Installation method of super large type light bulb through-flow type hydro-turbo generator set pipe type base

A technology of light bulb through-flow and generator set, which is applied in the directions of hydroelectric power generation, hydroelectric power station, reaction engine, etc., can solve the problem that the roundness of the outer ring cannot be guaranteed, so as to solve the installation problem, ensure the roundness and reduce the difficulty of installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

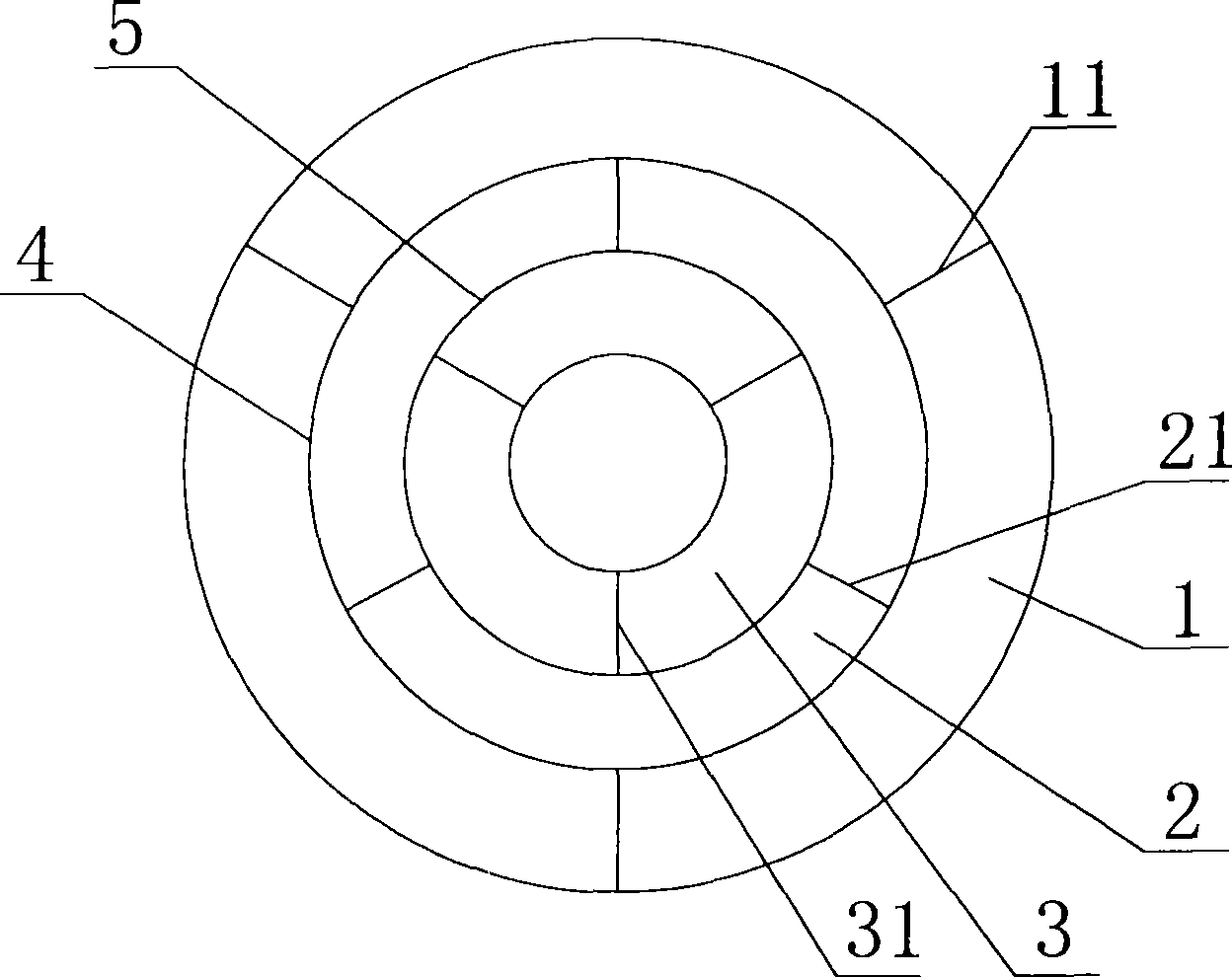

[0020] Such as figure 1 Schematic diagram of the side view of the outer ring of the extra-large bulb tubular hydroelectric generator set. In the figure, 1 is the transition lining, 2 is the outer ring lining, 3 is the outer ring, and 4 is the gap between the crossing lining and the outer ring lining. Welding seam, 5 is the welding seam between the outer ring lining and the outer ring, 11 is the welding seam between the three arcs forming the transition lining, 21 is the welding seam between the three arcs forming the outer ring lining The weld seam 31 is the weld seam between the three circular arcs forming the outer ring.

[0021] The method for installing the tubular seat of the extra-large bulb tubular hydroelectric generating set of the present invention, the steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com