Method for configuring product multi-BOM tree based on base products

A configuration method and product technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as long design and manufacturing cycle, inconsistent configuration and version, and inability to understand logical affiliation at a glance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] Embodiment 1, taking the multi-BOM tree configuration of an automobile product as an example:

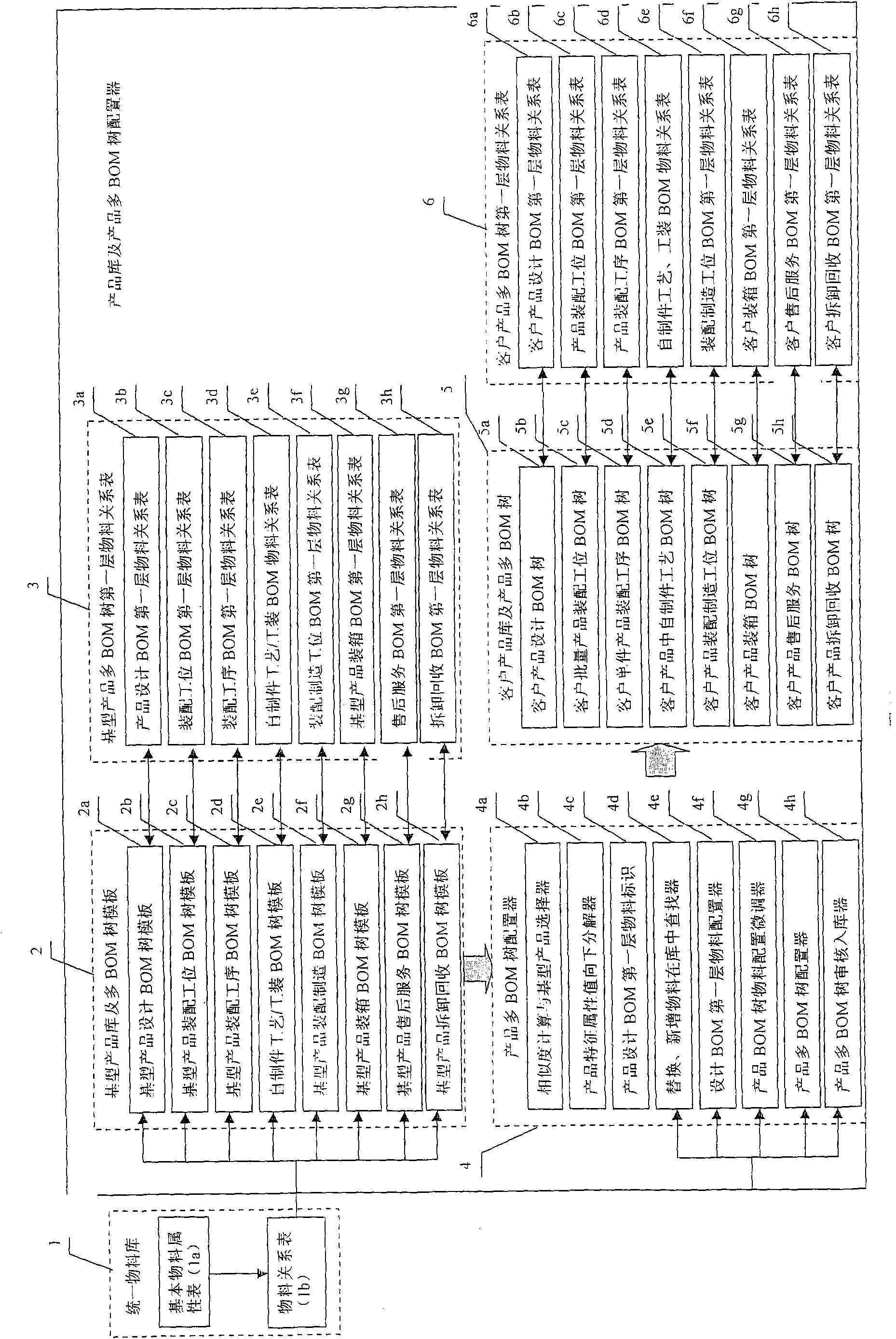

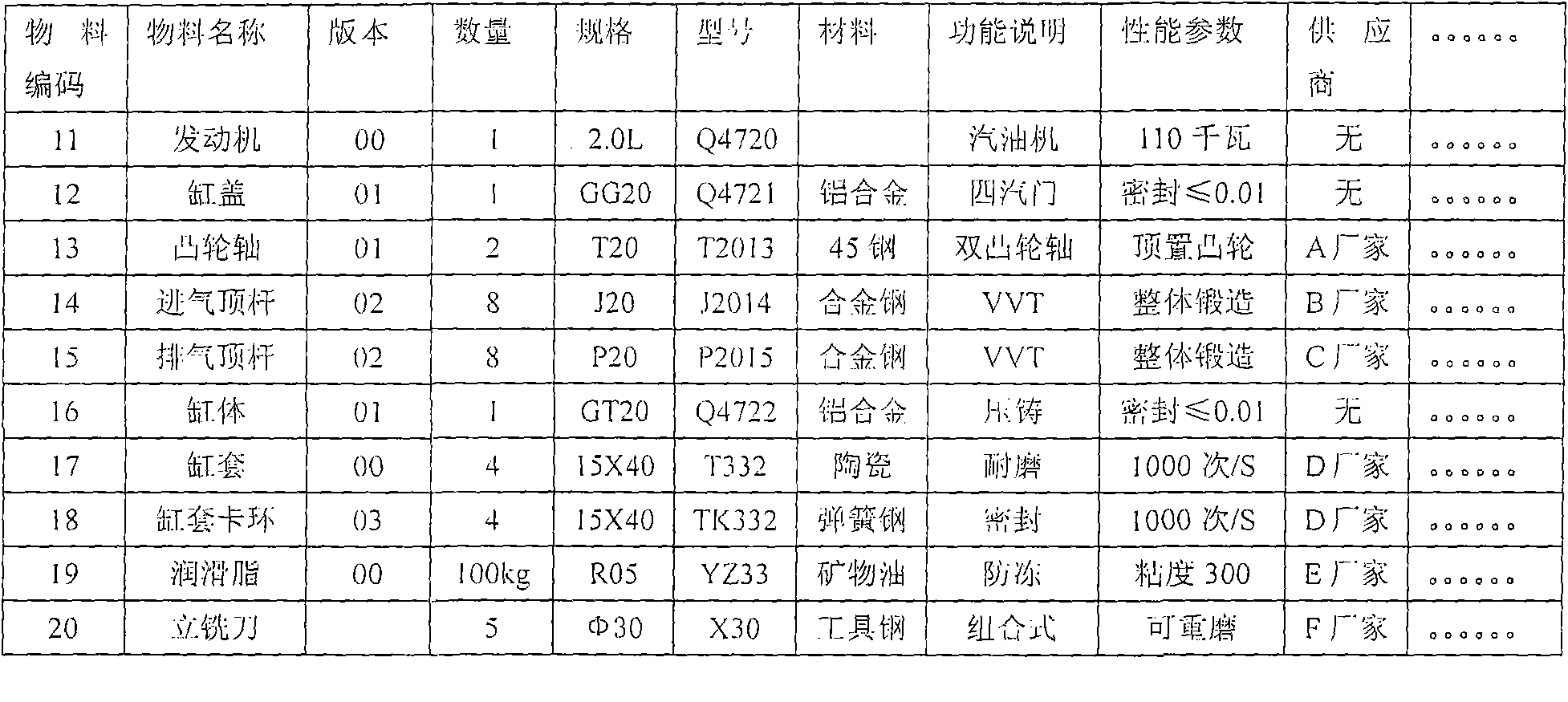

[0181] Such as figure 2 Shown: the basic material attribute table 1a and the material relationship table 1b are installed in the unified material library 1, and the input end of the material relationship table 1b is connected to the basic material attribute table 1a; each zero is listed in the basic material attribute table 1a. Item attributes such as code, name, version, weight, and material of components, raw and auxiliary materials, and tooling. The material name includes basic materials and their properties such as engine, cylinder head, camshaft, intake ejector rod, exhaust fixed rod, cylinder block, cylinder liner, cylinder liner snap ring, grease, end mill, etc.

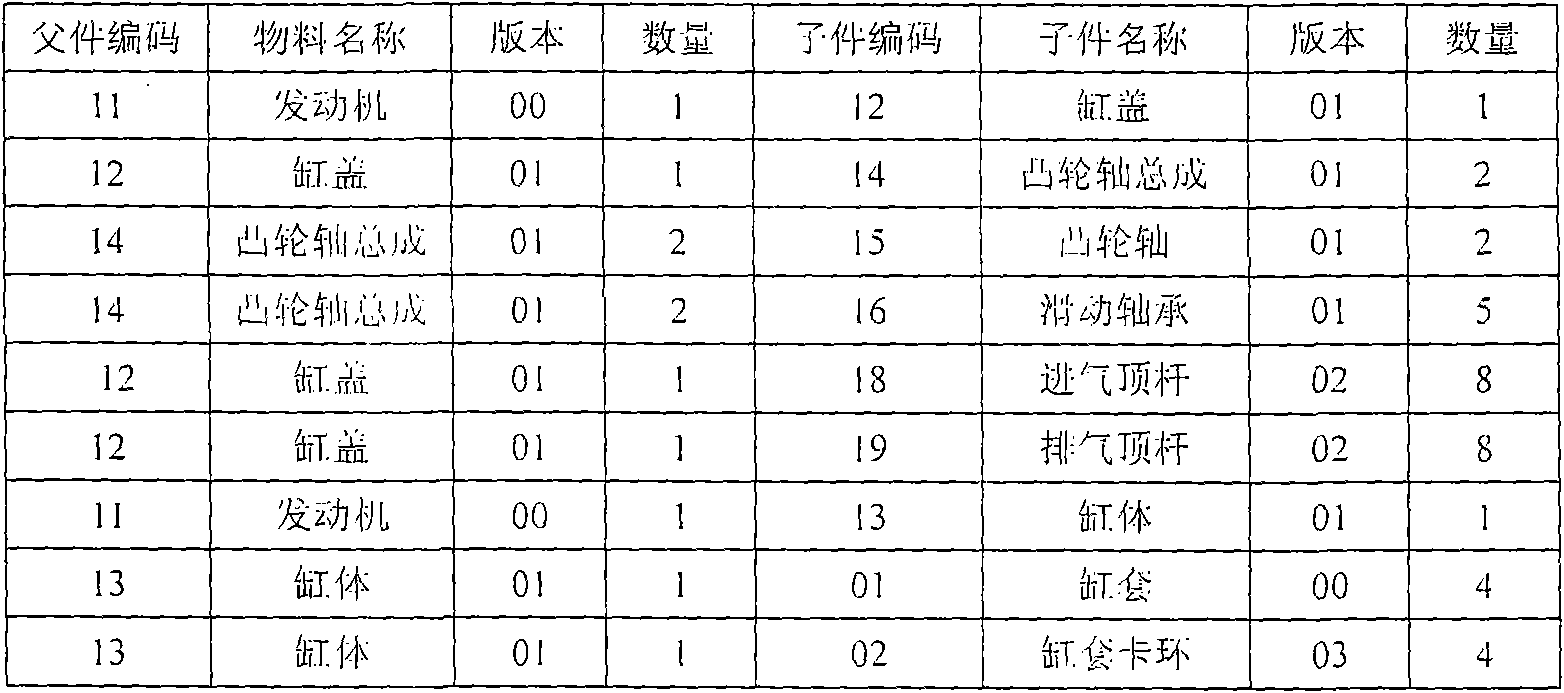

[0182] Such as image 3 Shown: The material relationship table 1b lists the material code, material name, component code and component name of each component in the engine. The first layer of material rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com