Patents

Literature

221 results about "Laser measurement system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser measurement system

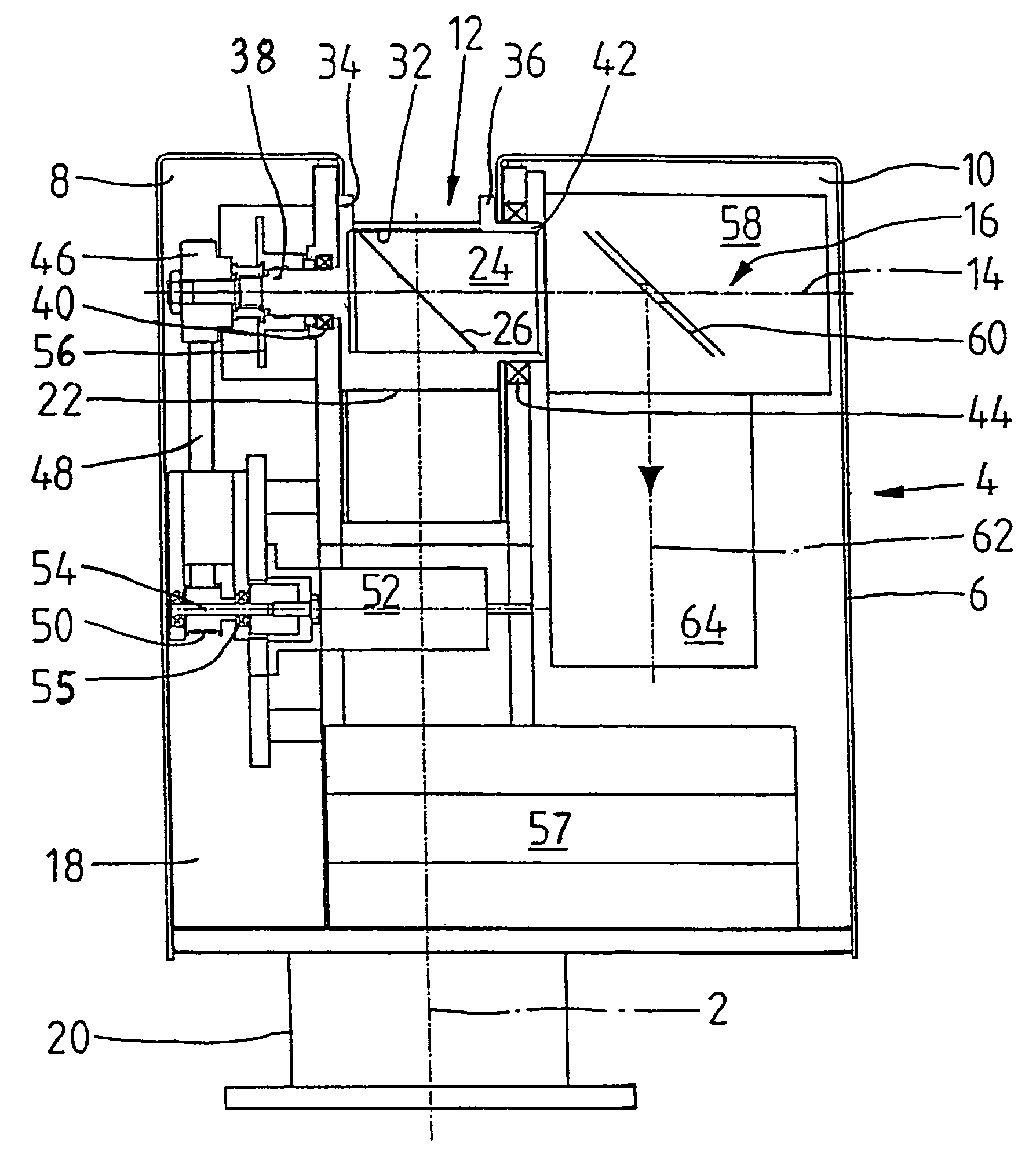

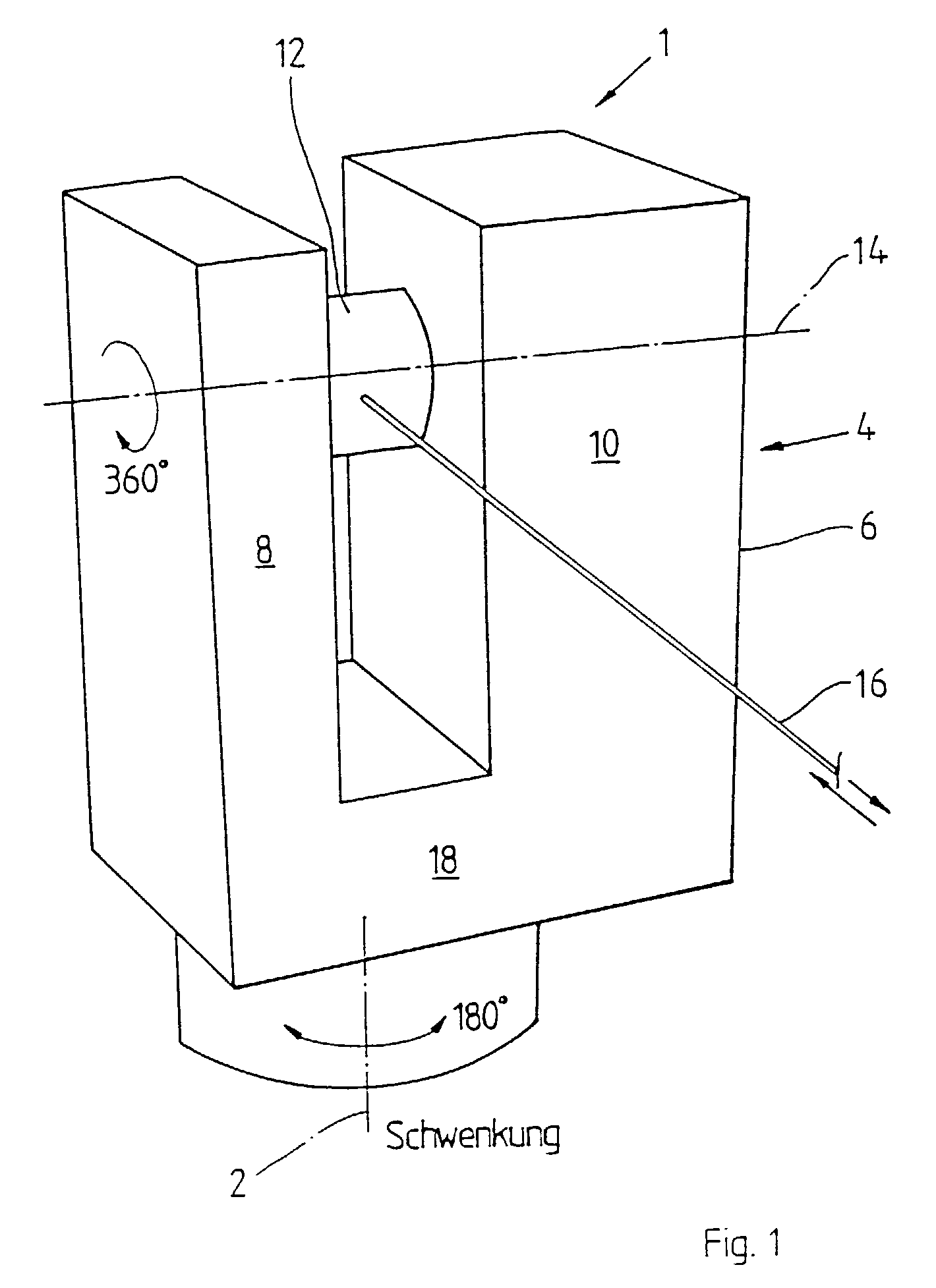

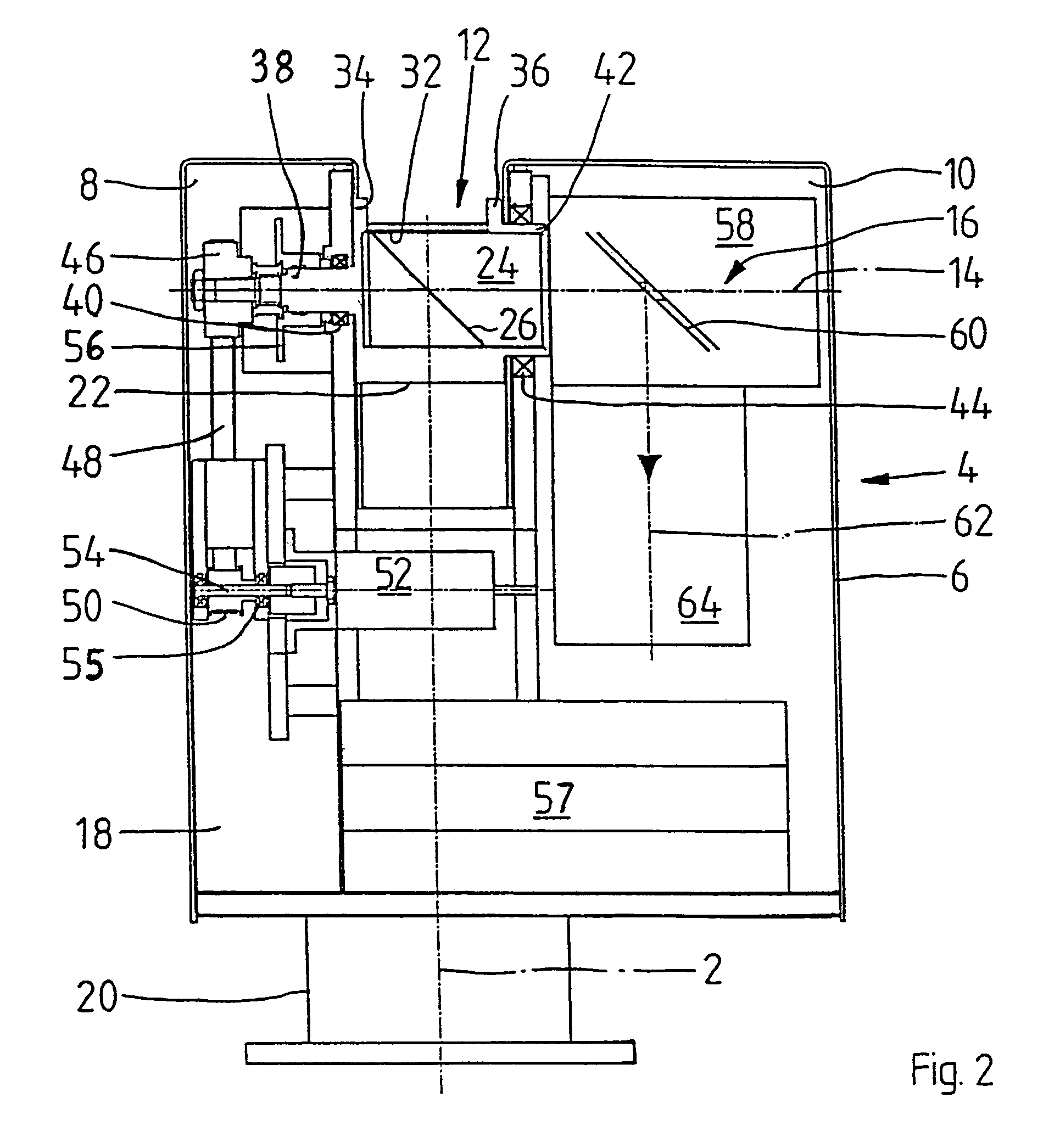

InactiveUS7190465B2High data densityDecreasing itActive open surveying meansUsing optical meansRotational axisLight beam

Owner:ZOLLER & FROEHLICH GMBH & CO KG

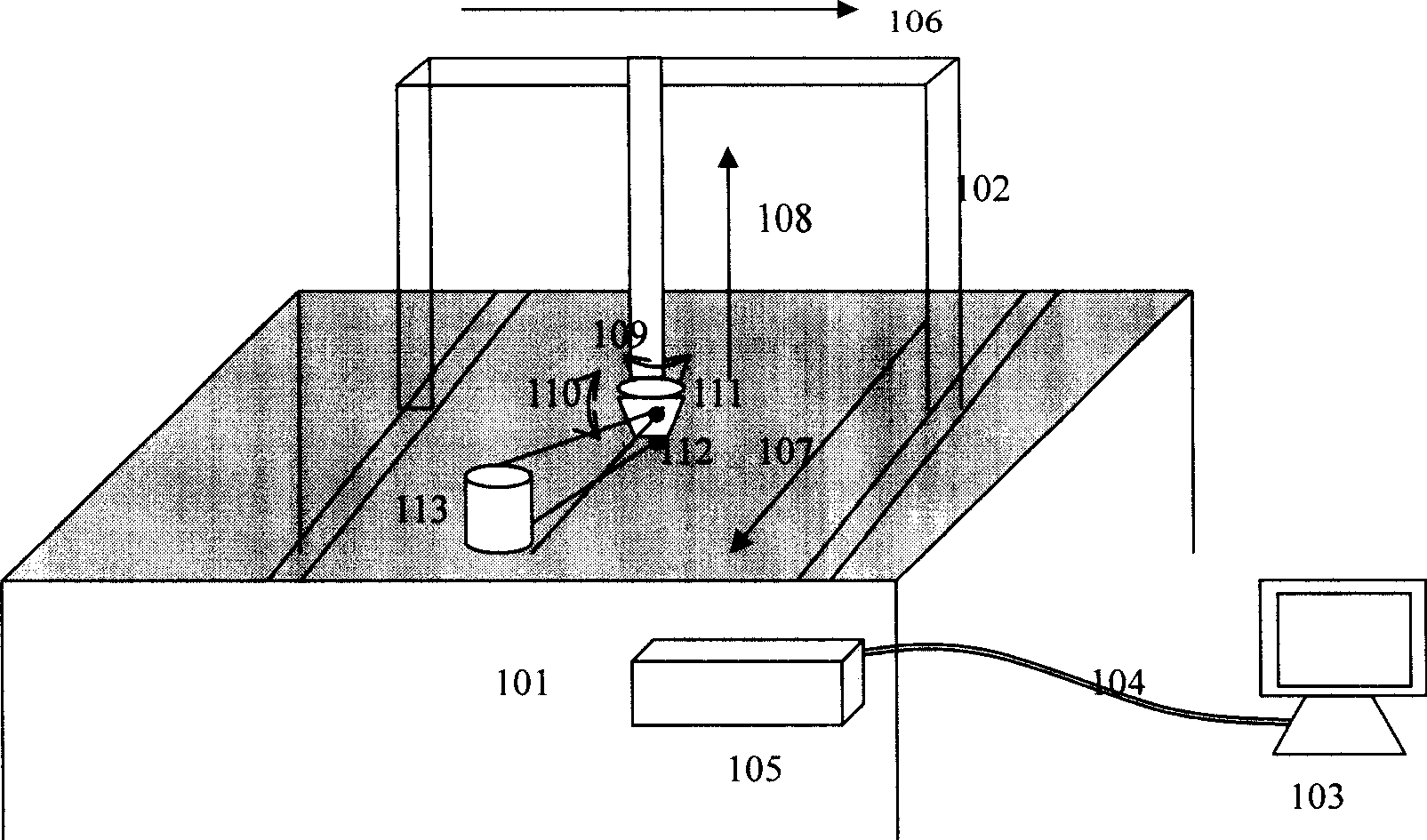

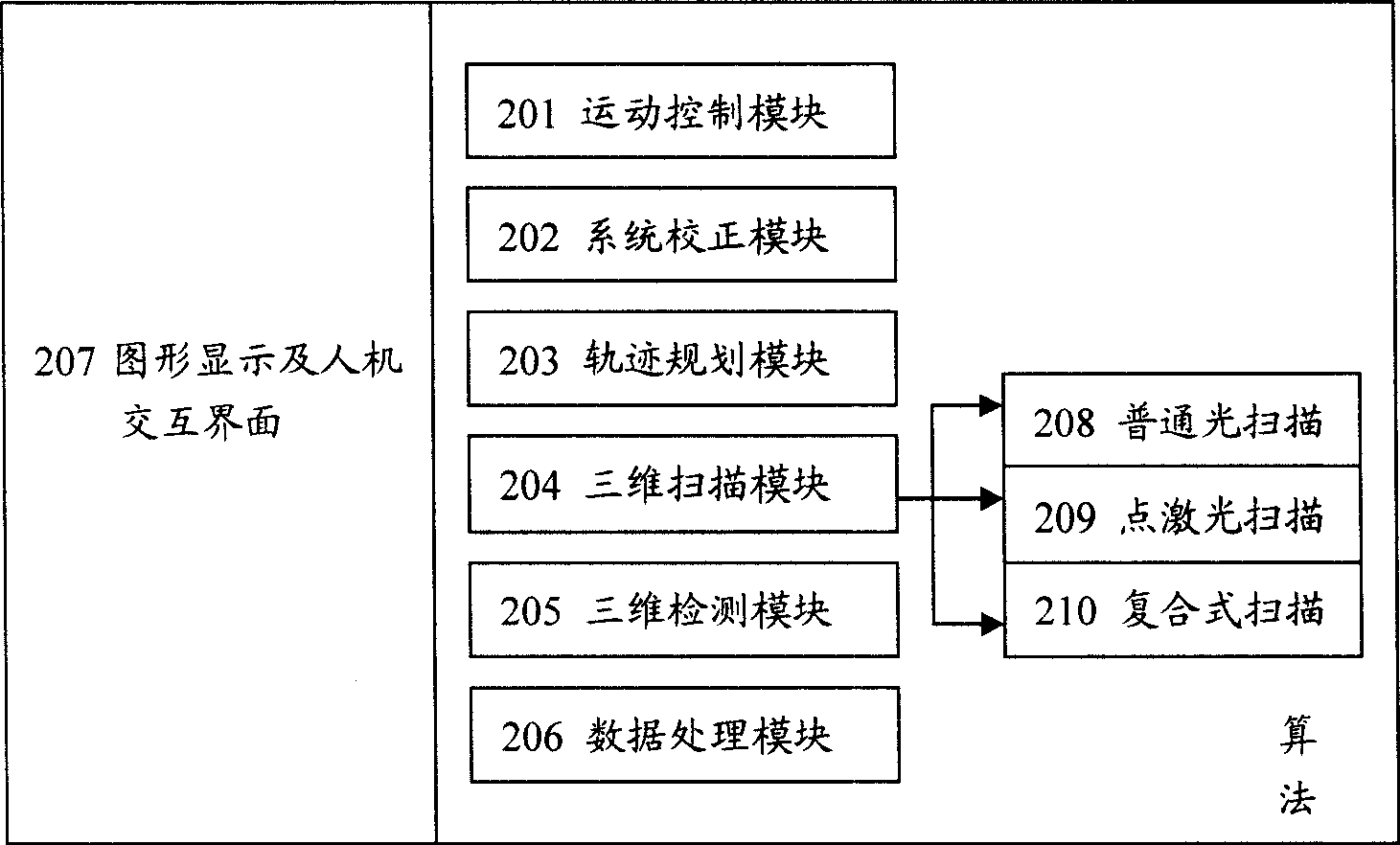

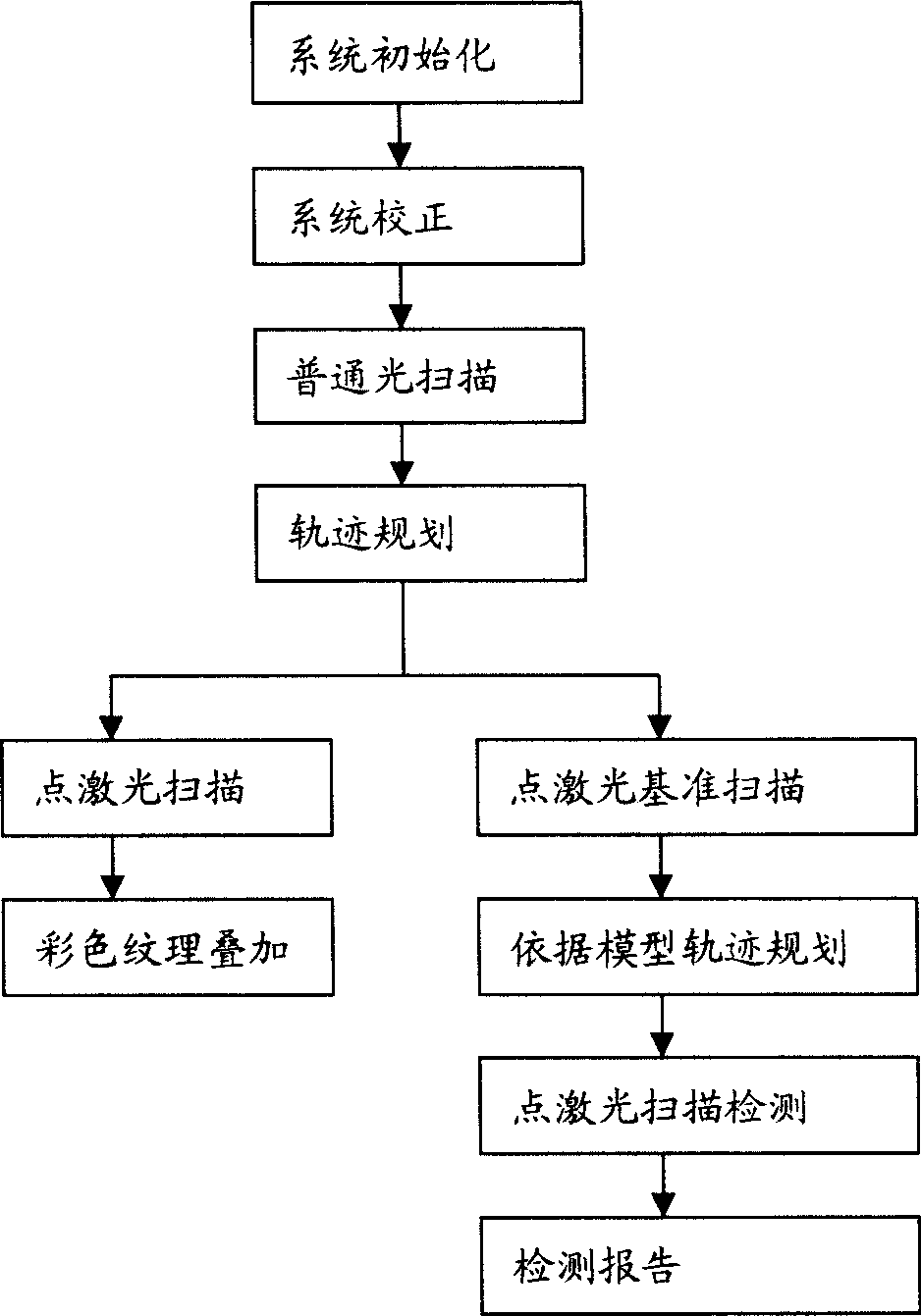

Composite three-dimensional laser measurement system and measurement method

InactiveCN101520319ARealize automated high-speed measurementAdjust light outputPhotogrammetry/videogrammetryUsing optical meansPoint cloudLaser probe

The invention provides a composite three-dimensional point laser measurement system and a measurement method, comprising three-dimensional scanning and three-dimensional detection. Normal optical scanning is adopted so as to obtain the profile information of the article quickly and establish a three-dimensional model; motion trajectory planning is carried out by the profile data; and a point laser probe is guided to carry out more precise measurement so as to obtain the three-dimensional point cloud data of higher precision and higher quality. The three-dimensional non-contact detection to the characteristic position, appointed section line and integer of the workpiece is obtained further on the basis of comparing the point cloud and model data. The system and the method have the advantages that the non-contact measurement can obtain the point cloud of good quality and high precision, the article can be positioned freely, precise clamping devices are not needed, the measurement speed is quick, the process is automatic and the measured article has wide applicable range.

Owner:深圳市精易迅科技有限公司

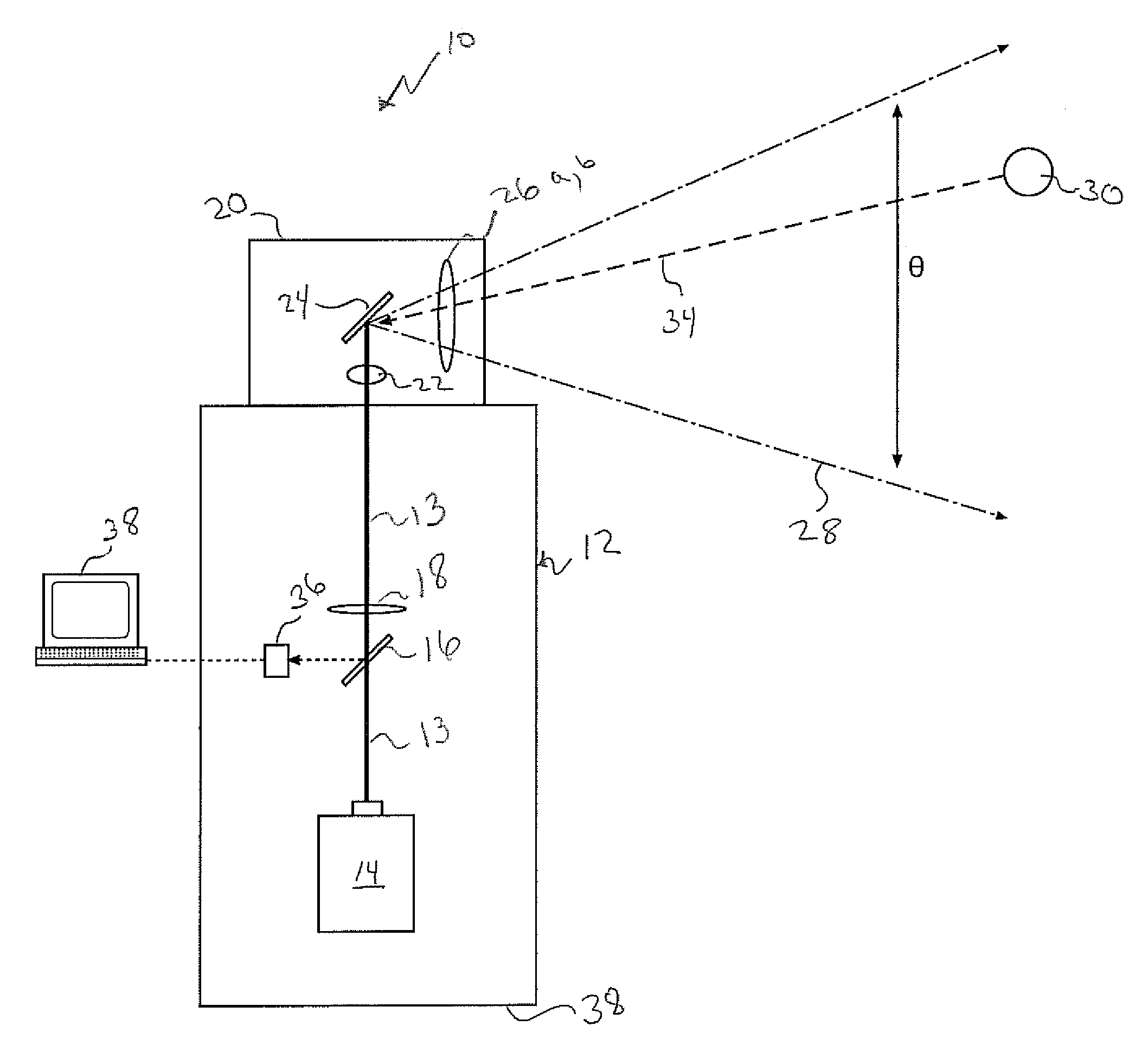

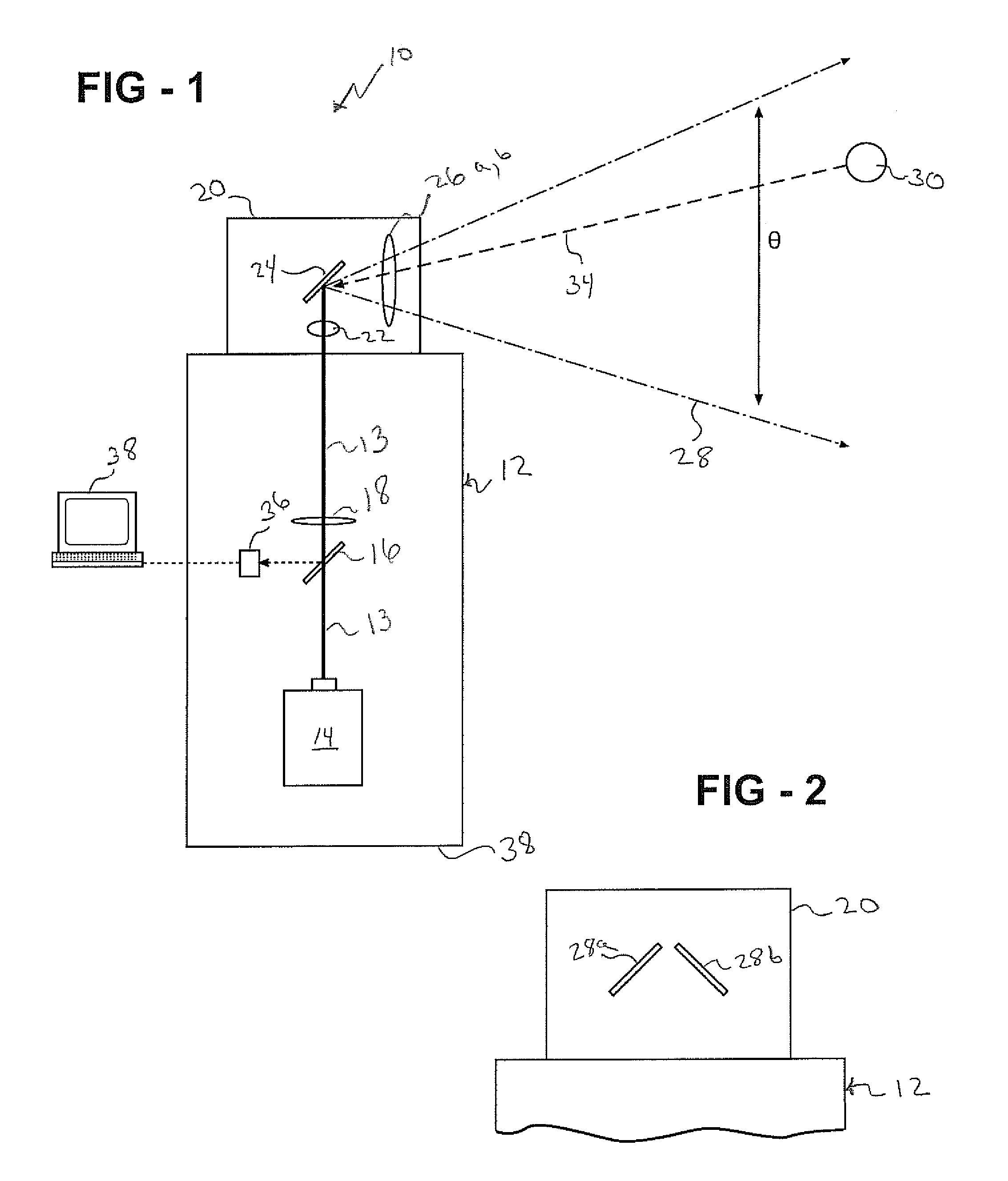

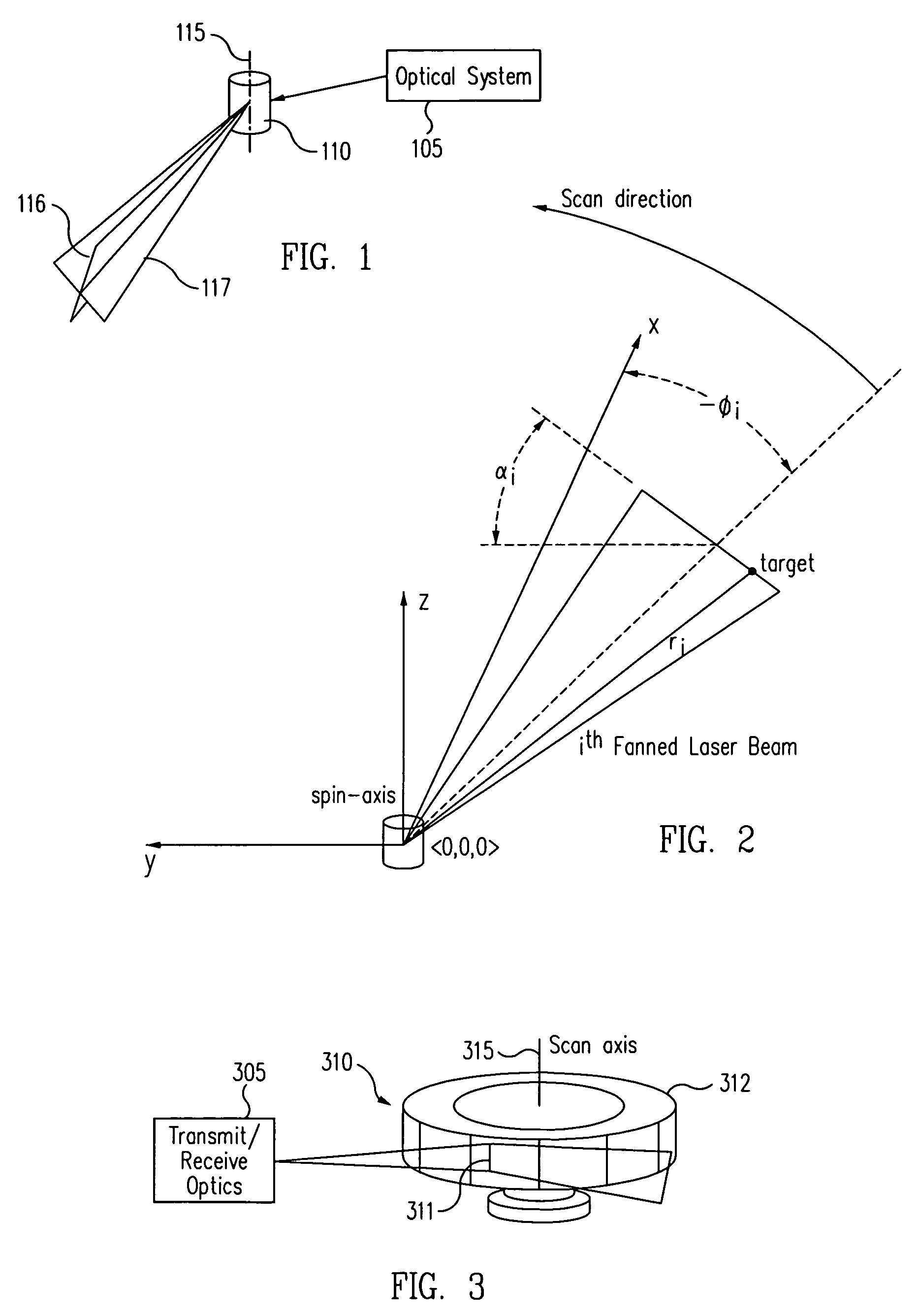

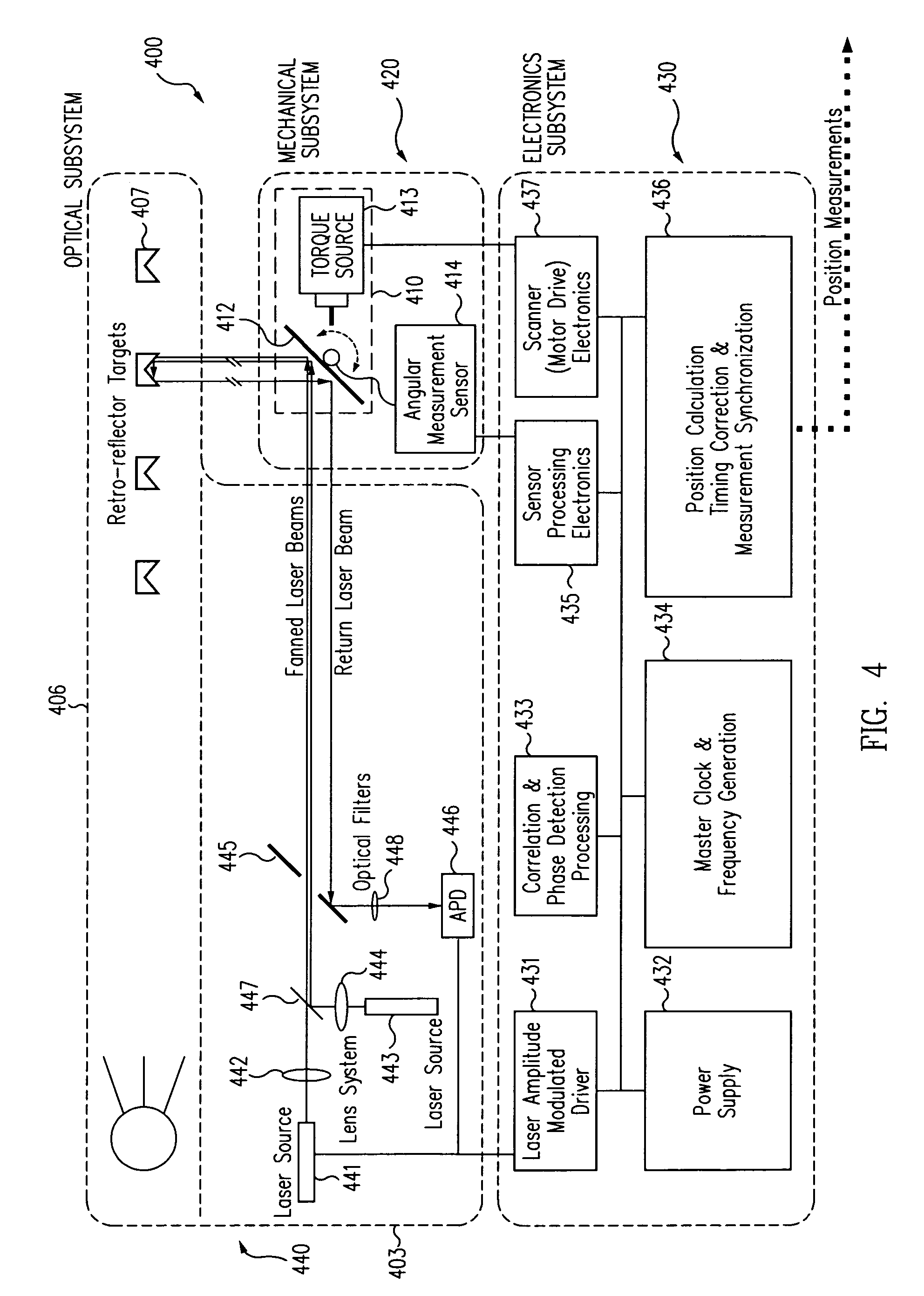

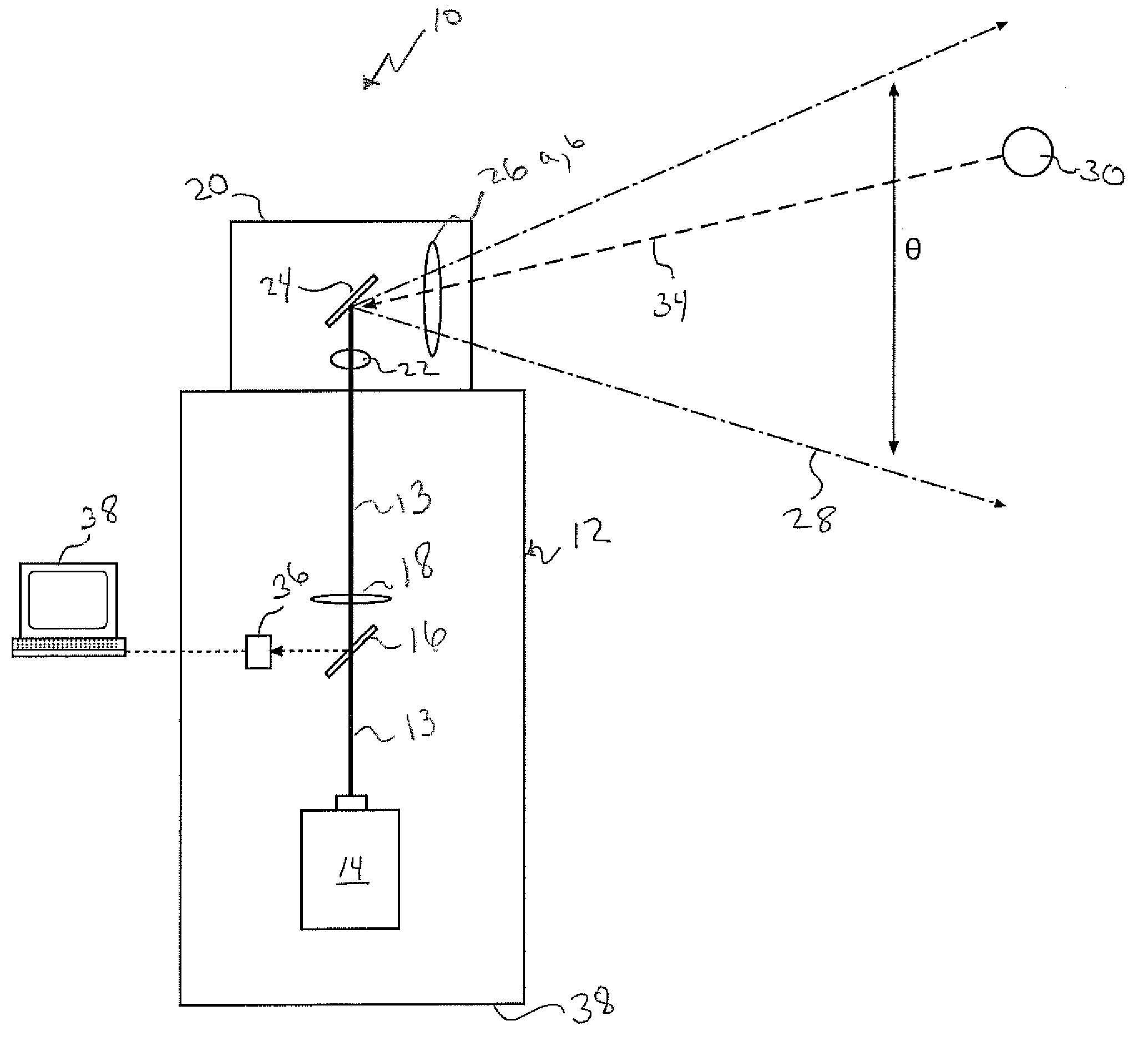

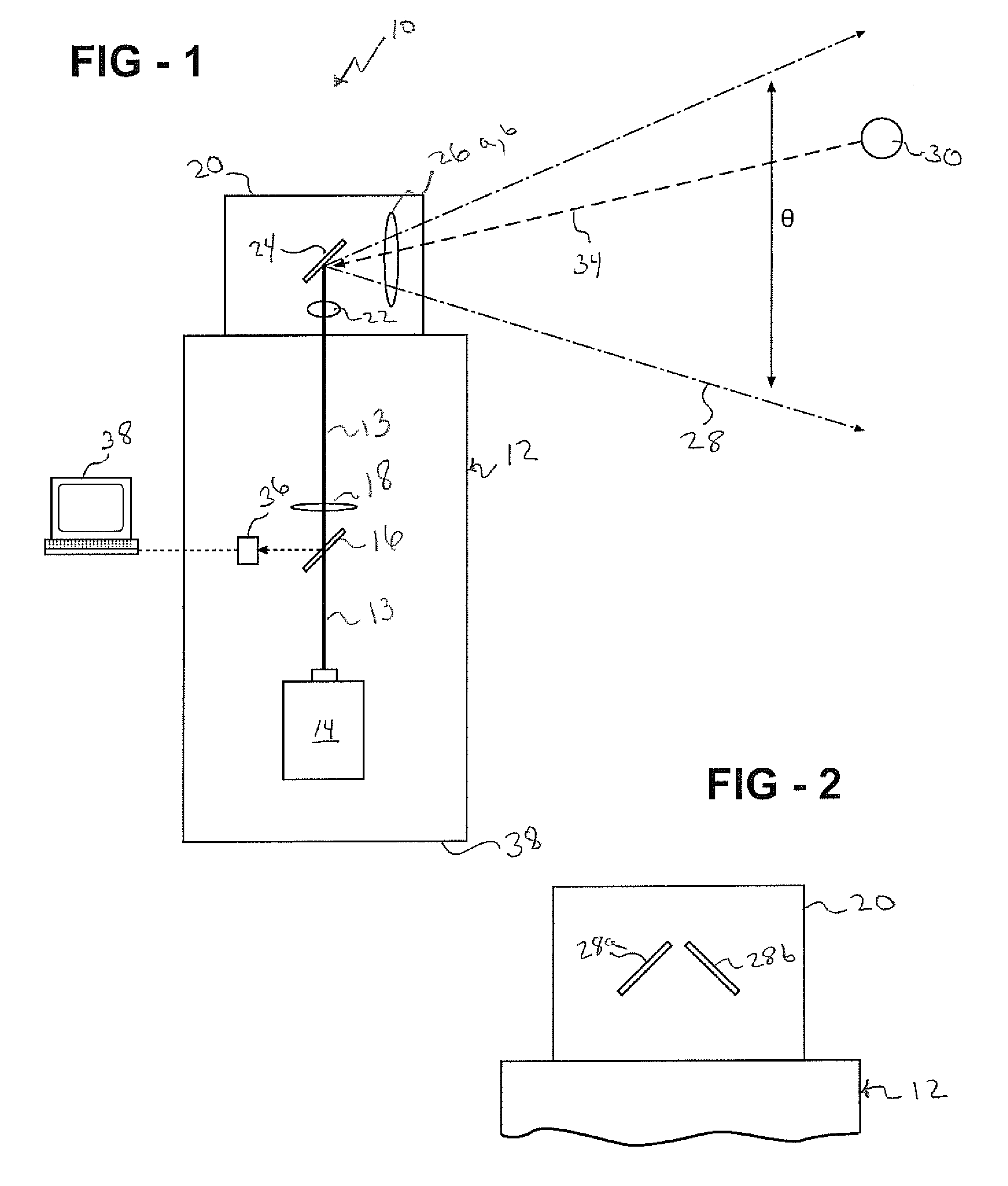

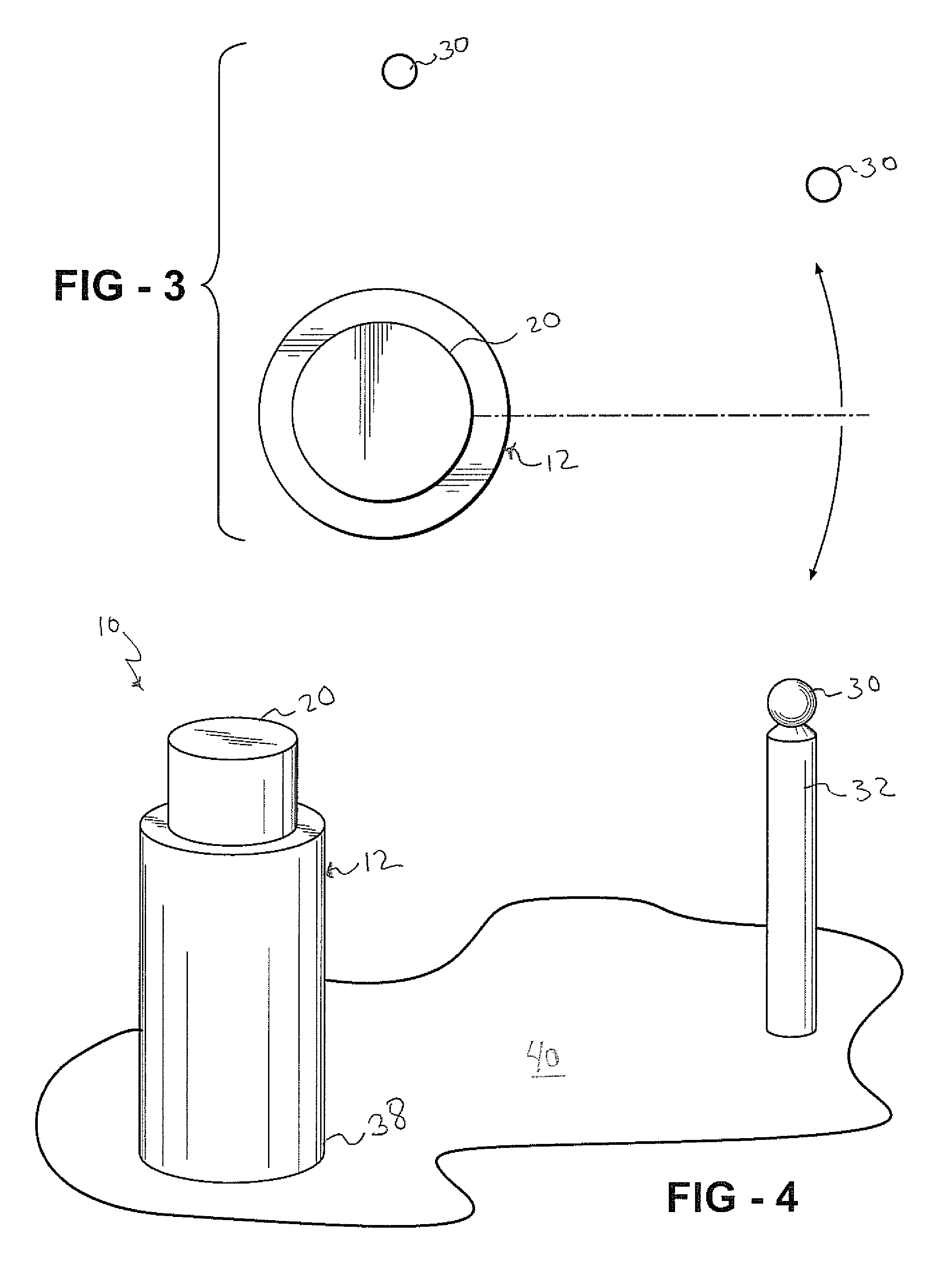

Laser metrology system and method

ActiveUS20080309949A1Reduce complexityLow costActive open surveying meansUsing optical meansMetrologyLight beam

A laser metrology system for determining a location of a target utilizes a laser projector having a laser source for projecting a laser beam. A rotating head directs the laser beam in a lateral direction. A sensor associated with the laser projector is capable of sensing the laser beam. A reflective target is configured to reflect the laser beam projector from the laser source toward the sensor in a manner indicative of the angle of the rotating head and the pulse of the laser beam to determine location of the target.

Owner:NIKON METROLOGY

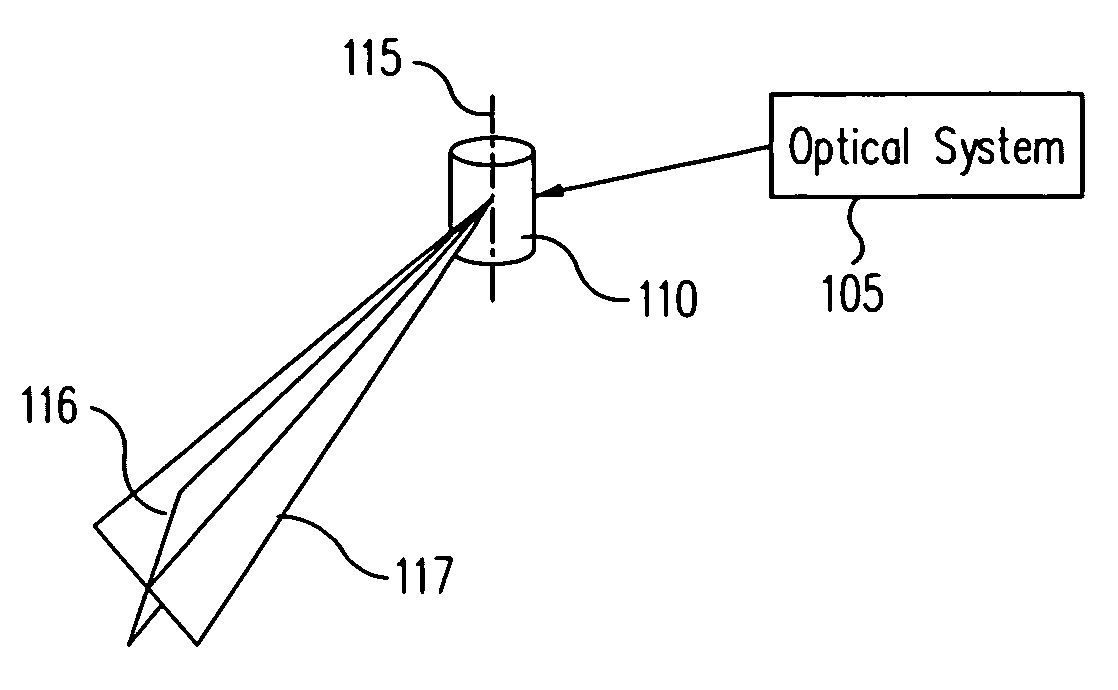

Multiple fanned laser beam metrology system

InactiveUS7787134B2Accurate informationOptical rangefindersSurveying instrumentsLocation detectionMetrology

Owner:THE BOEING CO

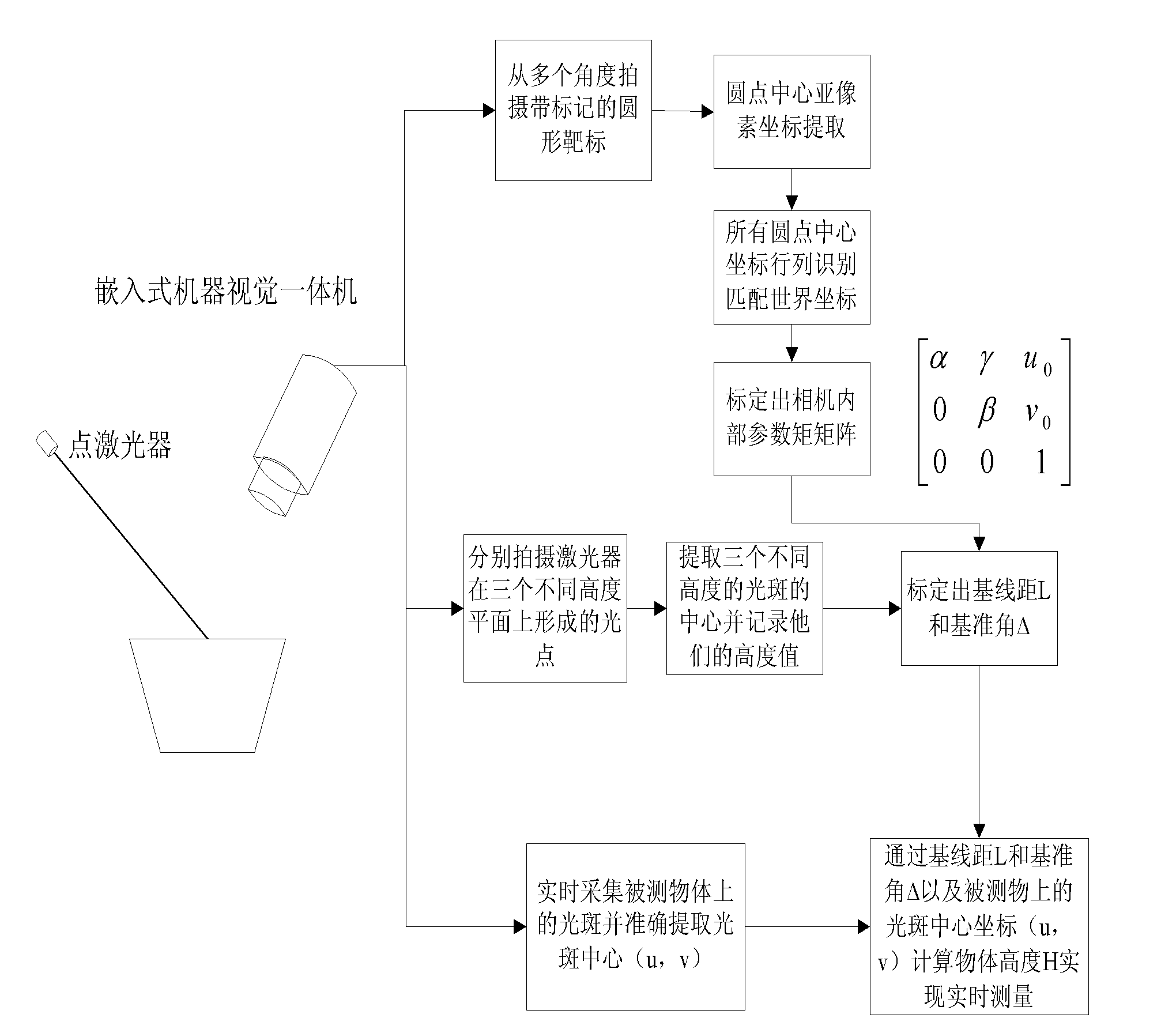

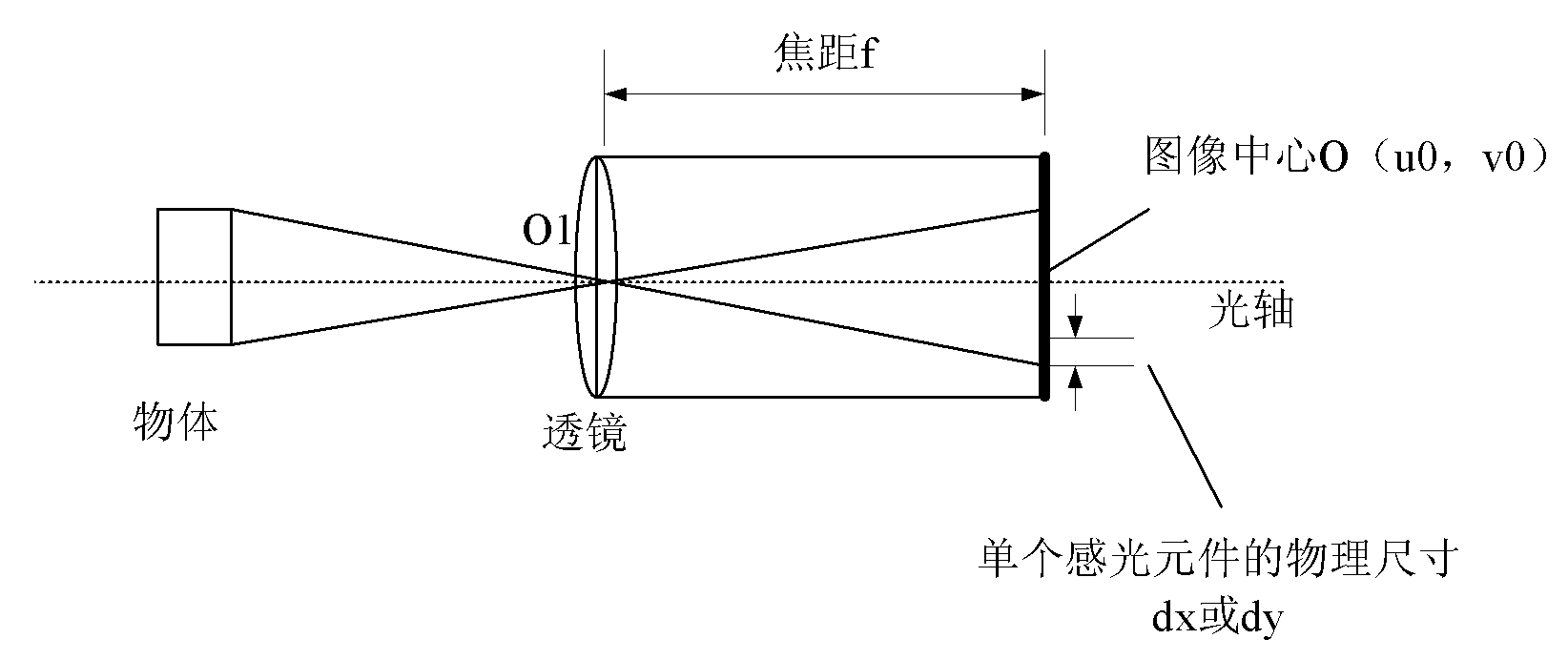

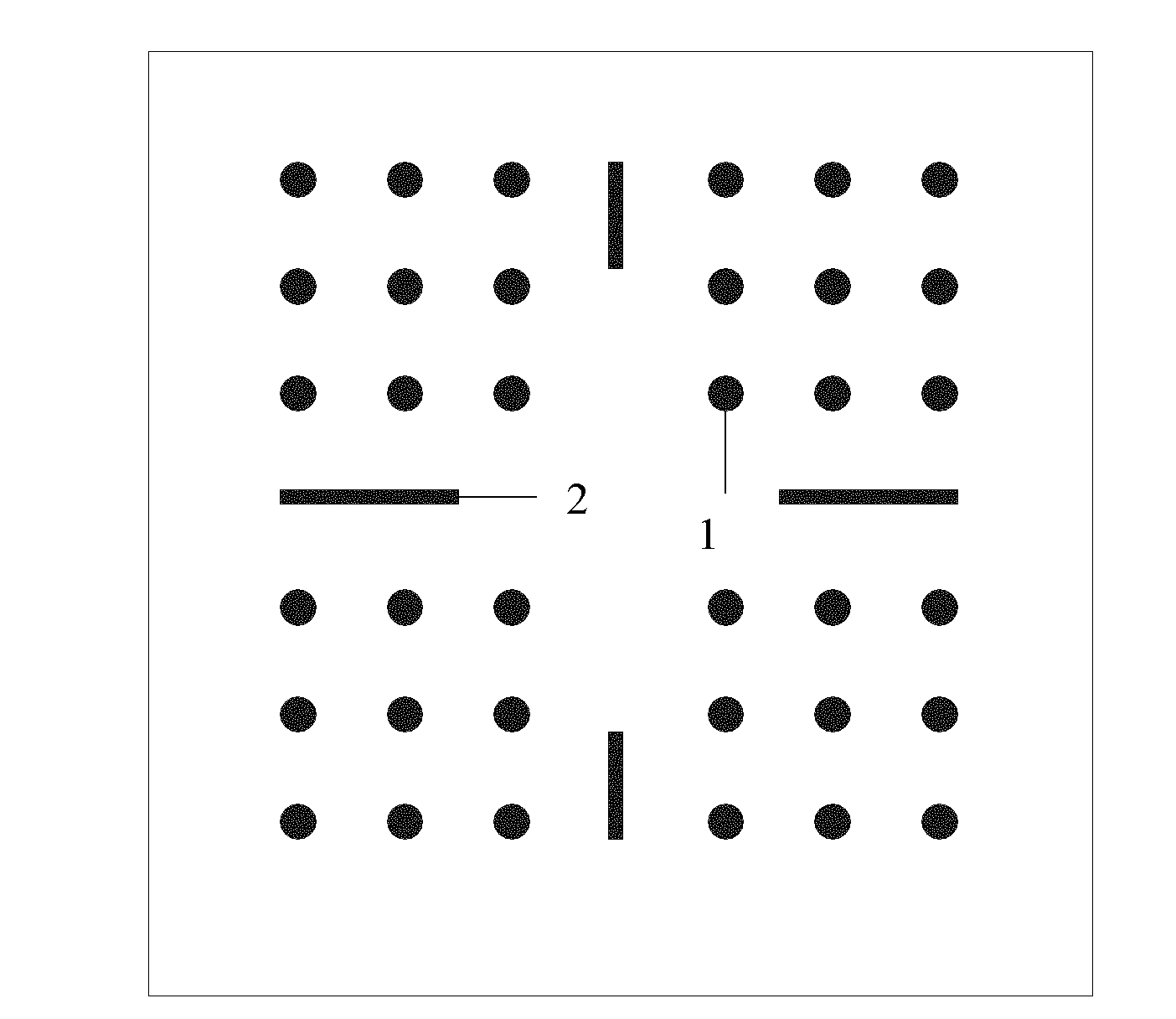

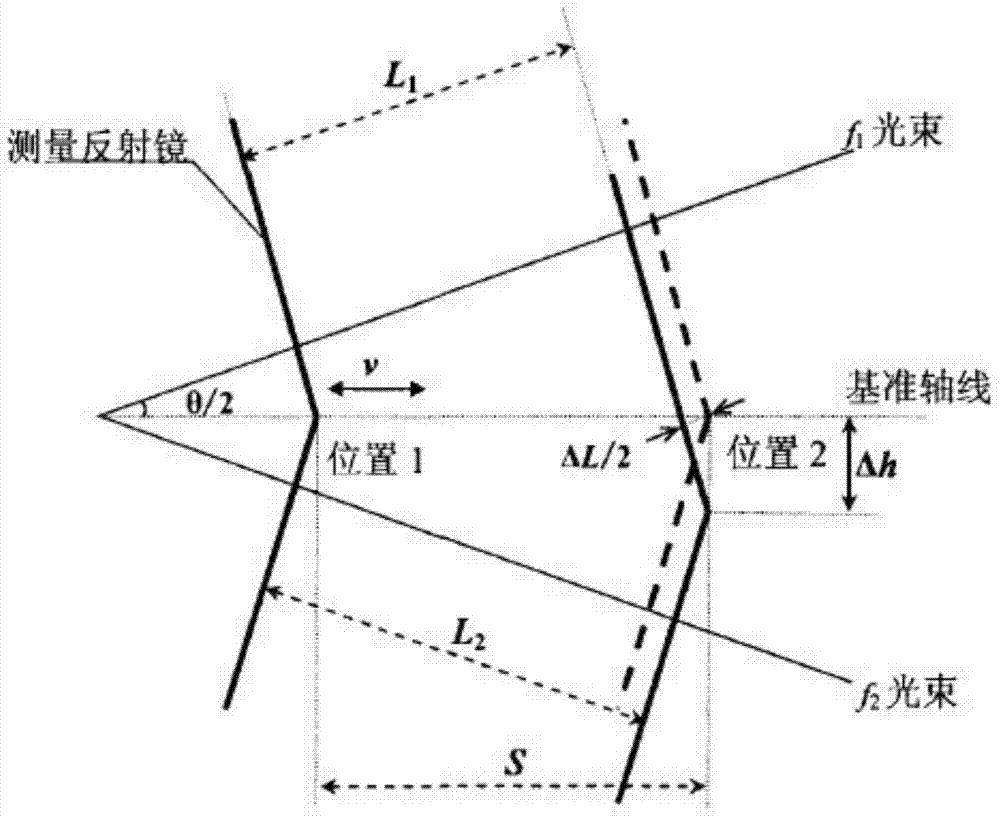

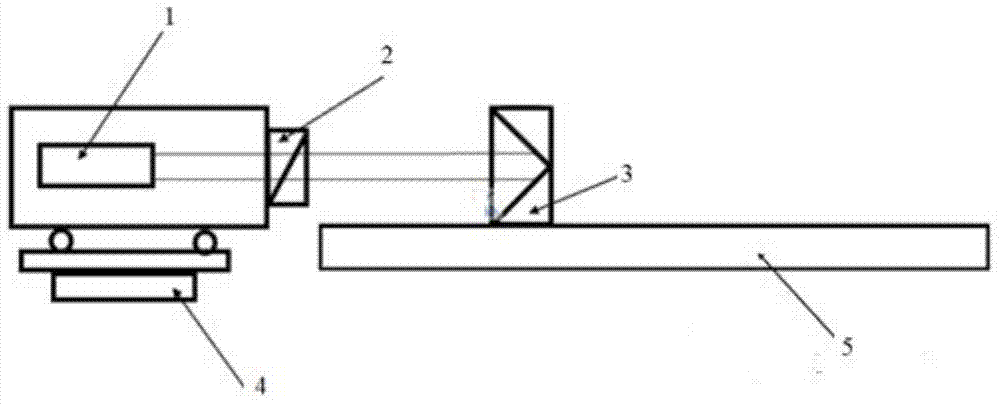

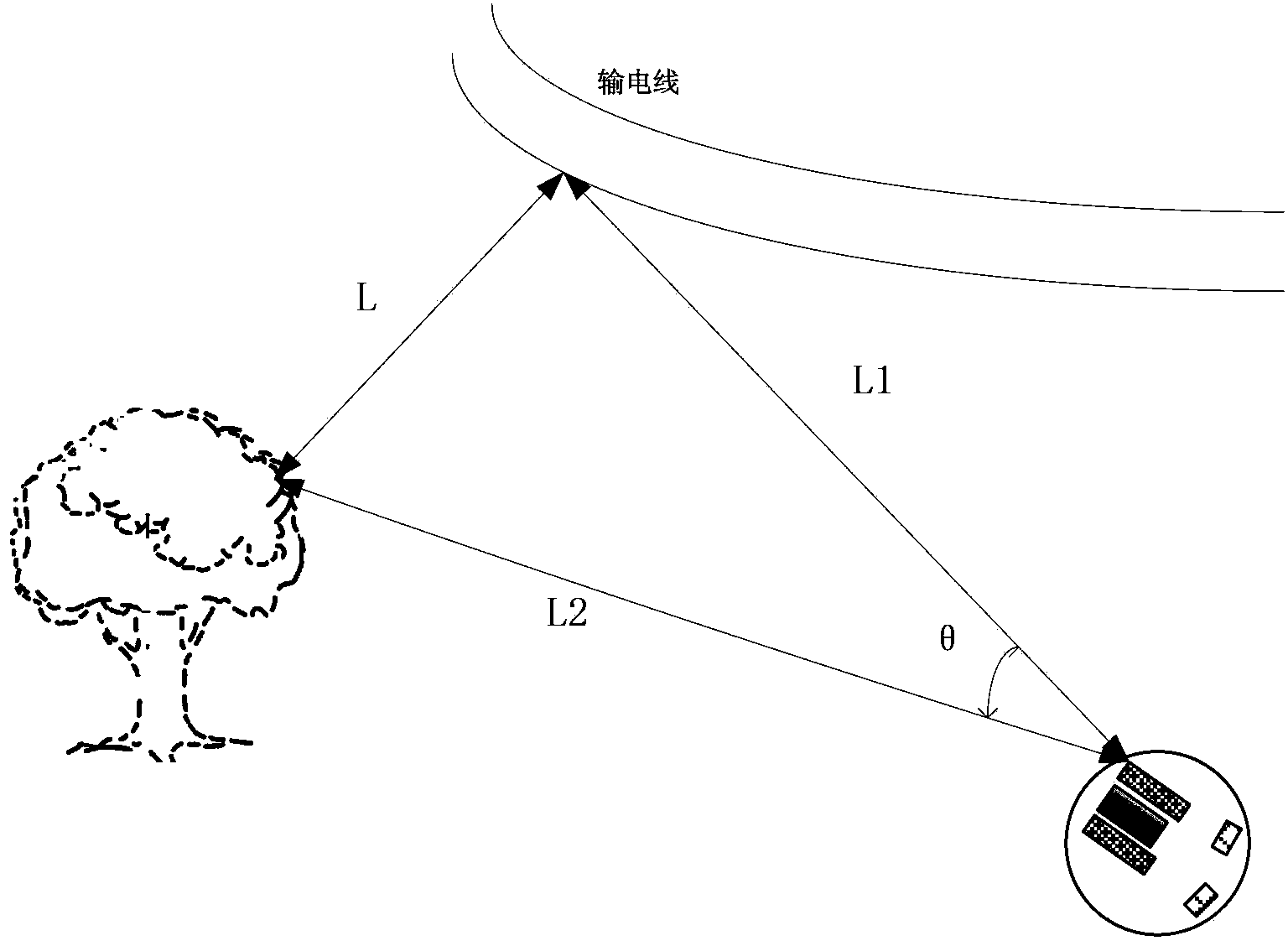

Field calibration and precision measurement method for spot laser measuring system

InactiveCN102063718AAdjustable structureHigh measurement accuracyImage analysisUsing optical meansCamera imageLaser ranging

The invention provides a simple and flexible field calibration and precision measurement method for a spot laser measuring system by analyzing the camera imaging principle, establishing a camera imaging model and introducing the concepts of two structural parameters, namely a basic line distance and a reference angle aiming at the defects of extreme calibration conditions and complicated calibration steps of the traditional spot laser-camera measuring system. In the method, only two standard planar heights H1 and H2 are needed to precisely complete the calibration task of the system structure, and the spot laser-camera measuring system of the algorithm has higher measuring precision so as to meet the requirement of precision measurement. The algorithm makes the spot laser-camera structure adjustable and field calibration of system structural parameters possible; and the flexibility of a laser ranging system is greatly improved and the method has important significance for actual vision measurement.

Owner:JIANGNAN UNIV

Laser measurement system

ActiveUS7181856B1Beacon systems using electromagnetic wavesDirection/deviation determining electromagnetic systemsVehicle frameTelecommunications link

A laser measurement system indicates the difference between an actual position of a vehicle frame reference point on a vehicle frame and a normal position employing a rotating laser scanner; an electro-optical detector and a host computer. A positioning arrangement is also provided for positioning the electro-optical detector at a known distance from the reference point. In operation, the host computer queries the scanner and detector via a communication link, calculates the actual position of the reference point, and displays the difference between the position of the vehicle reference point on the vehicle frame and the normal position.

Owner:ADVANCED MEASUREMENT SYST INC +1

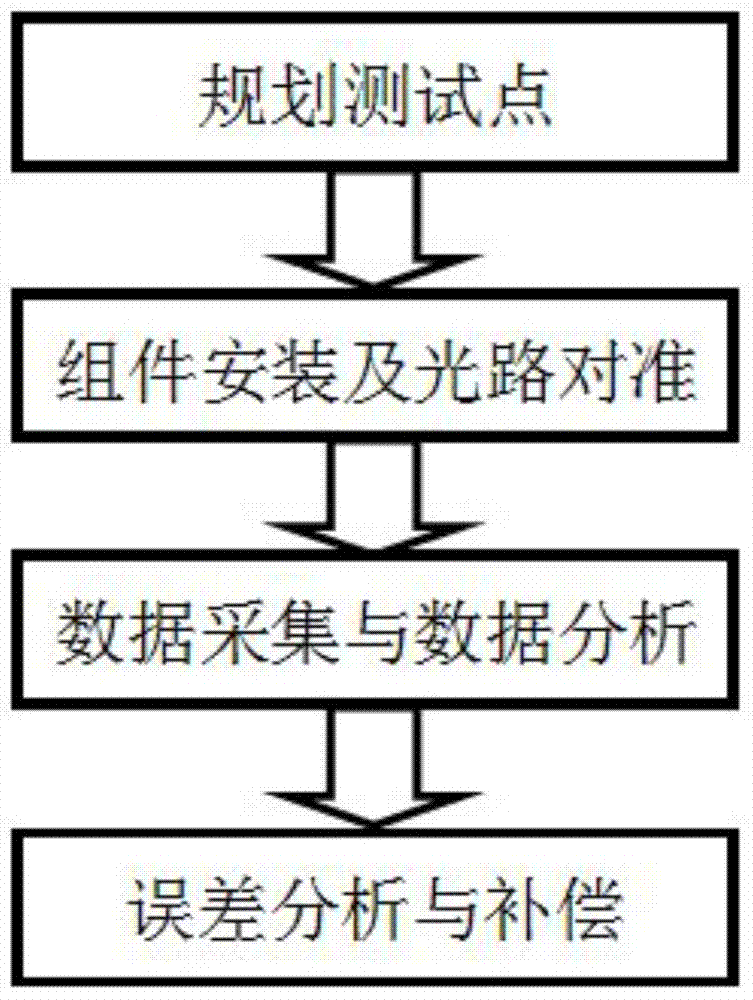

Rapid measuring and error compensation method for linearity error of linear guide rail

The invention provides a rapid measuring and error compensation method for linearity error of a linear guide rail, and aims at solving the problems of small measurement method, large error and complex data treatment in the prior art. The method comprises the steps of measuring and acquiring a plurality of data points on the linear guide rail through a laser interference instrument; analyzing the linearity measurement result for the data of the acquired points through a linearity data analyzing module in an XD laser measurement system so as to obtain the linearity error of the guide rail. With the adoption of the method, the mounting error, environmental error, delay error and the error caused by thermal expansion of a measured object in measuring can be analyzed; an error correcting model is built.

Owner:BEIJING UNIV OF TECH

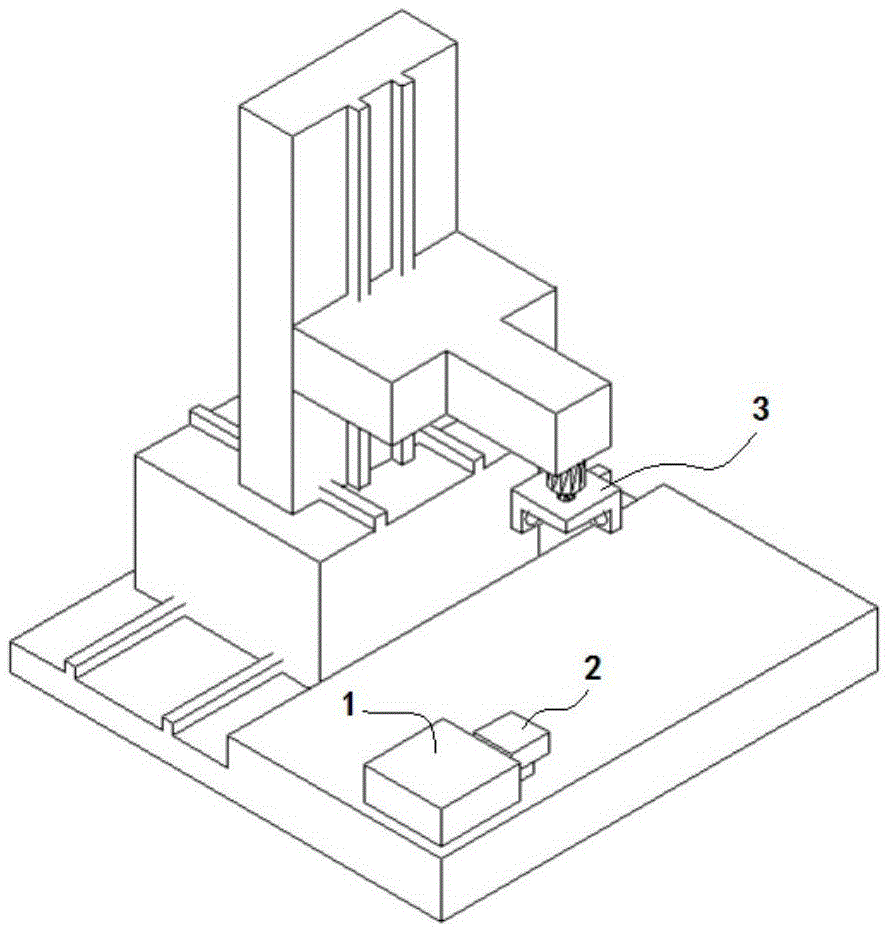

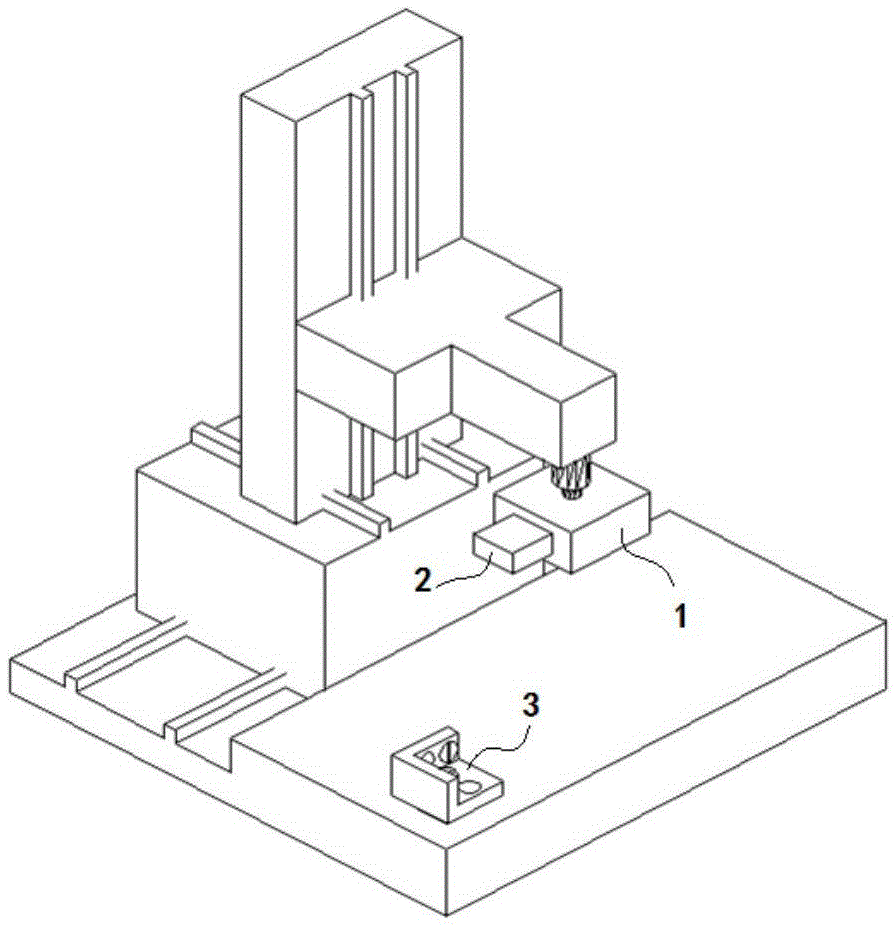

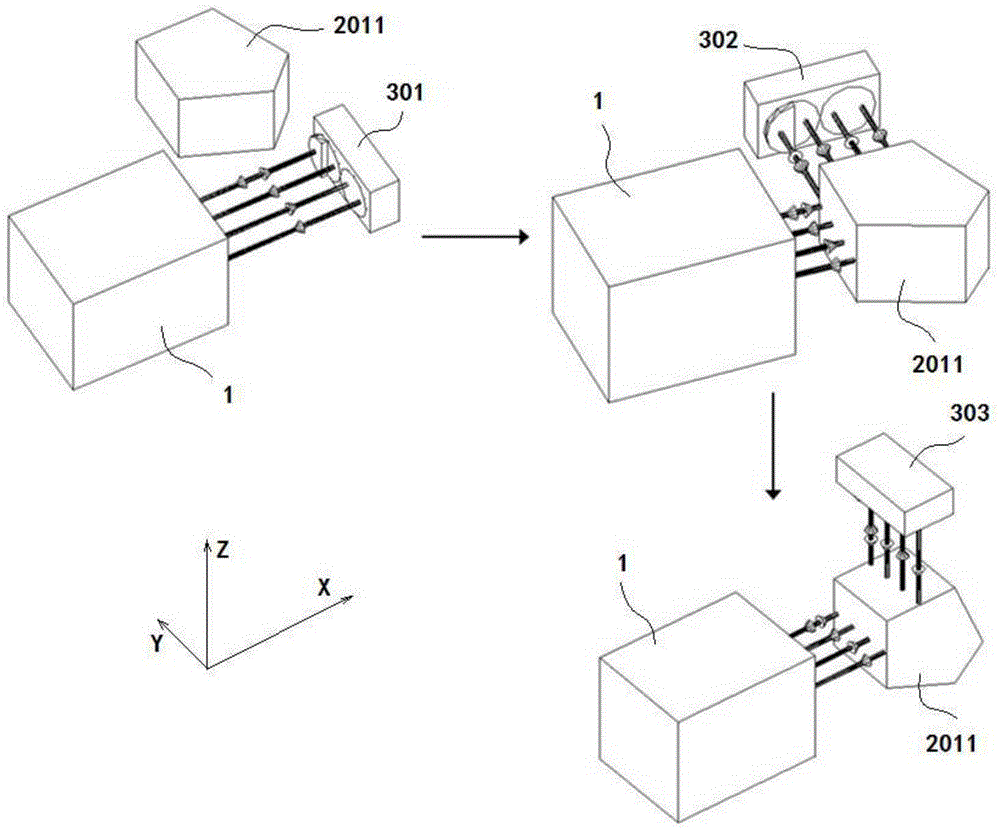

Laser measurement system and method capable of detecting 21 geometric errors

ActiveCN105492860AHighly integratedImprove detection efficiencyAngle measurementInterferometersLight beamEngineering

Owner:BEIJING JIAOTONG UNIV

Laser metrology system and method

ActiveUS7876457B2Increase usageReduce complexityActive open surveying meansUsing optical meansMetrologyLight beam

A laser metrology system for determining a location of a target utilizes a laser projector having a laser source for projecting a laser beam. A rotating head directs the laser beam in a lateral direction. A sensor associated with the laser projector is capable of sensing the laser beam. A reflective target is configured to reflect the laser beam projector from the laser source toward the sensor in a manner indicative of the angle of the rotating head and the pulse of the laser beam to determine location of the target.

Owner:NIKON METROLOGY

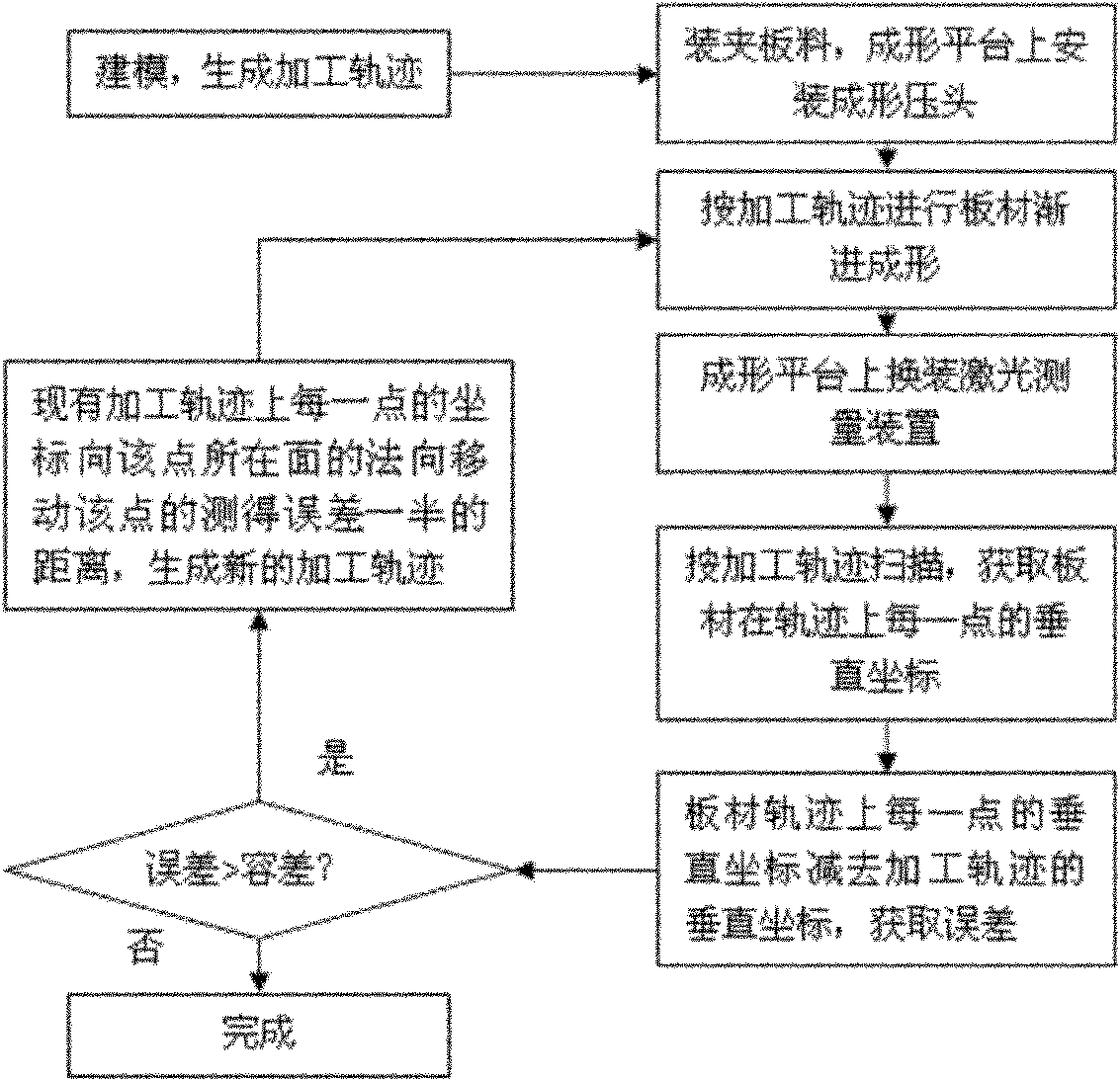

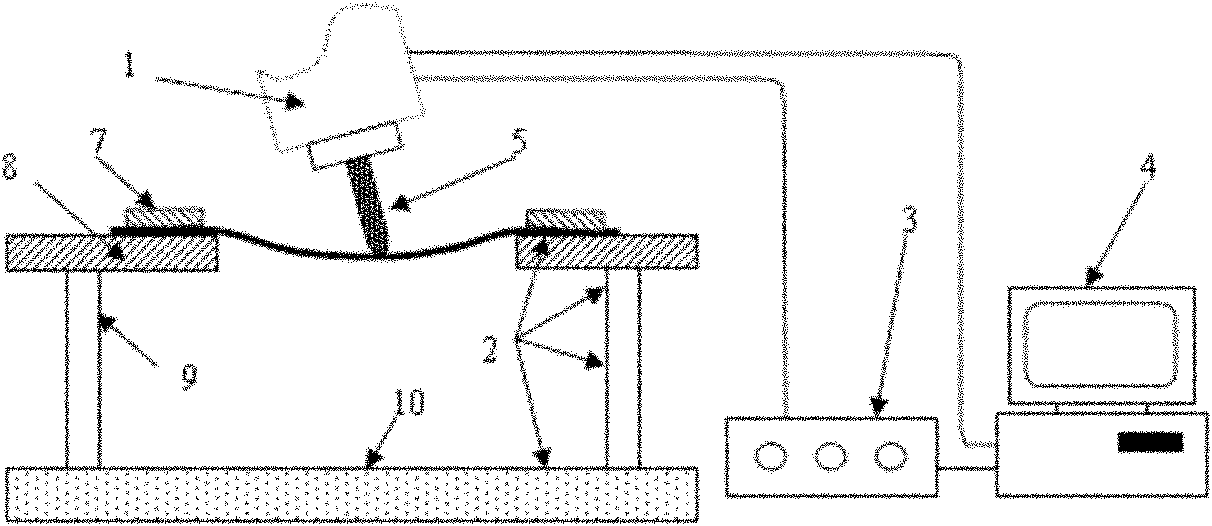

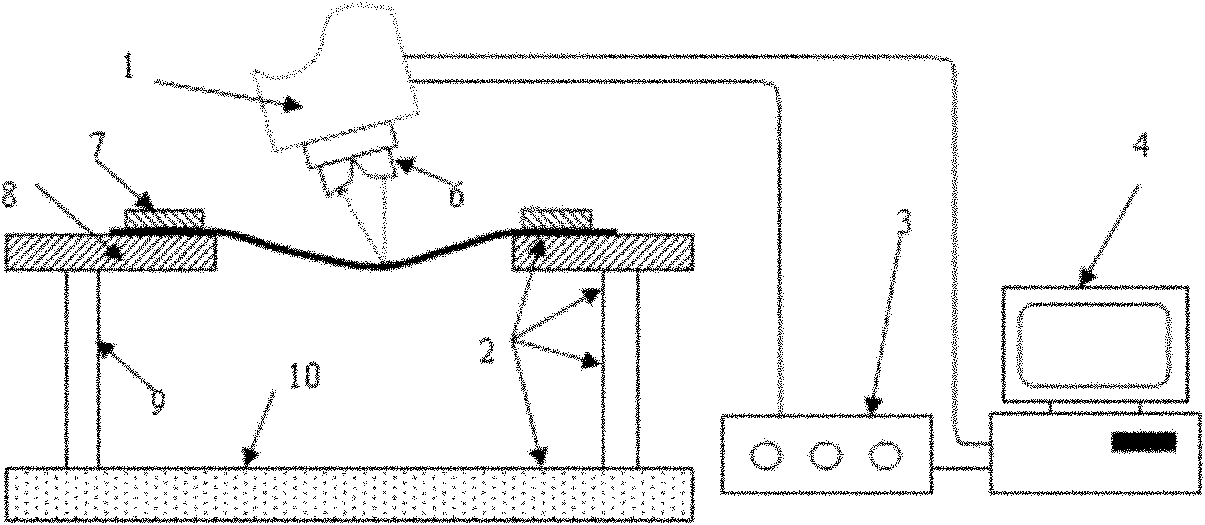

Numerical control precision progressive forming device and precision progressive forming method for plates

ActiveCN102211121AReduce development costsAvoid occupyingMetal-working feeding devicesMetal working apparatusNumerical controlGeometric error

The invention discloses a numerical control precision progressive forming device and a precision progressive forming method for plates, and belongs to the technical field of plate processing. The device comprises a five-axis numerical control forming machine, a plate fixture, a data acquisition system and an optimal control module, wherein the plate fixture is arranged on a worktable of the machine; the data acquisition system is connected with the five-axis numerical control forming machine and the optimal control module respectively, and transmits processing parameters and control instructions; the tail end of a spindle of the five-axis numerical control forming machine is provided with a forming pressure head or a laser ranging system; and the laser ranging system is connected with thedata acquisition system and transmits a laser ranging signal. By alternately using the forming pressure head and the laser ranging system, cyclic operation including plate progressive forming, error measurement and formed path modified forming is completed. The device can save development cost of a die, avoid occupying a press, ensure the dimensional accuracy of sheet metal parts, and reduce material loss due to geometric errors in actual production.

Owner:SHANGHAI JIAO TONG UNIV

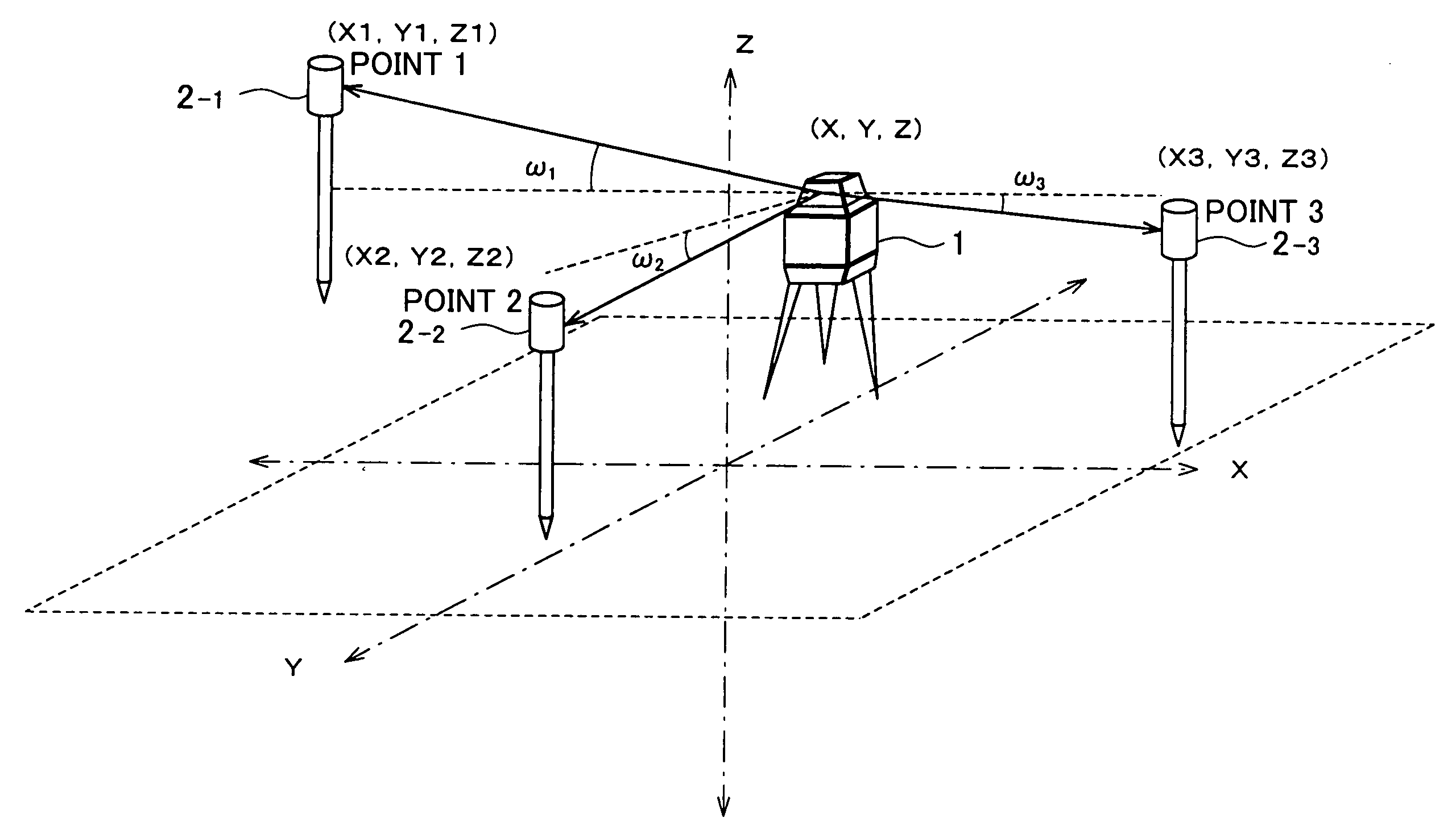

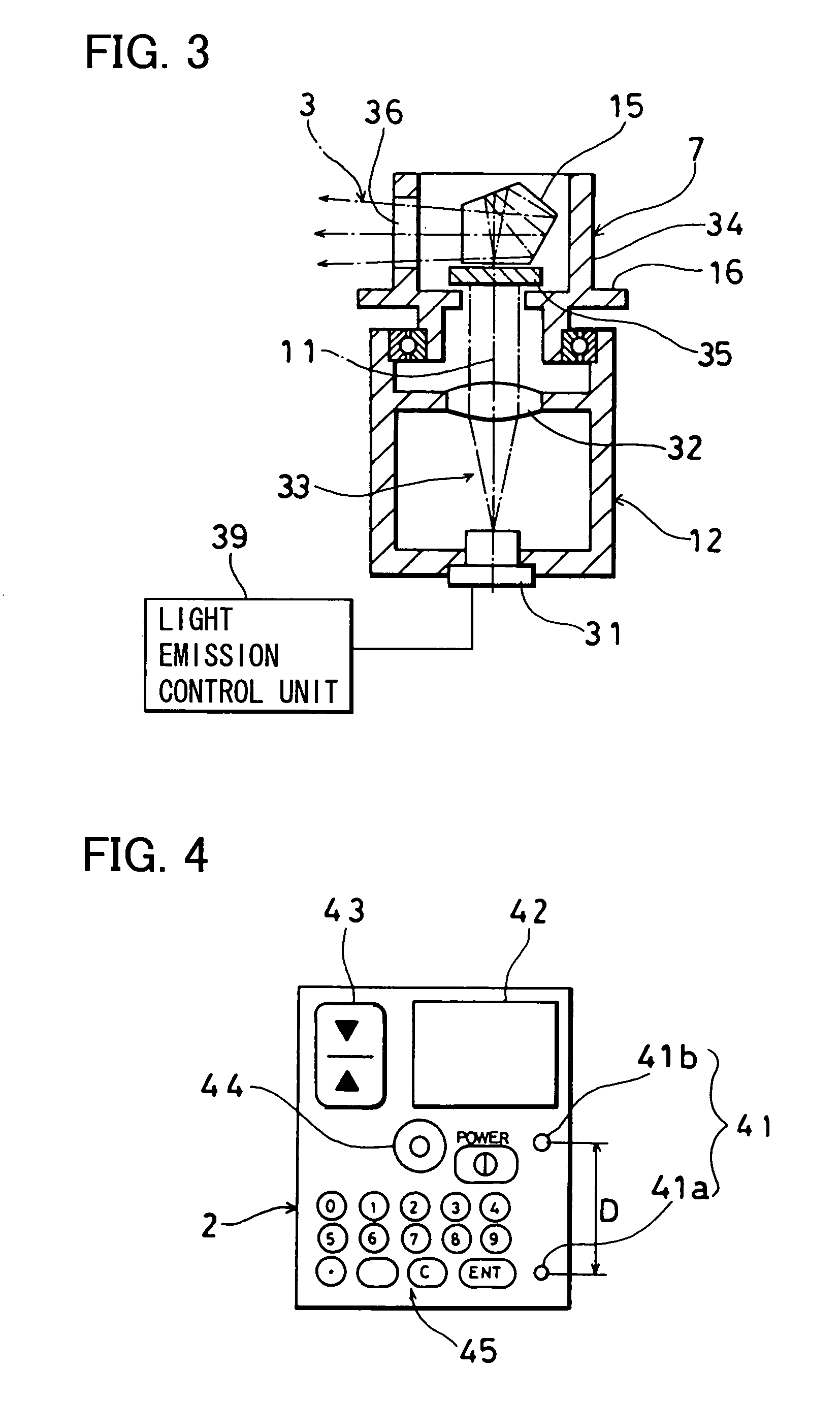

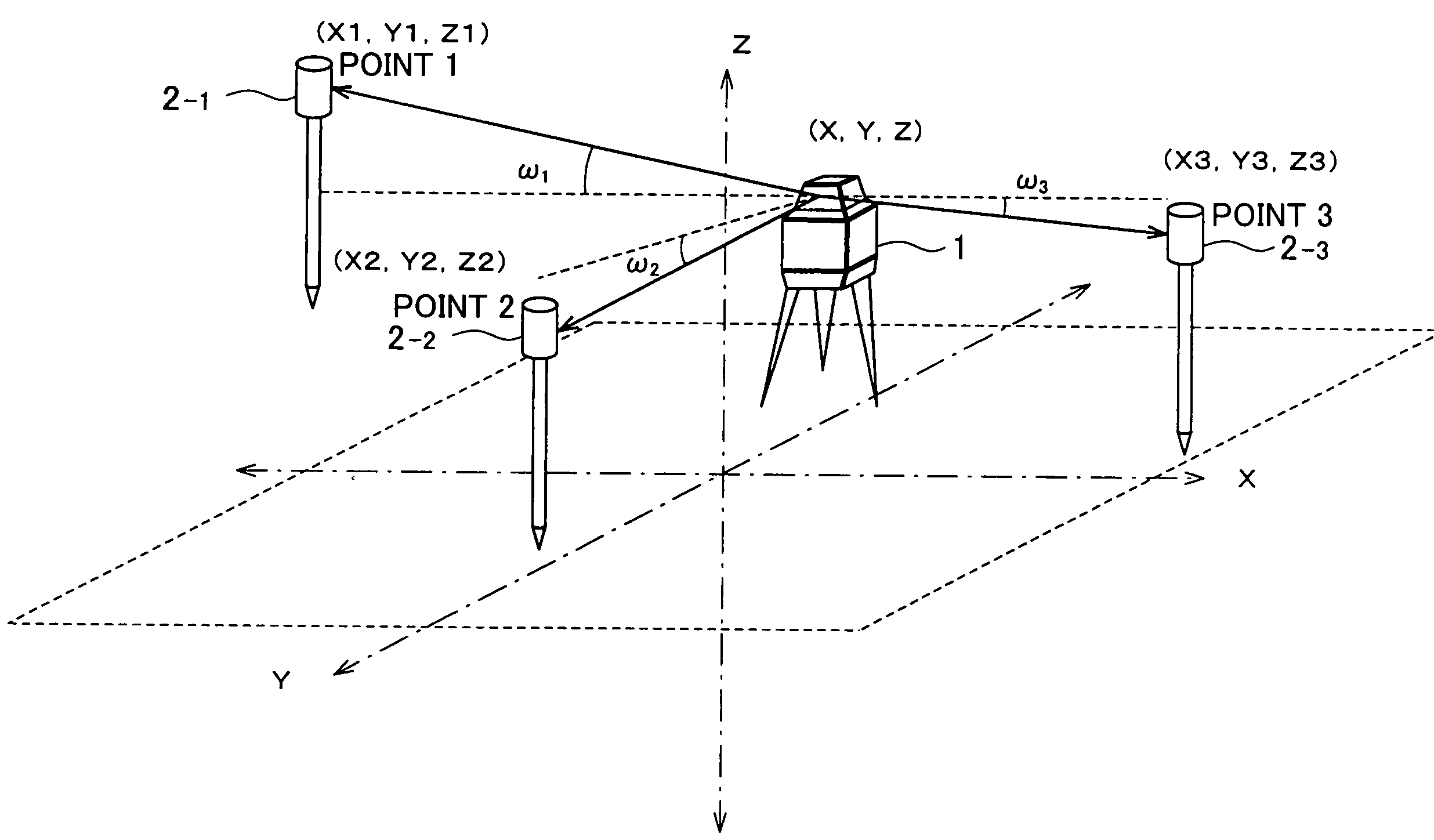

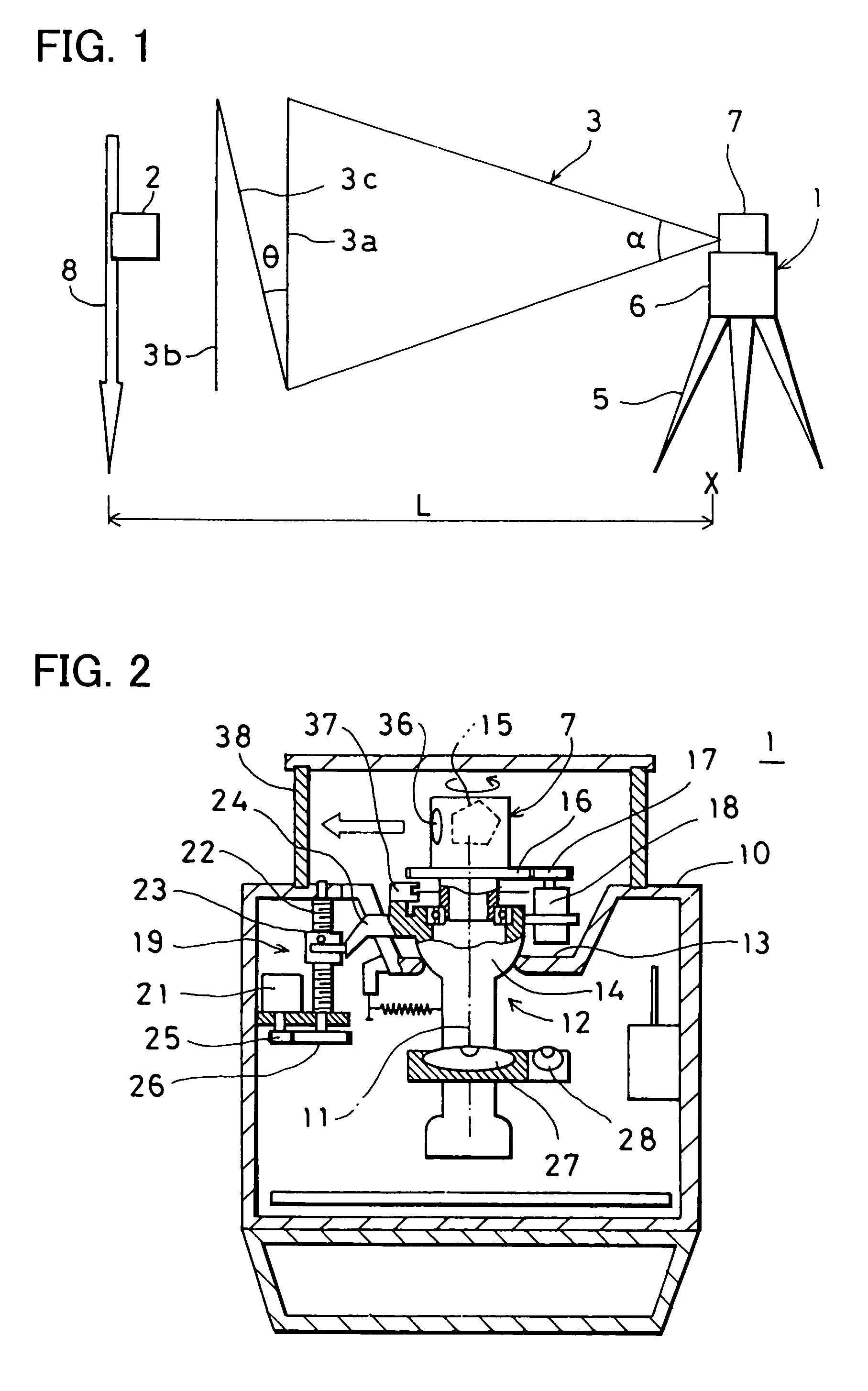

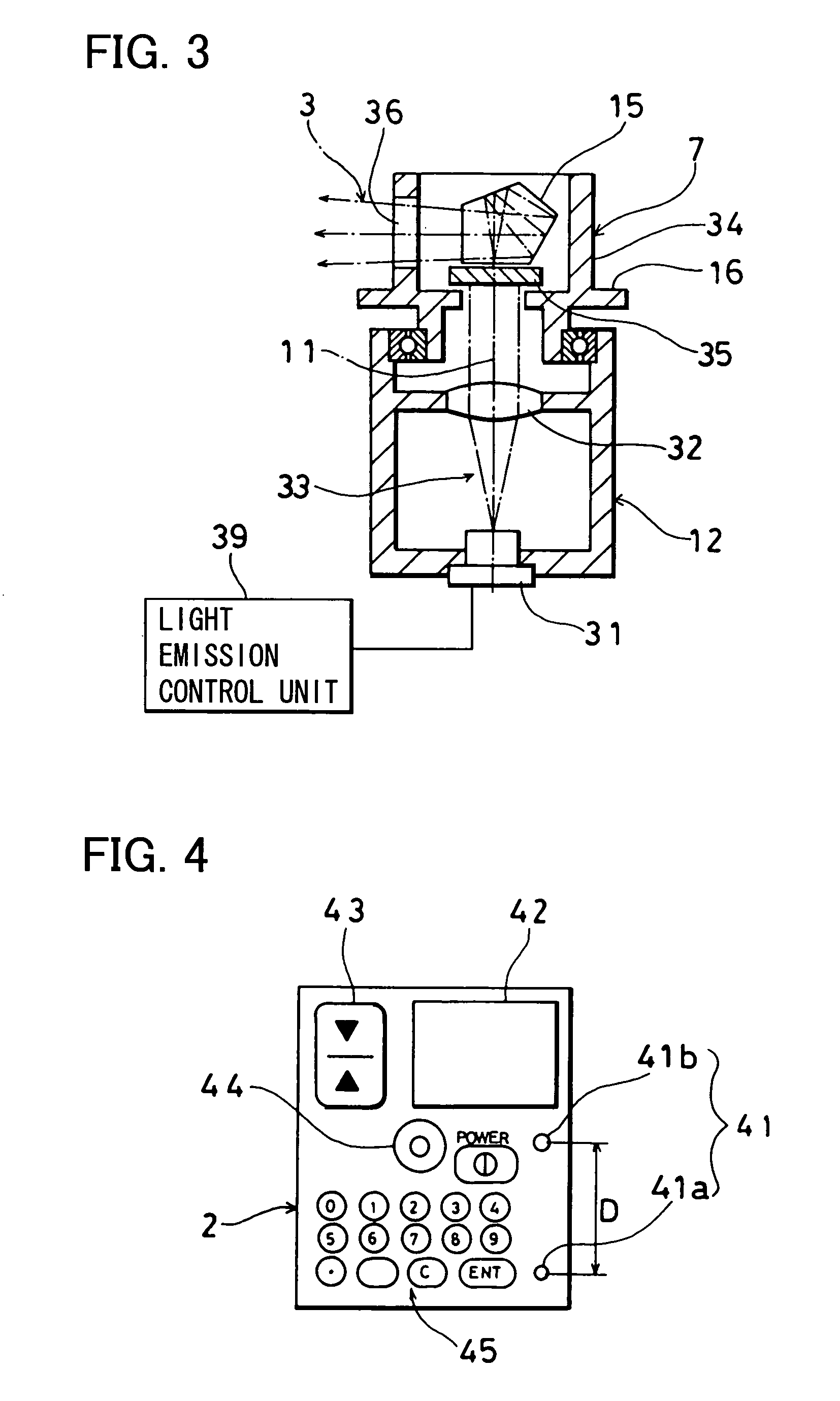

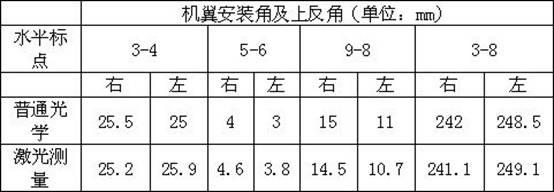

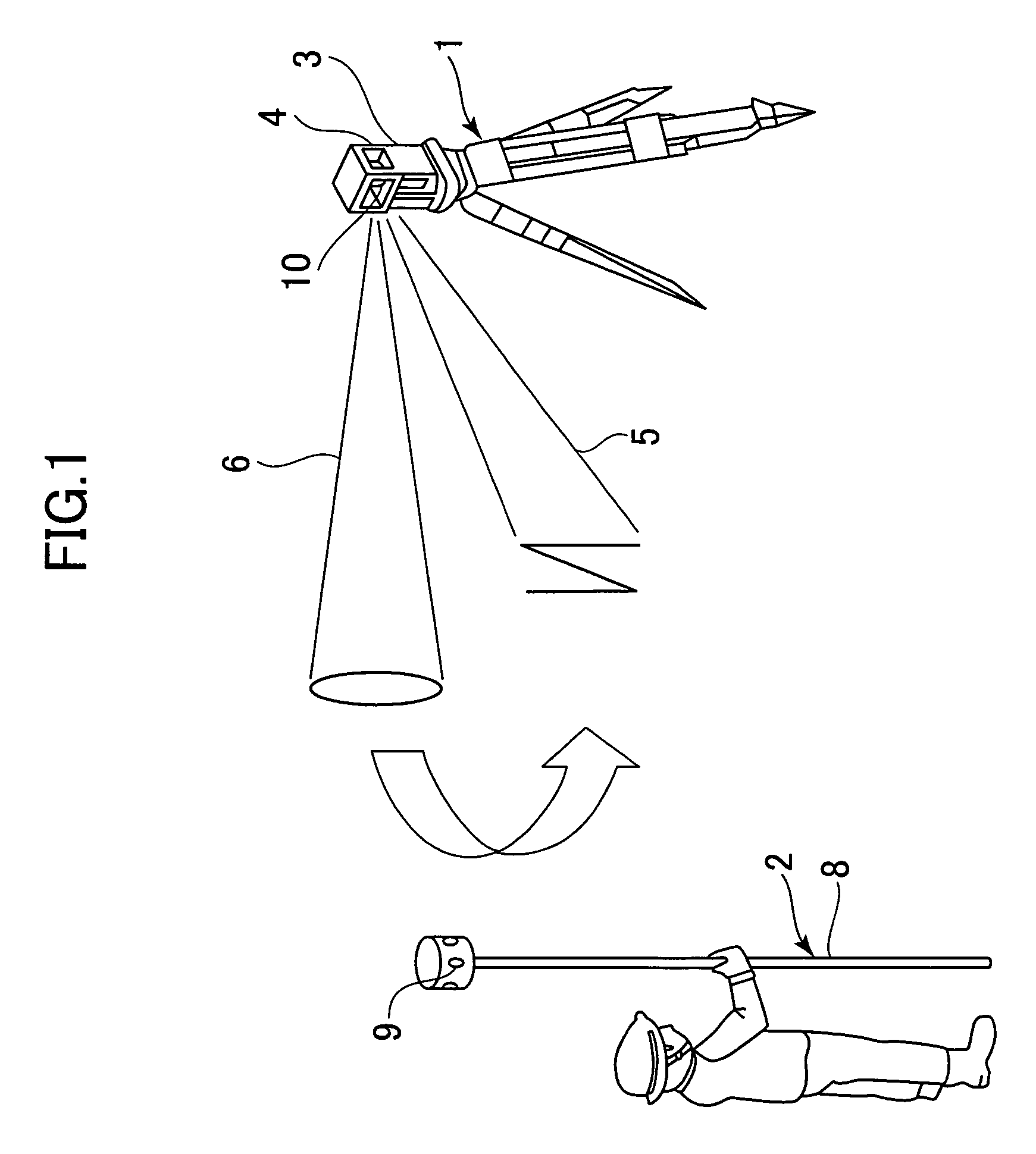

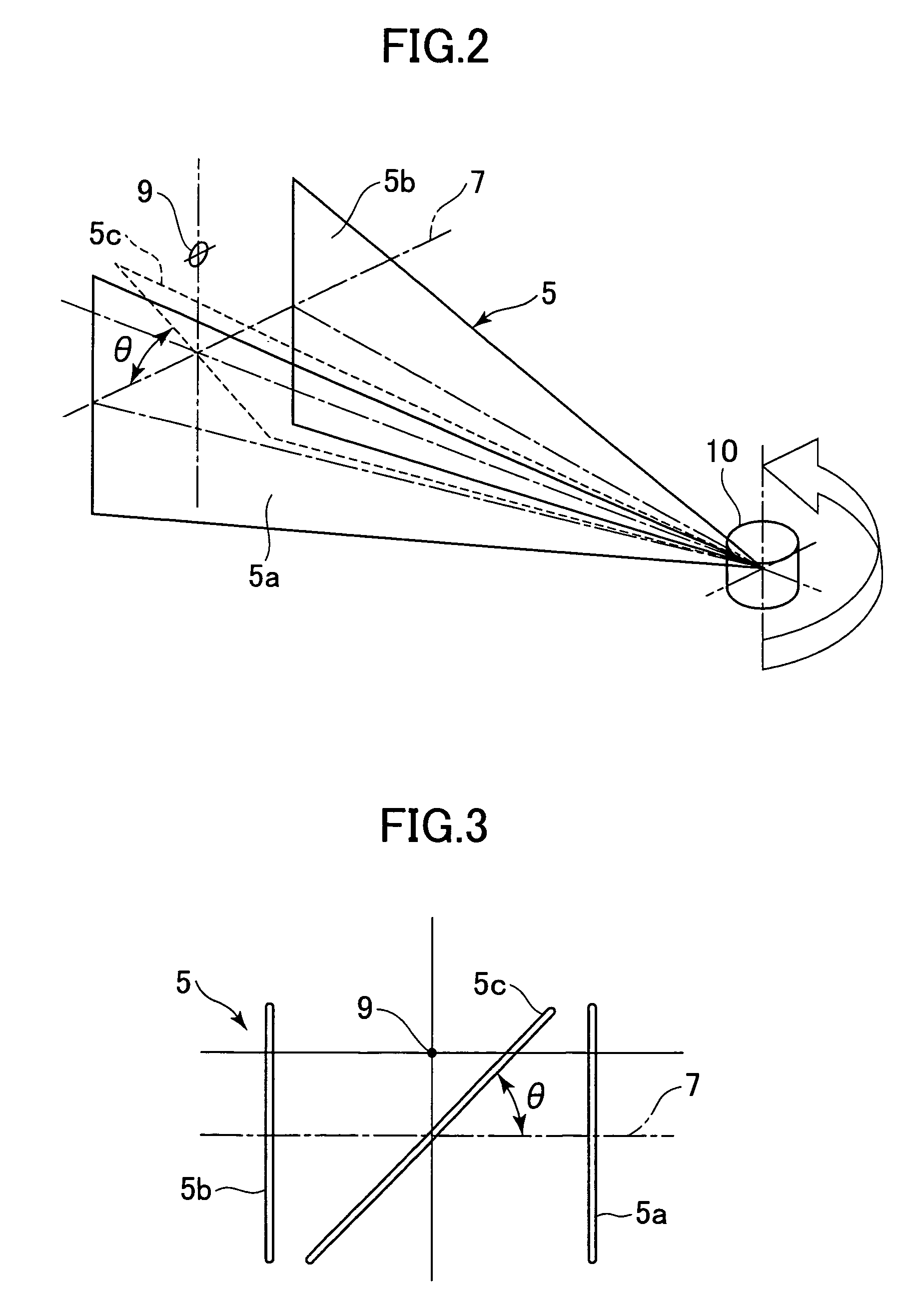

Laser measuring method and laser measuring system

ActiveUS20050211882A1Improve work efficiencyEliminate errorsSurveyor's staffsAngle measurementElevation anglePhotovoltaic detectors

A laser measuring method in a laser measuring system, which comprises a rotary laser system for projecting a laser beam by rotary irradiation and at least one photodetection system having at least one photodetector for receiving the laser beam, comprising a step of emitting at least two fan-shaped laser beams by the rotary laser system, at least one of the fan-shaped laser beams being tilted, a step of receiving the laser beams at least at three known points by the photodetection system, a step of obtaining elevation angles with respect to the rotary laser system based on photodetection signals which are formed when the photodetector receives the laser beam, and a step of measuring an installing position of the rotary laser system based on elevation angles and position data at the three known points.

Owner:KK TOPCON

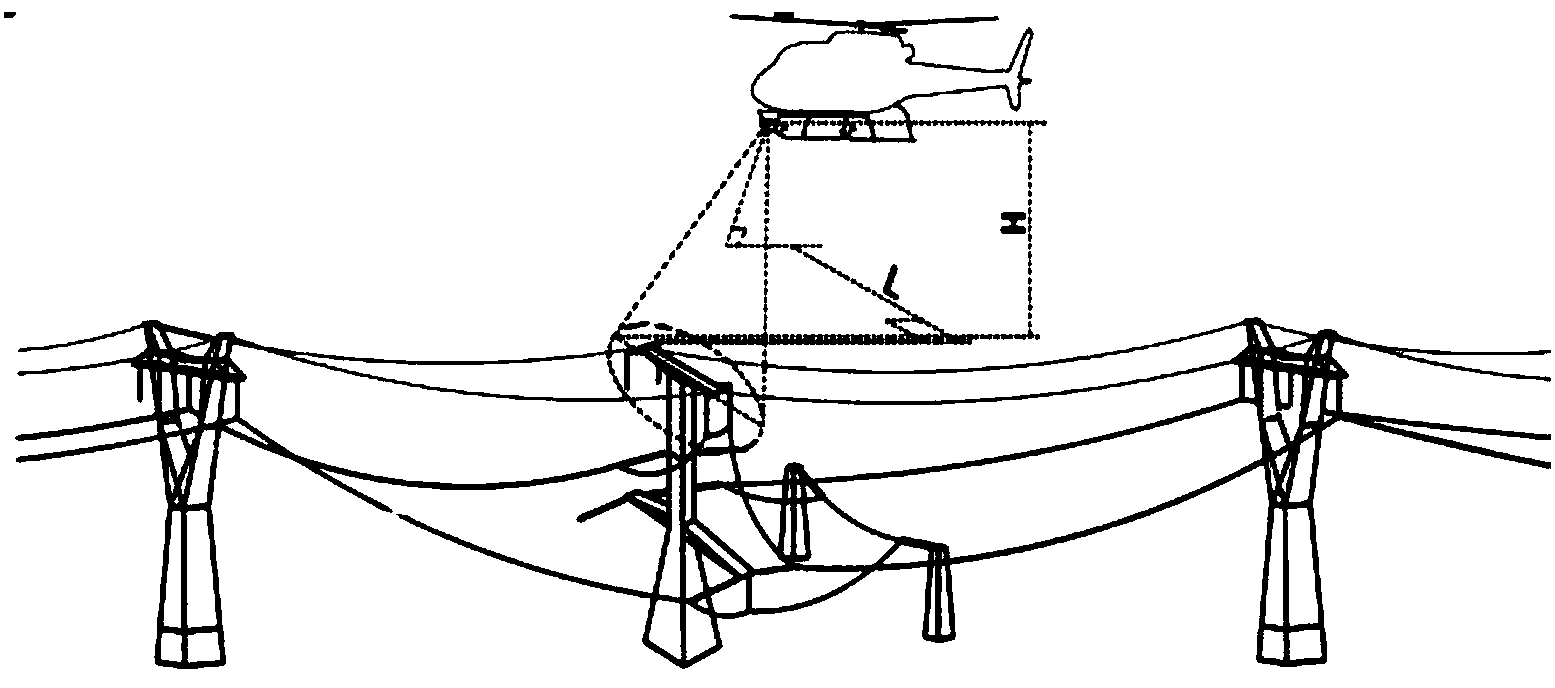

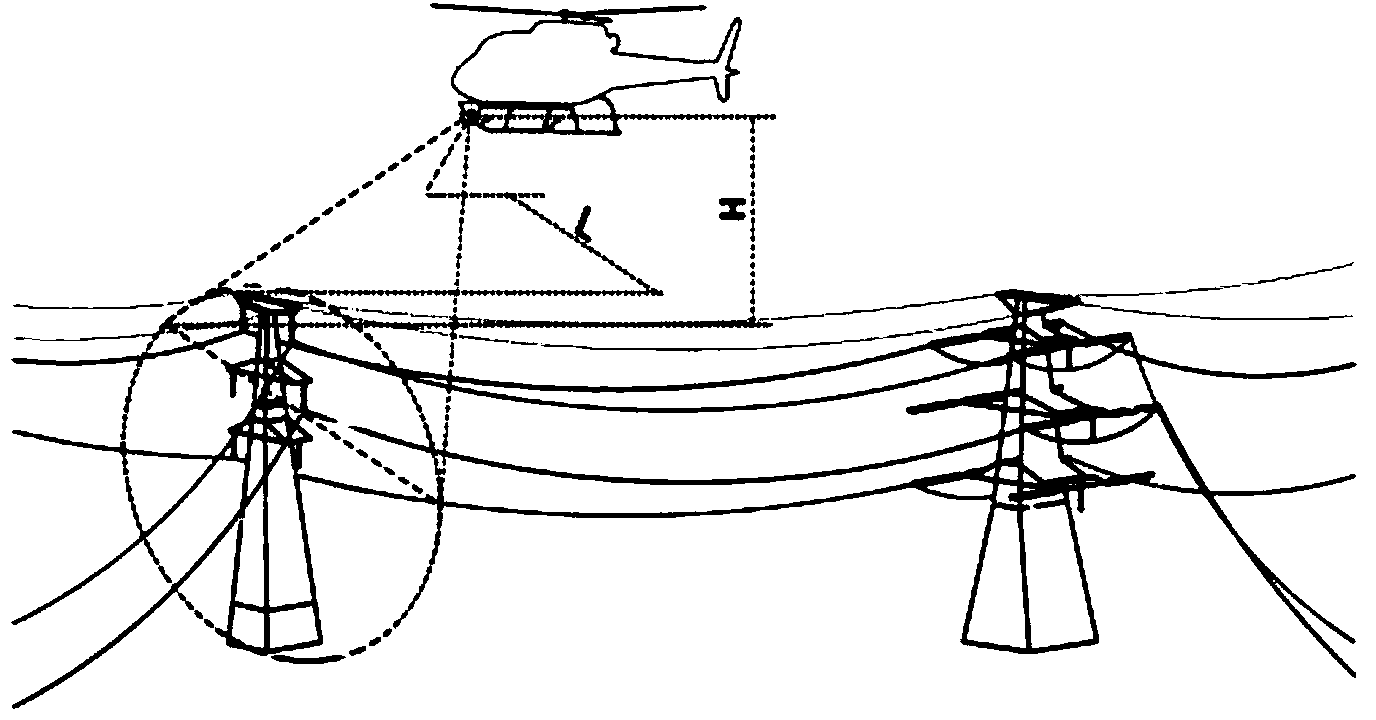

Airborne photoelectric measurement apparatus of dimensions and spacing of electric transmission line and target, and method thereof

InactiveCN103353297AReduce labor intensityQuality improvementOptical rangefindersMeasurement deviceEngineering

The invention relates to an airborne photoelectric measurement apparatus of the dimensions and the spacing of an electric transmission line and a target, and a method thereof, and belongs to the electrical line detection field. The apparatus comprises an unmanned plane, a photoelectric stabilized gondola and a ground system; and the photoelectric stabilized gondola is connected to the unmanned plane, and the ground system controls the unmanned plane and the photoelectric stabilized gondola through radio communication. The method comprises the steps of flight on a line, adjustment motion, measurement, acquisition and transmission. The apparatus has the advantages of flexible motion, simple operation and economy, and the exploitation of the airborne photoelectric automatic measurement apparatus of the remote target dimension and the spacing of the electric transmission line and the target through the combination of the photoelectric stabilized gondola and the design of a laser measurement system in the gondola greatly reduces the line inspection labor intensity of a worker, reduces the running and maintenance costs of electric transmission, improves the inspection work quality and the technological level of scientific management, enhances the electric production automation comprehensive capability, creates high economic and social benefits, and is of great significance.

Owner:CHANGCHUN UNIV OF SCI & TECH +3

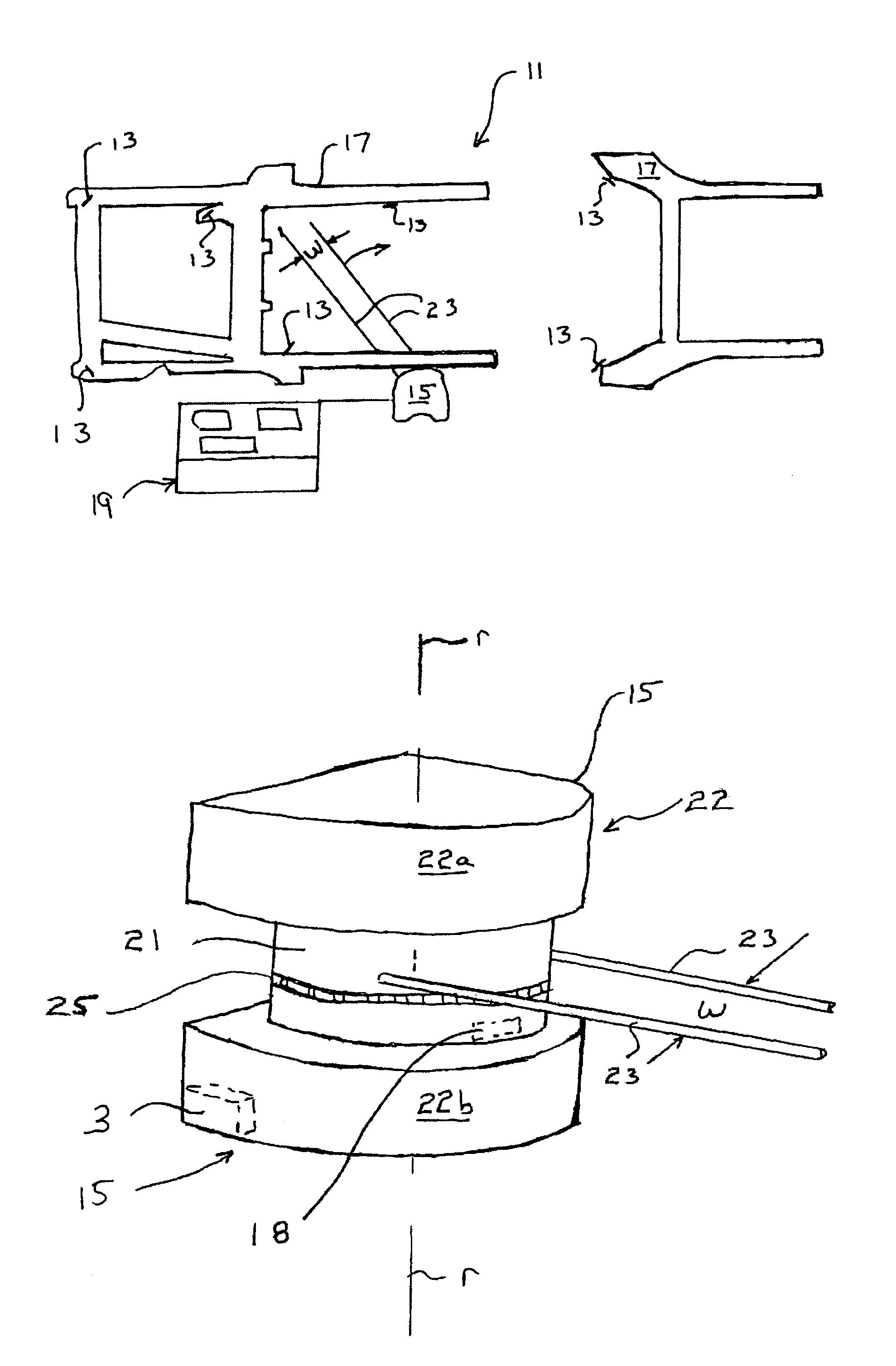

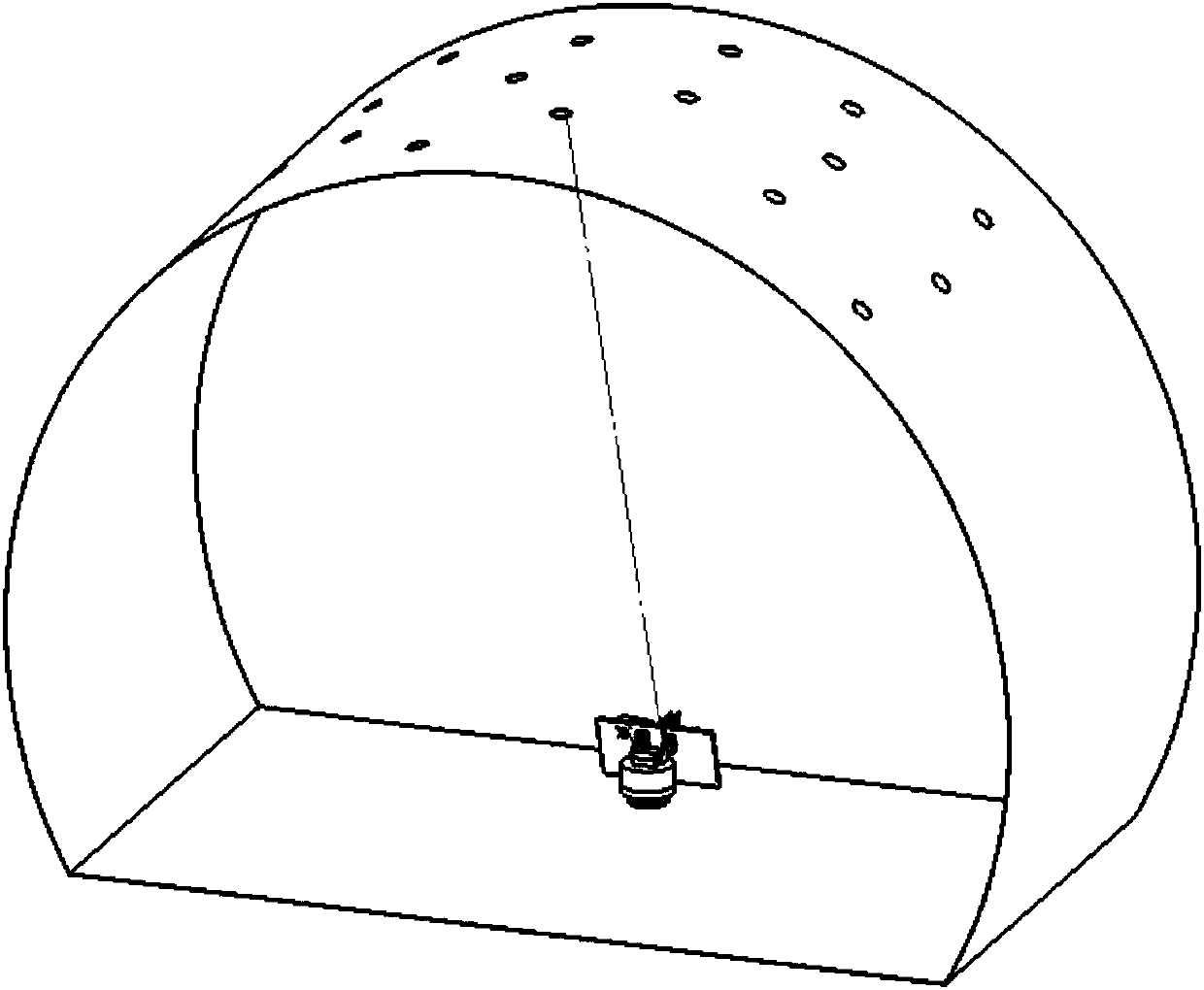

Rotating laser measurement system

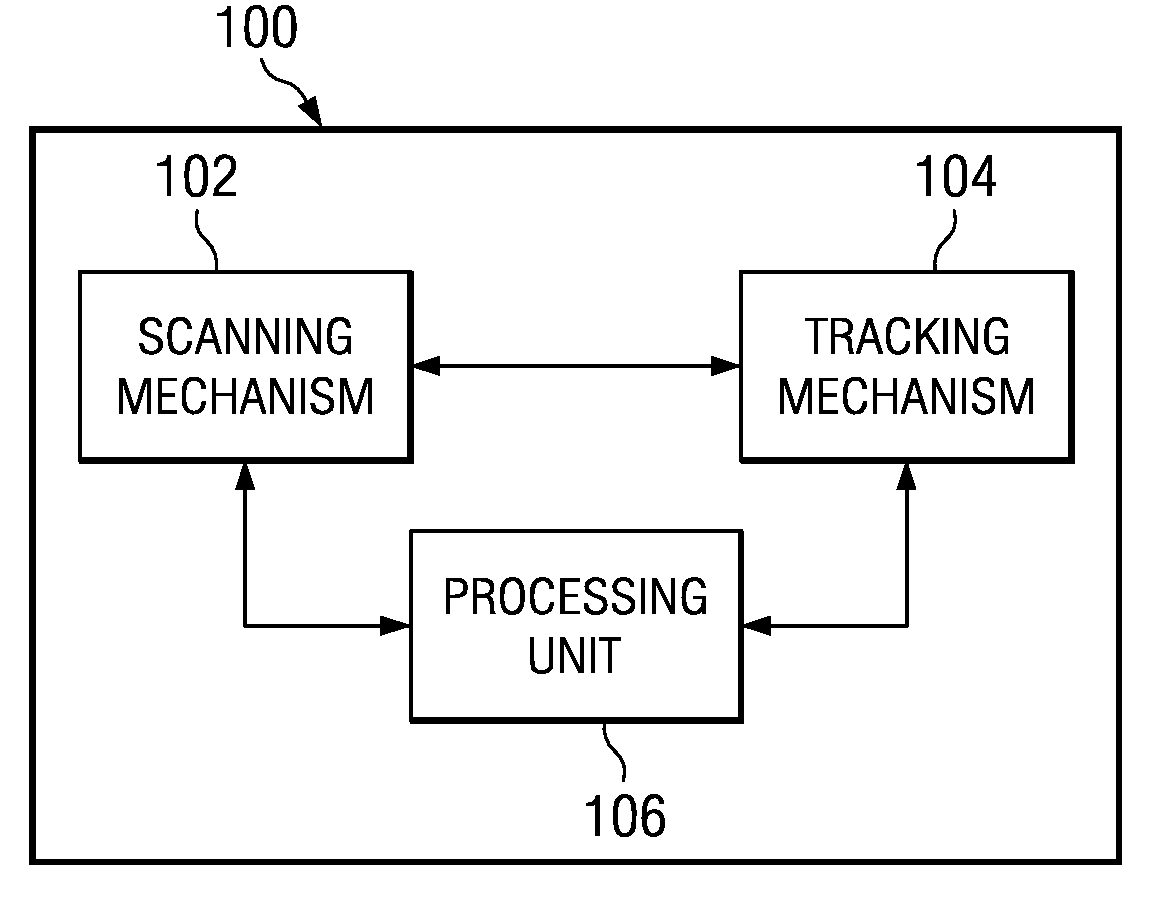

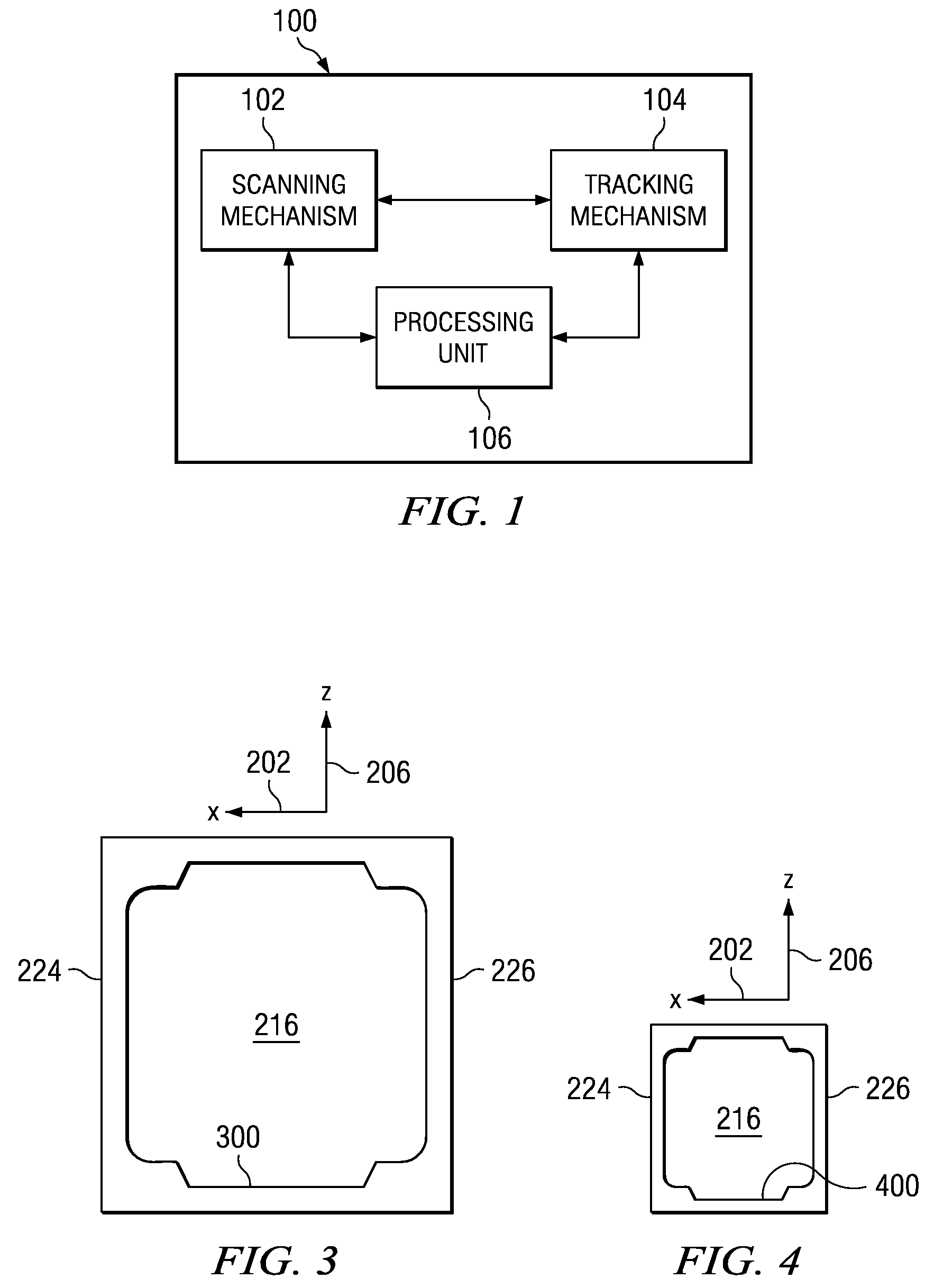

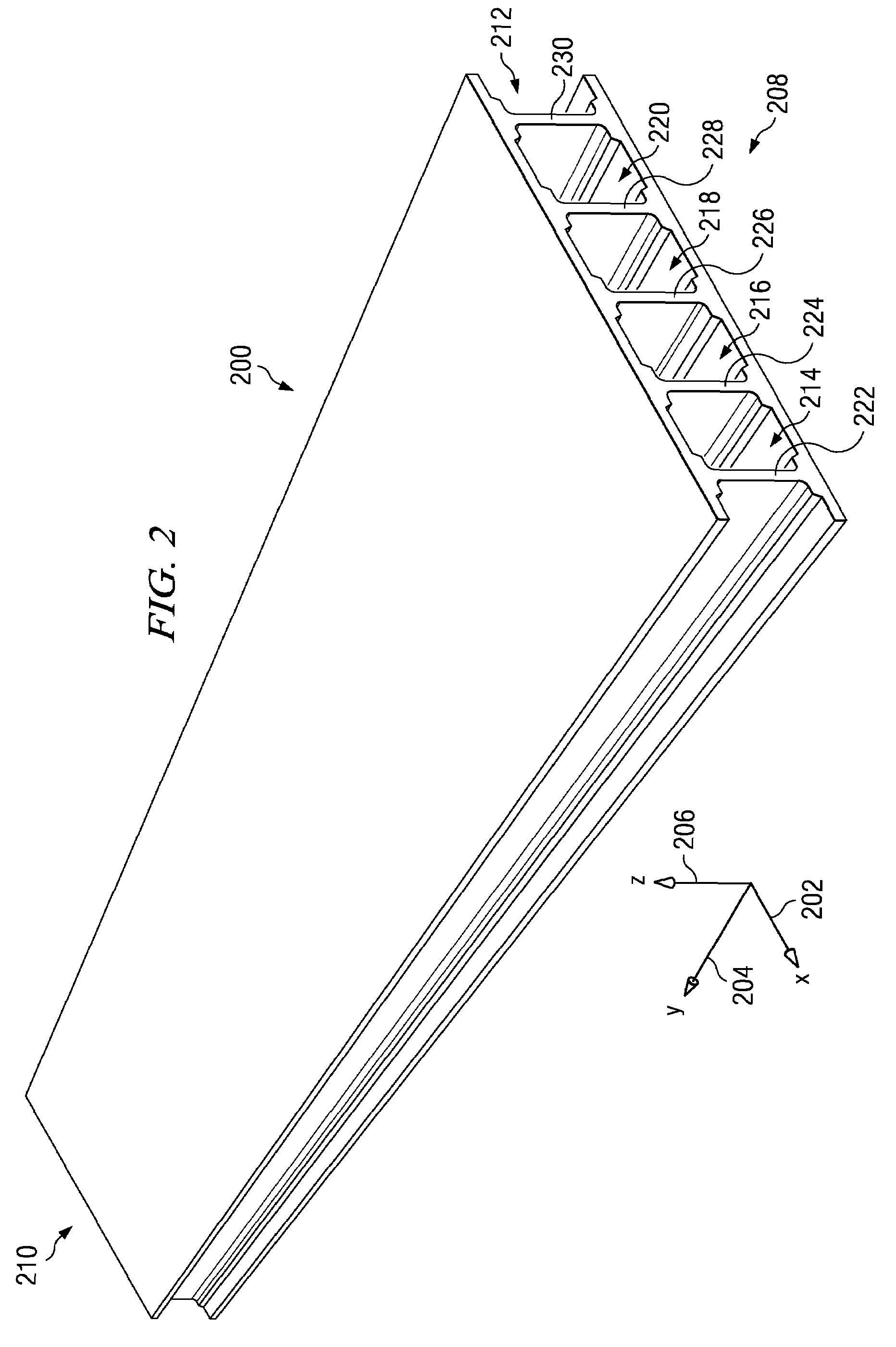

An apparatus including a scanning mechanism, a tracking mechanism, and a processing unit. The scanning mechanism includes a rotating mechanism, a mounting arm rotatably attached to the rotating mechanism, and a light source connected to the mounting arm. The scanning mechanism also includes a mirror connected to the mounting arm, wherein the mirror is positioned to reflect the coherent light. The scanning mechanism also includes a measuring system attached to the mounting arm. The measuring system measures a parameter associated with an object on which the coherent light falls. The tracking mechanism is in communication with the scanning mechanism. The tracking mechanism measures a distance from the tracking mechanism to the scanning mechanism. The processing unit is in communication with the scanning mechanism and the tracking mechanism. The processing unit collects measurement information from the scanning mechanism and the tracking mechanism.

Owner:THE BOEING CO

Laser measuring method and laser measuring system having fan-shaped tilted laser beams and three known points of photodetection system

ActiveUS7196302B2Convenience to workEliminate errorsAngle measurementSurveyor's staffsElevation anglePhotovoltaic detectors

A laser measuring method in a laser measuring system, which comprises a rotary laser system for projecting a laser beam by rotary irradiation and at least one photodetection system having at least one photodetector for receiving the laser beam, comprising a step of emitting at least two fan-shaped laser beams by the rotary laser system, at least one of the fan-shaped laser beams being tilted, a step of receiving the laser beams at least at three known points by the photodetection system, a step of obtaining elevation angles with respect to the rotary laser system based on photodetection signals which are formed when the photodetector receives the laser beam, and a step of measuring an installing position of the rotary laser system based on elevation angles and position data at the three known points.

Owner:KK TOPCON

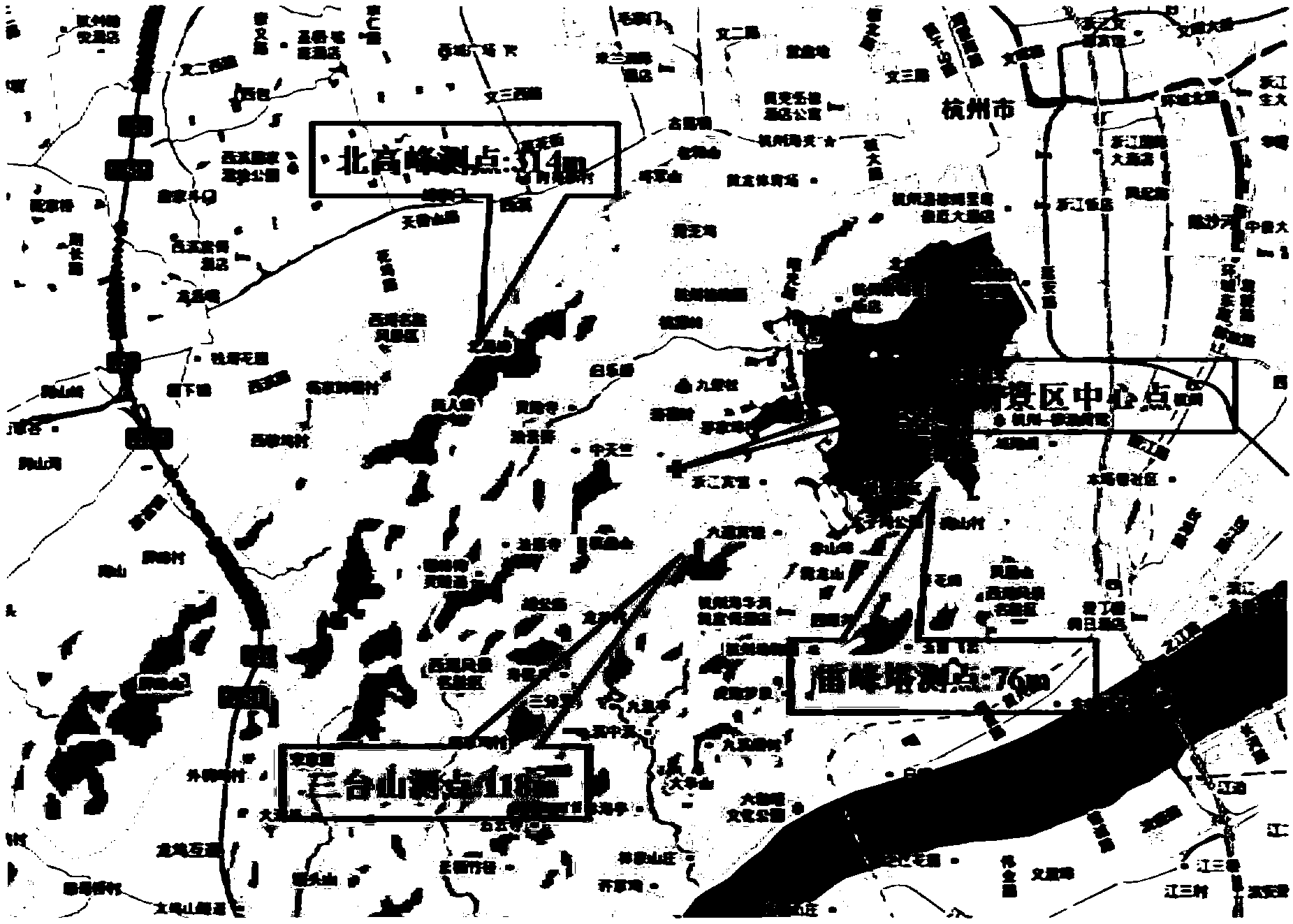

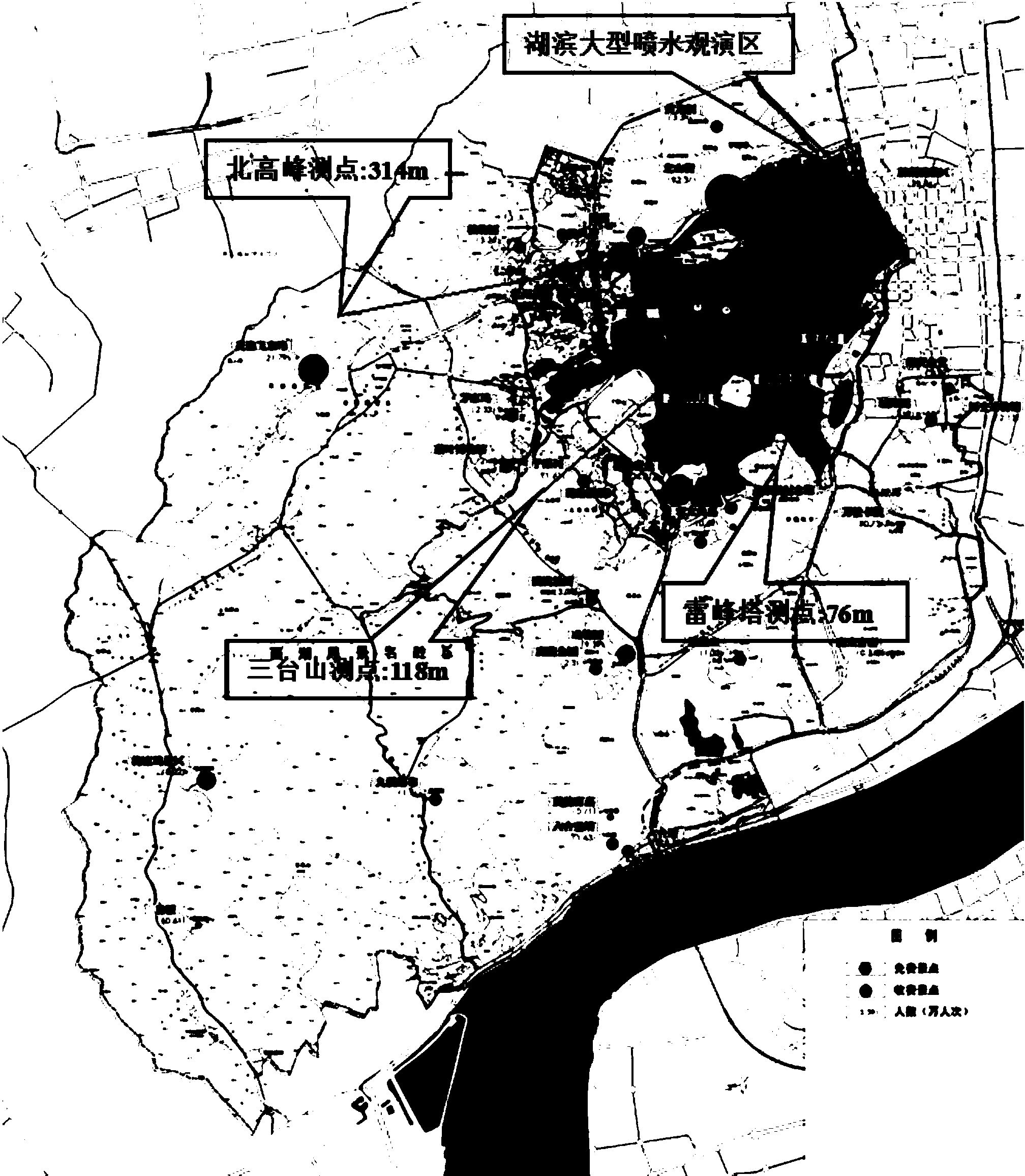

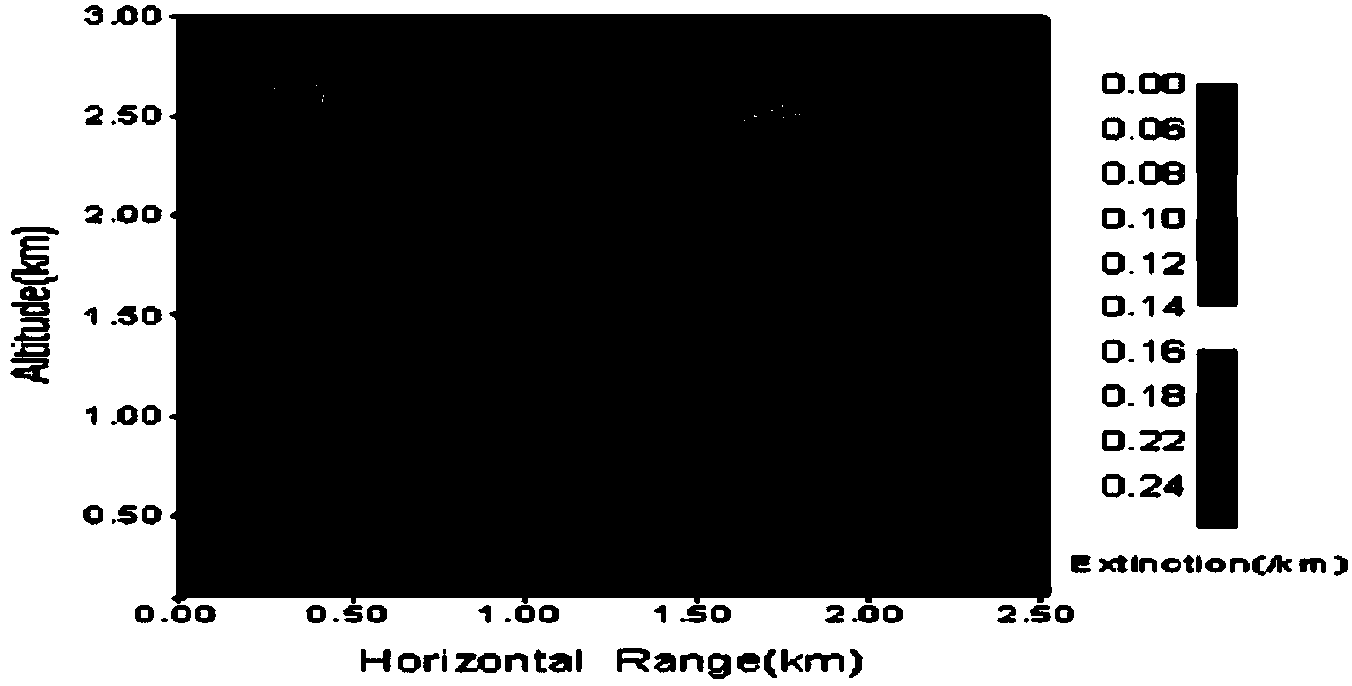

Scenic area road traffic pollution early-warning device based on remote sensing technique and scenic area road traffic pollution early-warning method based on remote sensing technique

InactiveCN104297117AAdjustable wavelengthStable and reliable output wavelengthParticle suspension analysisGeographic featureEngineering

The invention discloses a scenic area road traffic pollution early-warning device based on a remote sensing technique. Atmospheric laser measurement systems are arranged at measuring points of three to five commanding heights, and all of the atmospheric laser measurement systems are connected to a server; a monitoring result device which is used for detecting the concentration of pollutants of a scenic area road traffic environment air roadside fixed routine monitoring station is connected to the server; a monitoring device of a scenic area combined environment air fixed routine monitoring station is connected to the server; in consideration of various advantages and disadvantages of a current area environment monitoring platform, according to the geographic feature of 'on three sides are cloud-capped hills, on one the busy town' of a West Lake scenic area, NO2 and other chemical substances which are mainly generated by road traffic in the scenic area are monitored in real time by constructing an atmospheric remote sensing and remote measuring platform at the commanding heights around the West Lake.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

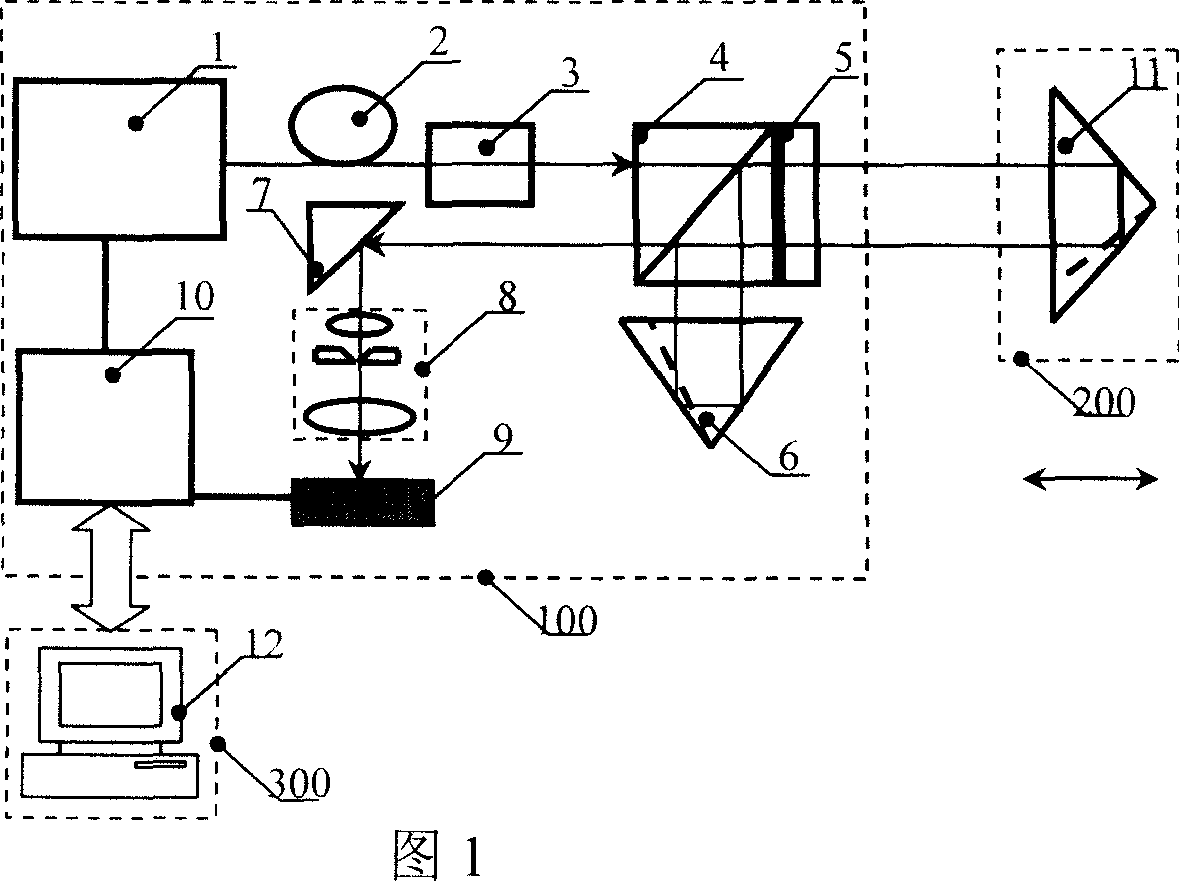

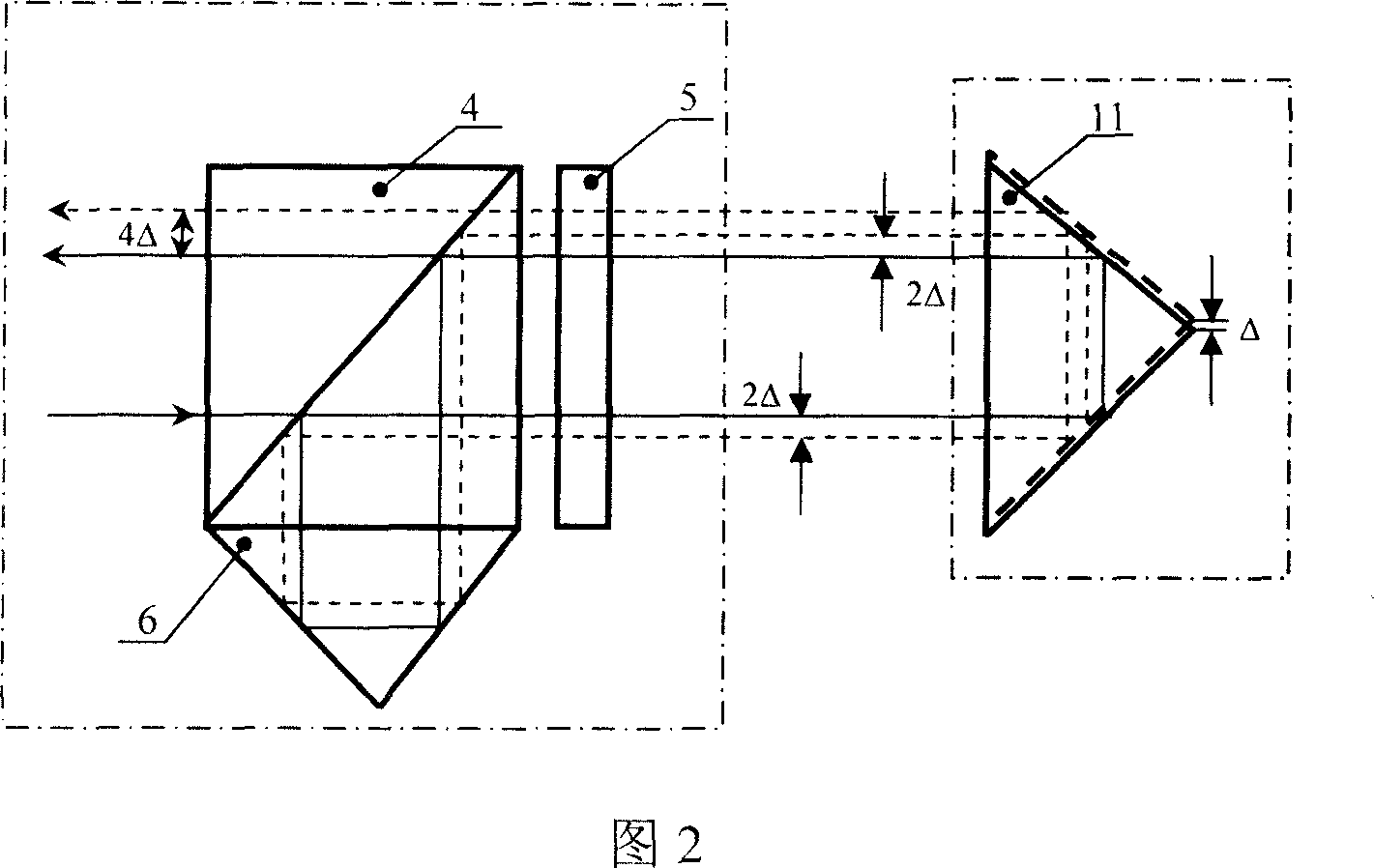

Method and device for improving straight line degree measurement sensitivity

InactiveCN1920478AHigh measurement sensitivityHigh sensitivityUsing optical meansLaser transmitterOpto electronic

The invention relates to a method for improving the sensitivity of linearity test, and a relative device, wherein it is a laser testing system formed by fixed unit, movable unit and computer; it comprises laser emitter, deviation splitter, lambada / 4 wave plate, reflector, photoelectric receiver and signal processor. The optical element sets the testing light to pass the movable target mirror several times, to magnify its testing sensitivity several times; and it sets lens group before the detector, to magnify the sensitivity more. The invention can test two-dimension linearity of straight track real time.

Owner:BEIJING JIAOTONG UNIV

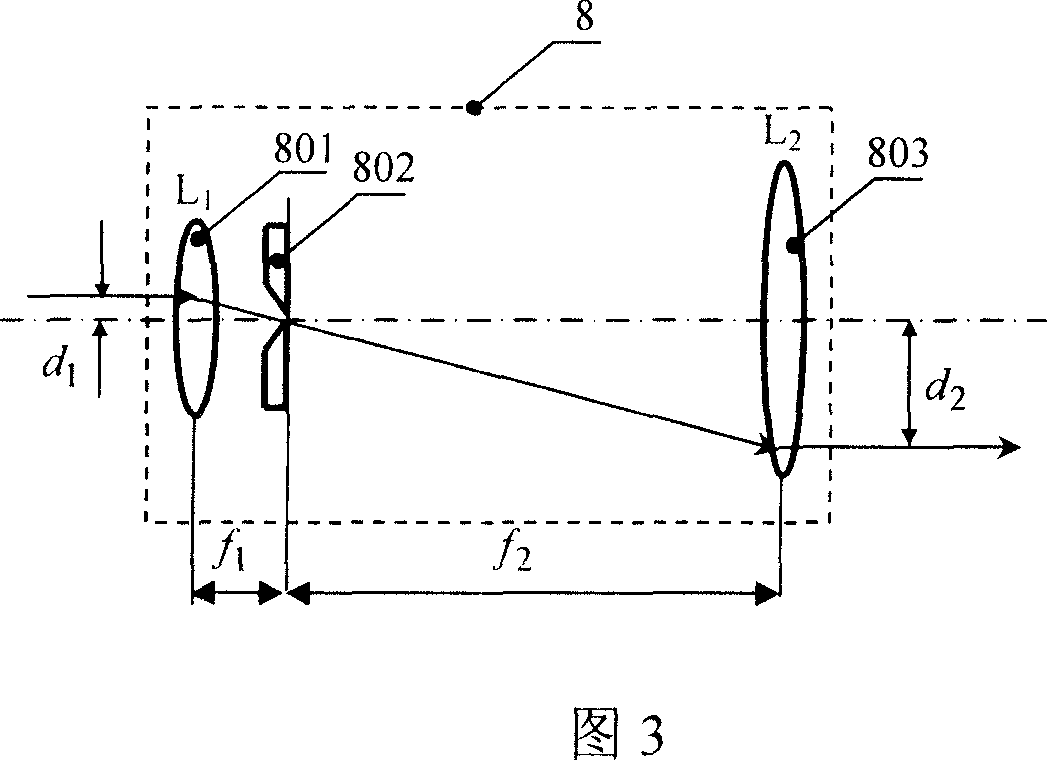

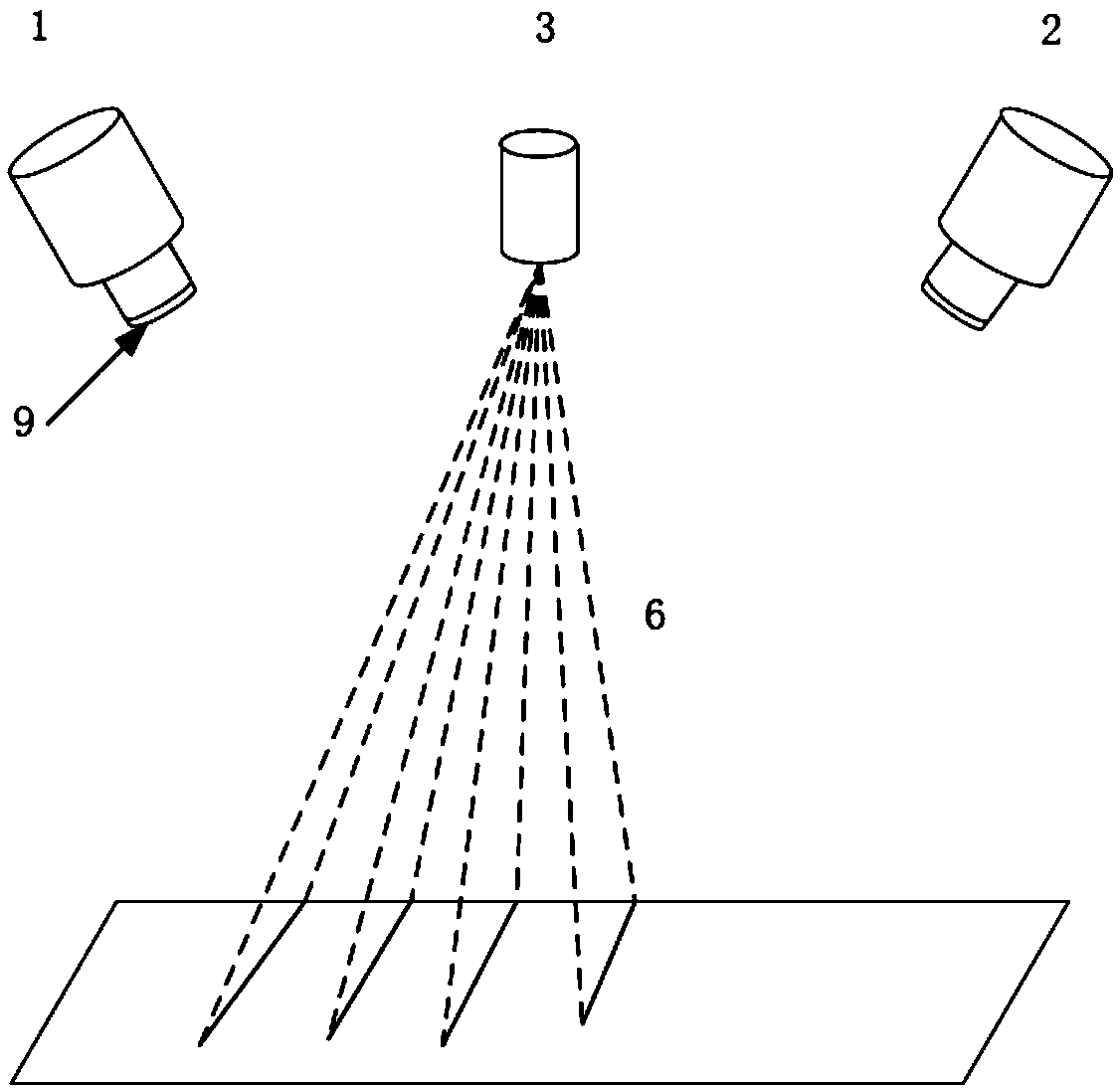

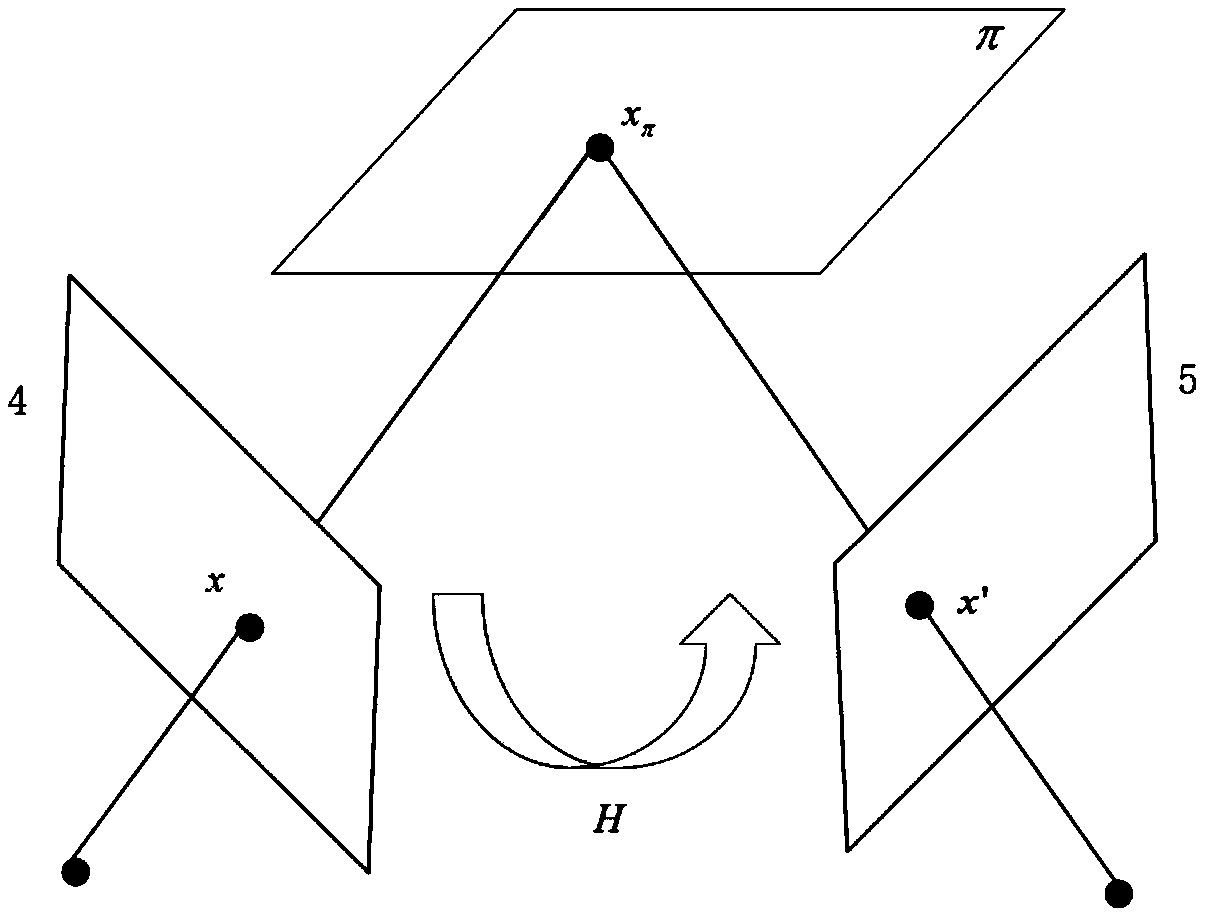

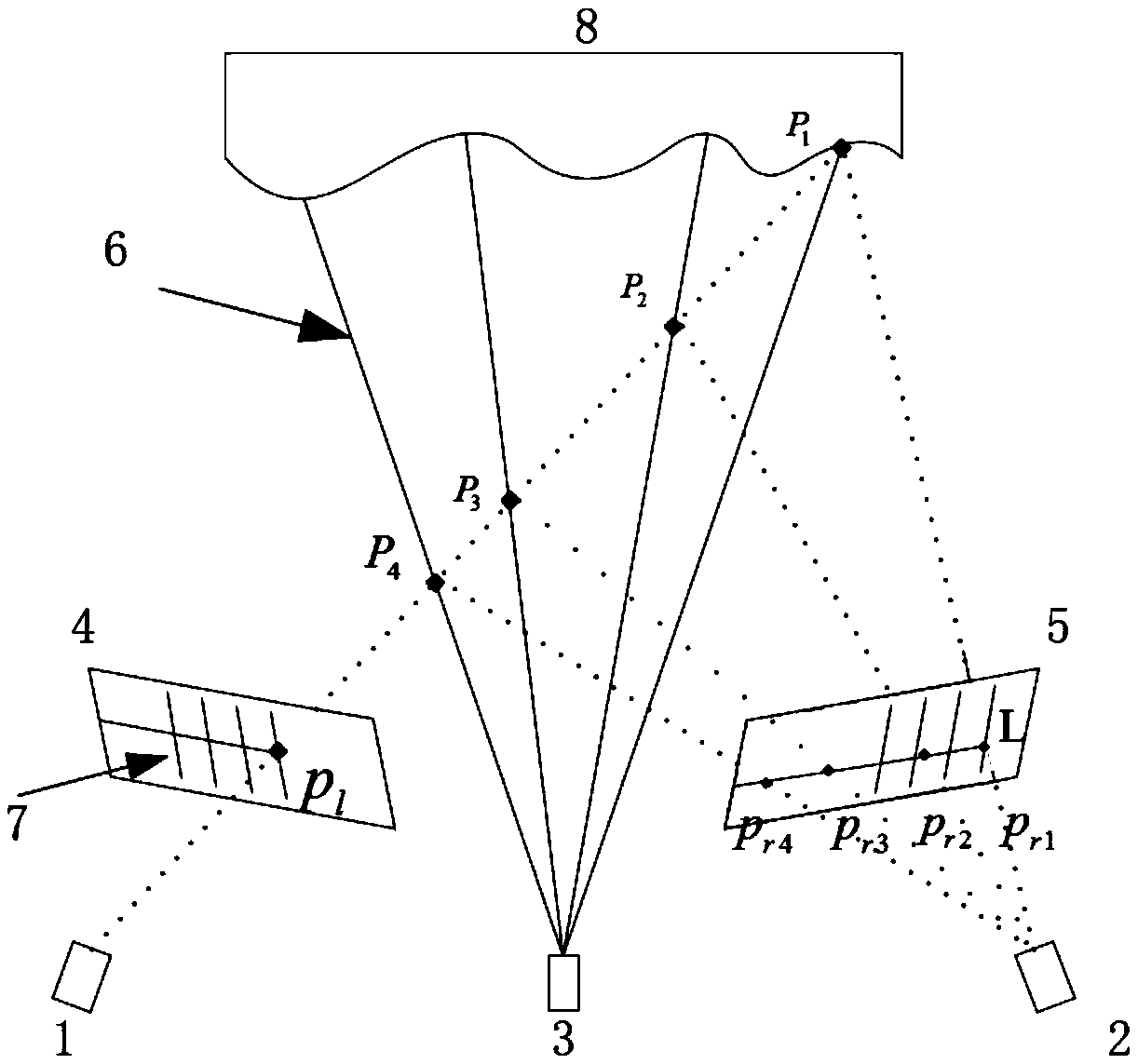

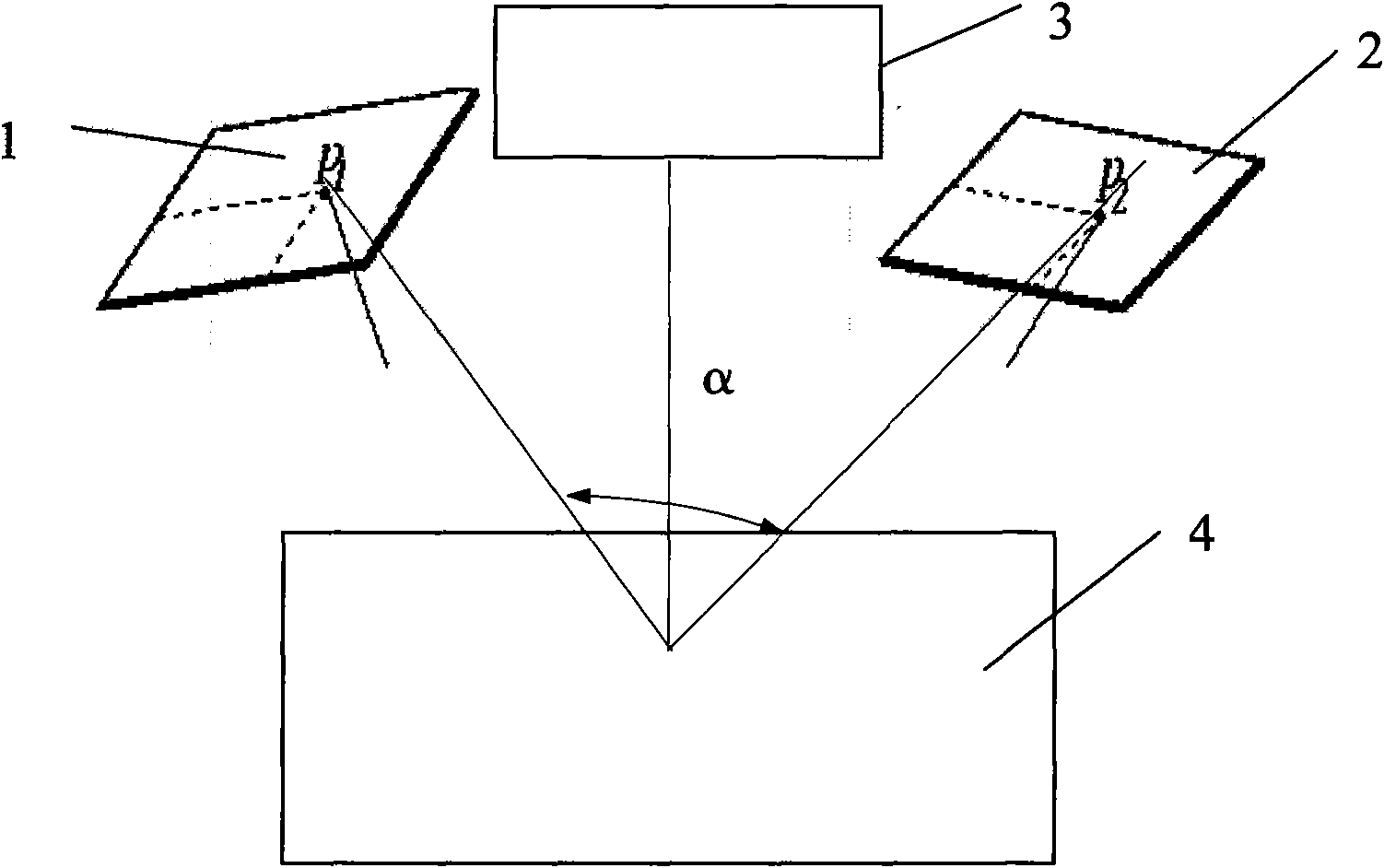

System and method for measuring parallel multi-line laser based on homography matrix

The invention provides a system and method for measuring parallel multi-line lasers based on a homography matrix. The method mainly comprises the following steps of: calibrating a camera system through a planar target to obtain internal and external parameters of the camera; calibrating the laser measuring system through a stereoscopic target, and inducing the homography relation between the leftand the right image planes of a binocular camera through the laser plane to obtain the calibration parameters of the laser system due to the relatively fixed characteristics of the laser plane and theplane positions of the left and the right cameras; mapping the laser lines to be matched of the left image to the right image to obtain a plurality of mapped laser lines through the calibration parameters of the laser measuring system; by calculating the coincidence degree of the mapped laser lines, taking a mapped laser line corresponding to the maximum coincidence degree as a laser line corresponding to the laser line to be matched so as to realize the correct matching of the laser lines in the left and the right images; and according to the correctly matched laser lines, reconstructing thethree-dimensional data of the laser lines to obtain the three-dimensional information of an object surface through the principle of the binocular stereovision measurement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

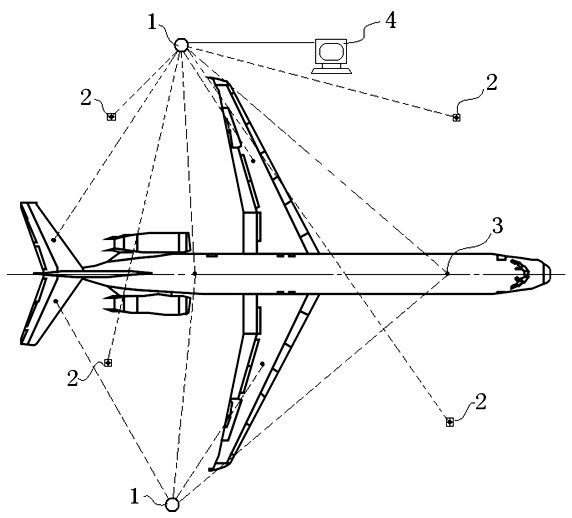

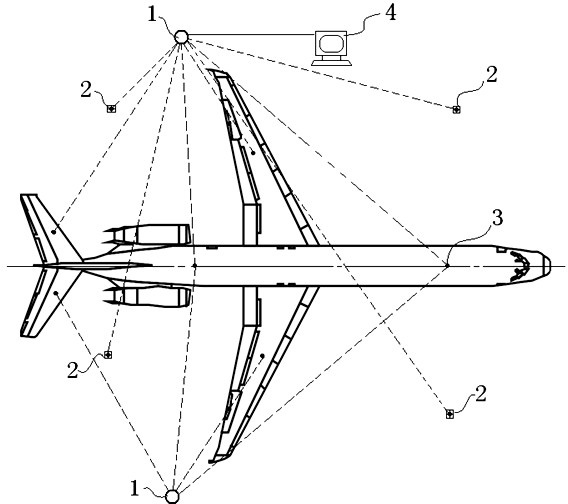

Horizontal laser measurement system and method for airplane

InactiveCN102519430ASave human effortImprove work efficiencyIncline measurementEngineeringLaser tracker

The invention discloses a horizontal laser measurement system and a method for an airplane. The horizontal laser measurement system is composed of a laser locating device, a horizontal reference coordinate point and a horizontal measurement point. The horizontal laser measurement system is characterized in that: at least four horizontal reference coordinate points are arranged around the airplane; the laser locating device is arranged at one side of the airplane; a plurality of horizontal measuring points are arranged on the airplane; and the laser locating device is connected with a computer. In a measuring process, the value of each measuring point is produced by a laser tracker according to the laser reflection principle, so that the measurement error caused by manual operation is reduced, and the measurement value is more accurate.

Owner:JIANGXI HONGDU AVIATION IND GRP

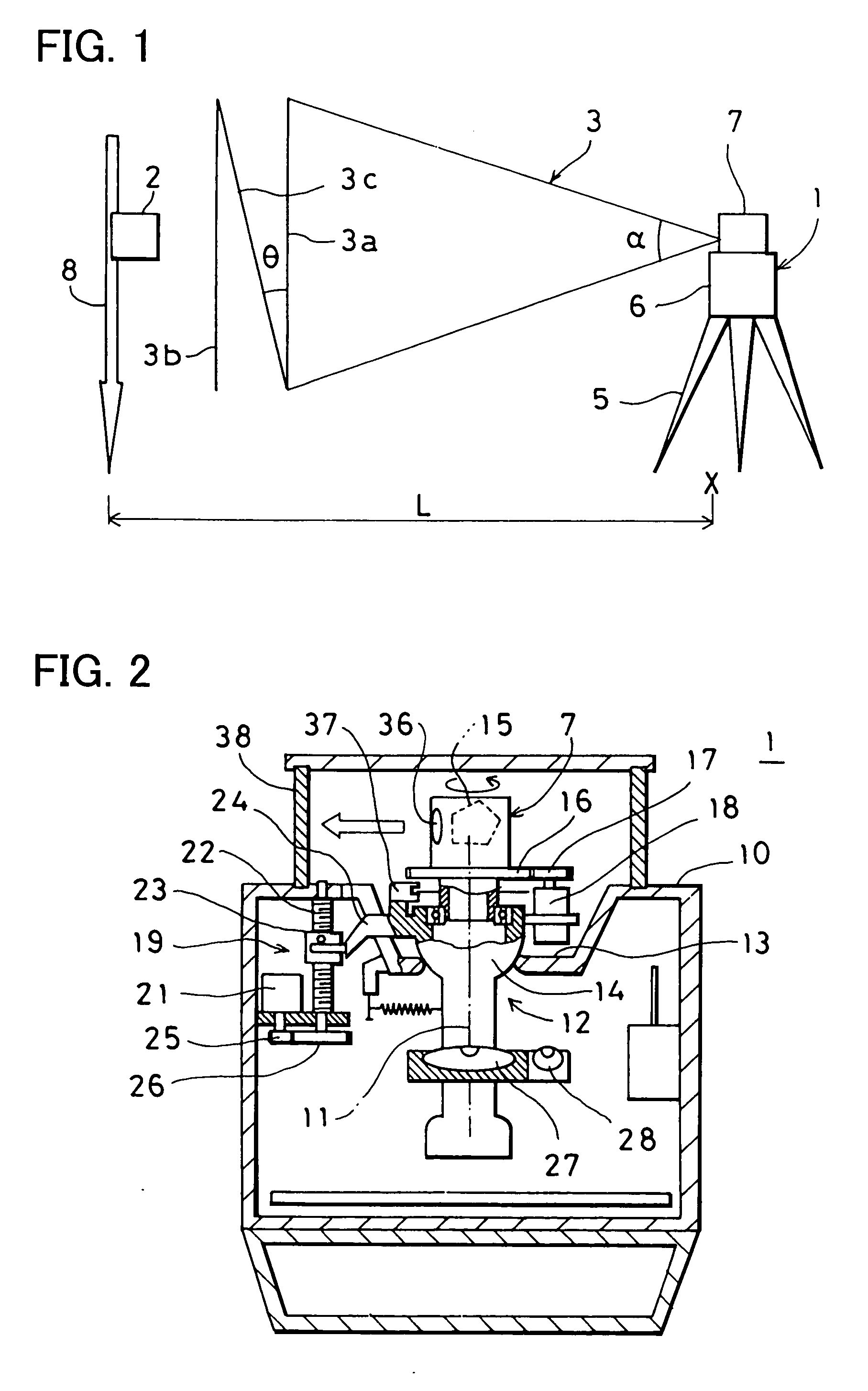

Laser surveying system

A rotary laser projecting device comprising a reference plane forming unit that projects two or more fan-shaped laser beams, a distance measuring unit that projects distance measuring light, a rotator for projecting the fan-shaped laser beams and the distance measuring light by rotary irradiation, a horizontal angle detecting unit, a photodetection unit for receiving the reflected fan-shaped laser beams and the reflected distance measuring light, a storage unit, and a control arithmetic unit is disclosed. The control arithmetic unit measures elevation angle of the object reflector from time difference of photodetection between the two or more laser beams, measures horizontal angle of the object based on the result of detection of the horizontal angle detecting unit when at least one of the reflected fan-shaped laser beams and the reflected distance measuring light is received and the distance measuring unit measures a distance to the object to be measured.

Owner:KK TOPCON

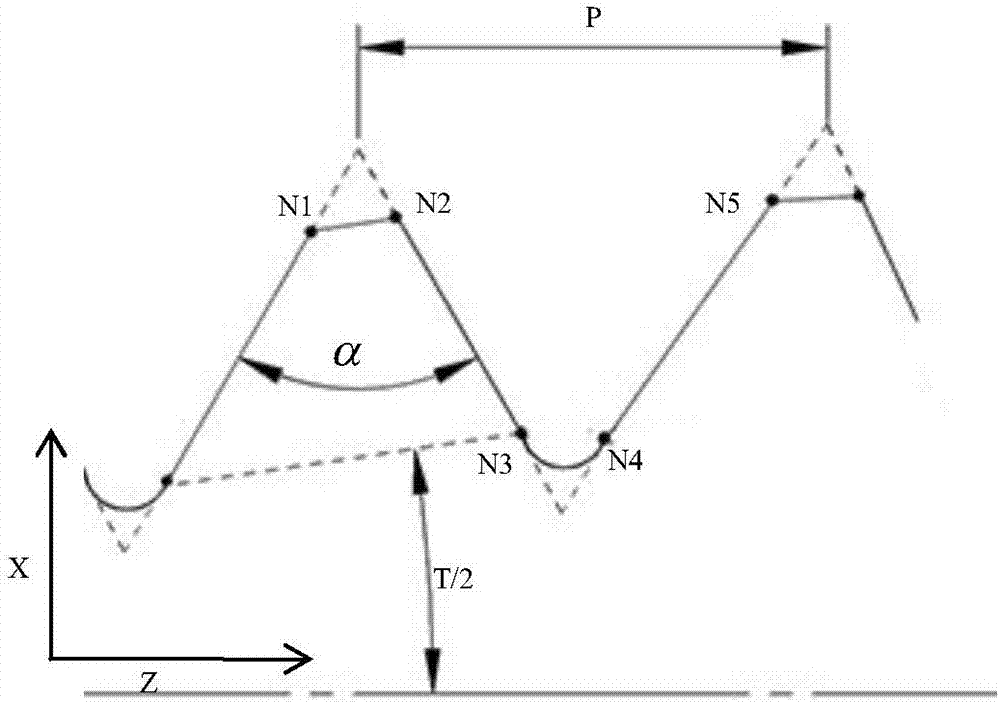

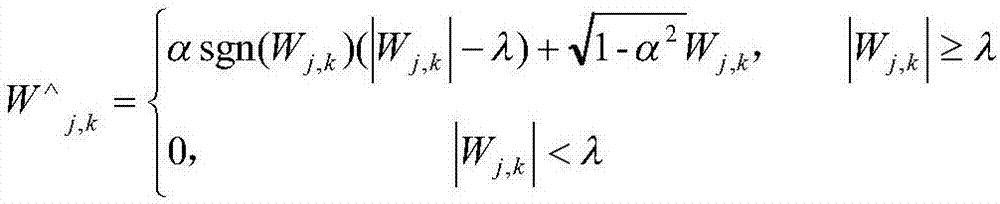

Laser measurement system-based taper thread data processing algorithm

ActiveCN107092775AImprove detection efficiencyEasy to handleUsing optical meansInformaticsResearch ObjectPoint cloud

The invention discloses a laser measurement system-based taper thread data processing algorithm. The method comprises the following steps of (1) removing gross errors in thread profile data collected by a displacement sensor through adopting a variable coefficient adaptive Laiyite criterion; (2) removing random noise points in the data subjected to the gross error removal by applying an improved wavelet threshold denoising method; (3) fitting the denoised data by applying a robustified least square method; and (4) performing segmentation according to a fitted profile derivative condition and extracting feature points; finally calculating thread parameters through the extracted feature points. According to the algorithm, a drill pipe thread is taken as a research object; the collected thread profile original point cloud data is subjected to the gross error removal and the denoising in combination with the improved wavelet adaptive threshold algorithm through the adaptive Laiyite criterion; the denoised data is fitted through the robustified least square method; a thread profile curve is obtained, the segmentation is performed according to the fitted profile derivative condition, and the feature points are extracted; and finally the thread parameters are calculated through the extracted feature points. Therefore, efficient and quick data processing after taper thread data collection can be realized and the taper thread detection efficiency is improved.

Owner:SHENYANG POLYTECHNIC UNIV

Rotating laser measurement system

An apparatus including a scanning mechanism, a tracking mechanism, and a processing unit. The scanning mechanism includes a rotating mechanism, a mounting arm rotatably attached to the rotating mechanism, and a light source connected to the mounting arm. The scanning mechanism also includes a mirror connected to the mounting arm, wherein the mirror is positioned to reflect the coherent light. The scanning mechanism also includes a measuring system attached to the mounting arm. The measuring system measures a parameter associated with an object on which the coherent light falls. The tracking mechanism is in communication with the scanning mechanism. The tracking mechanism measures a distance from the tracking mechanism to the scanning mechanism. The processing unit is in communication with the scanning mechanism and the tracking mechanism. The processing unit collects measurement information from the scanning mechanism and the tracking mechanism.

Owner:THE BOEING CO

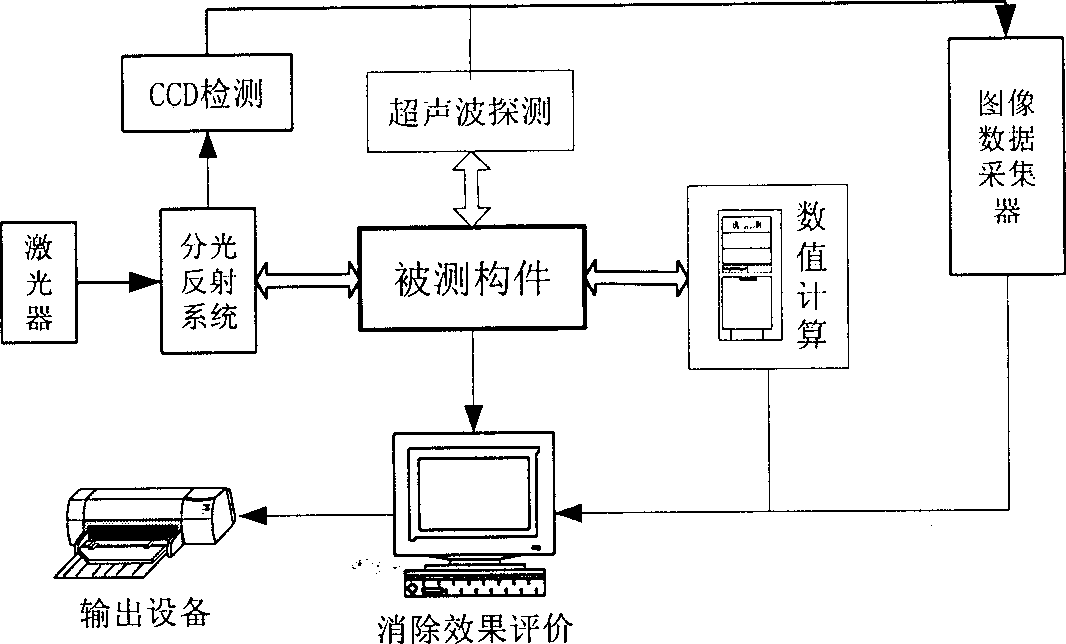

Evaluation system of visible deformation as residual welding stress eliminating effect

The evaluation system includes through paths of ultrasonic measurement of plate thickness change before and after eliminating residual stress, laser measurement of position change of some characteristic point or area in welded product and numerical calculation of residual stress eliminating effect and all the data of the three paths are transmitted to the eliminating effect evaluation. The resultobtained through analysis and calculation in the eliminating effect evaluation part is output via the output equipment to complete the evaluation. The present invention has important significance to evaluate the welded product and raise the reliability of important welded structure. Furthermore, it has some reference and application value to similar material and structure.

Owner:XI AN JIAOTONG UNIV

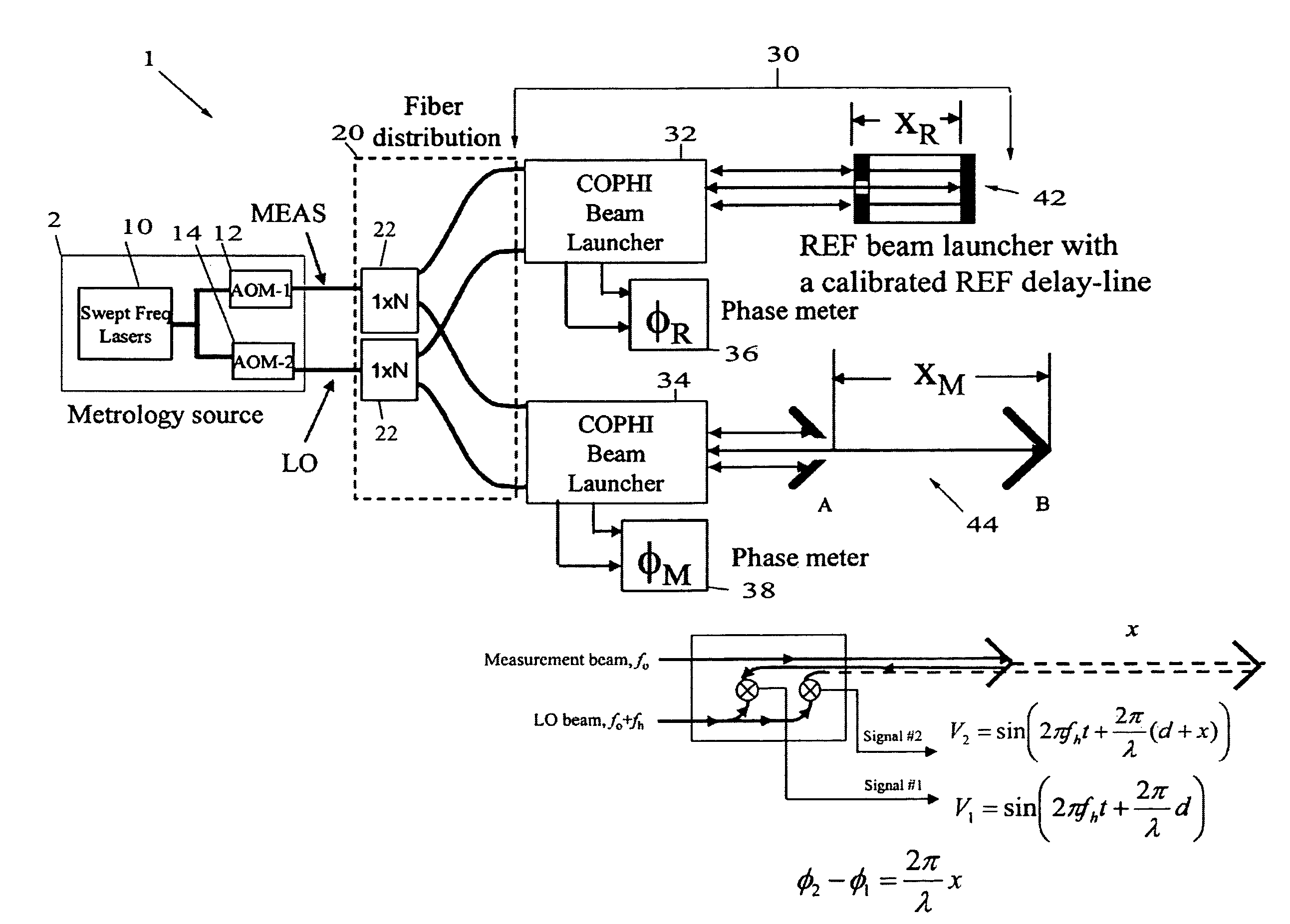

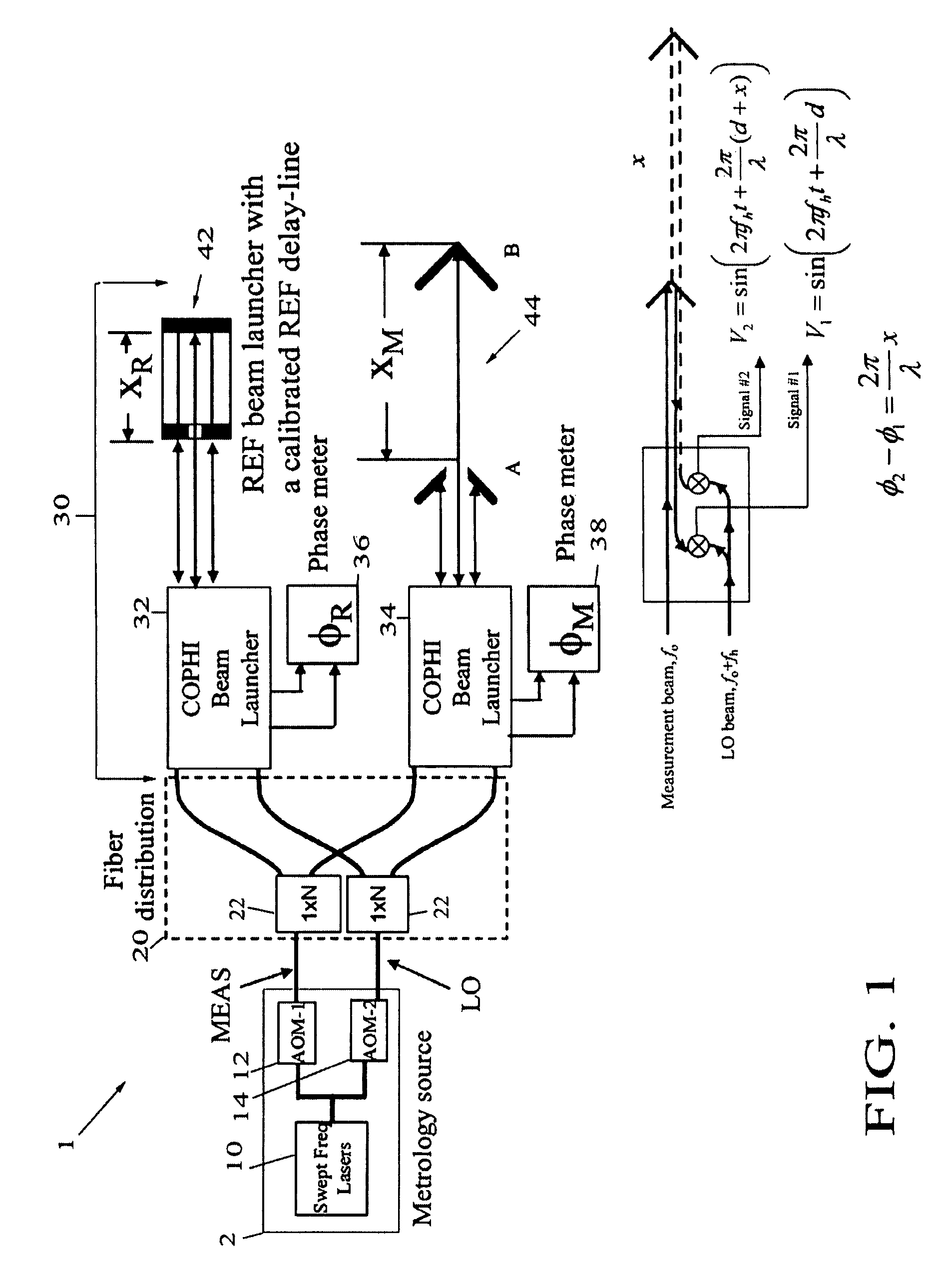

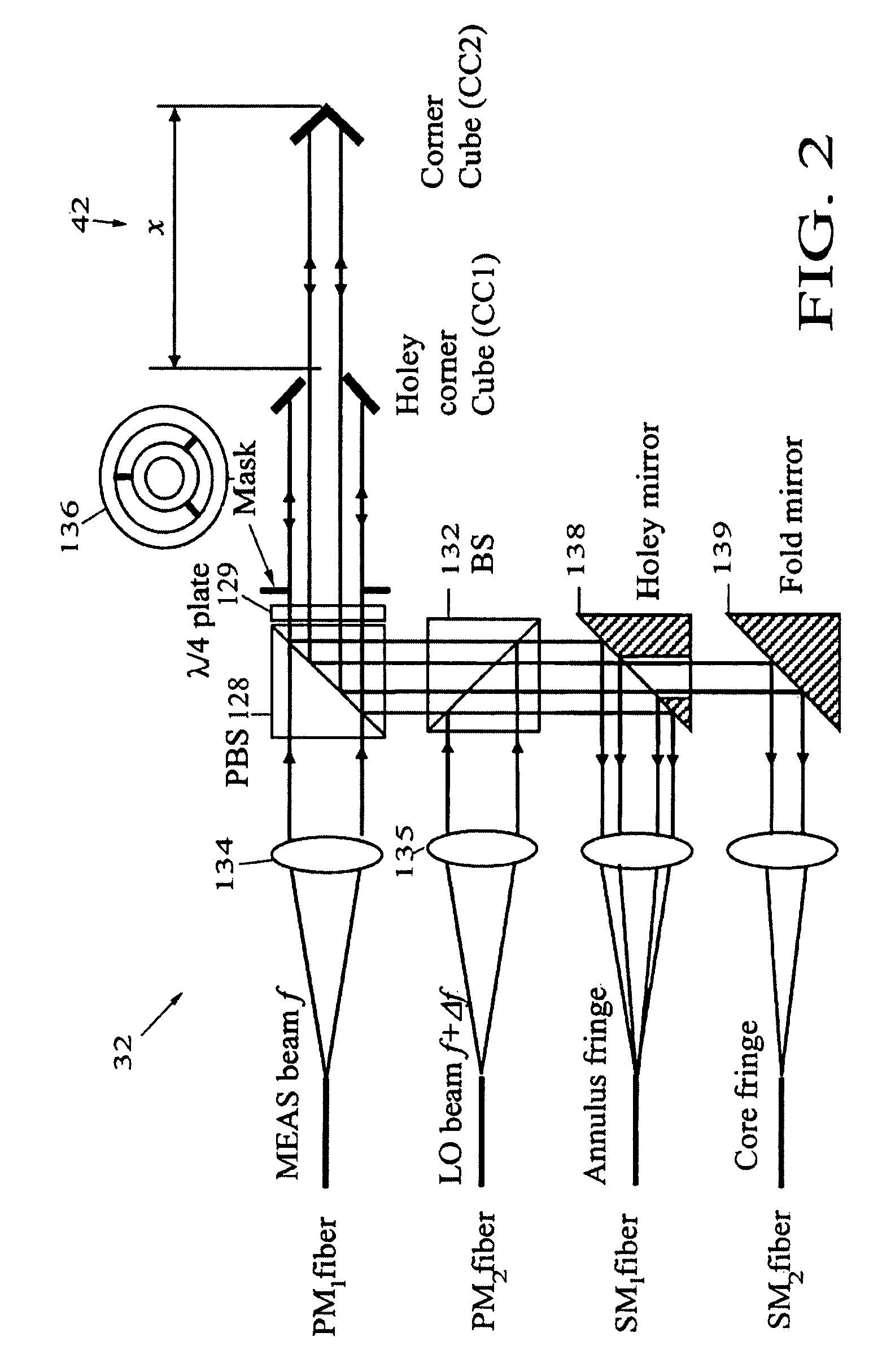

Swept frequency laser metrology system

InactiveUS7764384B1Improve immunitySimplify the metrology systemUsing optical meansLaser rangingMetrology

A swept frequency laser ranging system having sub-micron accuracy that employs multiple common-path heterodyne interferometers, one coupled to a calibrated delay-line for use as an absolute reference for the ranging system. An exemplary embodiment uses two laser heterodyne interferometers to create two laser beams at two different frequencies to measure distance and motions of target(s). Heterodyne fringes generated from reflections off a reference fiducial XR and measurement (or target) fiducial XM are reflected back and are then detected by photodiodes. The measured phase changes ΔφR and Δφm resulting from the laser frequency swept gives target position. The reference delay-line is the only absolute reference needed in the metrology system and this provides an ultra-stable reference and simple / economical system.

Owner:AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE NAT

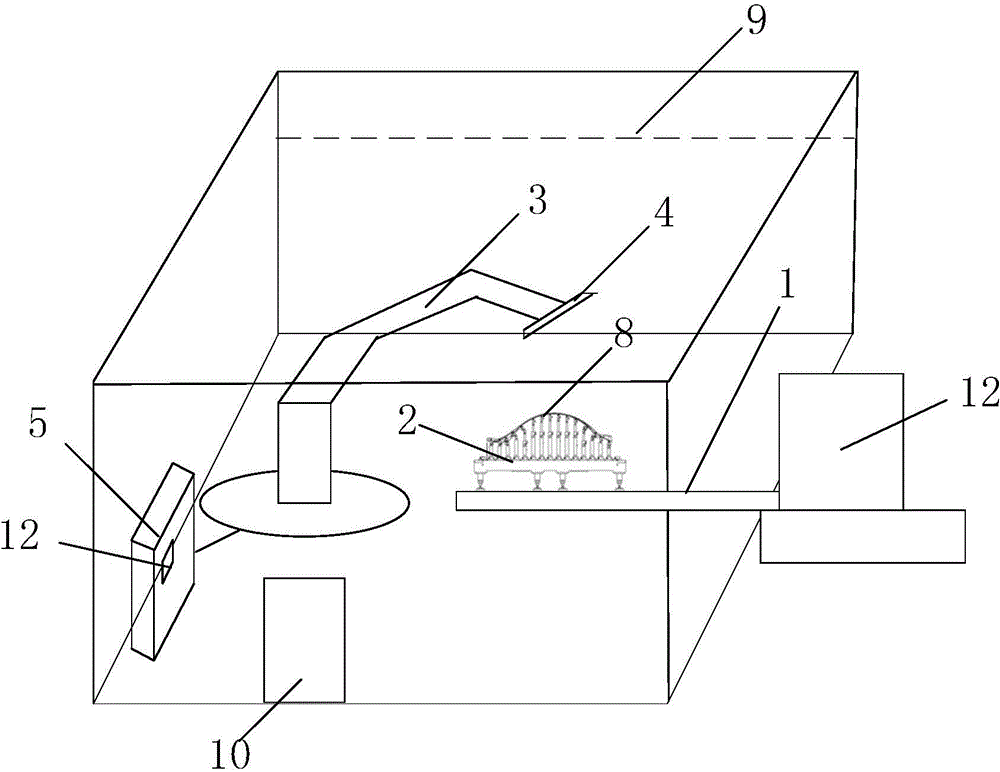

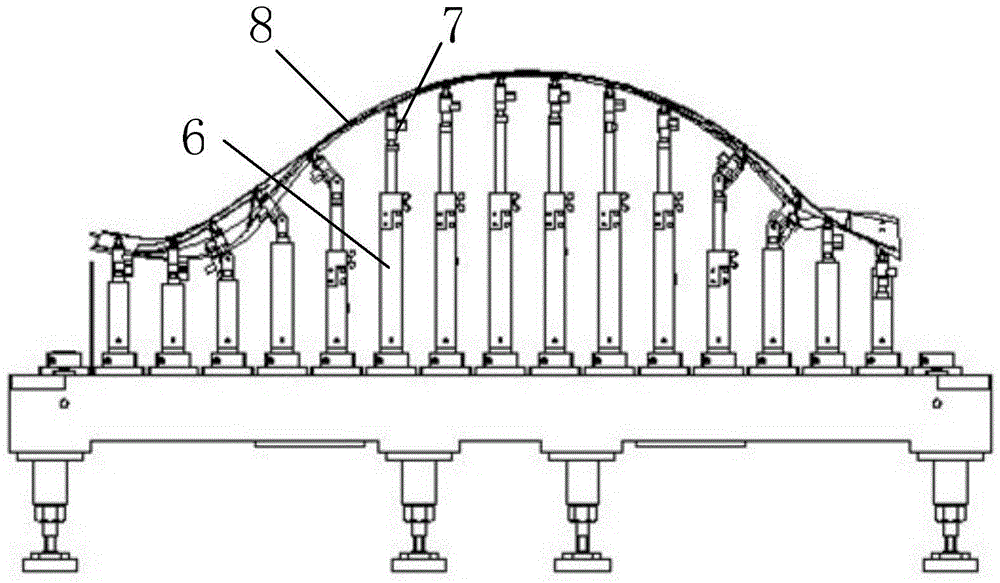

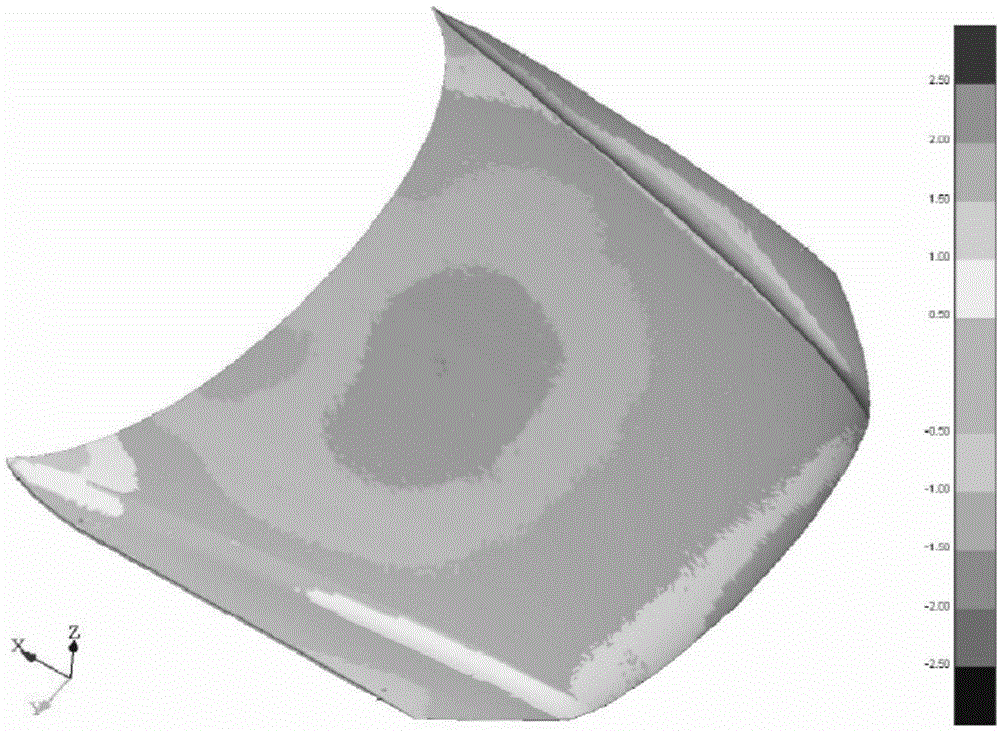

Laser measurement system suitable for non-feature space curve blank piece and processing location method thereof

InactiveCN106152935AReduce dependenceComprehensive analysis of forming qualityUsing optical meansLaser beam welding apparatusGraphicsImaging algorithm

The present invention relates to a laser measurement system suitable for non-feature space curve blank piece and a processing location method thereof. A robot is equipped with a three-dimensional laser to perform comprehensive scanning of formed blank piece and obtain dot cloud data of the blank piece, and then collected dot point data and the CAD numerical simulation are subjected to optimized matching through the rapid and effective graphic image algorithm so as to directly compare a tough piece theory numerical simulation with the dot cloud data, comprehensively analyze the size precision condition after the tough piece is formed and analyze the quality problem reason. The laser measurement system suitable for a non-feature space curve blank piece and the processing location method thereof can perform adsorption location of different blanks by using a flexible support, and the laser measurement system can be configured to perform measurement and location work of different blank pieces. The digitalization and the automation of the measurement and location matching process are realized, and the laser measurement system has high flexible characteristic to apply to the measurement and the location of different blank pieces; and moreover, the deviation caused by manual measurement can be effectively eliminated, and the cost is reduced.

Owner:SUZHOU BEISHUO INSPECTION TECH CO LTD

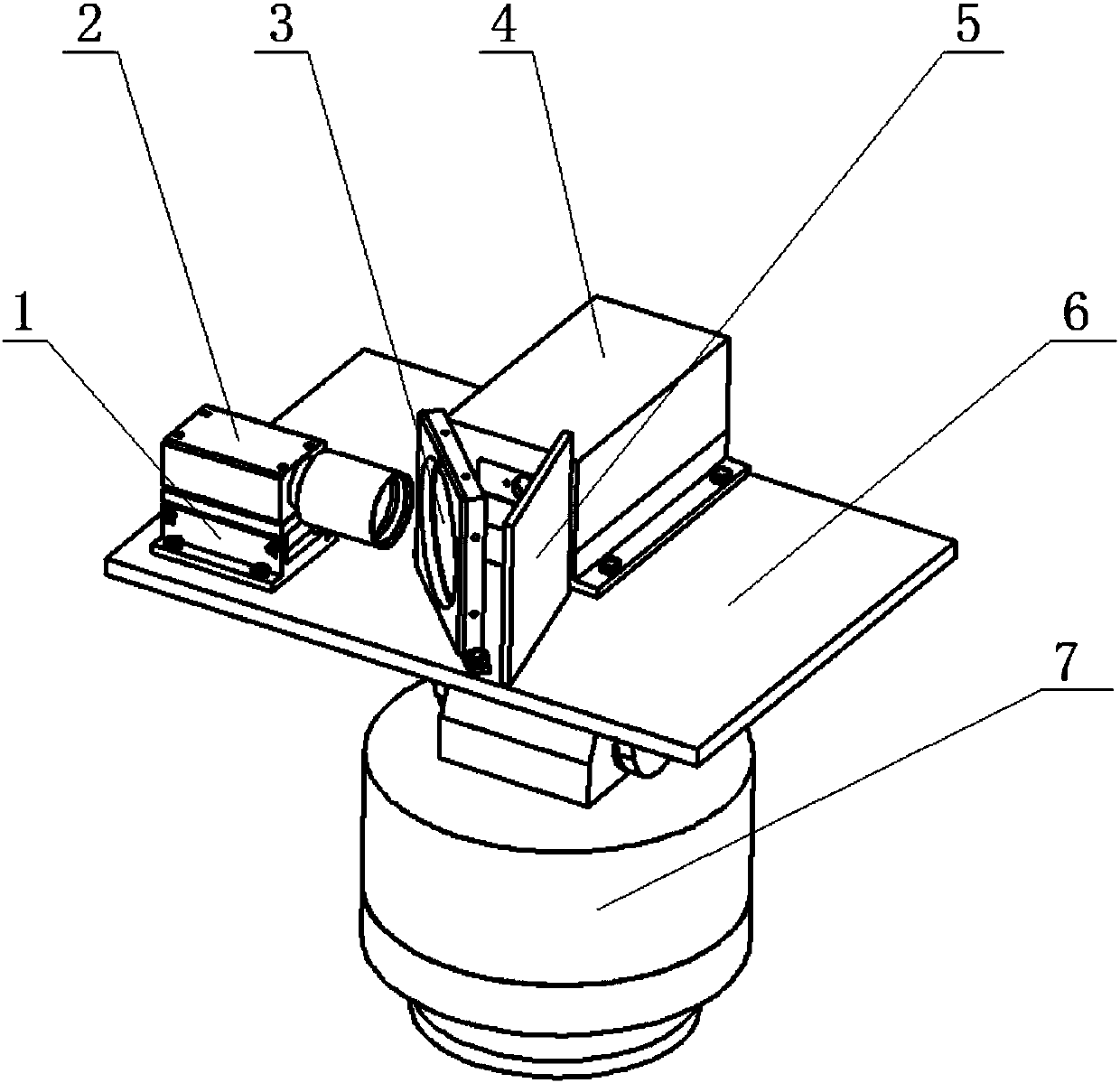

Vision guiding tunnel sign point coordinate laser measurement system and method

InactiveCN107747910AReal-time monitoringAccurate measurementUsing optical meansProfile tracingMeasurement deviceVisual perception

The invention discloses a vision guiding tunnel sign point coordinate laser measurement system and method. The system comprises a sign point arranged on a tunnel rock wall, a visible light lamp capable of irradiating onto the tunnel rock wall and a sign point coordinate measurement device, wherein for the sign point coordinate measurement device, a mounting plate is mounted on a top end of a holder capable of doing horizontal rotation and vertical pitching movement, an industrial camera and a laser displacement sensor are fixed on the mounting plate, the probe axis direction of the industrialcamera is perpendicular to the laser emission direction of the laser displacement sensor, a narrowband filter is further fixedly arranged at a crossing portion of the probe axis of the industrial camera and the laser emission line of the laser displacement sensor, the narrowband filter is fixed on the mounting plate, and a shadow shield is arranged at one side of the narrowband filter far from theindustrial camera. The device is advantaged in that the structure is simple, application is flexible, tunnel sign point coordinate measurement can be automatically accomplished, and automatic non-contact tunnel contour monitoring is realized.

Owner:ZHEJIANG UNIV

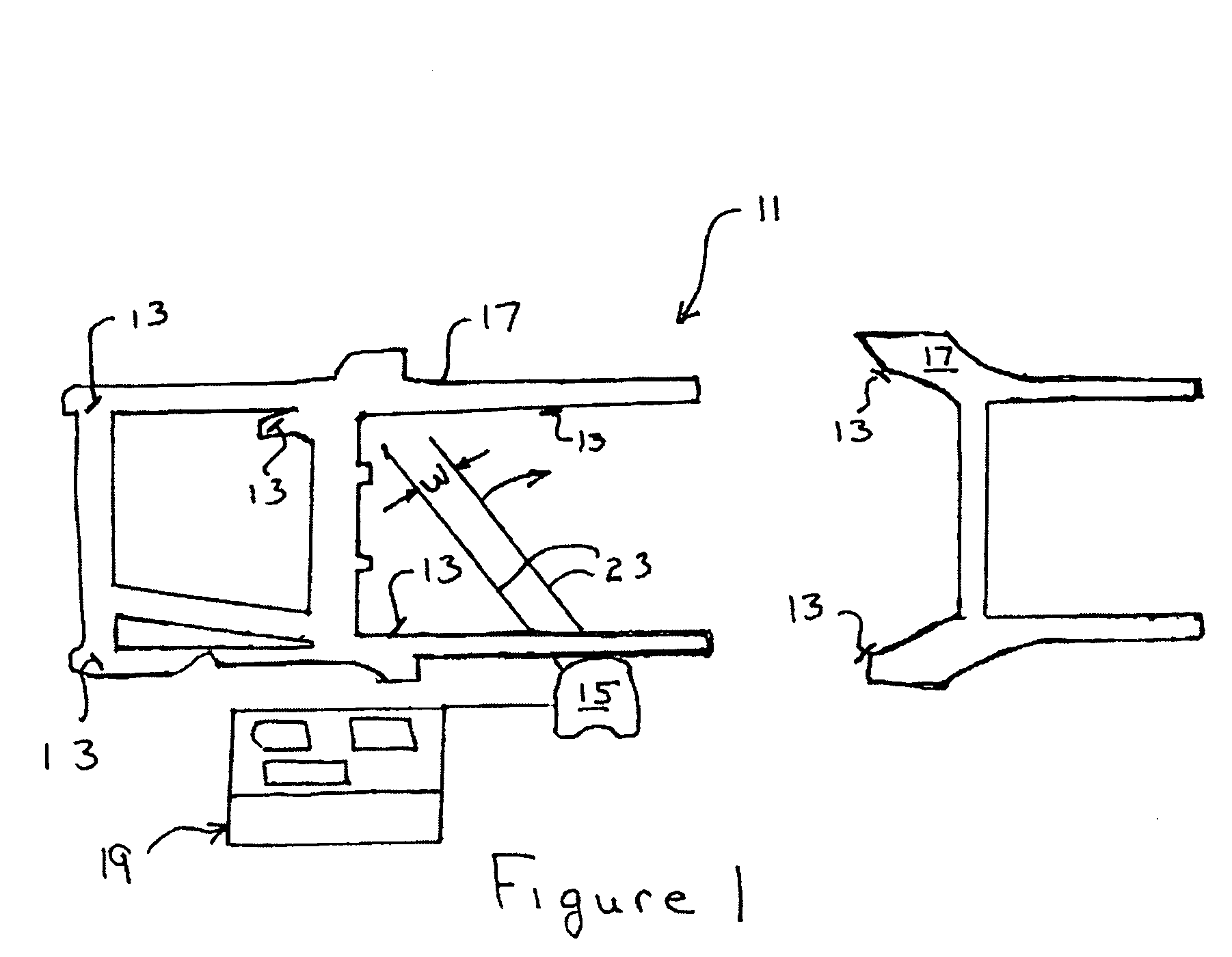

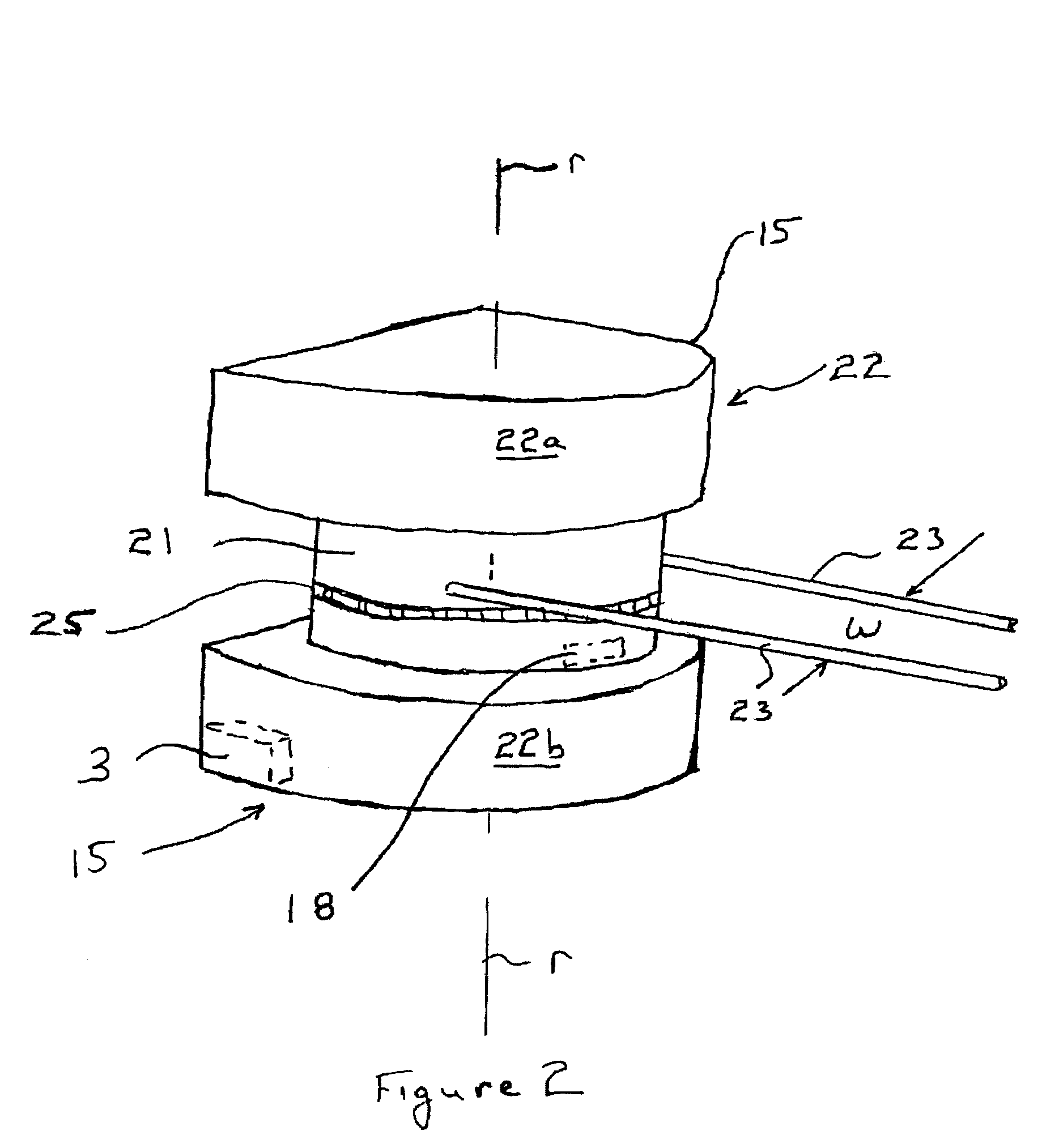

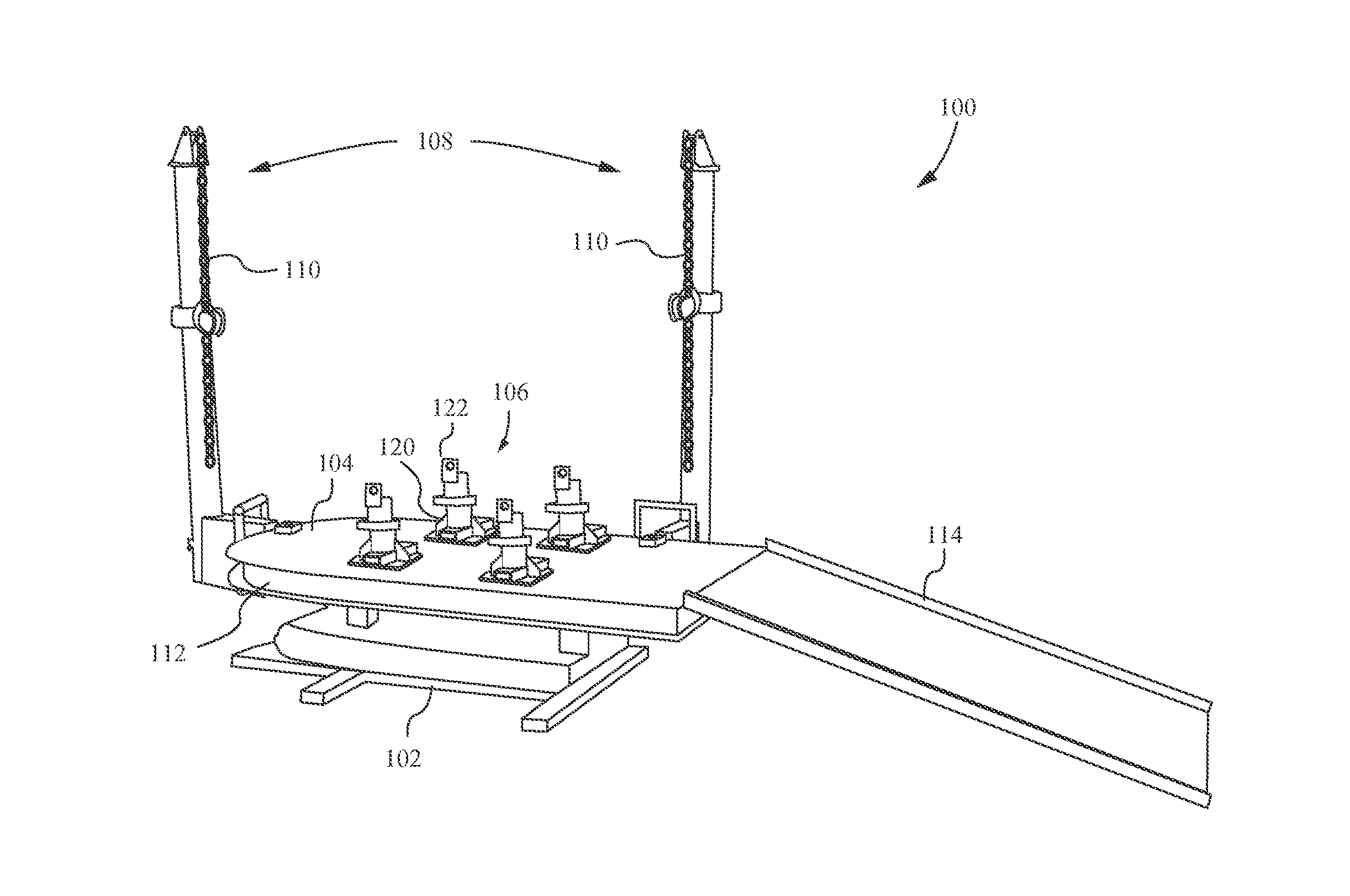

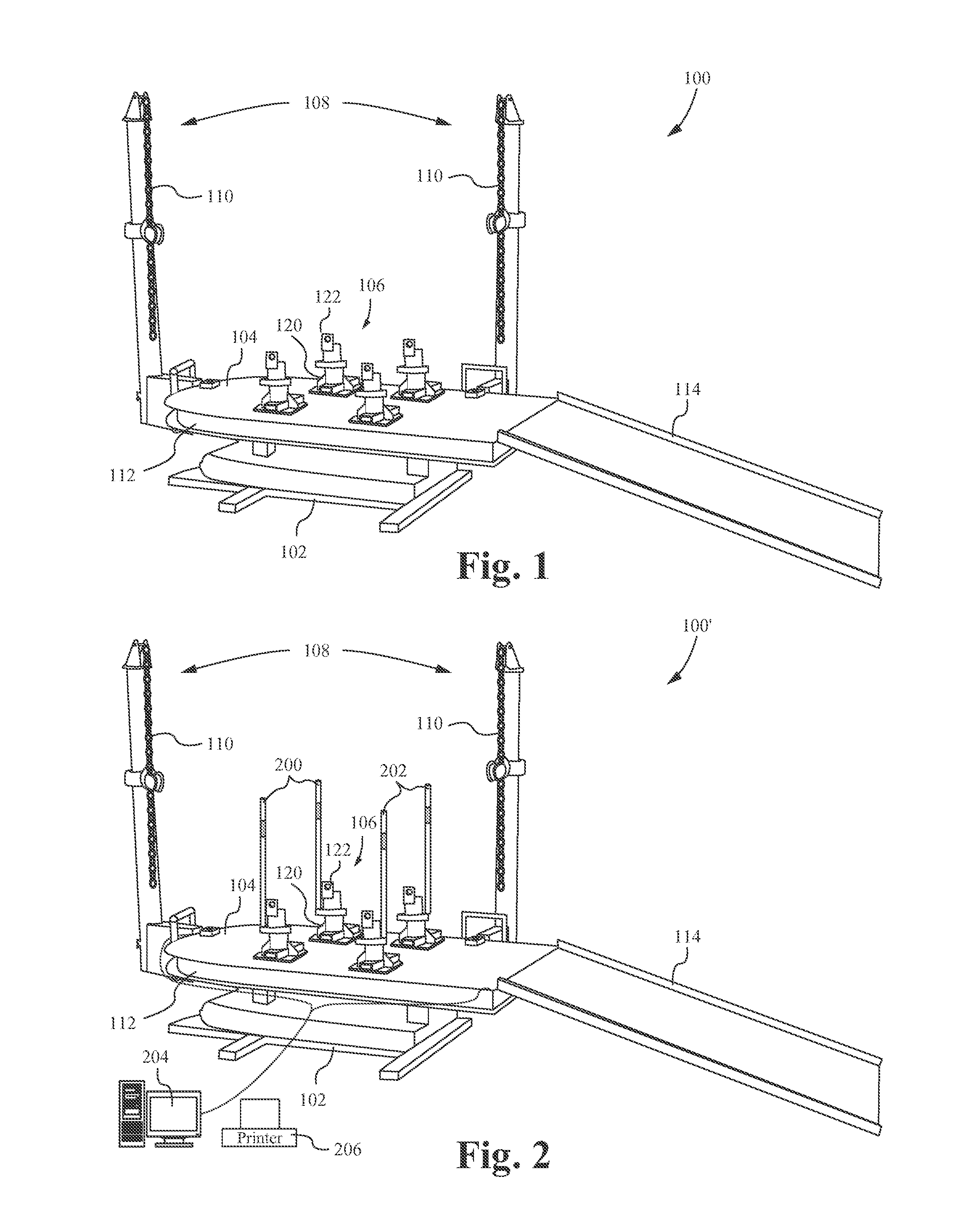

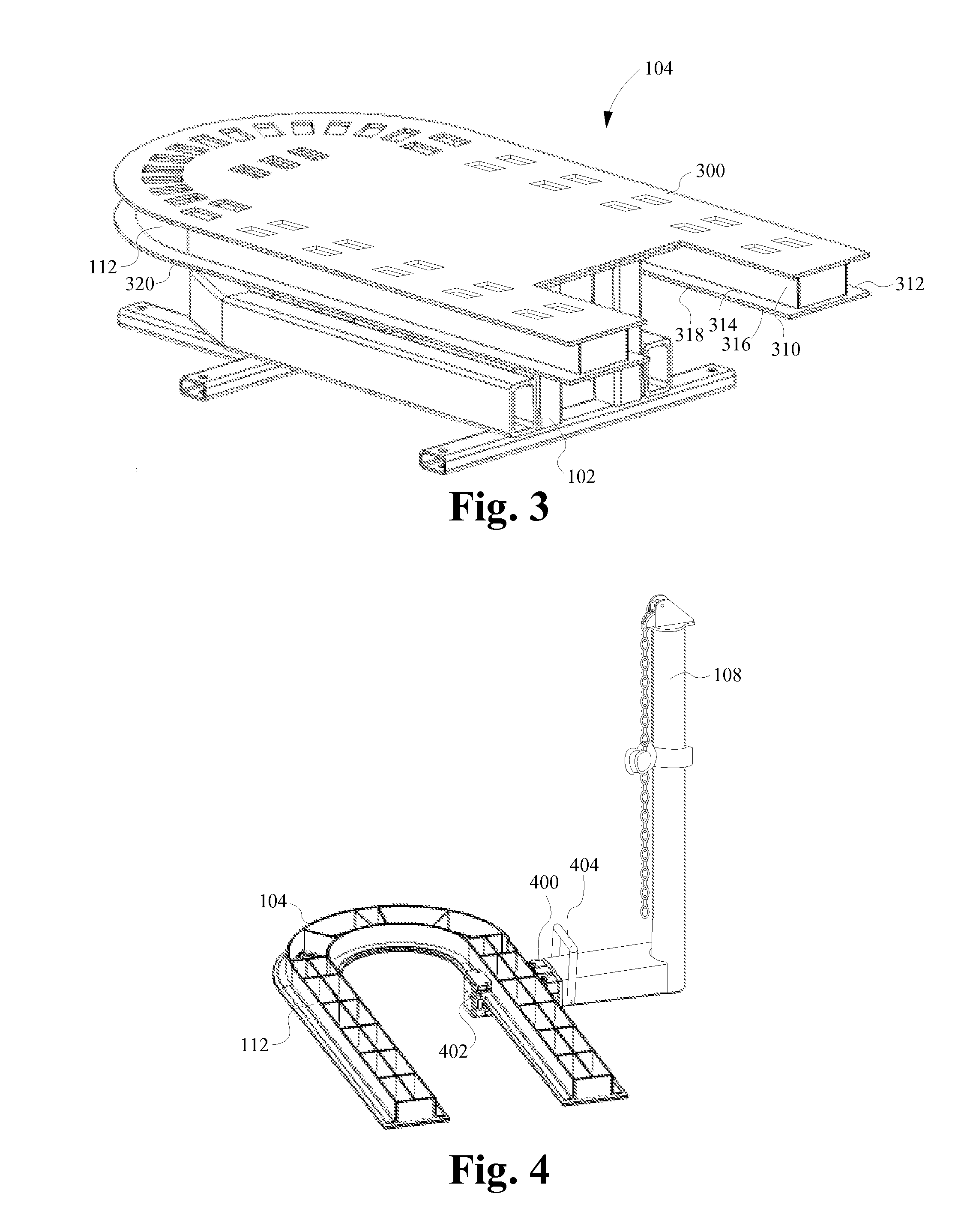

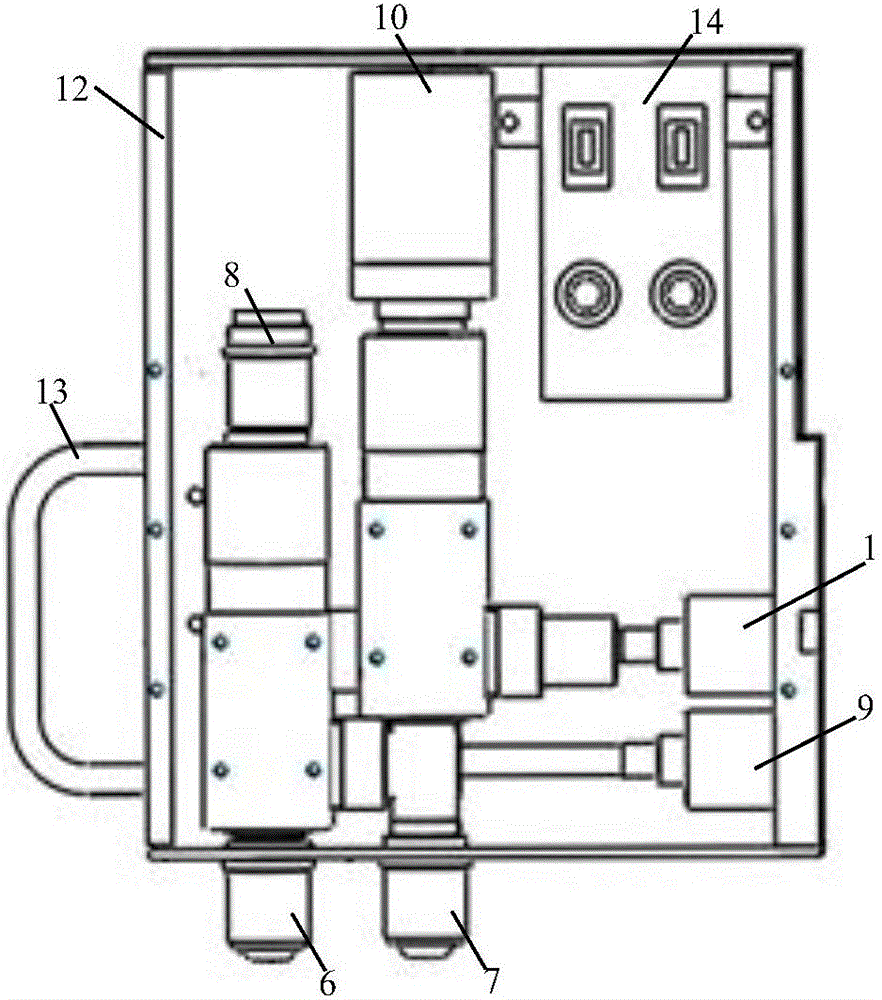

Laser measuring system for motorcycle frame repair

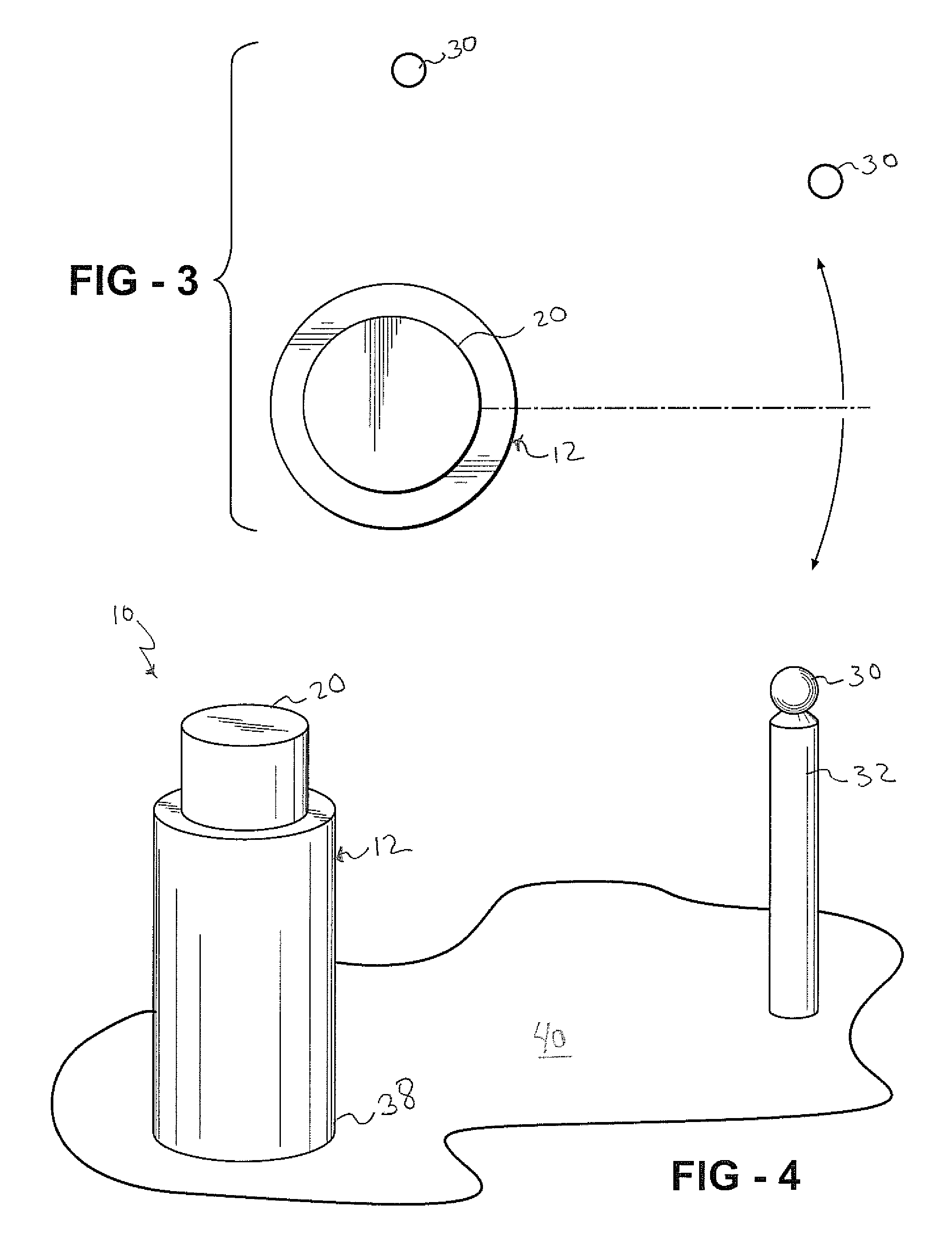

ActiveUS20150260508A1Easy to adjustStraighten a motorcycle frameUsing optical meansWork benchesVehicle frameEngineering

A motorcycle frame rack enables a motorcycle frame to be repaired without removing many components from the motorcycle. A motorcycle is positioned on the motorcycle frame rack, secured in place and then the frame is adjusted using chains coupled to towers. A self-centering laser measuring system is able to be used to analyze and measure damage to the motorcycle frame.

Owner:CAGLE ALLEN

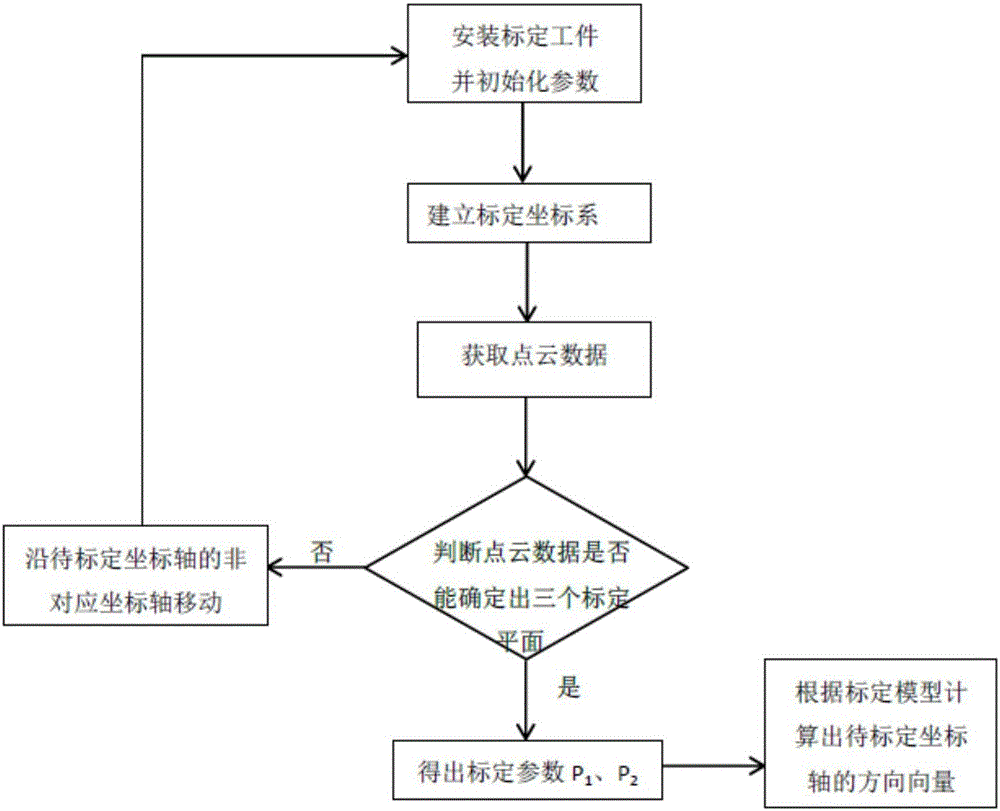

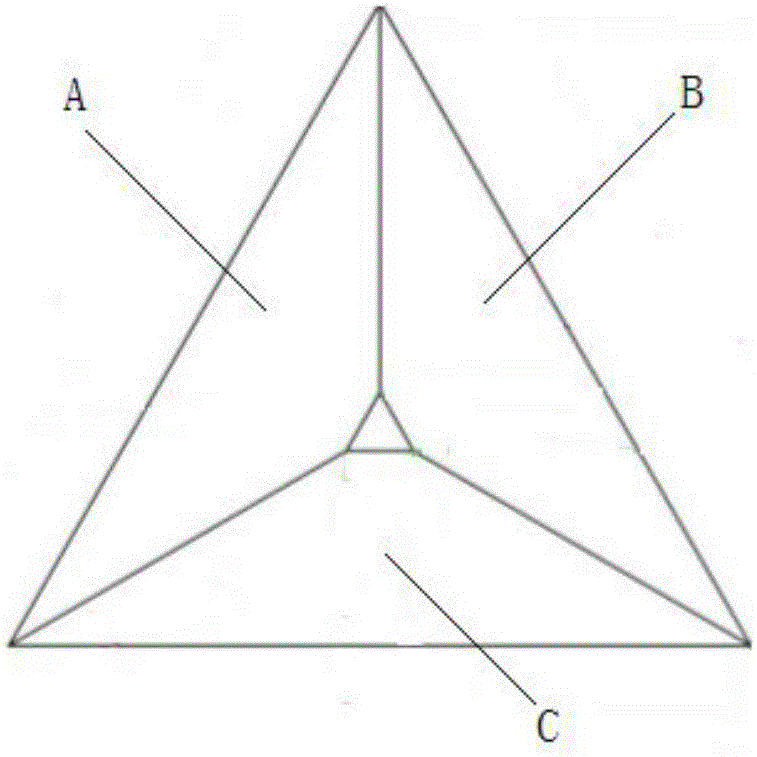

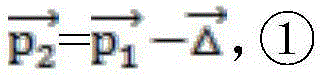

Calibration method for linear radar measurement system based on standard plane

The invention discloses a calibration method for a linear radar measurement system based on a standard plane, which comprises the following steps: step one, a linear laser sensor is enabled to be connected to a numerically-controlled moving platform, and a selected tetrahedron calibration workpiece is installed in the measurement system; step two, a calibration coordinate system is built according to a coordinate axis to be calibrated in a linear laser sensor coordinate system and a non-correspondence coordinate axis of the coordinate axis to be calibrated in a world coordinate system; step three, point cloud data of the calibration workpiece in the linear sensor coordinate system is acquired through the linear laser sensor; step four, calibration parameters in the calibration coordinate system are calculated according to the point cloud data acquired in the step three; step five, a direction vector of the coordinate axis to be calibrated is calculated according to the calibration parameters in the step four and a calibration model; and step six, the linear laser sensor moves along the direction of the other coordinate axis to be calibrated in the linear laser sensor coordinate system, executing the above steps in a repeated manner so as to acquire a direction vector of the other coordinate axis to be calibrated. The calibration method is high in reliability and small in system error.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

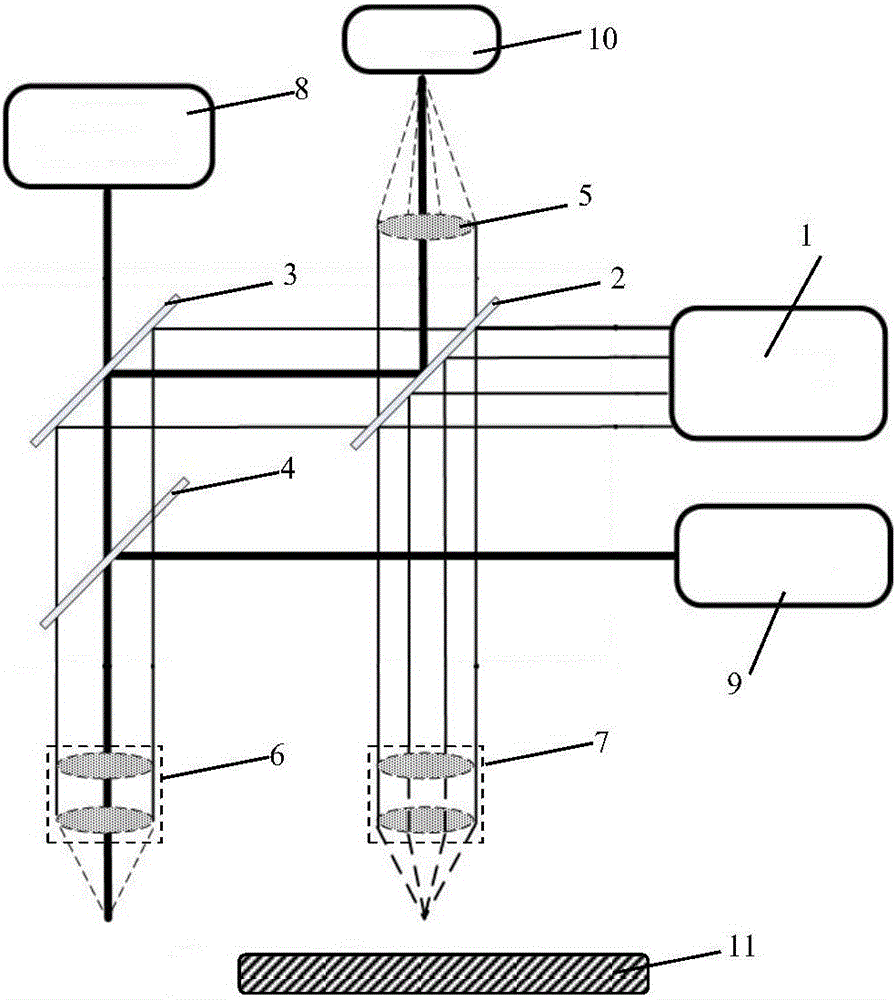

White light interference and laser scanning-based morphology measurement device

ActiveCN106595515AEasy to installSimple structureUsing optical meansFour quadrantsMeasurement device

The invention discloses a white light interference and laser scanning-based morphology measurement device comprising a three dimensional motion platform and a white light-laser measurement system positioned on the same. The measurement system comprises a white light source 1, three light splitting prisms, a microscopic ocular lens 5, a microscopic object lens 6, an interference object lens 7, a four-quadrant photoelectric sensor 8, a laser device 9 and an image sensor 10; two measurement optical paths and a laser measurement optical path are provided; the laser optical path has the following structure: light sent via the laser device 9 is turned via a third light splitting prism 4, and then the light is focused onto a surface 11 being measured via the microscopic object lens 6; the light passes through the microscopic object lens 6, the third light splitting prism 4, and a second light splitting prism 3 after being reflected by the surface 11 being measured; then the light is projected to the four-quadrant photoelectric sensor 8 and is used for measuring height information of the surface 11 being measured; light, reflected back by the surface 11 being measured, sent via the laser device 9 is turned via the second light splitting prism 3; after passing through a first light splitting prism 2 and the microscopic ocular lens 5, the light and illumination backlight formed via the white light source 1 are imaged onto the image sensor 10, and a collection image for laser measurement is formed.

Owner:TIANJIN UNIV

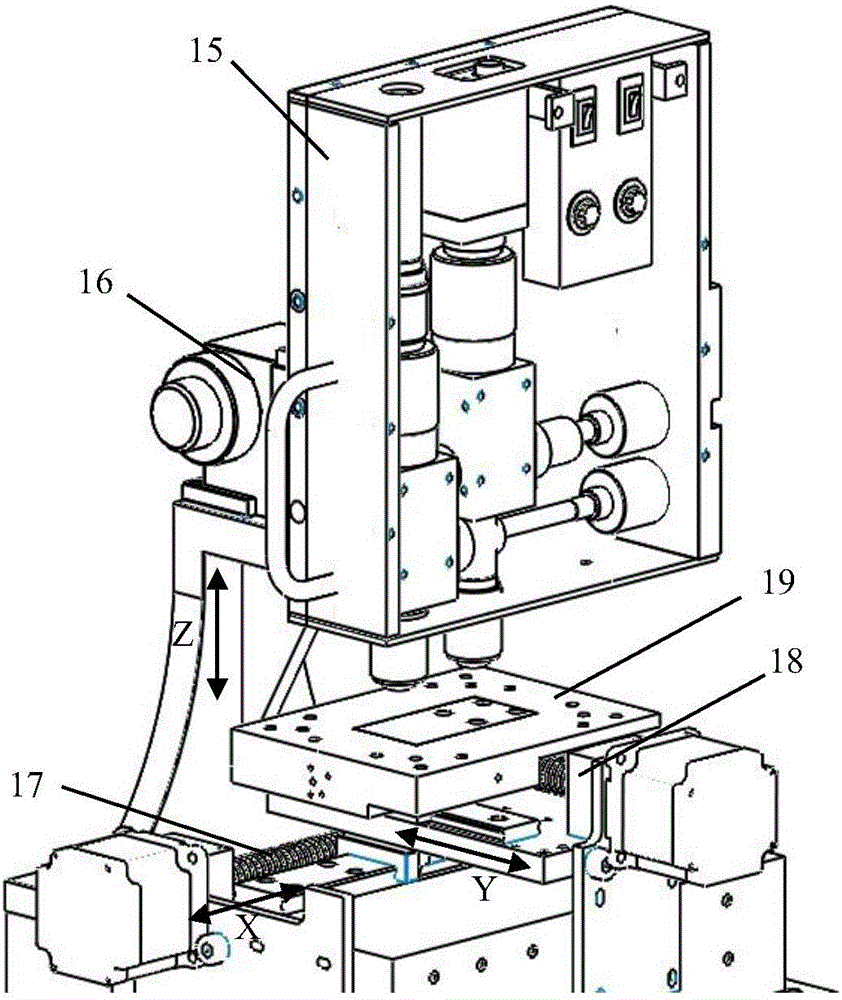

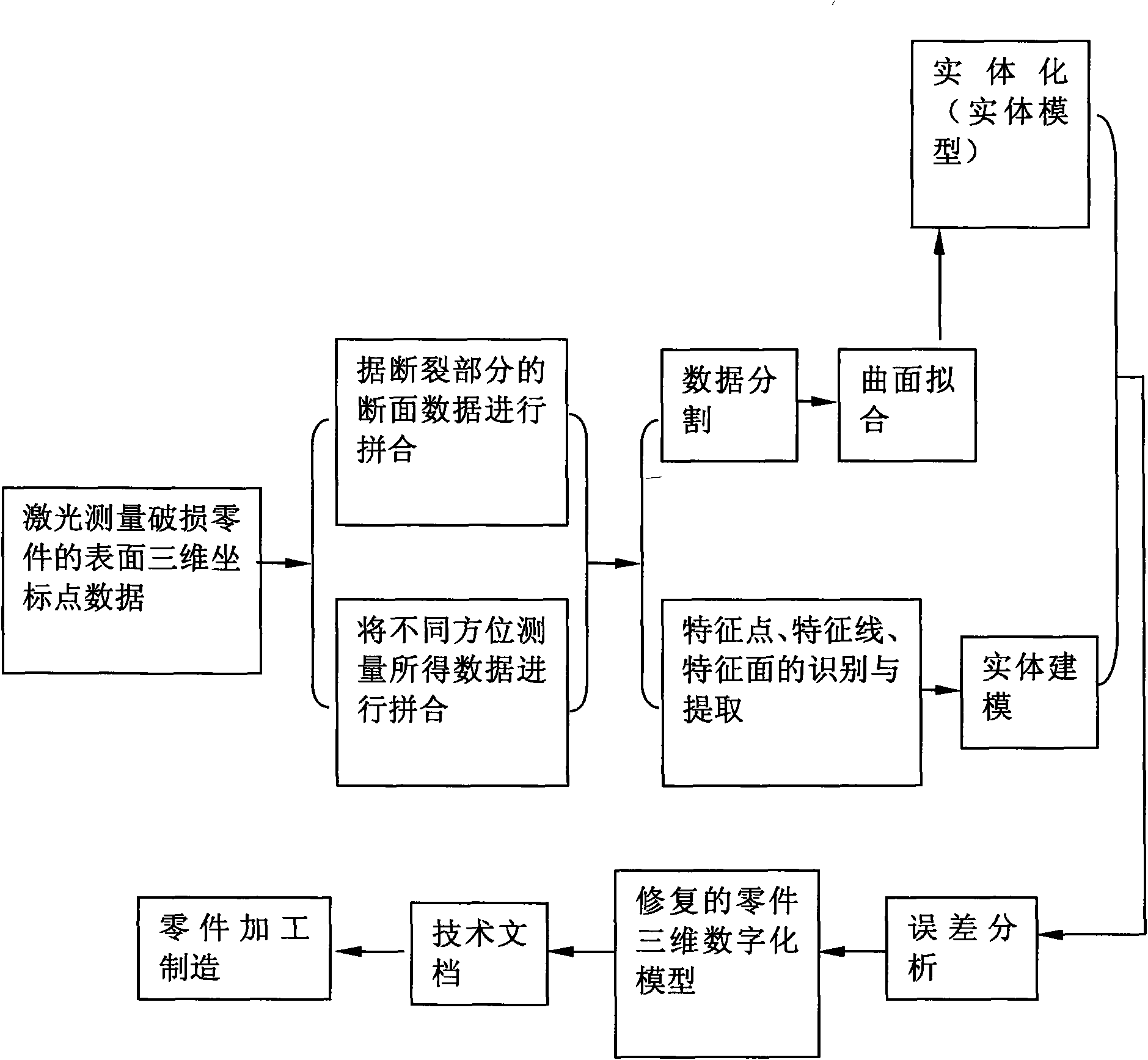

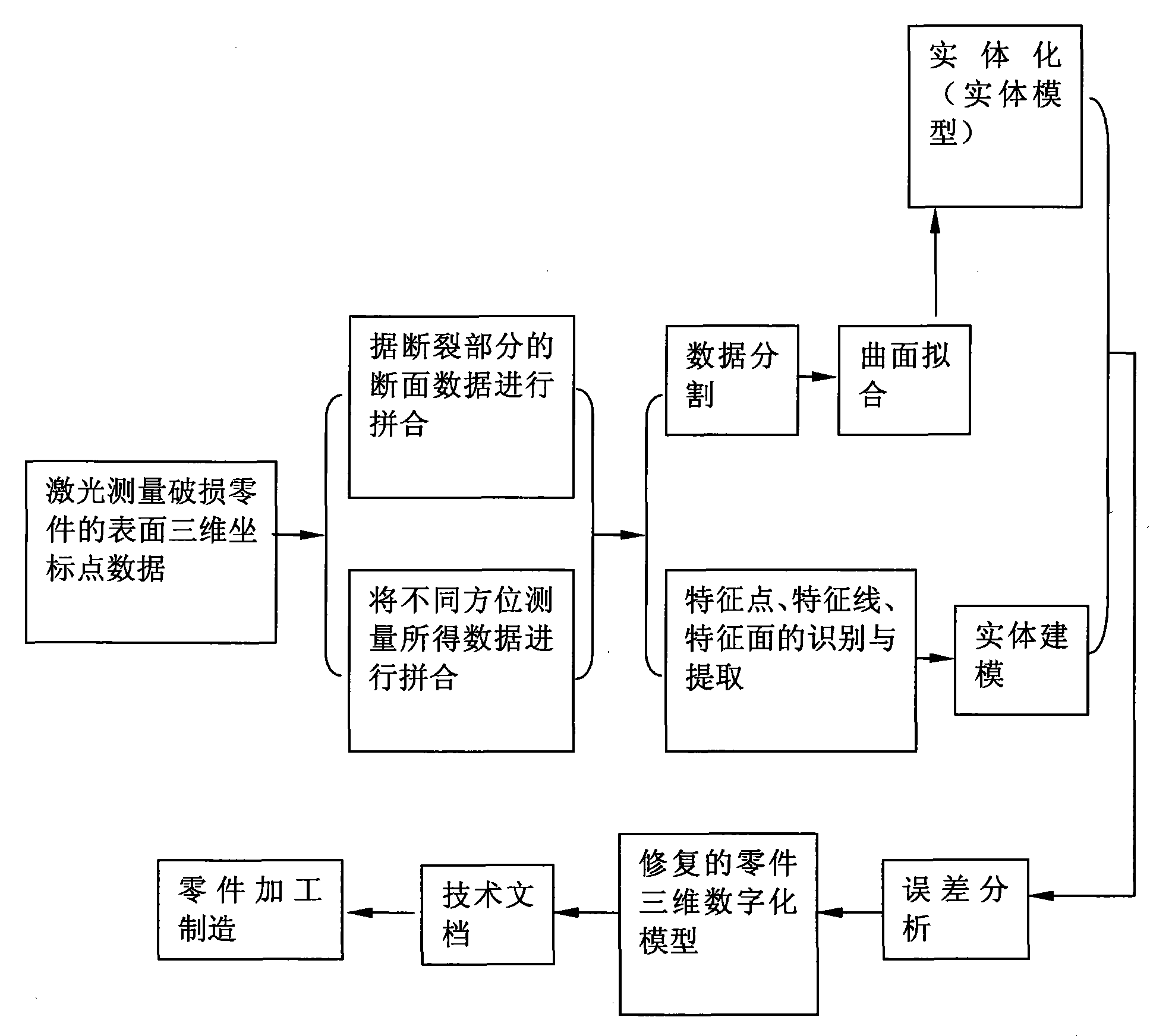

Method for repairing damaged machinery component based on three-dimensional digitization

The invention discloses a method for repairing a damaged machinery component based on three-dimensional digitization. The method comprises: firstly, a laser measurement system is adopted to obtain the superficial three-dimensional data points of a component to be measured; all the obtained superficial three-dimensional coordinate data information of the part to the measured are spliced; then the spliced three-dimensional coordinate data information is combined with a three-dimensional digitalized design method by characteristic recognition and extraction methods; the damaged part of the component to be measured is repaired, thus obtaining the three-dimensional physical model, the two-dimensional engineering drawing and the error analysis chart of the component to be measured; and then a technical document is returned to, thus duplicating and manufacturing the damaged part. The method has high repairing accuracy, the digitalized modeling is easy to edit and modify, the measurement cost is lower, the operability is strong, and the method is convenient for popularization and application.

Owner:HOHAI UNIV CHANGZHOU

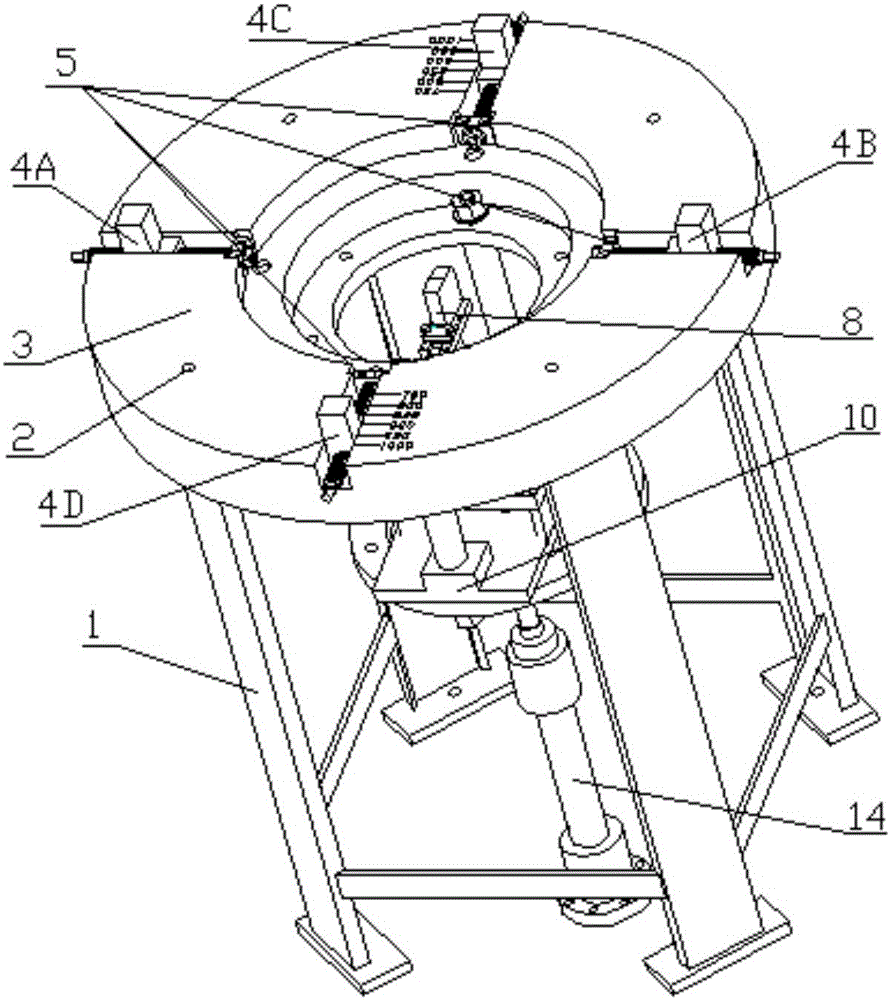

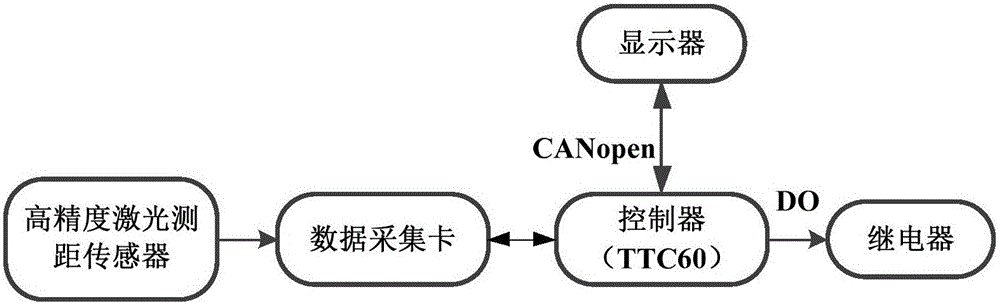

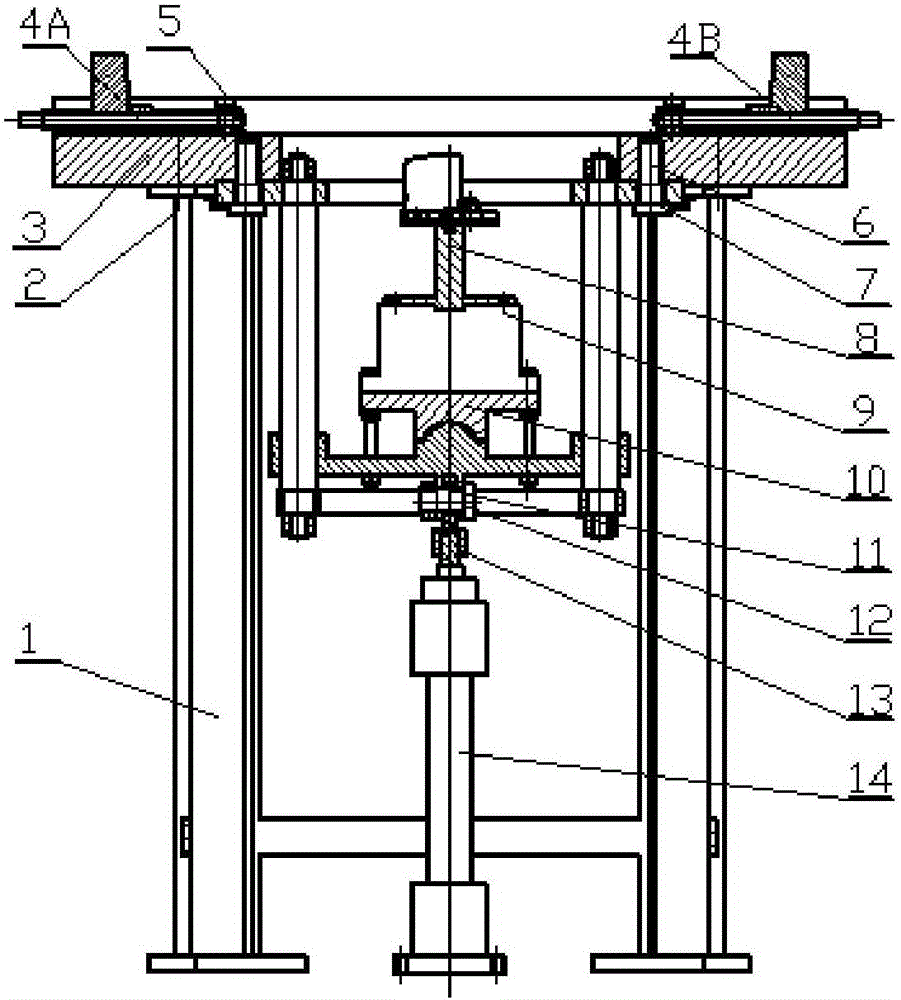

Train wheel hub inner hole diameter laser measurement system and measurement method thereof

The invention discloses a train wheel hub inner hole diameter laser measurement system and a measurement method thereof, and belongs to the technical field of measurement.The measurement system comprises a bottom frame, a worktable, limiting mechanisms, a high-precision laser distance measuring sensor assembly, a lifting mechanism, an oil cylinder head, an oil cylinder, connecting screws, a hydraulic station, a hydraulic valve station, a data acquisition card, a controller, a displayer, a relay, a cable power source, a signal communication module, a driving control module and a data acquisition and processing module.According to the train wheel hub inner hole diameter laser measurement system and the measurement method thereof, a laser ray is perpendicular to the surface of an inner hole when used for measuring the wheel inner hole, a laser device measures one piece of data at one part of the wheel inner hole every time rotating by 90 degrees to obtain four pieces of data, the diameter of the inner hole at the part is obtained through geometrical relationship calculation, and the distance between a laser emitting point and the rotating center of an indexing table is calibrated through the known diameter of the wheel inner hole.The train wheel hub inner hole diameter laser measurement system and the measurement method thereof have the advantages of being high in speed, precision and stability and the like, and can be applied to and popularized in detection of shapes of hole parts.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com