Method and device for measuring three-dimensional topography of nano structure

A technology of nanostructures and measurement methods, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to obtain three-dimensional shape information of nanostructures, and achieve the effect of promoting extended applications, wide application prospects, and high spectral sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

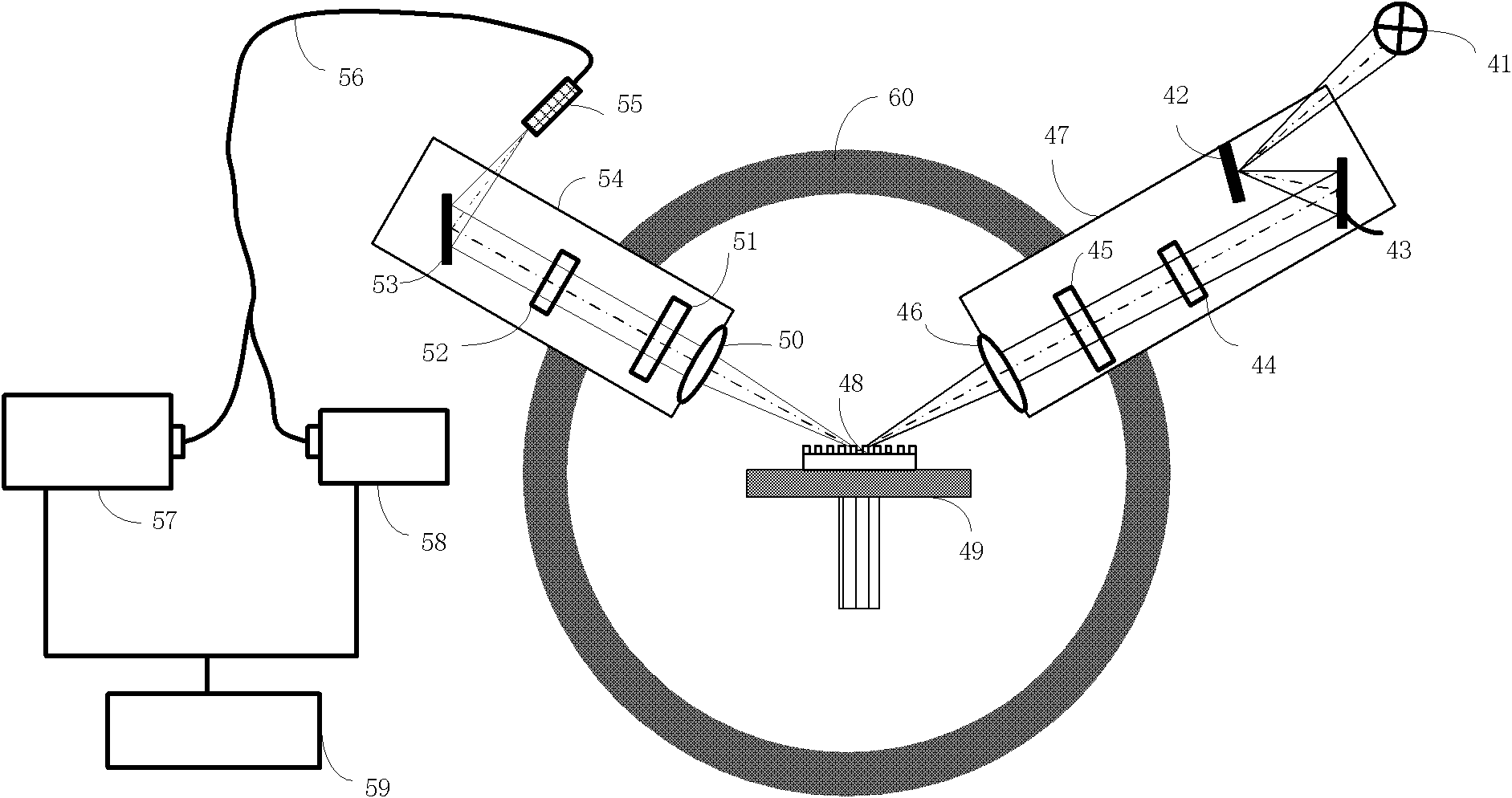

[0024] Below in conjunction with accompanying drawing and example the principle of the inventive method and working process are described in further detail:

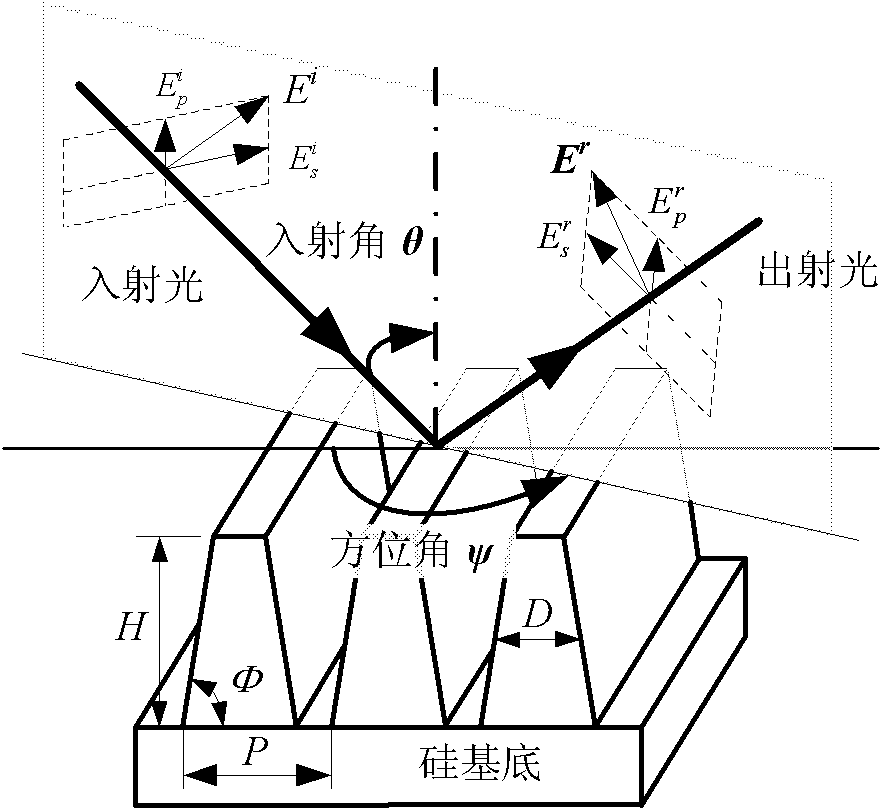

[0025] (1) After the incident beam with a wavelength ranging from ultraviolet to near-infrared is subjected to spectral splitting, polarization, and pre-phase compensation, an elliptically polarized beam is obtained and projected onto the surface of the structure to be measured containing nanostructures.

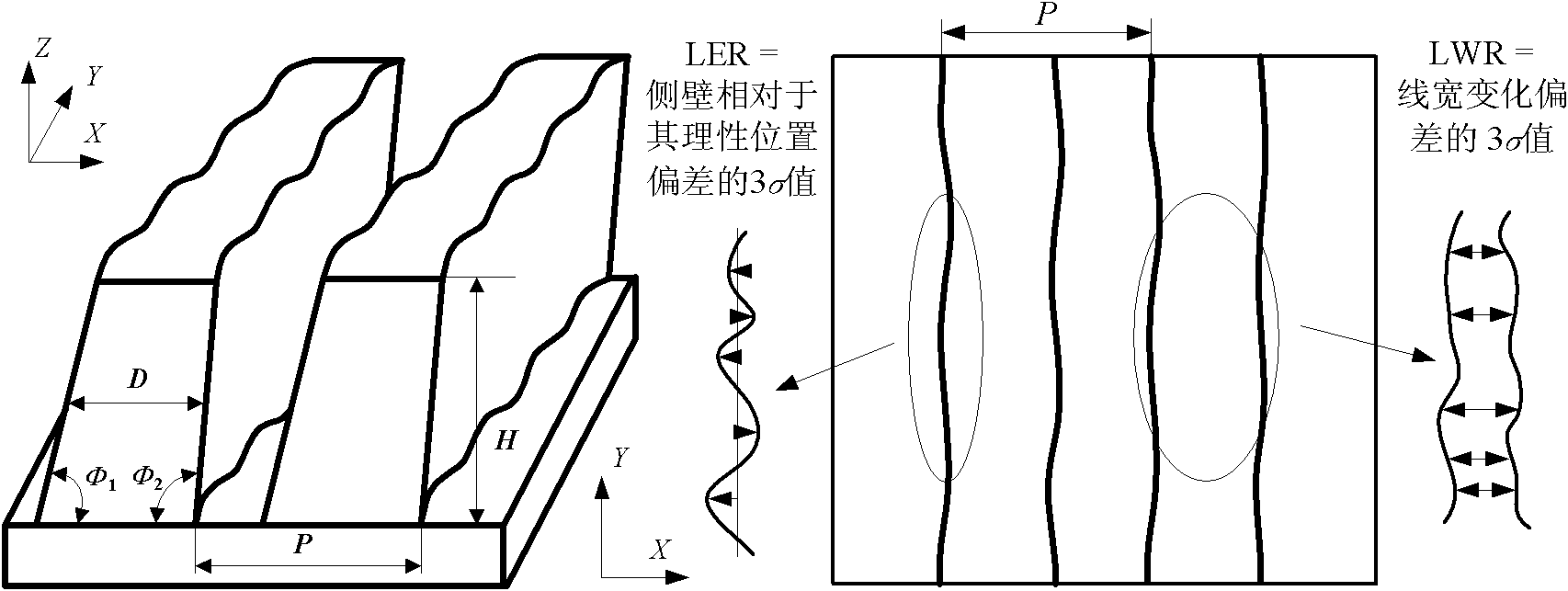

[0026] The wavelength of the incident beam can be selected from ultraviolet, visible light, near-infrared bands or a combination thereof according to the geometric characteristic scale of the structure to be measured. Taking the measurement process of the one-dimensional pattern array structure in the photolithography process as an example, the structure and shape parameters of the one-dimensional pattern array are as follows: figure 1 shown. The shape parameters of the one-dimensional graphic array structure to be me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com