Evaluation system of visible deformation as residual welding stress eliminating effect

A residual stress and evaluation system technology, applied in the direction of measuring force, measuring device, instrument, etc., to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings.

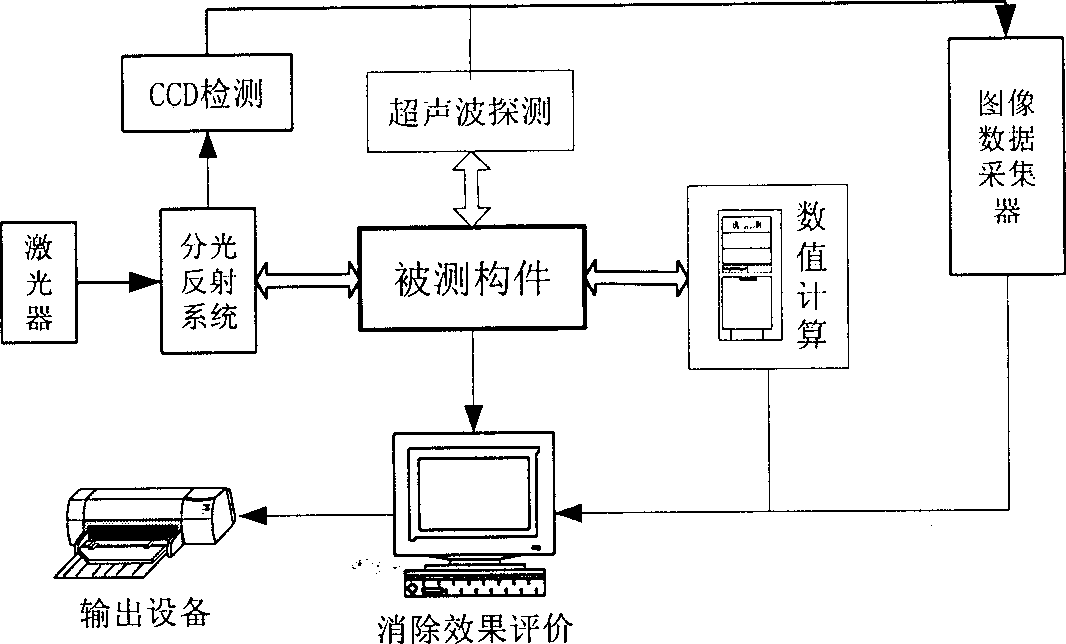

[0016] figure 1 It is a block diagram representing the system of the present invention. According to the technical scheme of the present invention, three methods for obtaining basic data adopted in the system are:

[0017] 1) Ultrasonic method: use the ultrasonic method to measure the thickness before and after the elimination of residual stress, and study the visible deformation in the thickness direction of the plate caused by the treatment of residual stress. The use of ultrasonic waves to measure thickness dimensions is very mature, and there are many related equipment. The invention adopts the Pan-American 25DL high-precision ultrasonic thickness gauge to measure the thickness with high precision, reliability and good repeatability. At the characteristic points of the stress field, such as the center of the weld, measure the thickness difference before and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com