Rapid measuring and error compensation method for linearity error of linear guide rail

A straightness error and error compensation technology, which is applied in the field of machine tool precision design, can solve problems such as complex data processing, low measurement methods, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

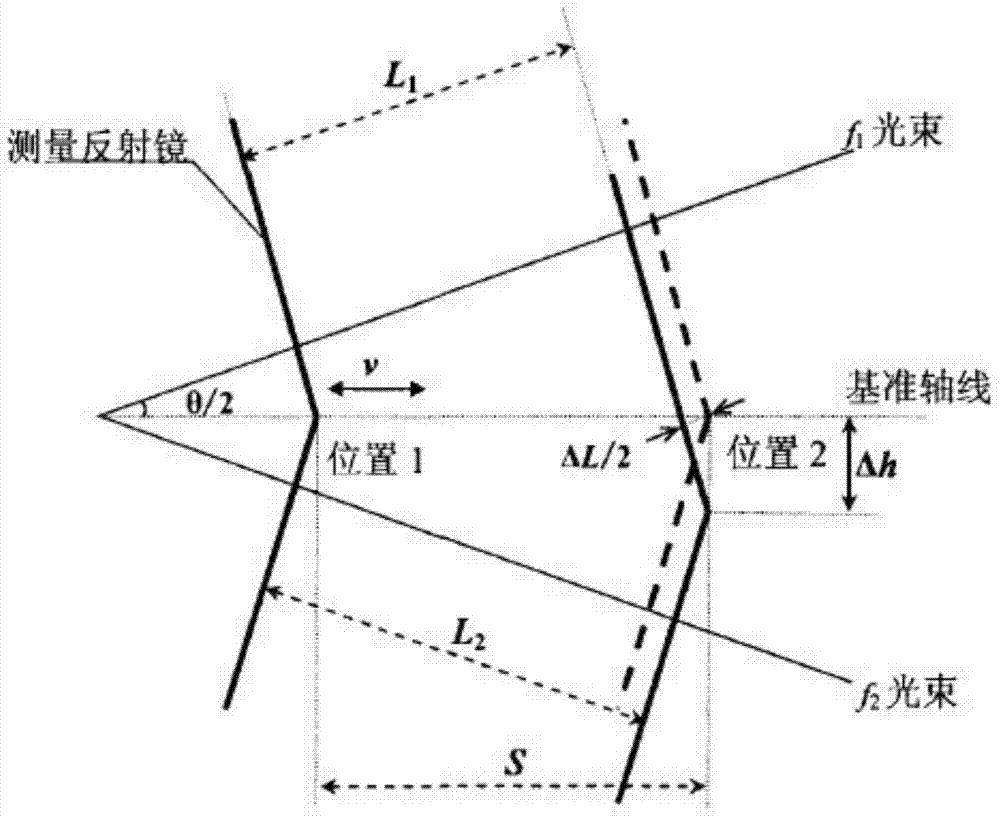

Method used

Image

Examples

Embodiment Construction

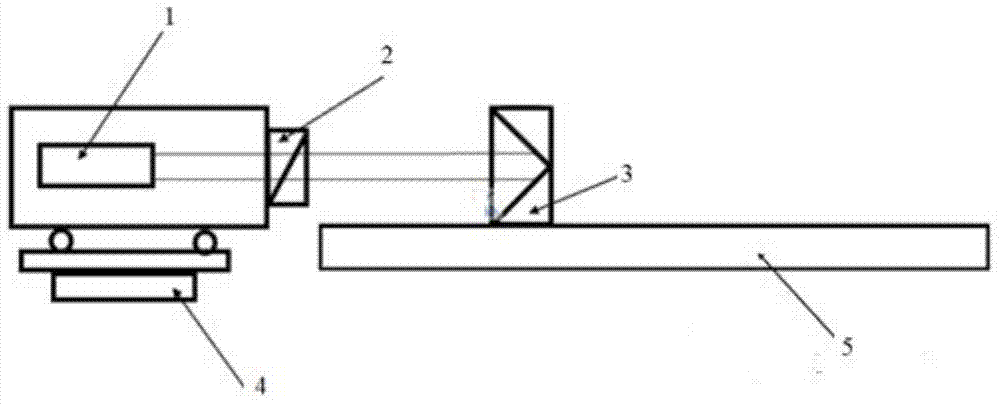

[0085] Taking the gantry-type five-axis processing machine tool as an example, the Cartesian coordinate system of the machine tool is established, such as Figure 4 shown. The invention adopts the XD series laser interferometer produced by the American Automatic Precision Engineering Company (API) to measure the straightness error of the x-direction rail of the gantry-type five-axis processing machine tool. The device involved in this method includes a laser head, a 6-D sensing unit 3, an adjustment fixture 6, and a measured x-direction linear guide; the laser head includes an interferometer host 1 and a front-end interferometer 2,

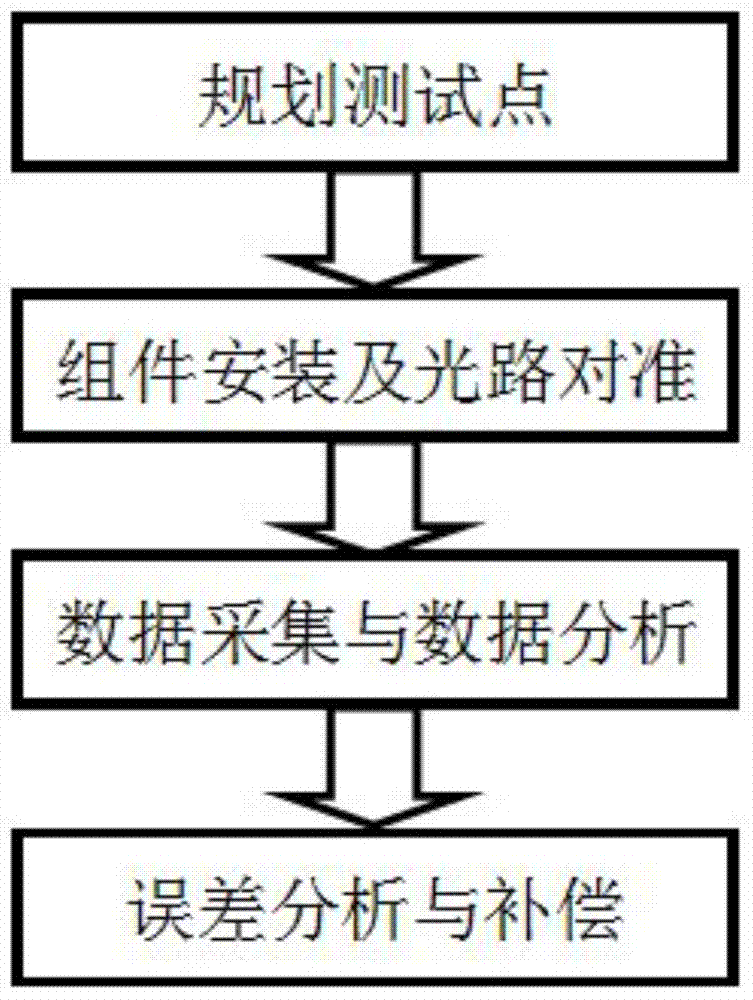

[0086] Step 1 Plan N test sampling points

[0087] Plan N test sampling points on the measured x-direction linear guide rail 5 at equal intervals.

[0088] Step 2 Component installation and optical path alignment

[0089] After planning the test sampling points, it is necessary to complete the component installation and optical path alignment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com