Fender mounting bracket of automobile

A technology for automobile fenders and mounting brackets, which is applied to vehicle components, transportation and packaging, and upper structures, and can solve problems such as damage to the cable skin, cable skin damage, and dimensional errors, so as to ensure the dimensional accuracy of the final assembly and improve Installation strength, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

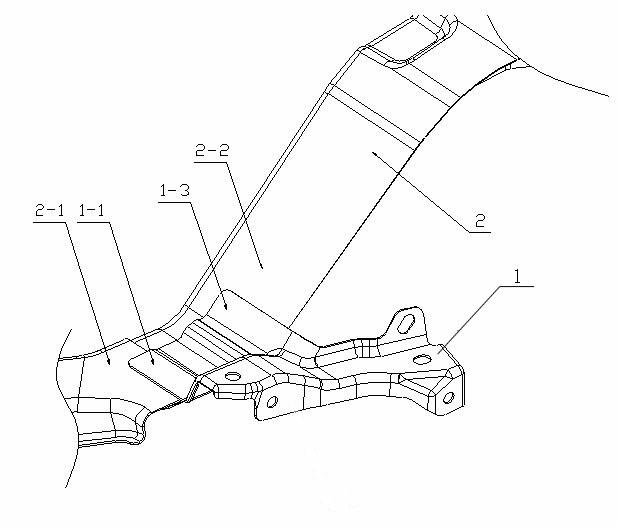

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

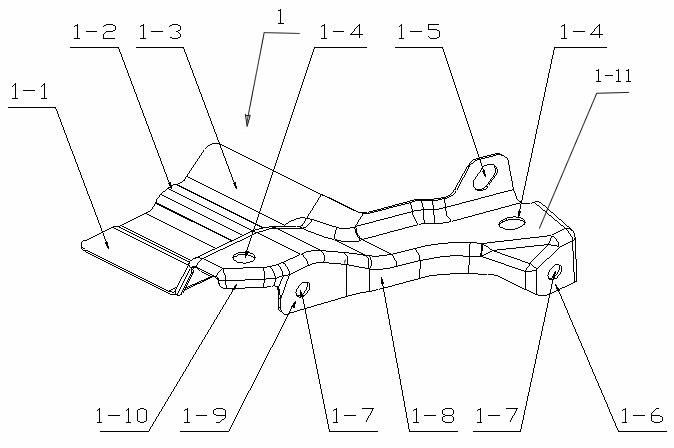

[0017] see figure 1 In the shown car fender mounting bracket, the main body 1 is a sheet metal part formed by stamping, the upper surface 1-11 of the main body is in the shape of a long strip, and the left part is convex and the right part is straight;

[0018] The rear edge of the left part of the upper surface 1-11 of the body is bent downward and connected with the straight first welding surface 1-1, the coordination rib 1-2 and the upwardly bent second welding surface 1-3;

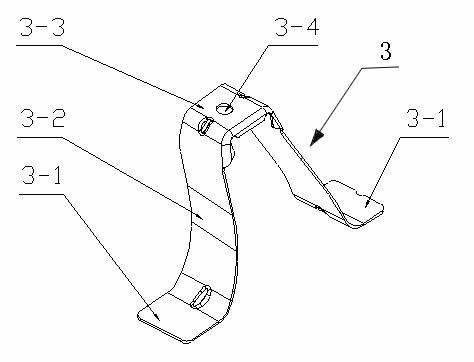

[0019] The rear edge of the right part of the upper surface 1-11 of the body is turned upwards, the left end of the turn is connected with the second welding surface 1-3, and a strip-shaped wiring harness installation hole 1-5 is provided on the right end of the turn; The car wiring harness can pass through the bend of the body of the fender mounting bracket, and the wiring harness can be fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com