Numerical control precision progressive forming device and precision progressive forming method for plates

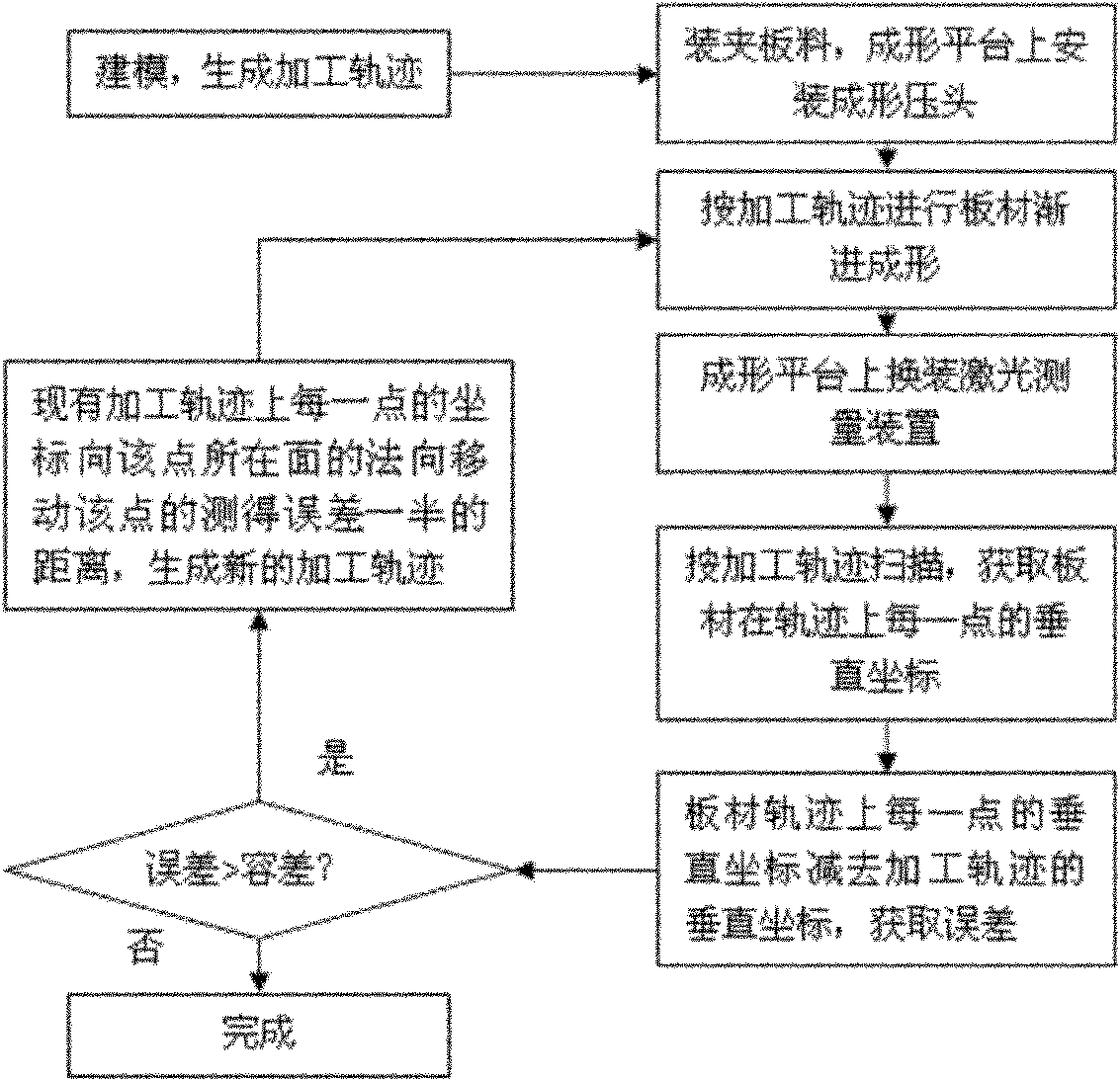

A progressive forming and precision technology, applied in the field of sheet metal processing, can solve the problems of slow three-coordinate measurement, measurement of sheet metal springback and warpage, and large geometric error of sheet metal, so as to avoid occupying the press and reduce material loss , The effect of saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

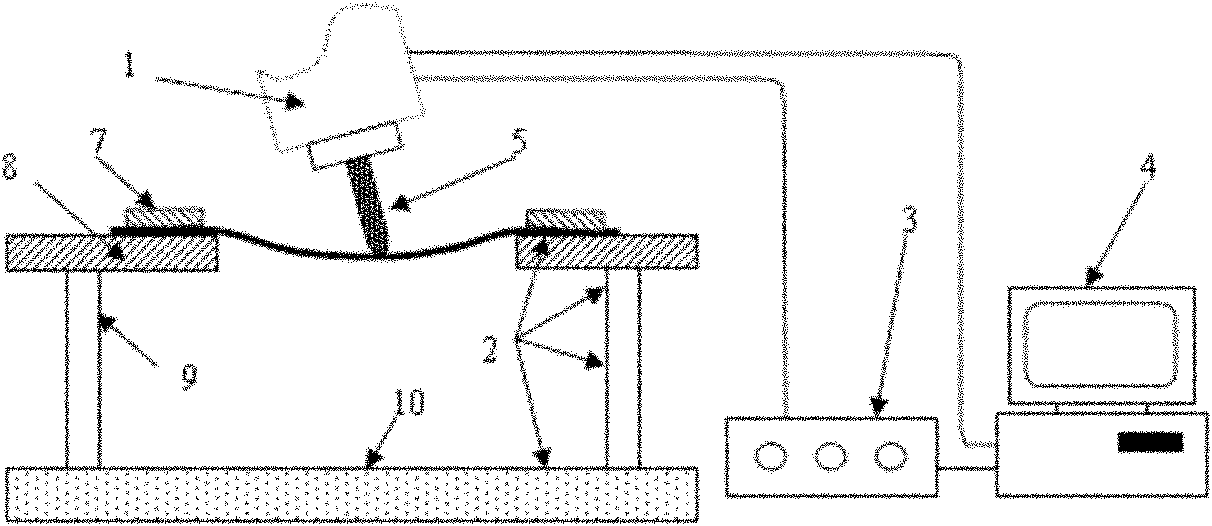

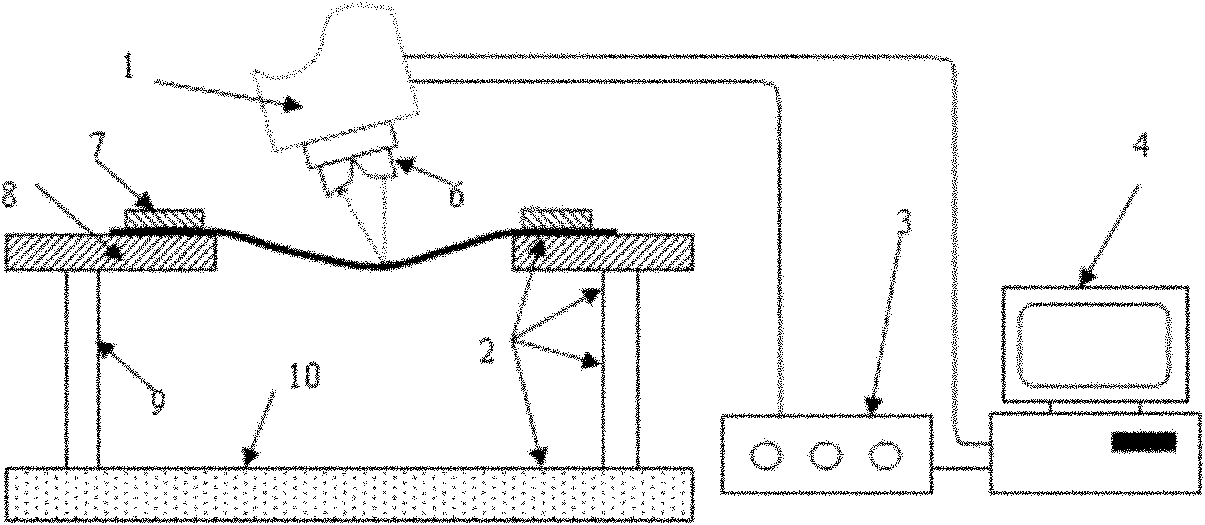

[0024] Such as figure 2 with image 3 As shown, this embodiment includes: a five-axis CNC forming machine tool 1, a sheet metal fixture 2, a data acquisition system 3 and an optimization control module 4, wherein: the sheet material fixture 2 is arranged on the workbench of the machine tool, and the data acquisition system 3 is connected to the machine tool respectively. The five-axis CNC forming machine tool 1 and the optimization control module 4 are connected and transmit processing parameters and control instructions.

[0025] The end of the main shaft of the five-axis CNC forming machine tool 1 is provided with a forming indenter 5 or a laser ranging system 6, which is connected to the data acquisition system 3 and transmits laser ranging signals.

[0026] The blank holder 2 is composed of a blank holder 7 , a hollow support platform 8 , a pillar 9 and a base 10 , wherein the blank is fixedly arranged between the blank holder 7 and the support platform 8 .

[0027] The...

Embodiment 2

[0035] Such as figure 2 , 3 Shown, the present embodiment processing method comprises the following steps:

[0036] 1) The product size is 300mm×300mm, and the aluminum plate with a thickness of 1mm is used;

[0037] 2) Use the CAD function of NX6.0 software to carry out CAD modeling of sheet metal parts, and use the CAM function of the software to generate processing paths for sheet metal;

[0038] 3) A ball forming indenter 5 with a diameter of 10mm is set on the five-axis forming unit;

[0039] 4) Cut the sheet into a 320mm×320mm square, and use the blank holder 7 to press the sheet around 10mm;

[0040] 5) Input the CNC machining trajectory code into the five-axis machine tool, and set the forming indenter 5 to the machining coordinates;

[0041] 6) Start the machine tool for progressive forming;

[0042] 7) After the forming is completed, the five-axis forming unit is replaced with a laser measuring device;

[0043] 8) Start the machine tool to scan by the machinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com