Design method of negative buoyancy immersed tube

A design method and negative buoyancy technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problem of increasing the amount of backfilling of the main structure and foundation trench, increasing the cost of prefabrication and construction, and the high section height of pipe joints and other issues, to achieve the effect of reducing installation risk, reducing design difficulty, and reducing structural height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

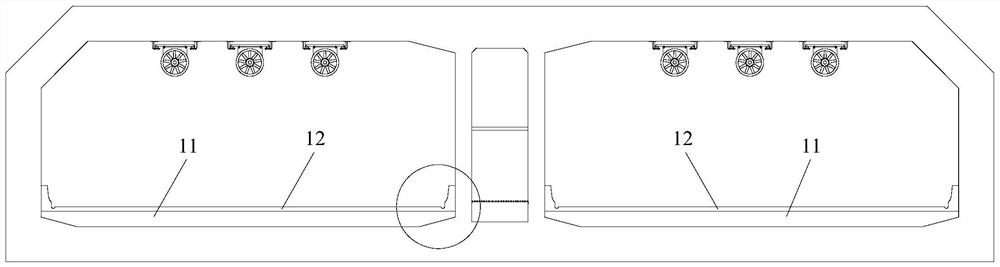

[0025] The design method of a kind of negative buoyancy immersed tube of the present invention comprises the following steps:

[0026] a. Determine the design thickness of the roof, the design thickness of the bottom plate, the design clearance height of the traffic lane and the design height of the fan, and obtain the first immersed tube;

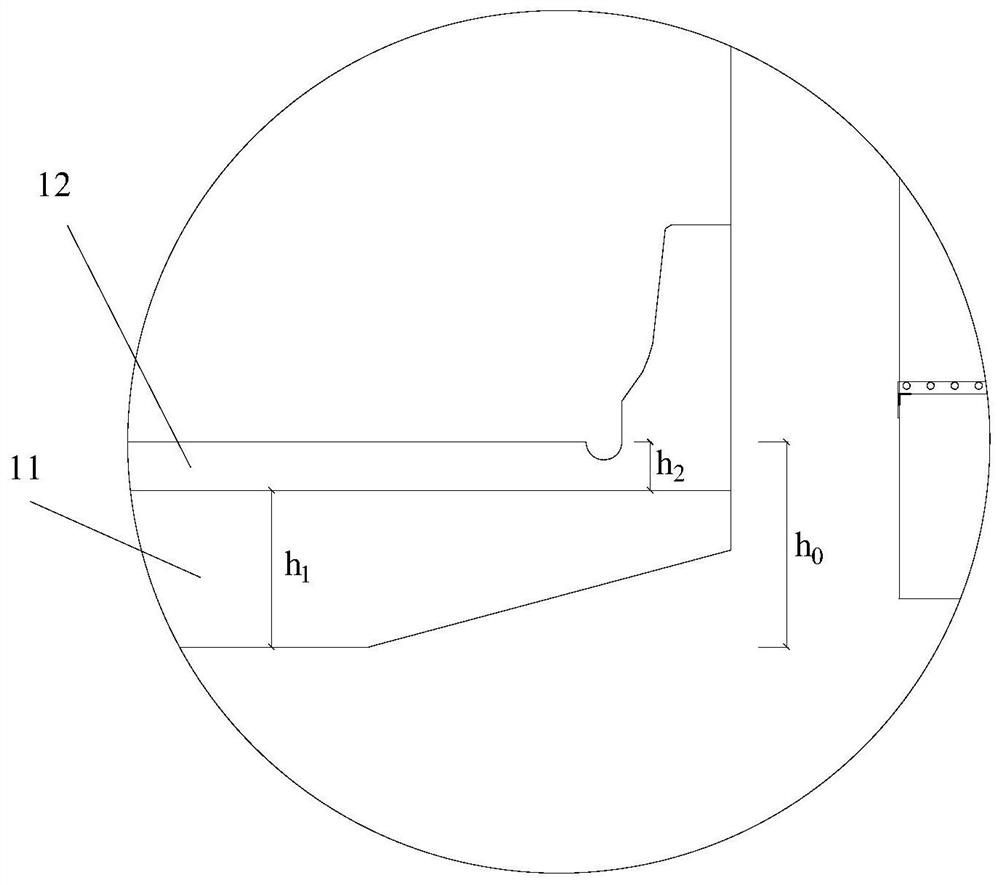

[0027] b. Determine the design thickness h of ballast concrete according to the larger of the layout requirements of the wastewater pump house and the layout requirements of the cross-cut trench section 0 , the ballast concrete is placed inside the first immersed tube, and the design headroom of the carriageway remains unchanged, so as to obtain the second immersed tube;

[0028] c. Check whether the design self-weight of the second immersed tube is greater than the weight required by the set first anti-float coefficient. The designed self-weight of the second immersed tube includes the designed structural self-weight of the second immerse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com