Cutting tooth for earth working equipment

A technology of working tools and cutting teeth, which is applied in the field of cutting teeth, can solve problems such as premature wear and increased cost of spare parts, and achieve reliable cutting, high cutting speed, and good cutting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

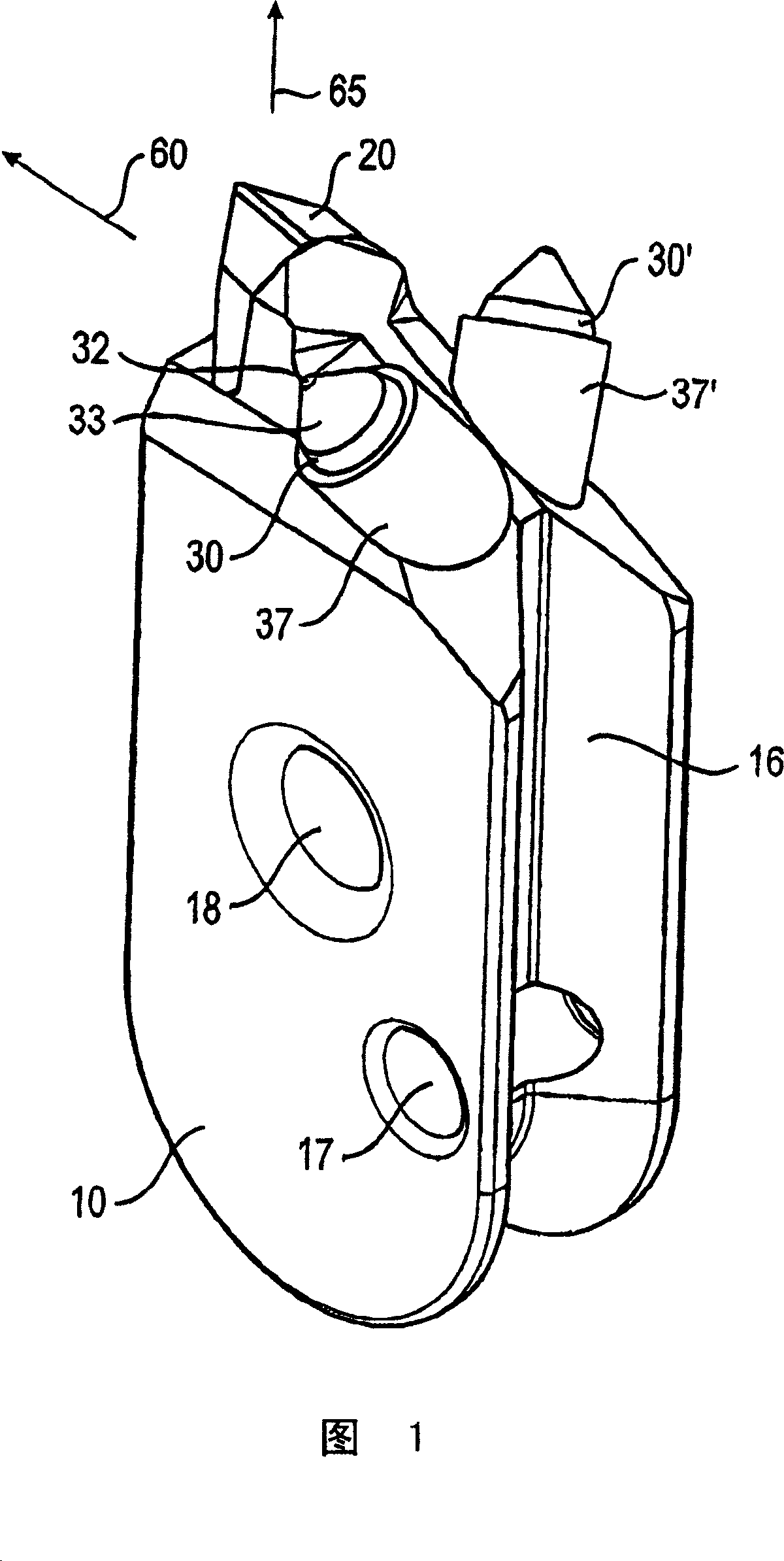

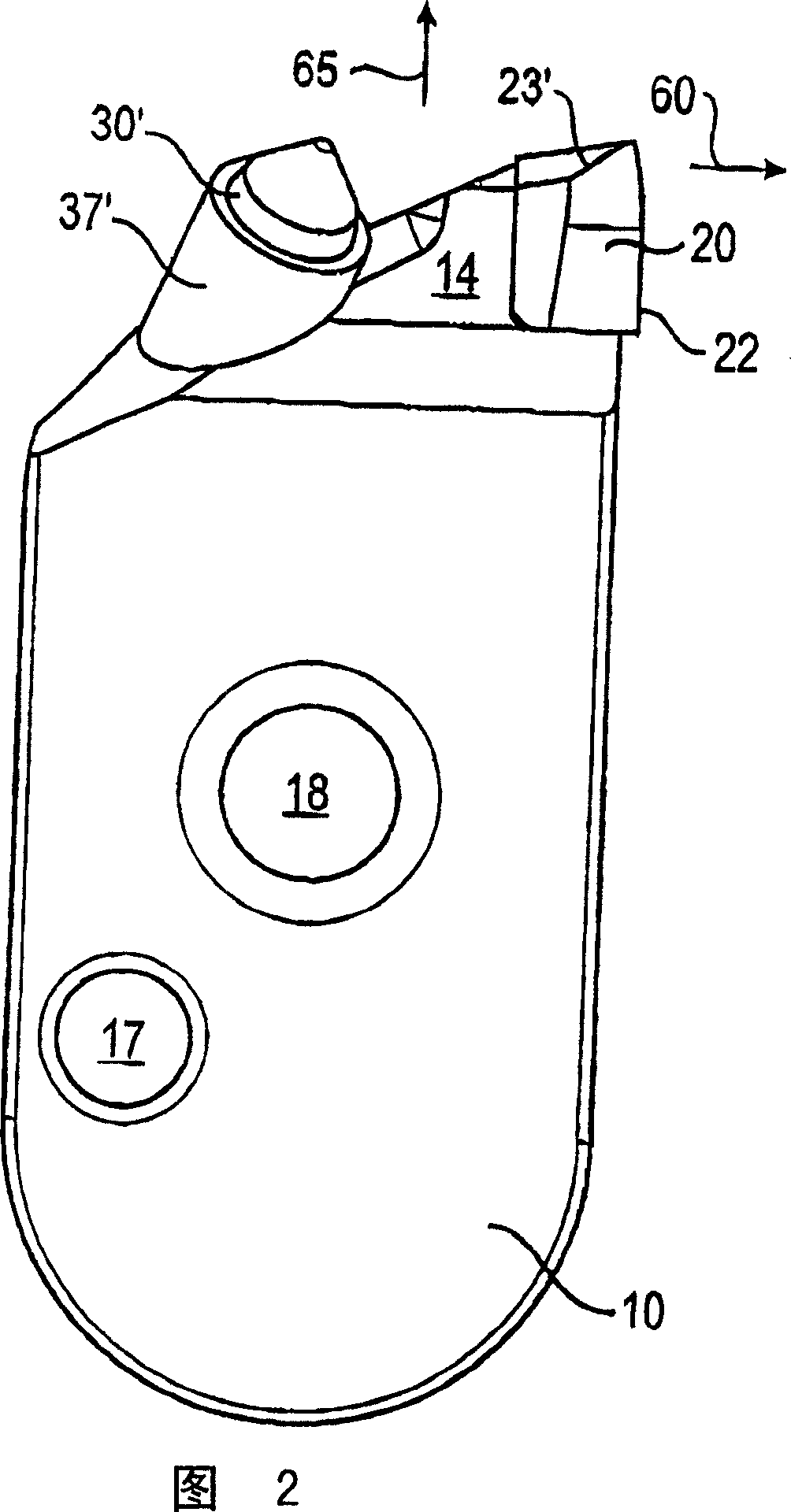

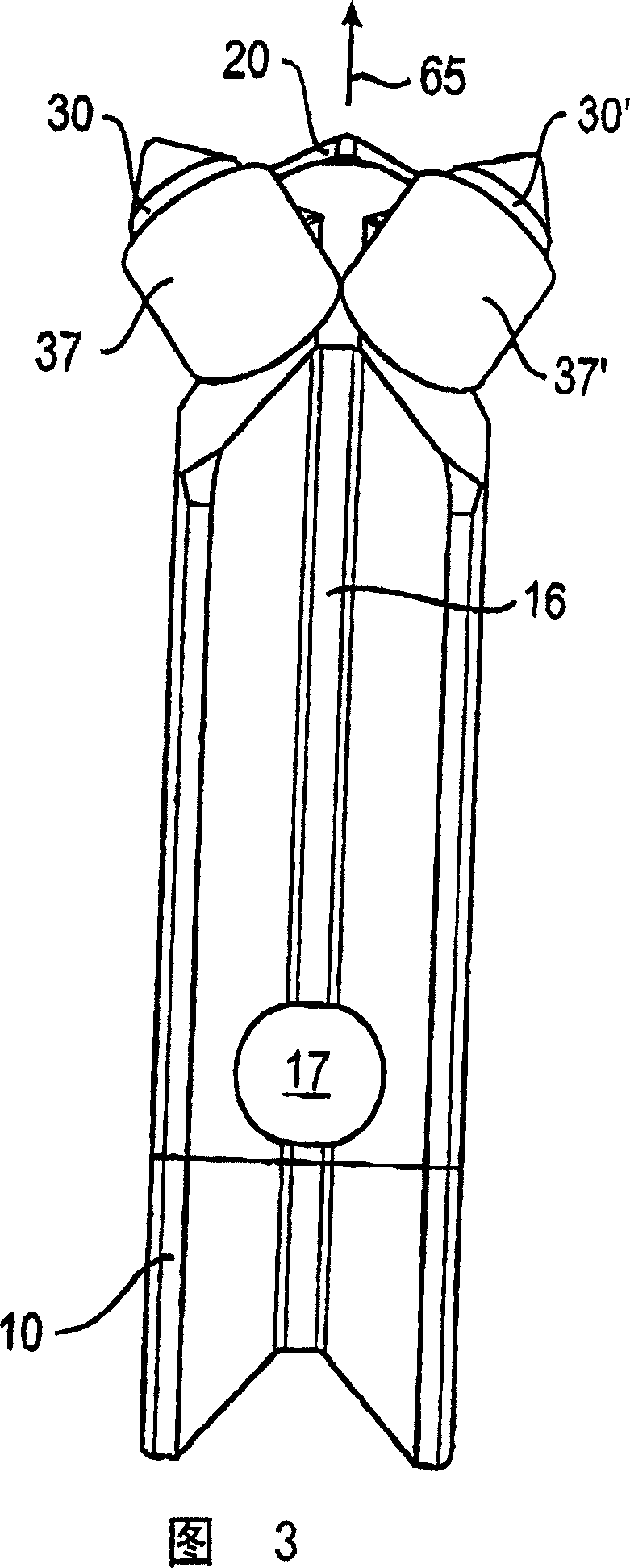

[0044] 1 to 4 show a first embodiment of a cutting tooth according to the invention. On the underside of the cutting tooth, the cutting tooth has a tooth root 10 which is received in a cutting tooth holder. In the side view shown in FIG. 2 , the dedendum 10 is U-shaped with two parallel front edges and a rounded bottom. A longitudinal groove 16 with a substantially V-shaped cross-section is provided on both front faces of the cutting tooth, which is approximately radial when placed on the cutting wheel, and in the base region of the tooth root 10 . The longitudinal groove 16 forms part of a positive connection by which the cutting tooth is releasably secured in a not shown cutting tooth holder.

[0045] The dedendum 10 also has a crosshole 17 which intersects the longitudinal groove 16 and also the solid part of the adjacent dedendum 10 . Intersecting holes 17 receive shear pins to secure the cutter 10 in the holder. A further cross hole 18 is provided on the tooth root 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com