Construction and processing method of great deep vertical inclinometer pipe in stratum containing gravels

A technology of inclinometer tube and large depth, which is applied in basic structure engineering, basic structure test, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

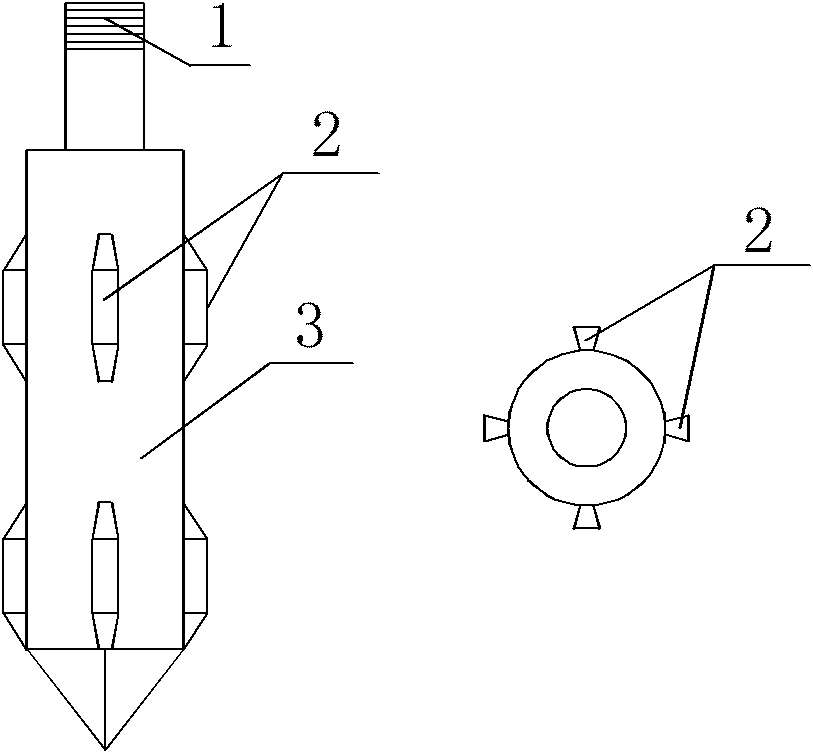

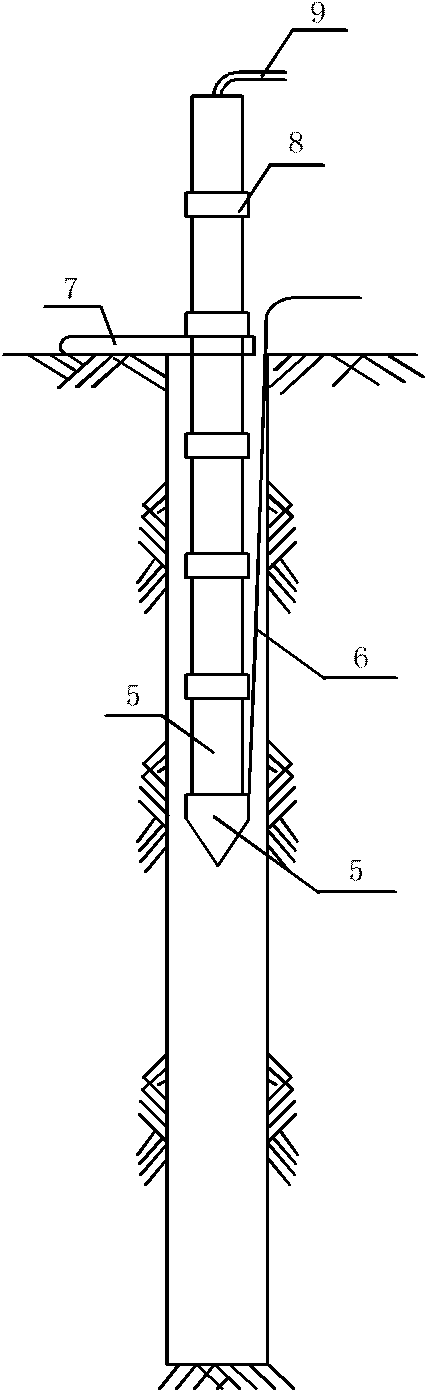

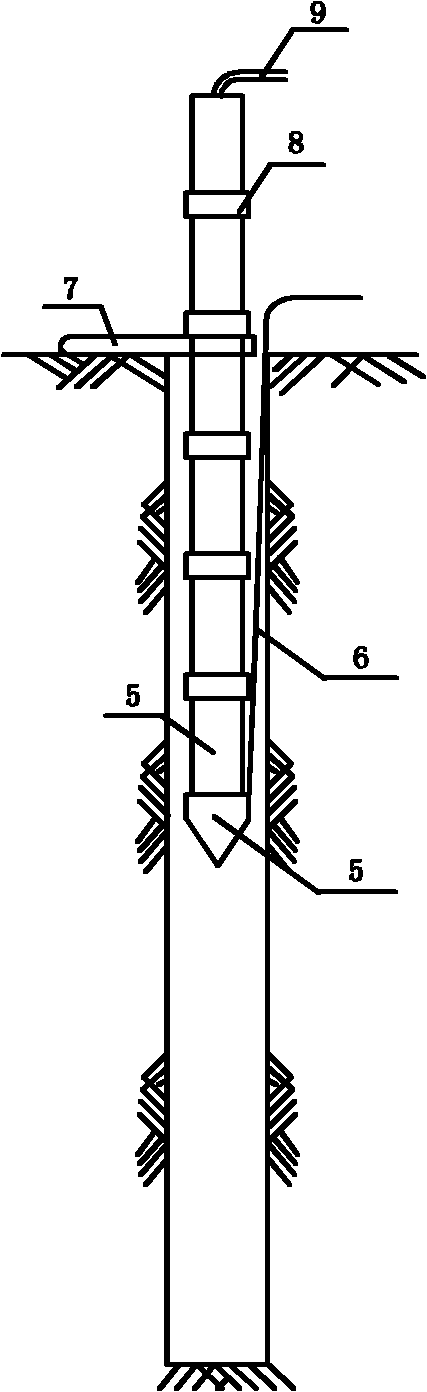

[0027] figure 1 It is a construction site of a pipe jacking project in Jiangsu Province. After geological exploration, it was found that there are sandstone layers with a thickness of about 1.5m and 2m at 15m and 20m below the surface, respectively. Ashstone is a kind of calcareous concretion in soil, mainly composed of calcium carbonate and soil particles, impervious to water, high in strength, large in block shape and small in granular shape, with a diameter of 0.5 to 3.0 cm. Drilling in this formation is very prone to the phenomenon of difficult drilling and hole collapse. There are 4 jacking pipes starting from the caisson one after another. In order to understand the response mechanism of the surrounding stratum to pipe jacking and the influence law between two adjacent pipe jackings, it is planned to install between 1# and 2# jacking pipes. An inclinometer pipe with a buried depth of 30m and a diameter of 70mm.

[0028] The specific implementation steps are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com