White light interference and laser scanning-based morphology measurement device

A white light interference and topography measurement technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of low sampling rate of measurement data and large impact on performance, and achieve the effect of easy installation, small quantity, and error avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

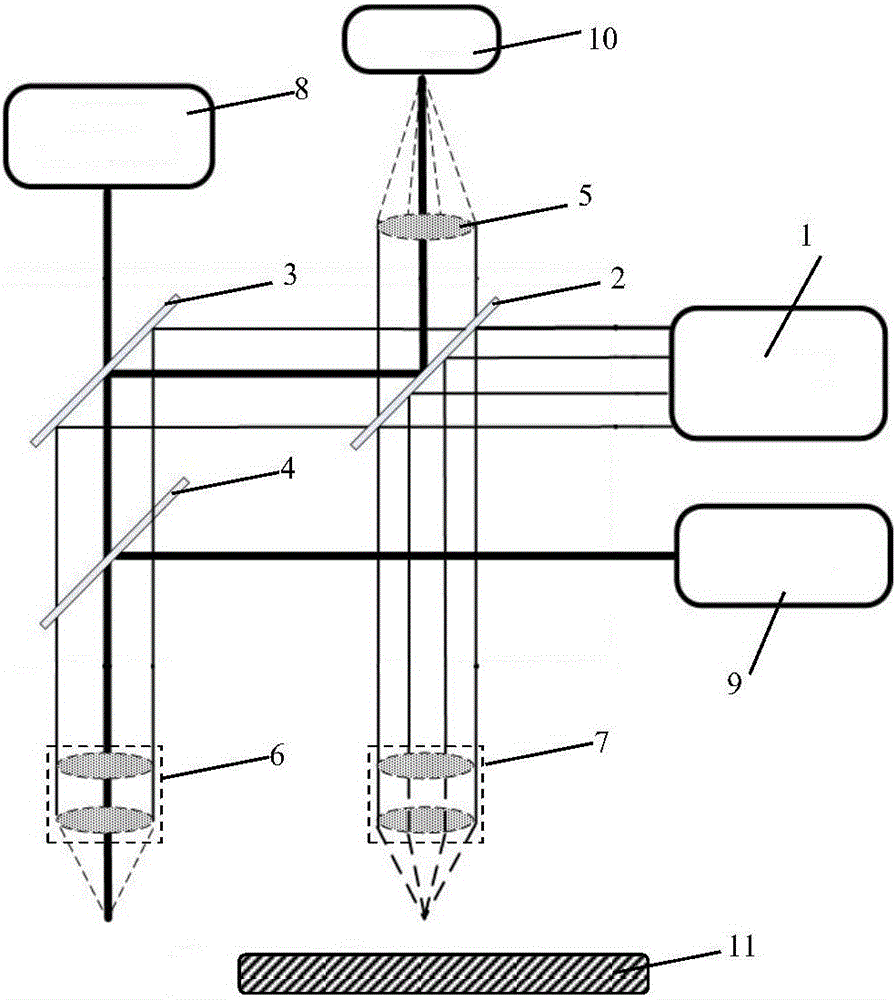

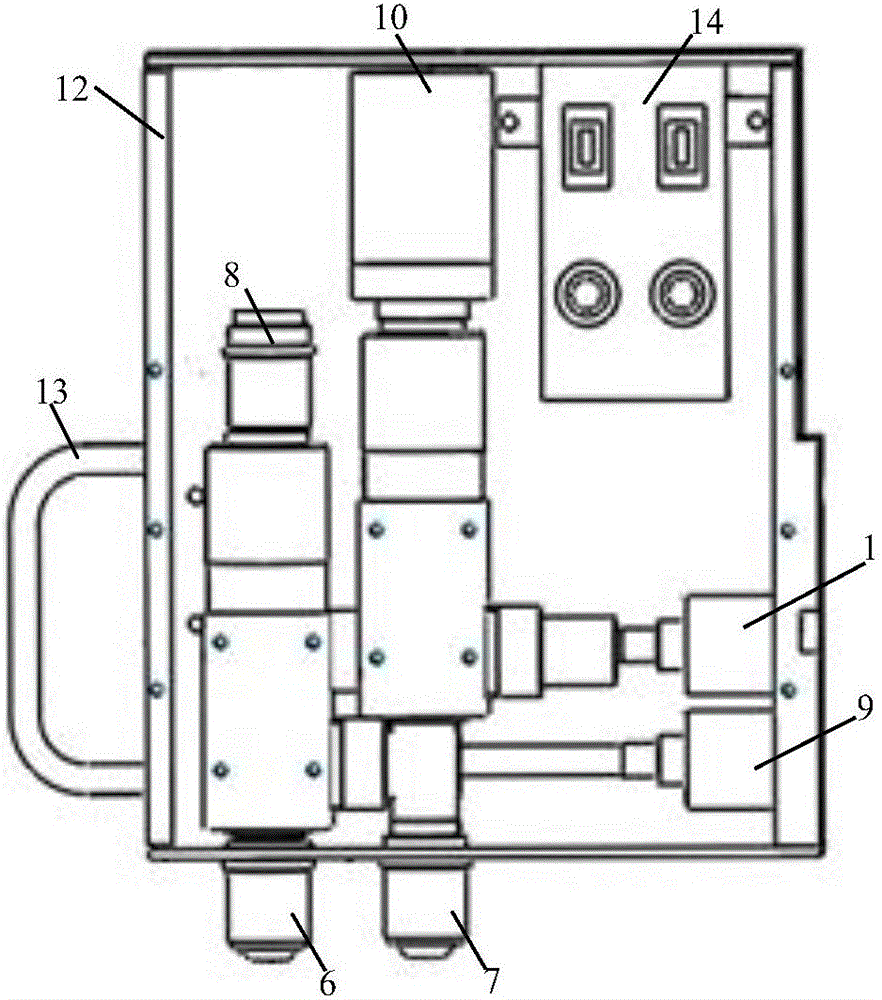

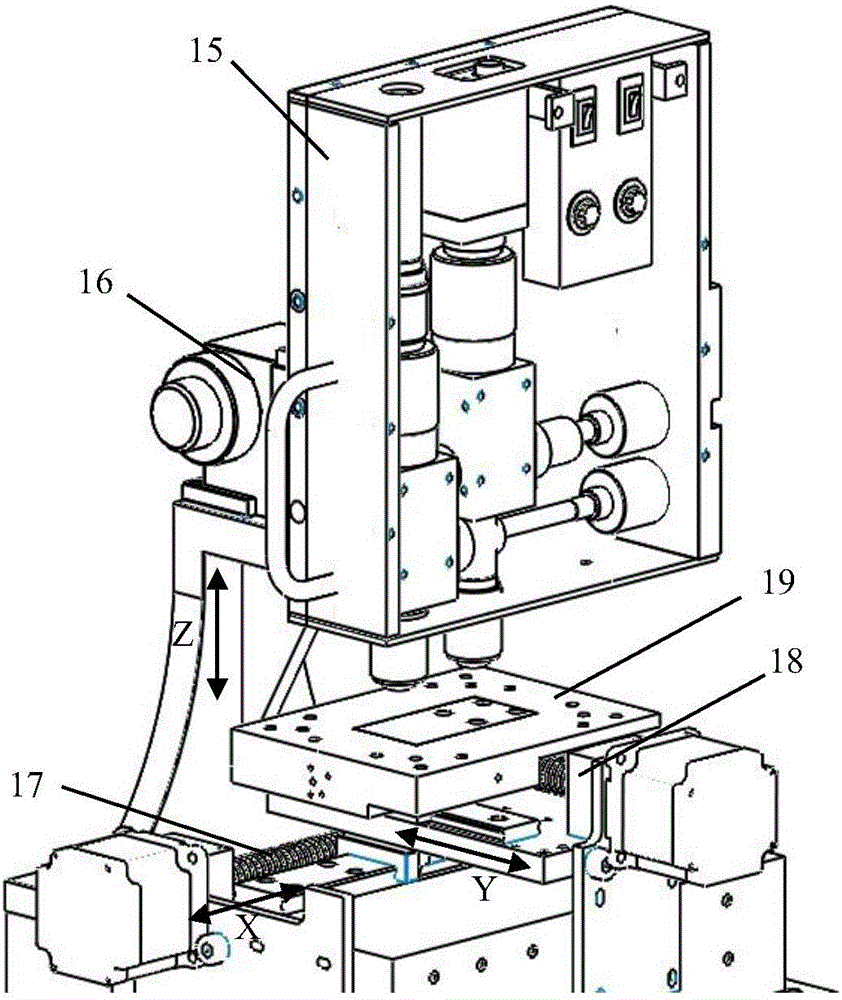

[0017] The invention combines white light interference and laser scanning methods to realize surface topography measurement in a large range and full frequency range. White light interferometry can quickly realize nanometer-precision measurement of surface topography in a small field of view. Due to the large number of sampling points for local measurement, it can achieve full-band surface information acquisition. For large-scale surface topography, multiple single-field data need to be spliced and fused. However, due to the complex shape of the surface to be measured, how to reasonably plan the measurement path to achieve fast measurement and high-precision stitching is a difficult problem in realizing large-scale surface topography measurement by white light interferometry. Therefore, the introduction of the laser scanning method in the present invention can quickly predict the surface to be measured, fully understand the characteristic information of the surface to be mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com