A flat leaf area nondestructive measuring system and method thereof

A technology of blade area and measurement method, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of large measurement errors of blades and single blades, complicated and time-consuming operations, and high prices, so as to meet measurement needs, guarantee costs, and reduce costs. The effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Figure 1 is the calibration plate and the photos taken, in which the blade to be tested is attached to the calibration plate.

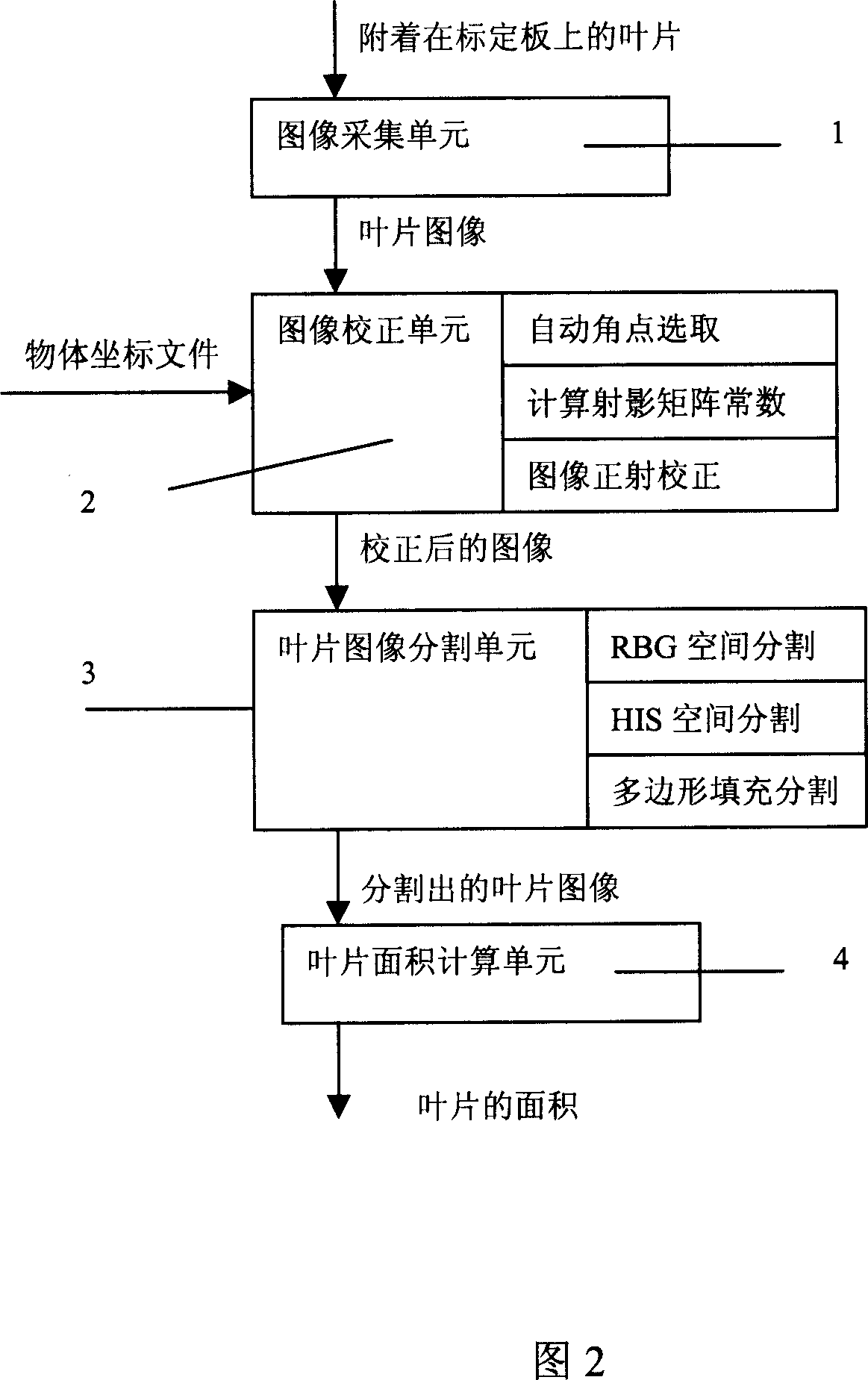

[0028] Fig. 2 The planar blade area non-destructive measurement system includes an image acquisition device, an image correction device, a blade image segmentation device, and a blade area calculation device. Wherein, the image acquisition unit, the image correction unit, the leaf image segmentation unit, and the leaf area calculation unit are sequentially connected to each other.

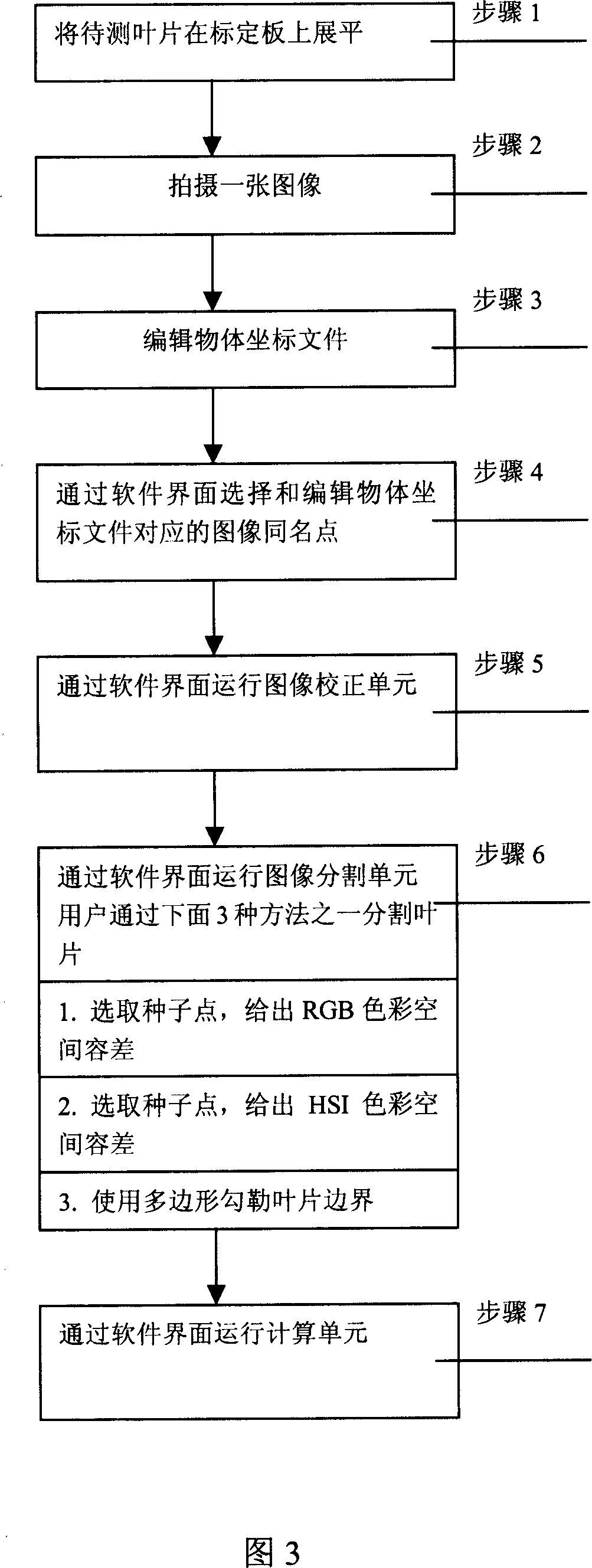

[0029] The specific operation process of the non-destructive measurement method of plane blade area in Fig. 3 is:

[0030] (1) Attach the blade to be measured to the calibration plate, flatten it, and use a digital camera to take an image of the calibration plate;

[0031] (2) The user creates an object coordinate file corresponding to the point with the same name in the image;

[0032] (3) Load image and corresponding point file with the same name;

[0033] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com