Concrete formwork structure and construction method thereof

A technology of concrete formwork and formwork, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building construction, etc., and can solve the problems of high quality of reinforcement components and difficulty in installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

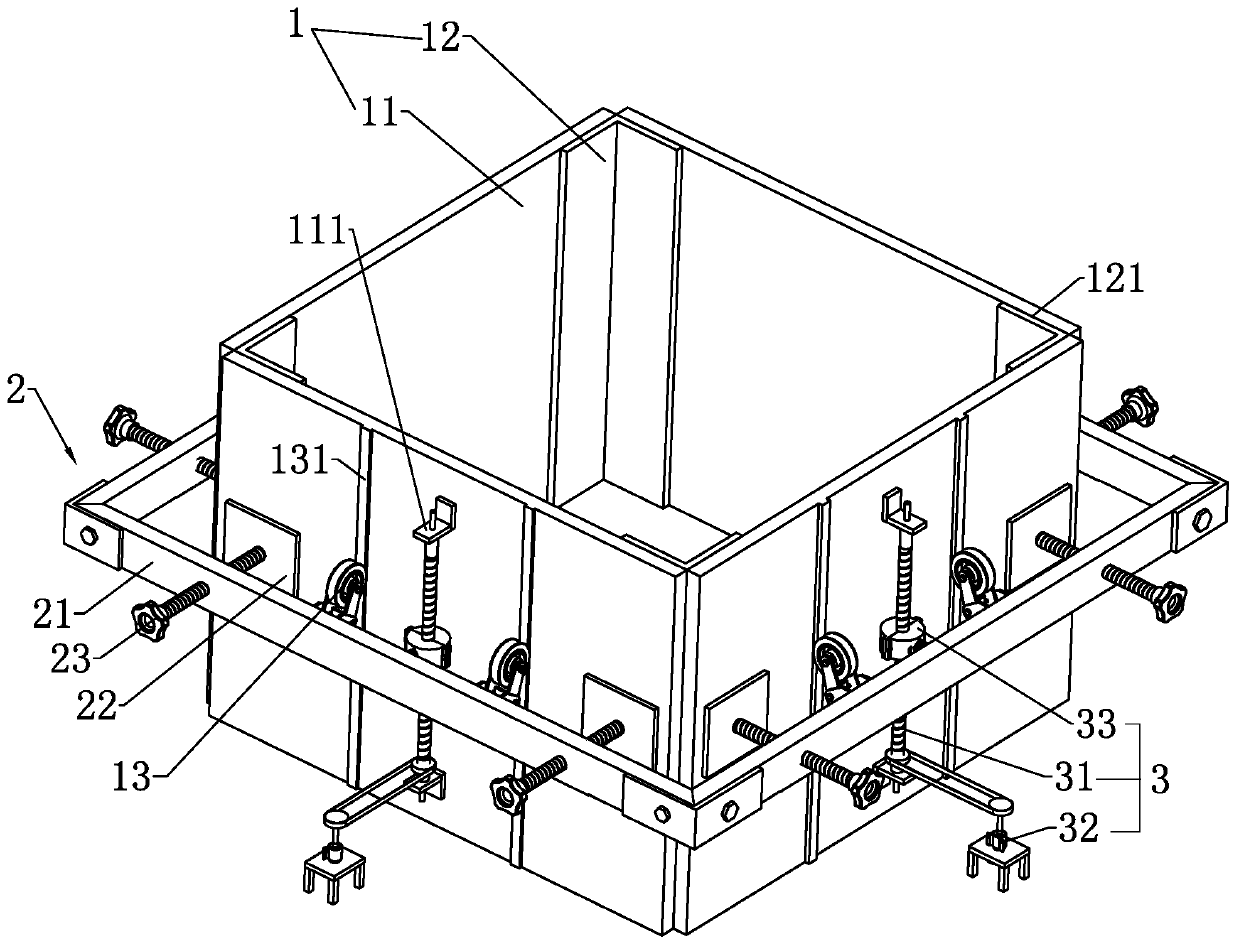

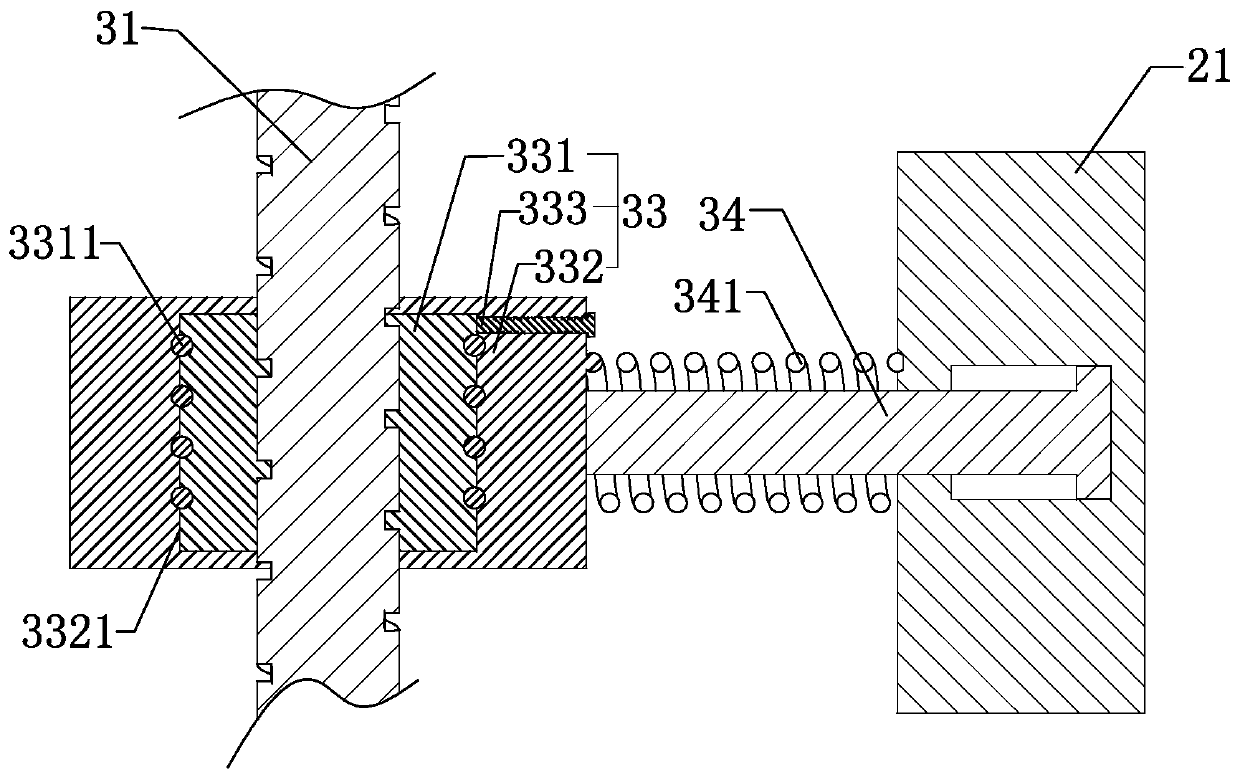

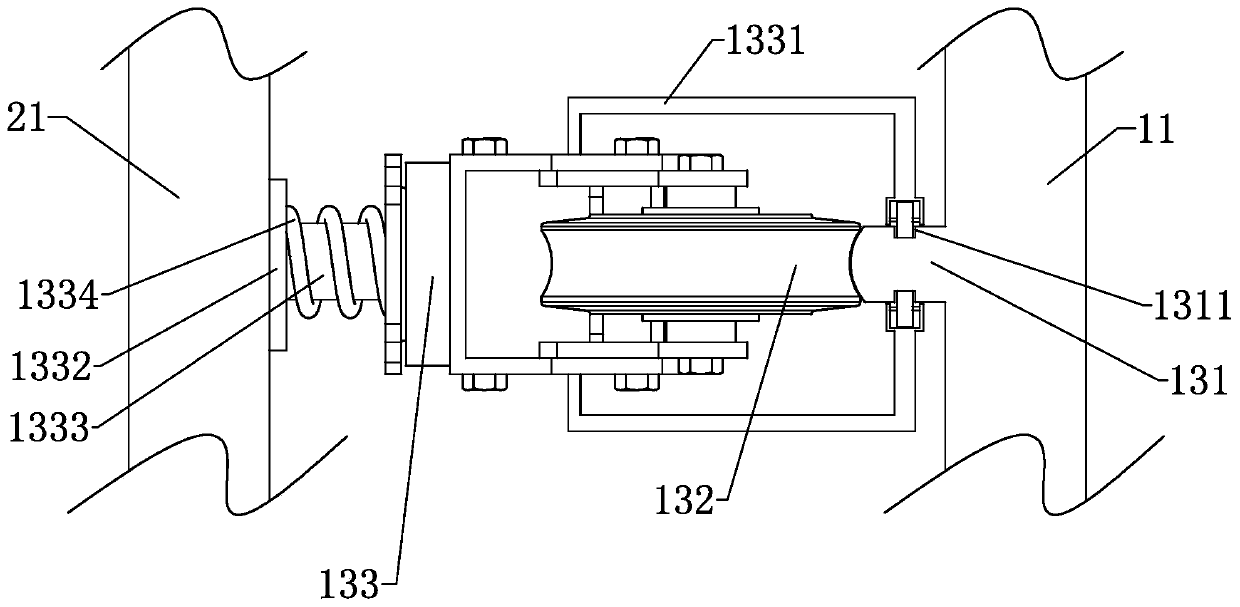

[0021] Such as figure 1 As shown, the present invention introduces a concrete formwork structure, including a formwork assembly 1, a reinforcement assembly 2 and a lifting mechanism 3, the formwork assembly 1 forms a concrete pouring space, and the reinforcement assembly 2 is used to reinforce the formwork assembly 1, The reinforcement assembly 2 has multiple groups, and the formwork assembly 1 is fixed at different heights of the formwork assembly 1 to ensure the stability of the formwork assembly 1, while the lifting mechanism 3 is located between the formwork assembly 1 and the reinforcement assembly 2. The reinforcement assembly 2 is lifted relative to the formwork assembly 1 . In this way, the reinforcement assembly 2 can be assembled at a low place close to the ground, and then the reinforcement assembly 2 is lifted to a reasonable position by the lifting mechanism 3, and finally the reinforcement assembly 2 is fastened to fix the formwork assembly 1, and the reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com