Method for measuring inclination of ship stern bearing through laser

A technology of laser measurement and stern bearing, applied in the direction of measuring inclination, active optical measurement device, measuring instrument, etc., to achieve the effect of high measurement accuracy, simple structure and reduced installation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

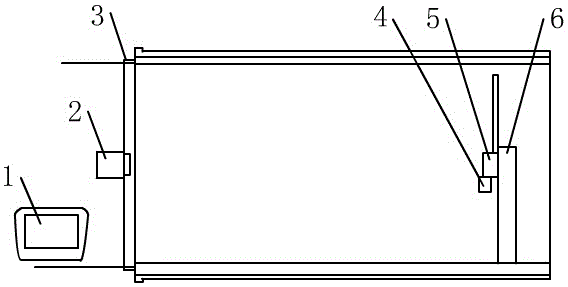

[0017] As shown in the figure, a Bluetooth 4, a laser receiver 5 and a measurement unit 6 are installed on the transmitter bracket 3, a laser transmitter 2 is installed on one side of the transmitter bracket, and a display 1 is connected to the measurement device.

[0018] The three stages of tail bearing inspection and installation need to be measured. First, the inspection before tail bearing installation should meet the drawing design requirements; secondly, measure the processed tail bearing housing, which should meet the tail bearing installation requirements; The measurement of the inner hole of the stern bearing should meet the requirements of the installation process.

[0019] Installation and use of the present invention:

[0020] 1. Install the laser measurement system:

[0021] Assemble the laser transmitter on the transmitter bracket, and set the transmitter bracket on the seam at one end of the tail bearing, adjust according to the center of the outer diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com