Laser measurement system-based taper thread data processing algorithm

A laser measurement system and data processing technology, applied in electrical digital data processing, special data processing applications, measurement devices, etc., can solve the problems of local damage, wear, easy deformation of the shoulder surface of the drill pipe and thread profile, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

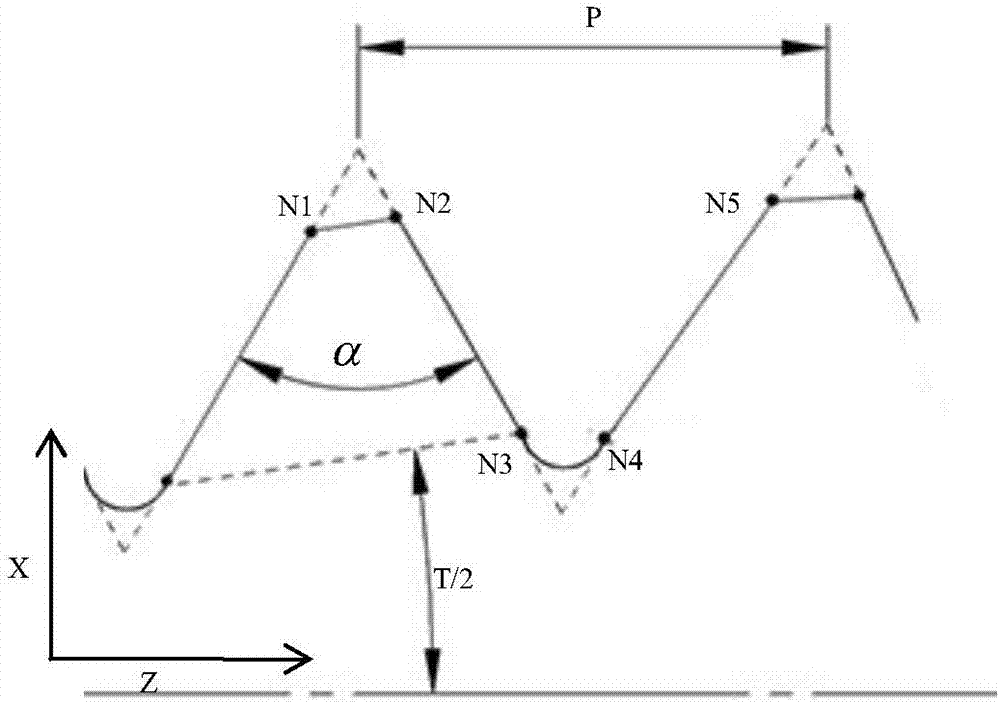

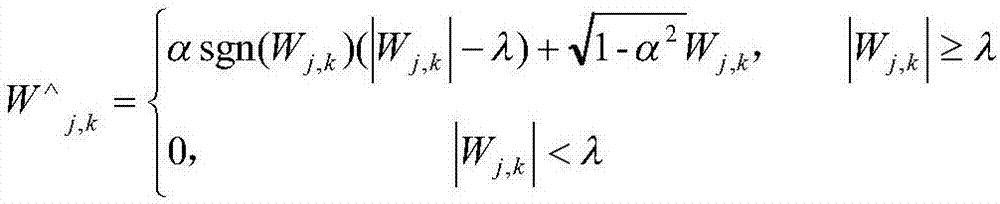

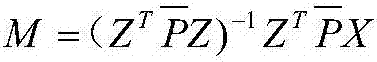

[0083] The invention provides a taper thread data processing algorithm based on a laser measurement system. The non-contact acquisition of thread data by the laser measurement system avoids the error caused by the contact pressure between the probe and the workpiece during the contact measurement process and the contact between the probe and the surface of the workpiece. Scratch, with higher detection speed and higher detection accuracy. Principle errors are removed according to the adaptive Leite criterion. Then the data is denoised by improving the wavelet adaptive threshold to remove random errors. Finally, the noise-reduced data is fitted by robust least square method to obtain the thread profile, the feature points are divided according to the slope, and the thread parameters are calculated according to the feature points, realizing the data acquisition and processing of taper thread based on the laser measurement system.

[0084] The taper thread data processing algorit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com