Accumulated continuous pre-assembly construction method for large special-shaped steel structure

A construction method and technology for steel structures, which can be used in measuring devices, building structures, instruments, etc., and can solve the problems of easy deformation, installation difficulty, and enlargement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further illustrated below by specific examples.

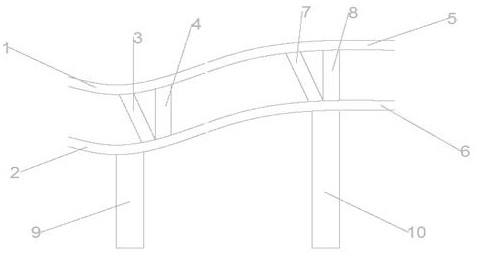

[0017] Such as figure 1 As shown, a large-scale special-shaped steel structure cumulative continuous pre-assembly construction method; including

[0018] Step 1: Divide the large special-shaped steel structure into the first segment 1 to the eighth segment 8;

[0019] Step 2: Use the total station to simulate the pre-assembly operation: specify each section in turn in the detailed design model, and select the key measurement and control points of each section. The selection of the measurement and control points is automatically selected through the secondary development of the detailed design software , after the measurement and control points of all segments are selected, they will be displayed in the deepened model;

[0020] Step 3: After the measurement and control points of each segment are determined, the drawings of theoretical measurement points are automatically output in the detailed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com