Construction method of prefabricated fair-faced concrete exterior wall cladding connecting structure

A technology of fair-faced concrete and construction methods, which is applied to the processing of building components, building structures, and building materials to achieve the effects of convenient installation and lifting, avoiding damage, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

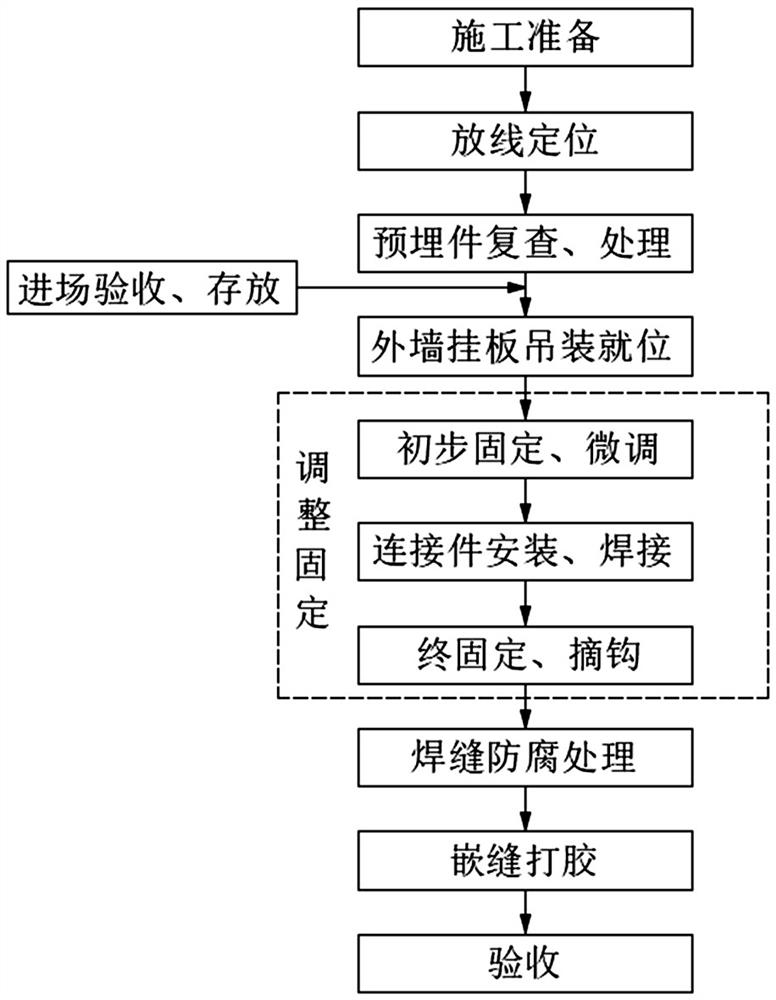

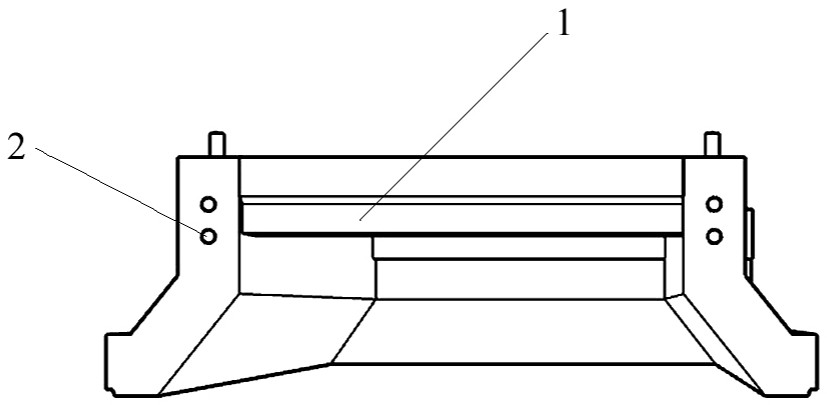

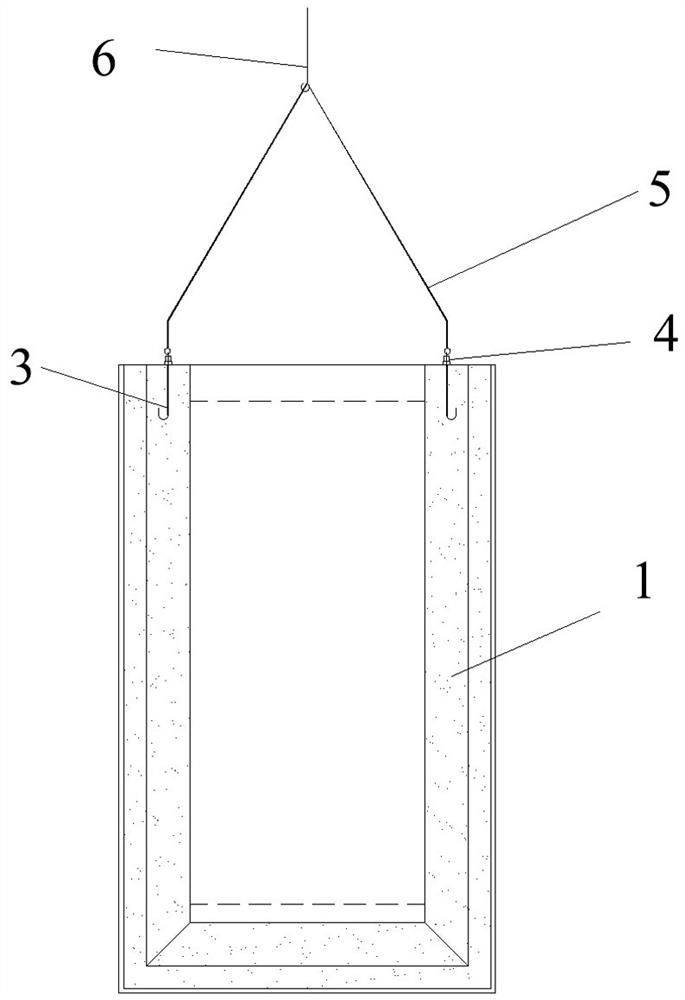

[0048] Taking the prefabricated fair-faced concrete exterior wall hanging panels as an example for the external protection system of a certain building, the types of exterior wall hanging panels include the whole panel spanning the entire floor height and setting window openings in the panel, and the gable solid panel spanning the entire floor height. The number of external wall hanging panels (1) is large, the volume of a single panel is large, the installation accuracy is high, and the installation risk is high. Research on the positioning of embedded parts, connection nodes, and in-place installation and adjustment, using the external wall hanging panel connection structure, in which adjustable connectors and multi-directional linkage initial adjustment and final adjustment, etc., overcome the external wall hanging panel in place A series of problems such as difficulty in installation.

[0049] Such as Figure 2 to Figure 11 As shown, the connection structure of the exteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com