supporting base and a sensor module, and the supporting beam and the supporting base are connected with the end of the electronic automobile weigher; and the axle number identification weighing platform is arranged at the end of the electronic automobile weigher, which is different from an independent mounting structure of the axle number identification weighing platform and the electronic automobile weigher, thereby avoiding troubles of manufacturing a concrete foundation for mounting the axle number identification weighing platform; and the axle number identification weighing platform is not directly arranged on the concrete foundation, thereby reducing mounting errors and damp risks and being convenient to overhaul, wherein the axle number identification weighing platform is further provided with a weighing sensor and can be used for measuring the weight of vehicle on the axle number identification weighing platform so that the weighing measurement of the electronic automobile weigher does not have a dead angle and an exacter result is obtained.

Owner:重庆大唐科技股份有限公司

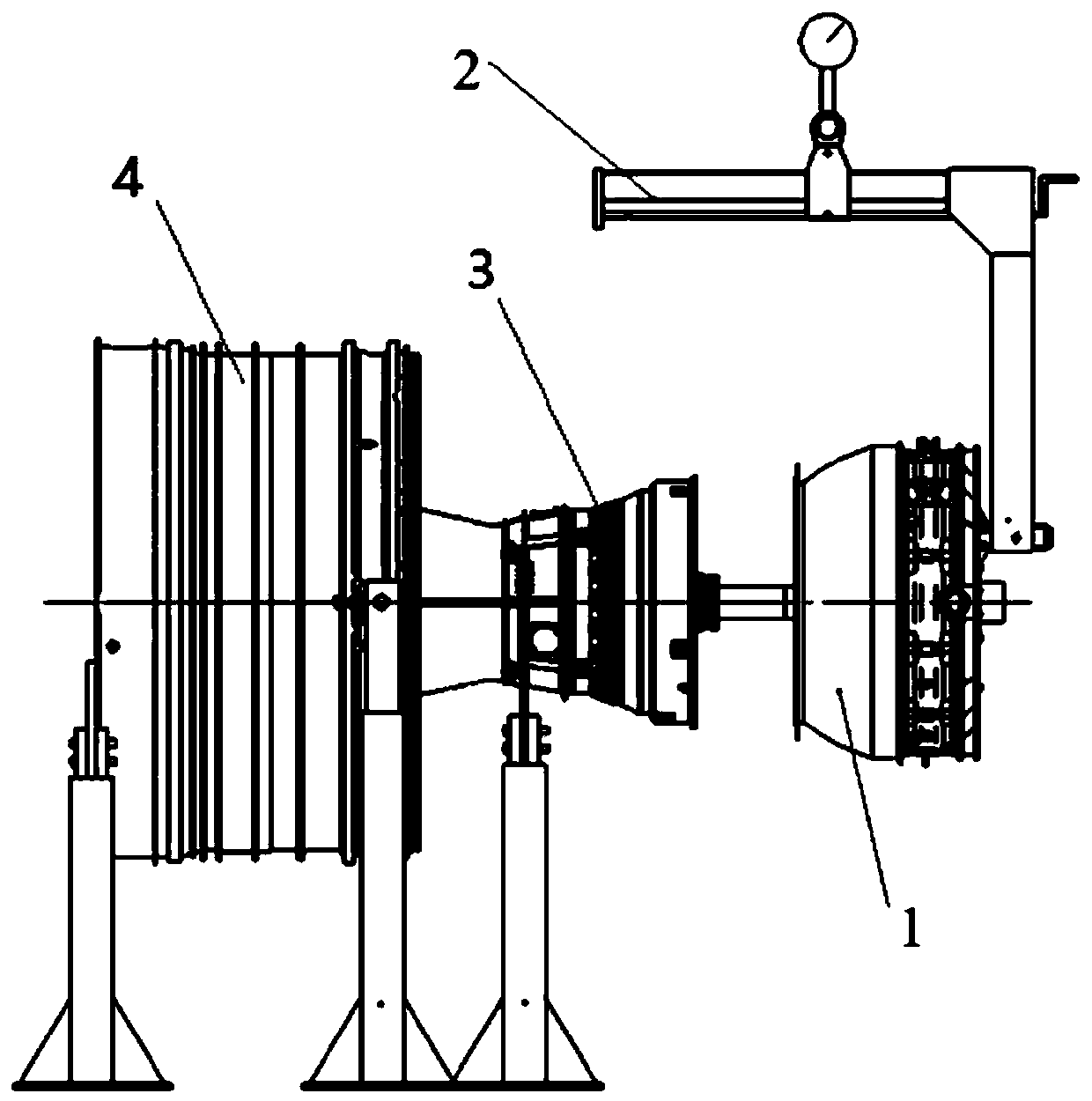

Traction tool for low-pressure turbine of engine

The invention provides a traction tool for a low-pressure turbine of an engine. The tool comprises a torque transmission bushing and a traction shaft sleeve, wherein in an assembly process, the traction end of a low-pressure turbine shaft sequentially passes through a core machine, the traction shaft sleeve and a connecting shaft sleeve and extends to the outside of a fan rotor, in an assembly process of a low-pressure turbine, torsion force is applied to a traction shaft outside, the traction shaft and the connecting shaft sleeve rotate synchronously, in the rotation process of the fan rotor,the traction shaft is driven to move axially through threads, so that the low-pressure turbine shaft has double acting force of rotation and axial movement, furthermore, a bearing cylindrical rolleron the low-pressure turbine shaft is gradually assembled into a bearing outer ring during rotation, thus solving the problem of mechanical collision between the cylindrical roller and the bearing outer ring in an existing assembly process.

Owner:AECC AVIATION POWER CO LTD

Rapid positioning device for traveling block lifting beam

ActiveCN107746015ARapid positioningReduce labor intensityTrolleysTraveling blockMechanical engineering

The invention discloses a rapid positioning device for a traveling block lifting beam. The rapid positioning device comprises a left side plate, the lifting beam, a right side plate and lock tongue assemblies. The lock tongue assemblies are mounted in the central positions of the ends of the lifting beam, and the lower portions of the lock tongue assemblies are fixed with bottom baffles in a supported mode, and the front portions of the lock tongue assemblies are fixed with limiting plates in a clamped mode. The lifting beam is inlaid in the left side plate and the right side plate and then fastened through bolts. By controlling the lock tongue assemblies to extend or retract in the predetermined positions, rapid positioning and assembling of the traveling block lifting beam are achieved,the labor intensity and risks of workers are reduced greatly, and the assembling time is saved. The rapid positioning device is convenient and reliable to use and easy and convenient to operate and maintain.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

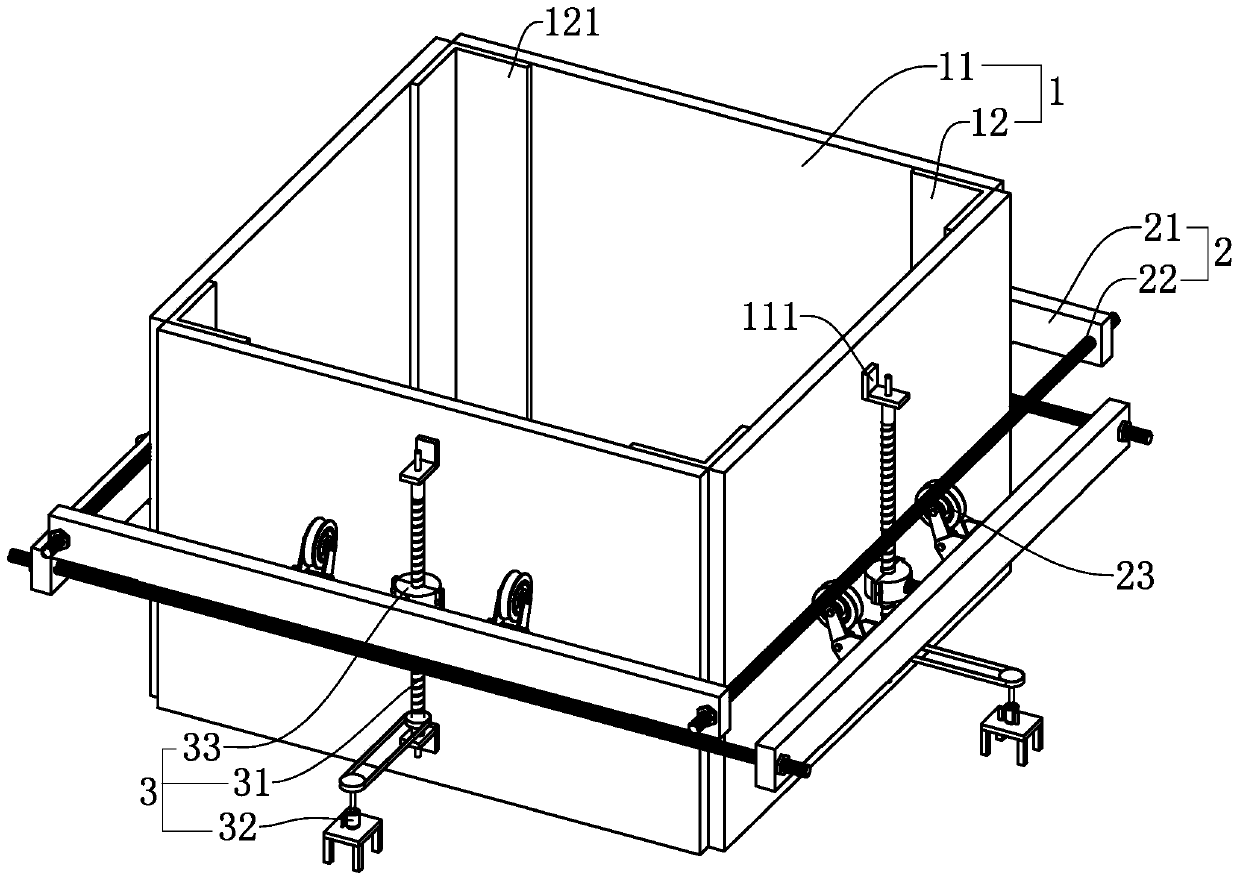

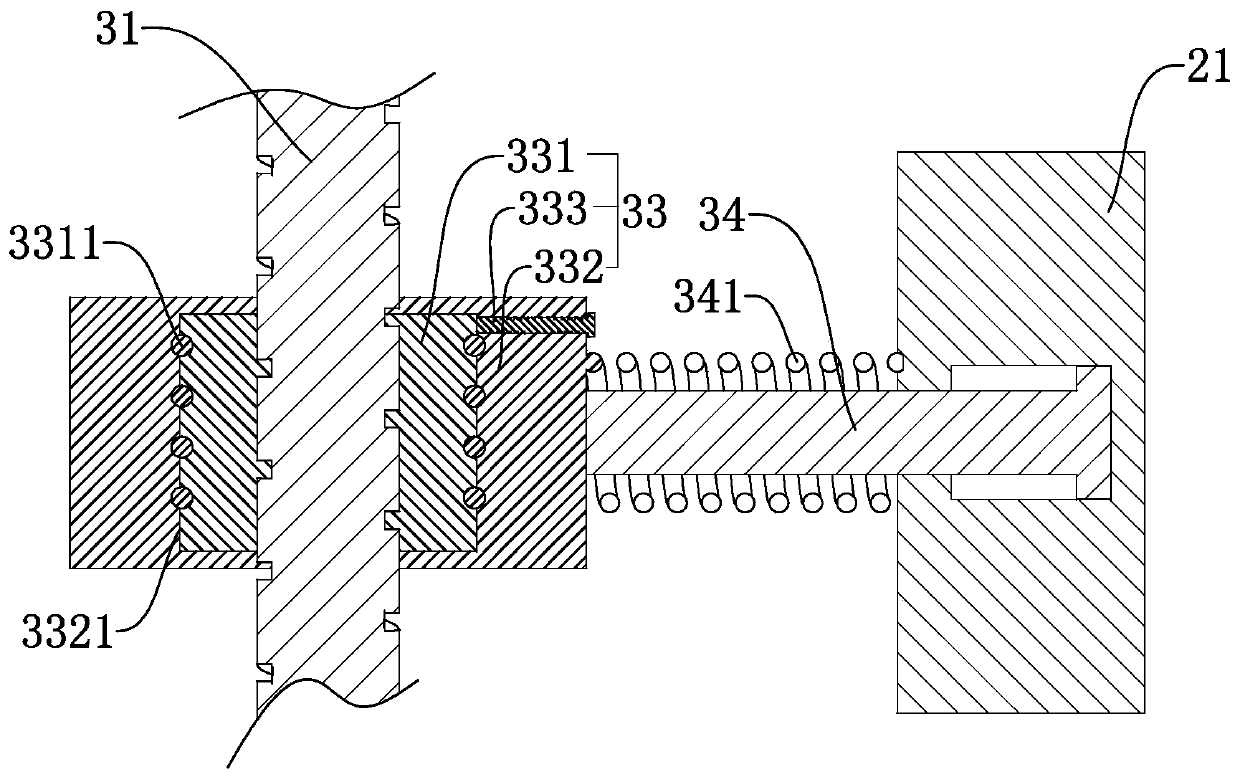

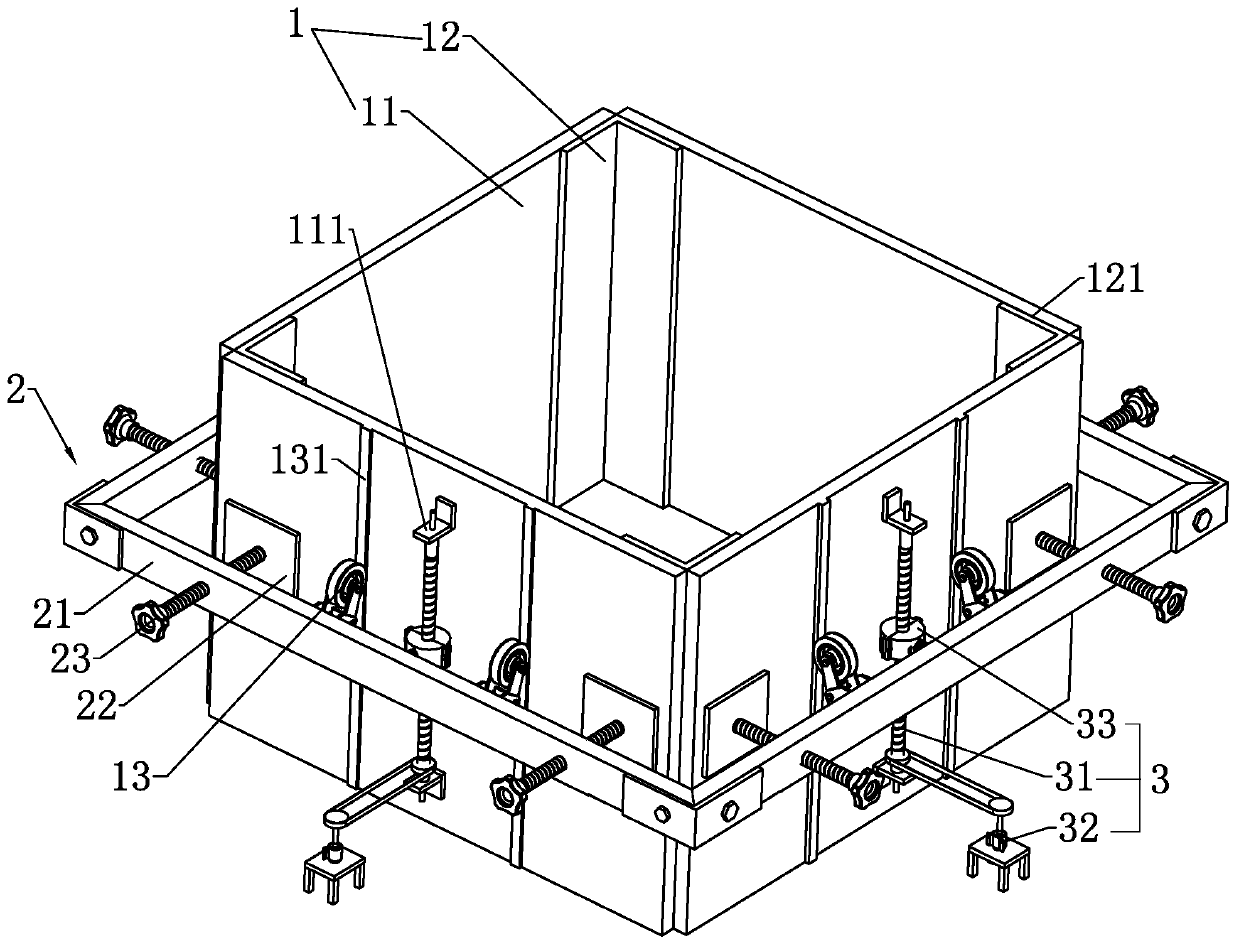

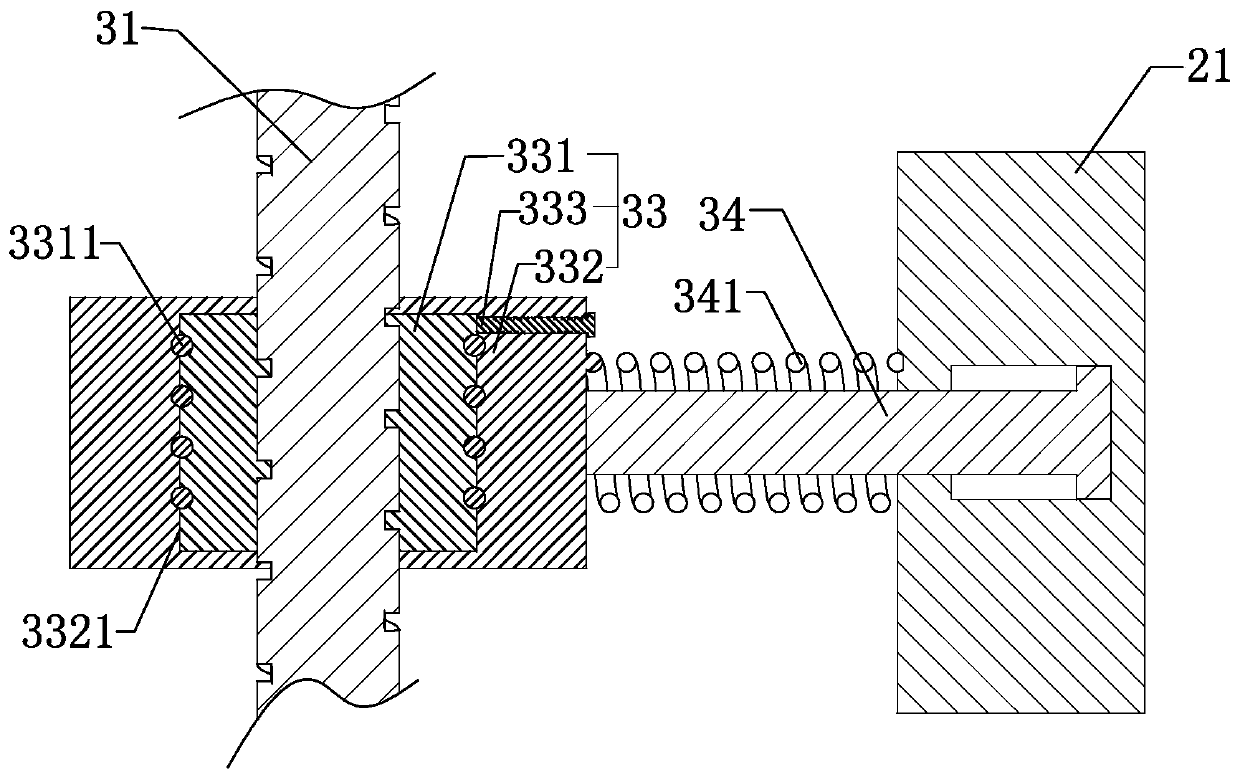

Reinforcing system of concrete formwork and construction method

ActiveCN110499912AImprove installation efficiencyReduce installation riskForms/shuttering/falseworksEngineeringScrew thread

The invention relates to a concrete pouring formwork, and particularly relates to a reinforcing system of a concrete formwork. The system comprises a formwork assembly and a reinforcing assembly, wherein the reinforcing assembly comprises two reinforcing plates and a tensioning part; the two reinforcing plates are correspondingly arranged on the opposite surfaces of the formwork assembly and are close to each other through the tensioning part in order to clamp the formwork assembly; a lifting assembly, comprising a lead screw, a driving part and a lifting sleeve, is arranged between the formwork assembly and the reinforcing assembly; the lead screw is vertically arranged and is rotated about own self and relative to the formwork assembly along a vertical shaft; the driving part is capableof driving the lead screw to rotate; the lifting sleeve is in thread connection with the lead screw; and the lifting sleeve is connected to the inner sides of the reinforcing plates. With the adoptionof the system, the difficulty and time of high-altitude construction work are greatly reduced; and the lifting mounting efficiency can be improved, and the mounting risk can be reduced.

Owner:广州凌鼎建筑工程有限公司

Concrete formwork structure and construction method thereof

ActiveCN110748158AImprove installation efficiencyReduce installation riskForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringElectric machinery

The invention provides a concrete formwork structure and a construction method thereof. The concrete formwork structure comprises a formwork assembly and a reinforcing assembly; the reinforcing assembly comprises four reinforcing plates and connecting pieces, the four reinforcing plates are spliced to form a frame-shaped structure, and the reinforcing plates are connected through the connecting pieces; the formwork structure further comprises a lifting mechanism which comprises a lead screw, a driving motor and a lifting sleeve; the lead screw is vertically arranged and automatically rotates along a vertical shaft relative to the formwork assembly; the driving motor can drive the lead screw to rotate through belt transmission or chain transmission; and the lifting sleeve is in threaded connection with the lead screw and is connected to the inner sides of the reinforcing plates. The effect of lowering the mounting difficulty of the reinforcing assembly is achieved.

Owner:石丽

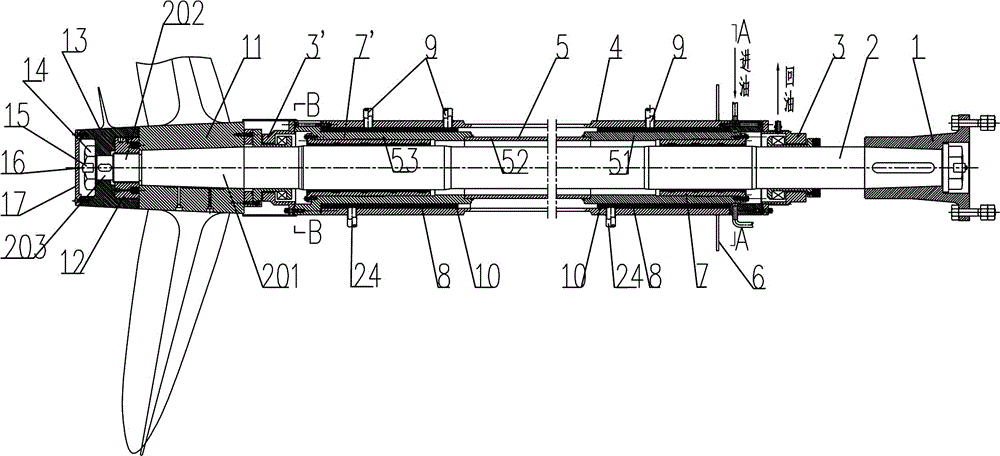

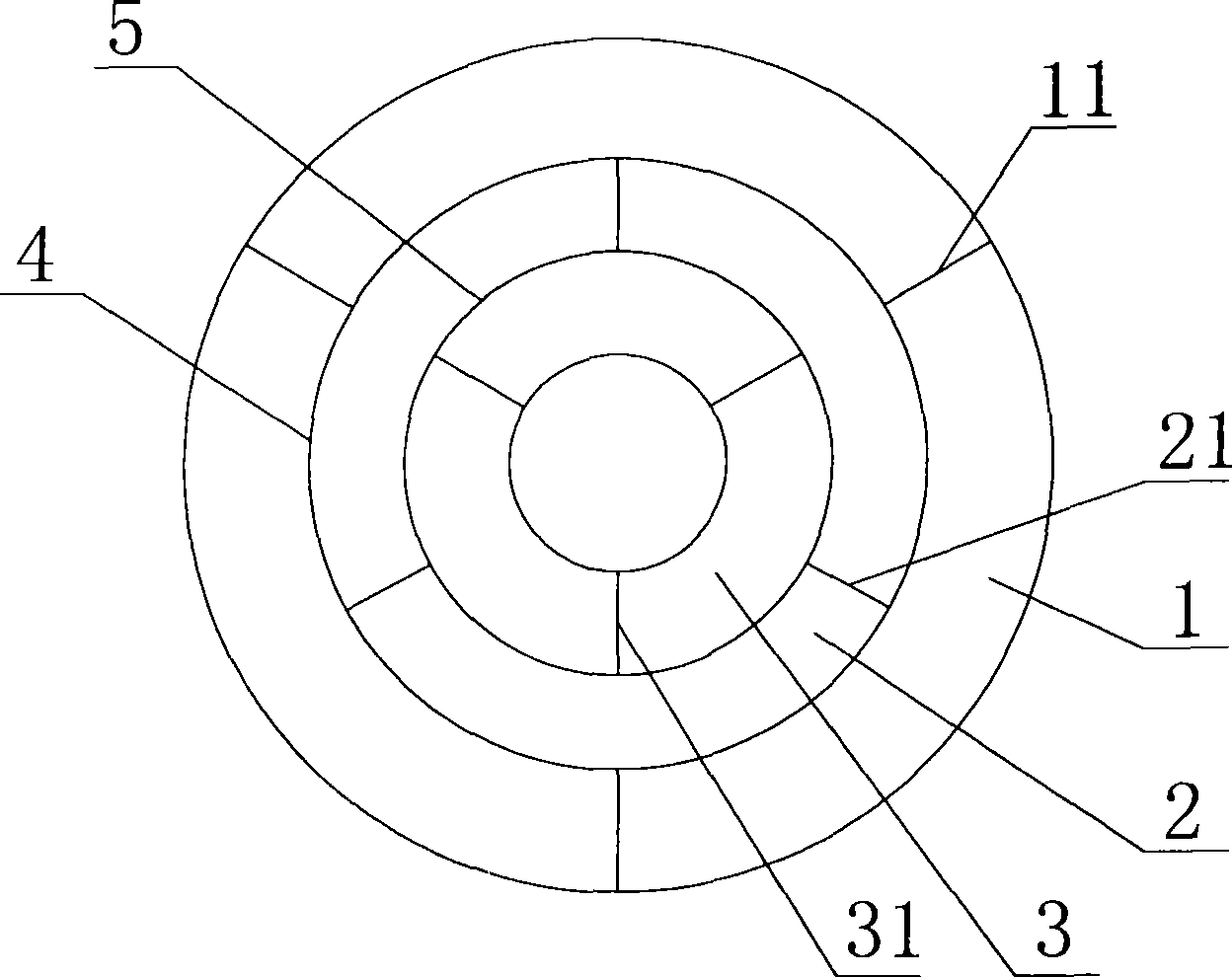

Installation method of super large type light bulb through-flow type hydro-turbo generator set pipe type base

ActiveCN101418559ASolve the installationGuaranteed roundnessWater-power plantsReaction enginesEngineeringWeld seam

The invention provides a method for mounting a tube-shaped base of an ultra-large bulb tubular turbine generator set. The method comprises the following steps: an inner ring is assembled; circular arcs forming a transitional lining, an outer ring lining and an outer ring respectively are lifted in mounting positions to assemble into a circular ring; the positions of the transitional lining, the outer ring lining and the outer ring are adjusted, so that end faces of the circular ring correspond to form two ring-shaped weld seams; connecting plates are welded between the transitional lining and the outer ring lining and between the outer ring lining and the outer ring; the concentricity, the roundness and the center height of the inner and outer rings of the tube-shaped base are adjusted; a support frame is welded between the inner ring and the outer ring of the tube-shaped base; the concrete is cast; the parts of the ring-shaped weld seams, which are not blocked by the connecting plates, are welded; the connecting plates are cut off, and the parts of the ring-shaped weld seams, which are blocked by the connecting plates, are welded; and the support frame is cut off. The mounting process has the advantages of greatly lowering deformation caused by thermal stress, ensuring the roundness of the outer ring of the tube-shaped base, reducing mounting difficulty, lowering mounting risk and improving mounting precision.

Owner:HOHAI UNIV +1

Design method of negative buoyancy immersed tube

InactiveCN112252366AReduce design difficultySmall amount of workArtificial islandsUnderwater structuresFreeboardButt joint

The invention relates to the technical field of immersed tube tunnel construction, in particular to a design method of a negative buoyancy immersed tube. The method does not need to consider the design of a freeboard adjustment layer or consider the design contradiction between a freeboard value and floating resistance in an operation period, through the design thickness of ballast concrete determined by meeting the structural arrangement requirement, whether the preset first anti-floating coefficient is exceeded or not is inversely calculated, so that negative buoyancy larger than the corresponding preset requirement is obtained, then the design thickness of the first ballast concrete and the design thickness of the second ballast concrete are distributed according to the thickness calculated when the negative buoyancy is equal to the first anti-floating coefficient, it is effectively guaranteed that the immersed tube can meet the negative buoyancy requirement in the sinking and buttjoint stage specified by the existing specification, the negative buoyancy requirement after replacement of a ballast water tank is completed through butt joint specified by the existing specificationcan be met, meanwhile, the bearing capacity requirement of a transport ship is lowered, the lifting force needed in the immersed tube installation process can be reduced, the installation risk is reduced, and the transportation and installation cost is reduced.

Owner:CCCC FOURTH HARBOR ENG CO LTD +2

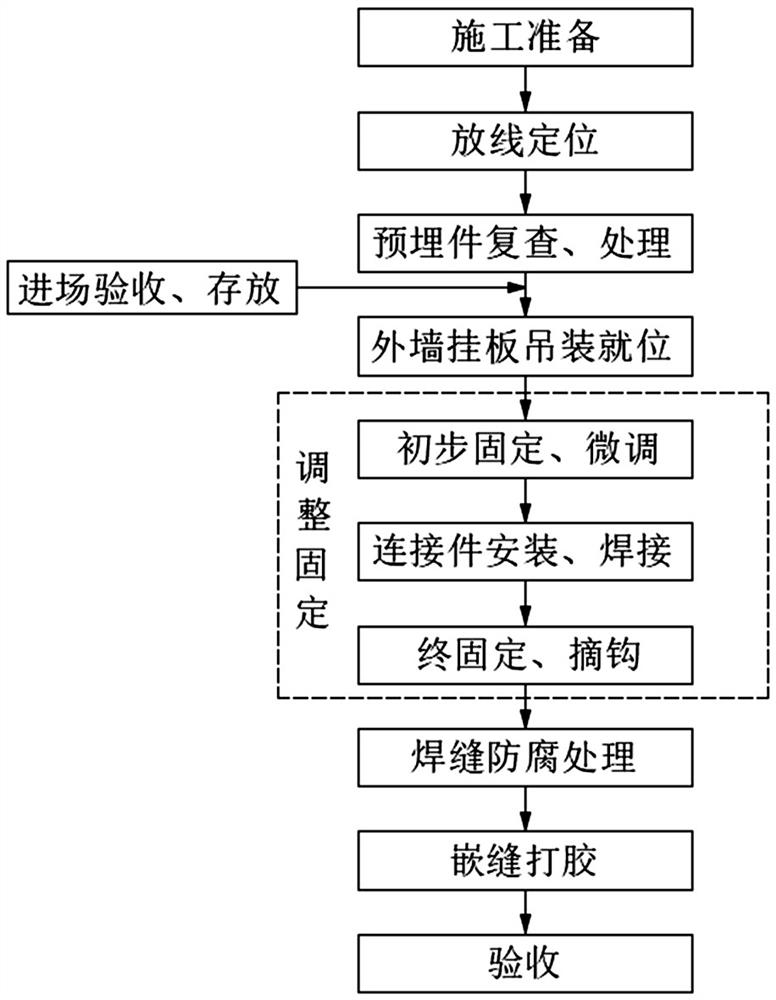

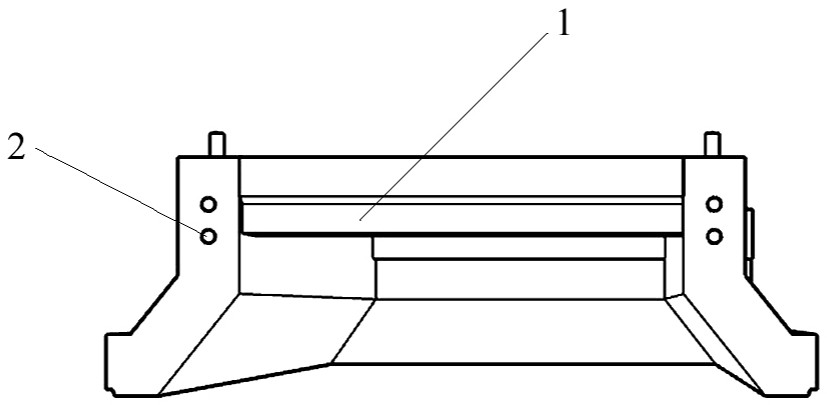

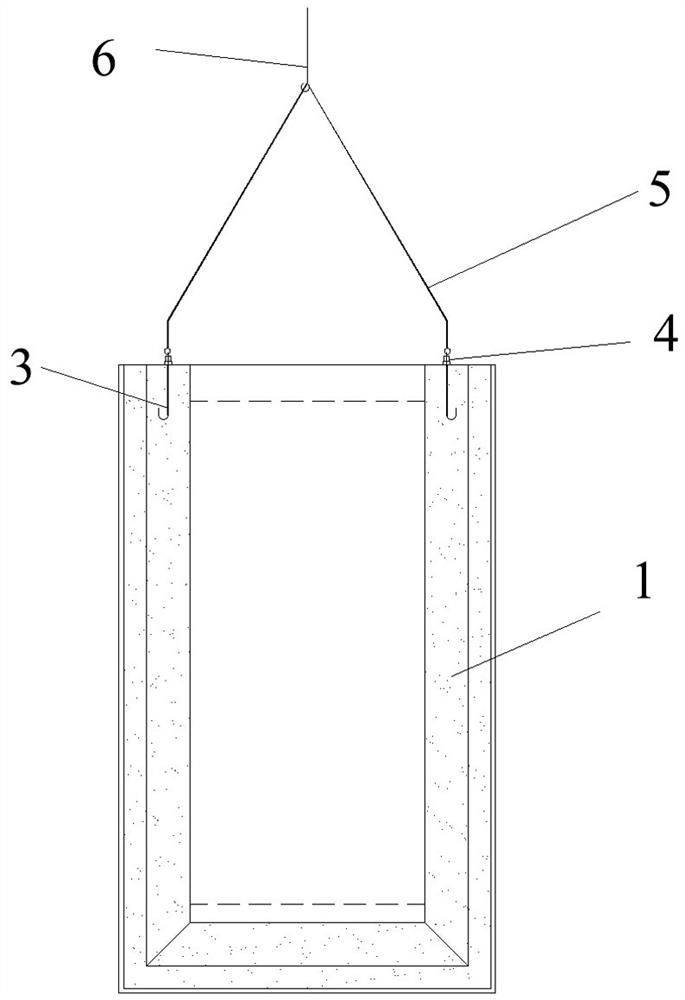

Construction method of prefabricated fair-faced concrete exterior wall cladding connecting structure

ActiveCN113833220AImprove the forceEasy to disassembleCovering/liningsBuilding material handlingFloor slabArchitectural engineering

The invention discloses a construction method of a prefabricated fair-faced concrete exterior wall hanging plate connecting structure, which comprises a building exterior wall hanging plate, an upper connecting plate, a bracket connecting piece and an adjustable bolt, a floor slab at the top of the exterior wall hanging plate is connected with a plate top chain block, and the middle of the exterior wall hanging plate is detachably connected with an in-plate chain block; a jack is detachably connected to the top face of the lower floor. By arranging the hoisting holes, the buried anchorage devices and the special hoisting devices in the exterior wall hanging plate, convenient and fast installation and hoisting can be achieved when the externally-hung wall plate is hoisted, and overall stress and convenient and fast disassembly are facilitated due to the arrangement of the buried anchorage devices and the internal threaded sleeves; through the comprehensive application of the in-plate chain block, the jack and the plate top chain block, the exterior wall cladding can be accurately positioned and adjusted in the hoisting process, the plate top chain block can accurately position the vertical direction, and the in-plate chain block and the jack can accurately position the horizontal direction, so that the installation quality of the exterior wall cladding is improved.

Owner:BEIJING FOURTH CONSTR & ENG

Accumulated continuous pre-assembly construction method for large special-shaped steel structure

PendingCN113513173AReduce installation riskReduce difficultyGeometric CADSurveying instrumentsManufacturing engineeringAssembly (construction)

The invention relates to an accumulated continuous pre-assembly construction method for a large special-shaped steel structure. The accumulated continuous pre-assembly construction method comprises the steps that 1, the large special-shaped steel structure is divided into a plurality of segments; step 2, simulation of a pre-assembly operation is conducted by using a total station; 3, after the measurement and control points of all the segments are determined, a theoretical measurement point drawing is automatically output in a deepened design model for a measurer to contrast and check and actually measure all the segmented components; 4, jig frames are set on site according to the measurement and control points of respective segments, and pre-assembling of the segments on the corresponding jig frames is conducted; and step 5, all the assembled segments are re-measured, and the segments are sequentially hoisted to actual mounting positions for mounting after the segments are accurate. According to the accumulative continuous pre-assembly technology, the requirement for installation of components in a narrower space can be met, large components are segmented, the hoisting difficulty is lowered, the problem that due to the fact that the rigidity of the components is not enough, the components are prone to deformation during hoisting, and the installation difficulty is increased is solved, and the transportation and manufacturing difficulty of the components is lowered.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

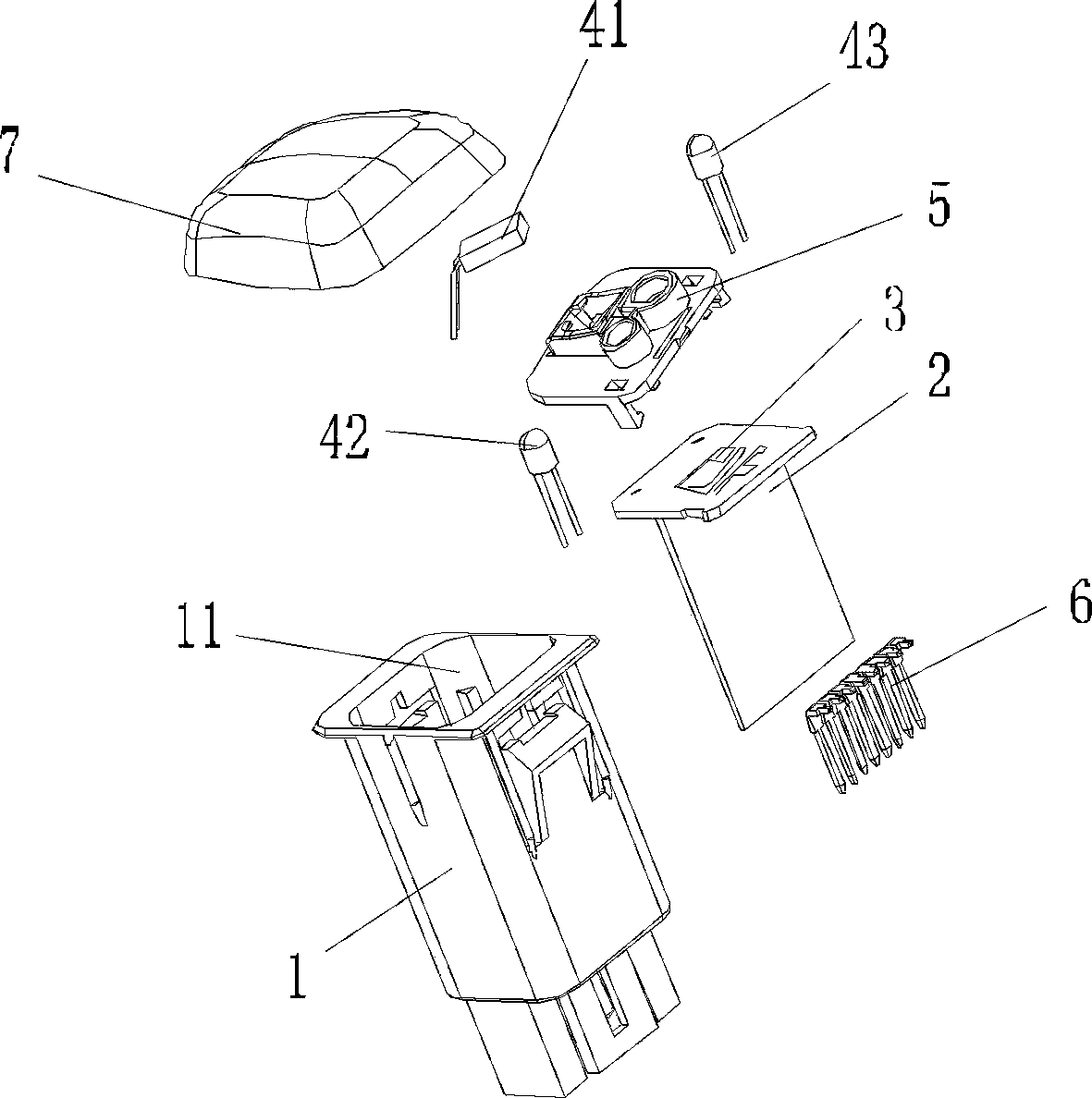

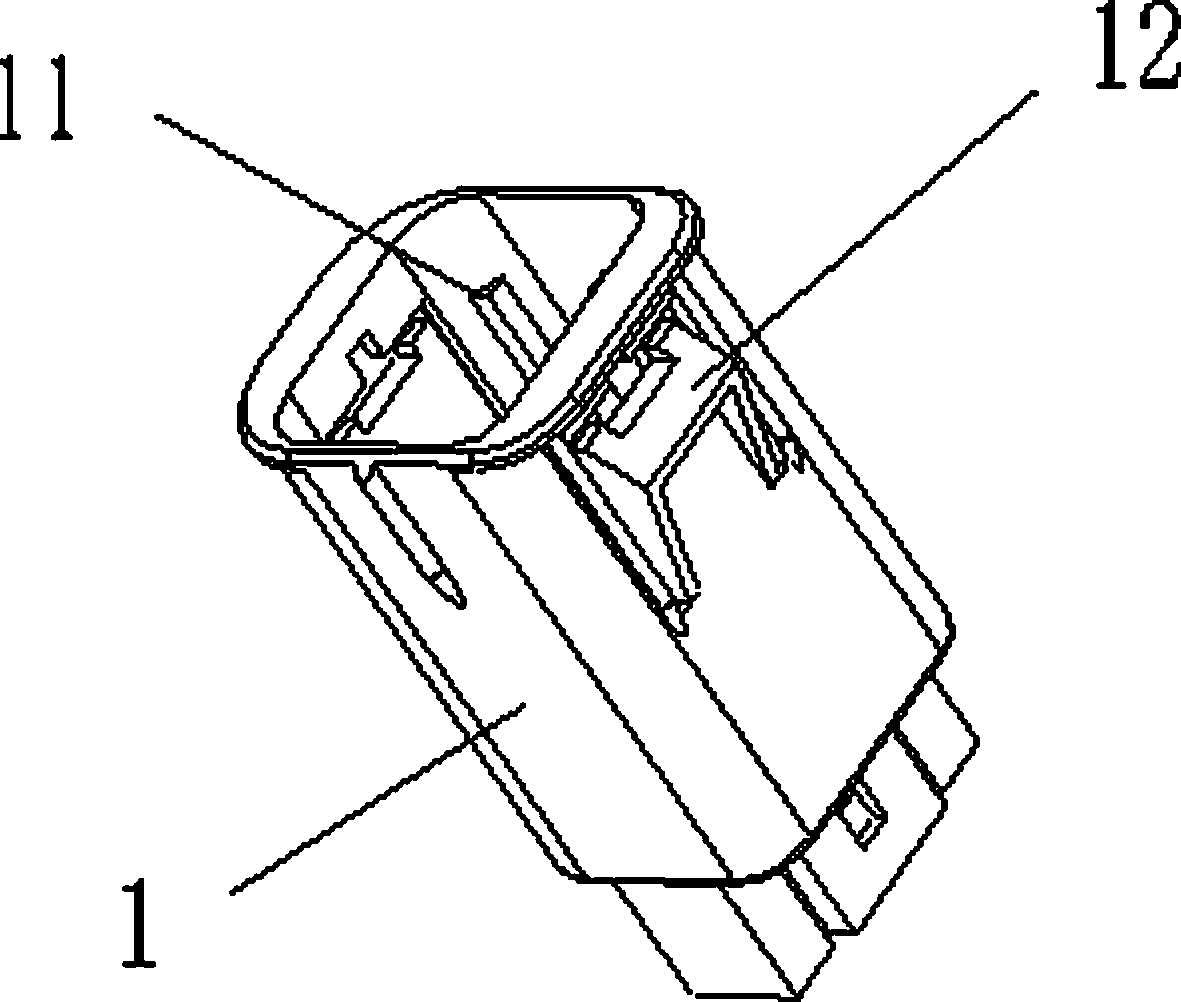

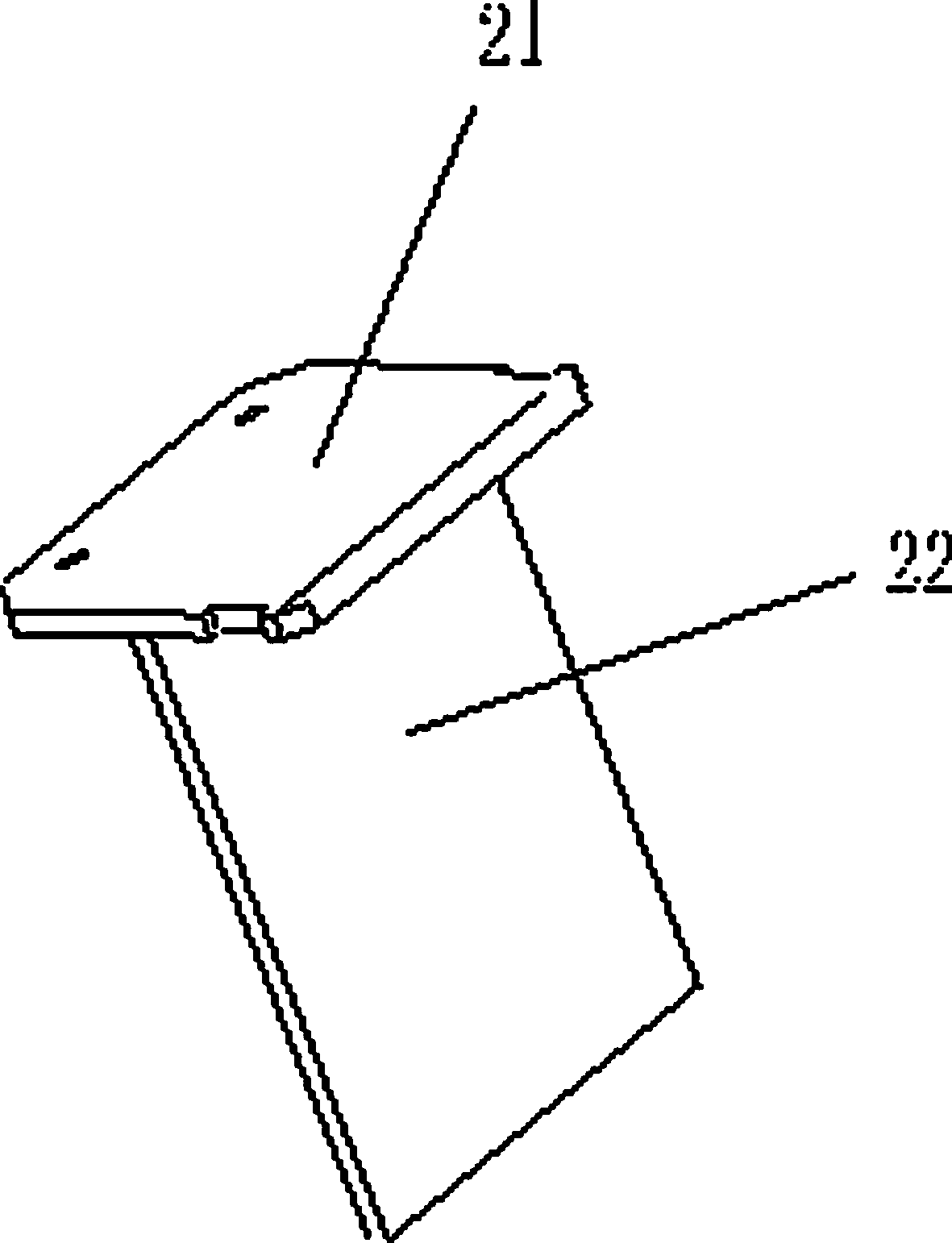

Multifunctional optical sensor device with alarm lamp

ActiveCN104108341ASimple installation structureReduce in quantityAir-treating devicesVehicle heating/cooling devicesLight sensingEmbedded system

The invention discloses a multifunctional optical sensor device with an alarm lamp. The multifunctional optical sensor device comprises a sunlight sensing system, an ambient light sensing system and an alarm execution system. The sunlight sensing system comprises a sunlight sensing circuit capable of automatically regulating temperature of a vehicular air conditioner; the ambient light sensing system comprises an ambient light sensing circuit capable of automatically regulating brightness of vehicular headlights; the alarm execution system comprises an alarm lamp executing circuit capable of realizing execution of the alarm lamp automatically. The alarm execution system, the sunlight sensing system and the ambient light sensing system are packaged in the same device, thereby guaranteeing various system functions while effectively reducing amount of vehicular parts, greatly simplifying installation structure of a sunlight sensor, an ambient light sensor and the alarm execution device of a vehicular integrated system, saving installation space of the parts, lowering installation cost and reducing potential risk of failure.

Owner:HUBEI KAIT AUTOMOTIVE ELECTRONICS & ELECTRICAL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com