Patents

Literature

123 results about "Product information management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product information management (PIM) means managing the information required to market and sell products through distribution channels. A central set of product data can be used to share/receive information with media such as web sites, print catalogs, ERP systems, PLM systems and electronic data feeds to trading partners.

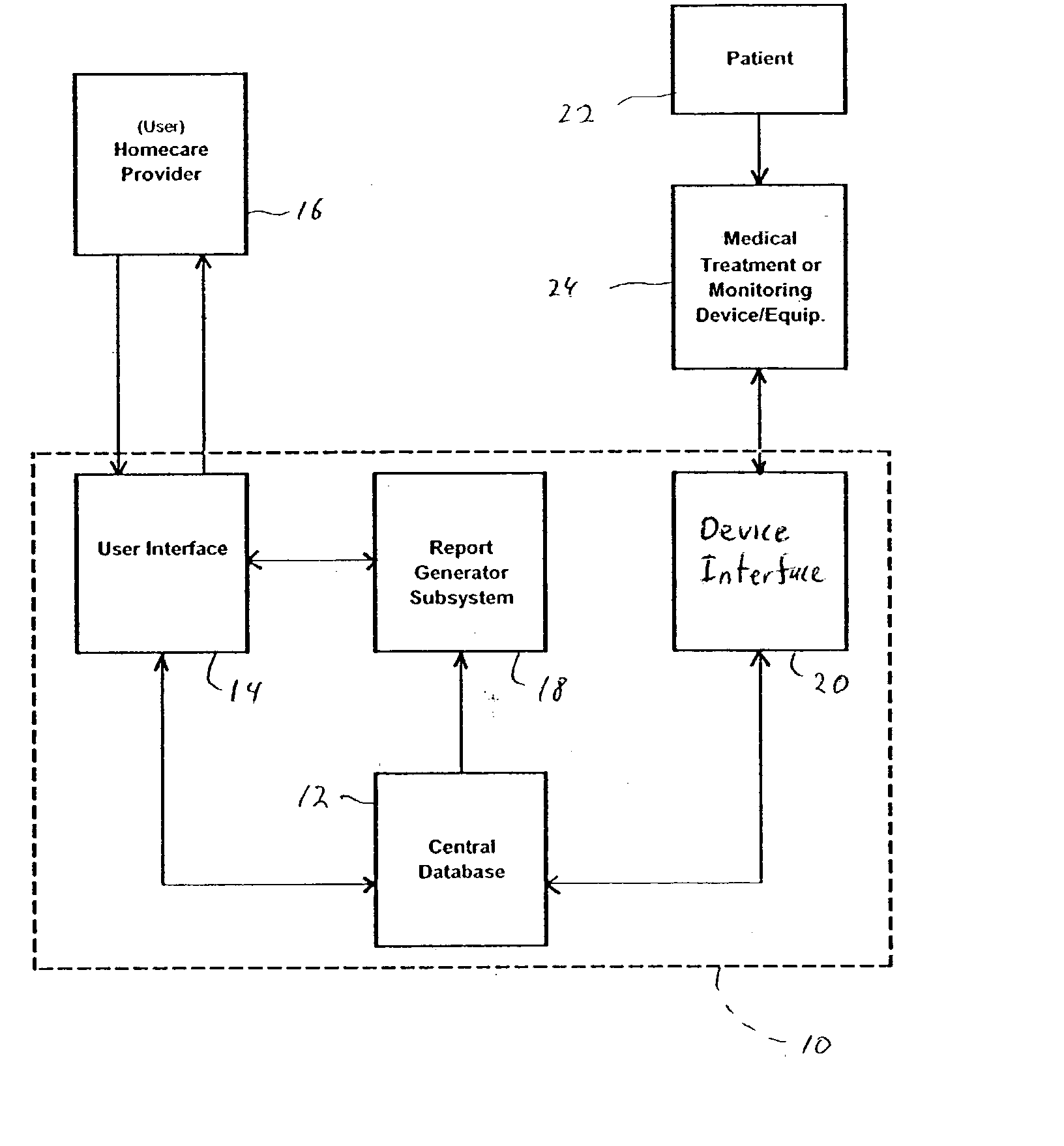

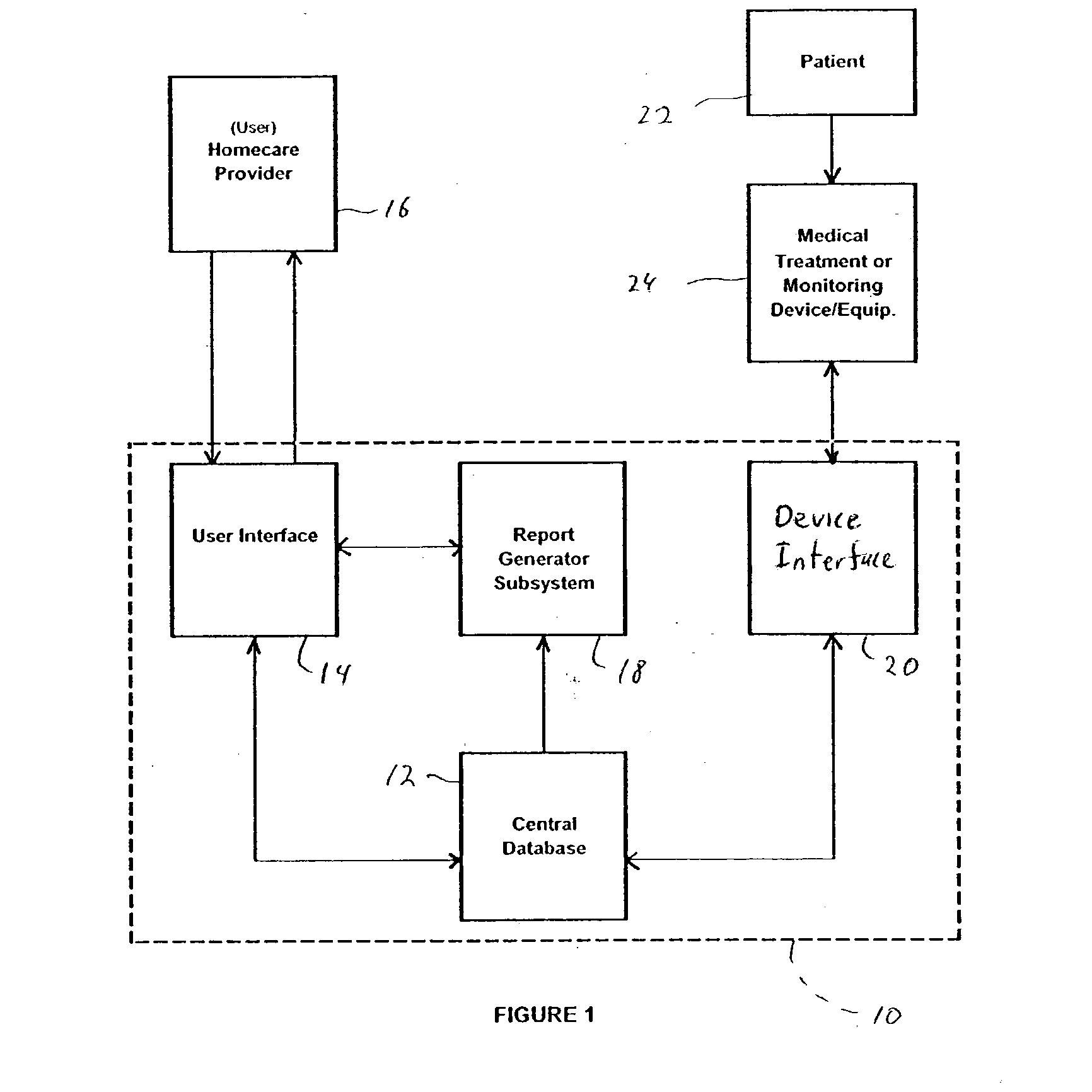

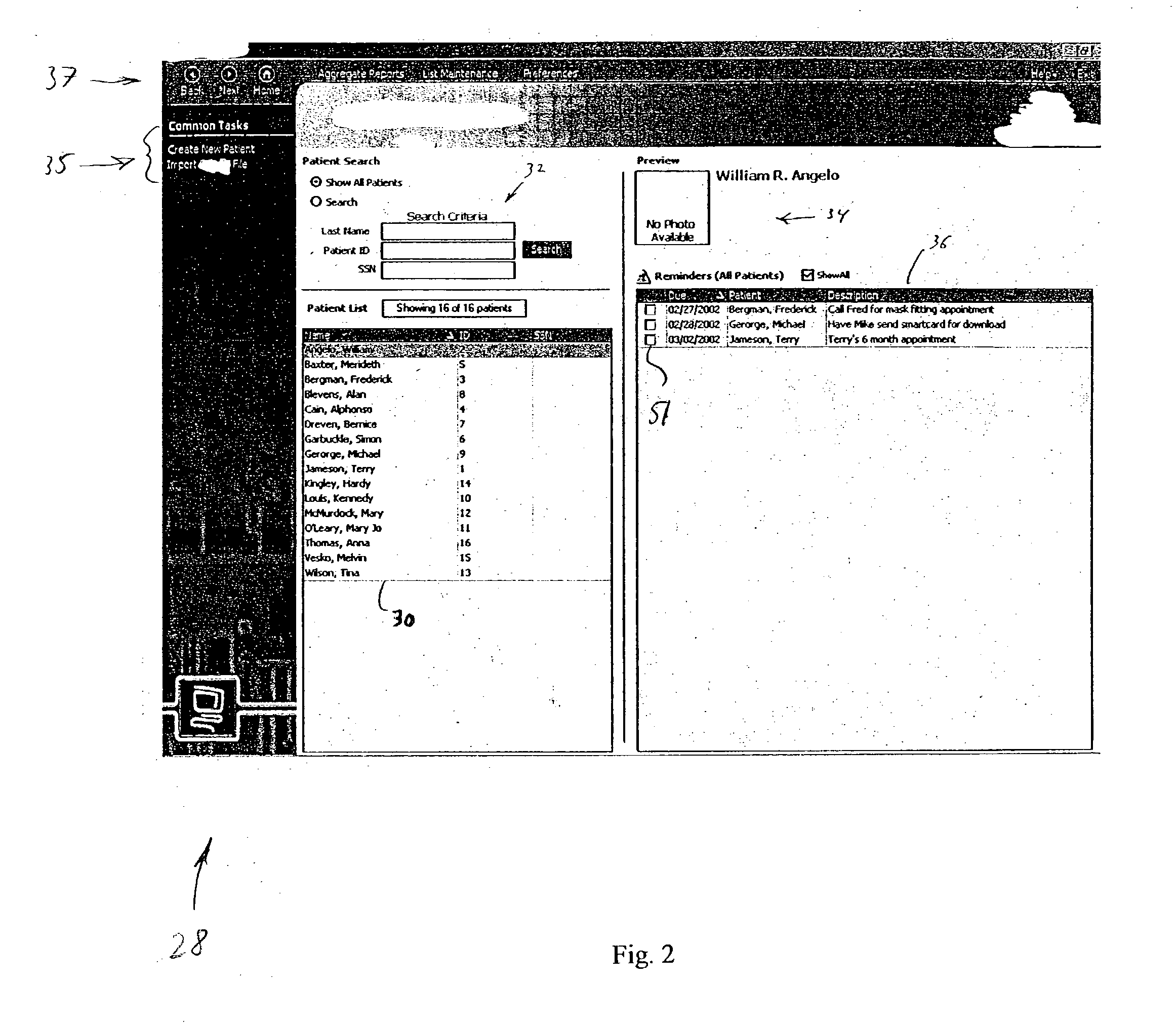

Method for managing medical information and medical information management system

InactiveUS20030208465A1None of data is presentedEffective trackingMechanical/radiation/invasive therapiesDigital data processing detailsUser inputData field

A computer-implemented method for managing medical information that includes the steps of: providing a central database of information having disparate data fields containing data, and performing an action based upon the data in the disparate data fields. The method includes of sorting, providing warnings or reminders, searching, organizing, transmitting, and presenting data from the database. The medical information management system includes a central database resident on a computing system. The central database has multiple disparate data fields containing data pertaining to patient-related information. A user interface communicates with the central database for accepting user input and transmitting system output. A visual display also communicates with the user interface to display the disparate data fields in selected or selectable formats. The system can include a report generating module, a device interface, and a compliance calculation module, all of which are in communication with the central database.

Owner:RIC INVESTMENTS LLC

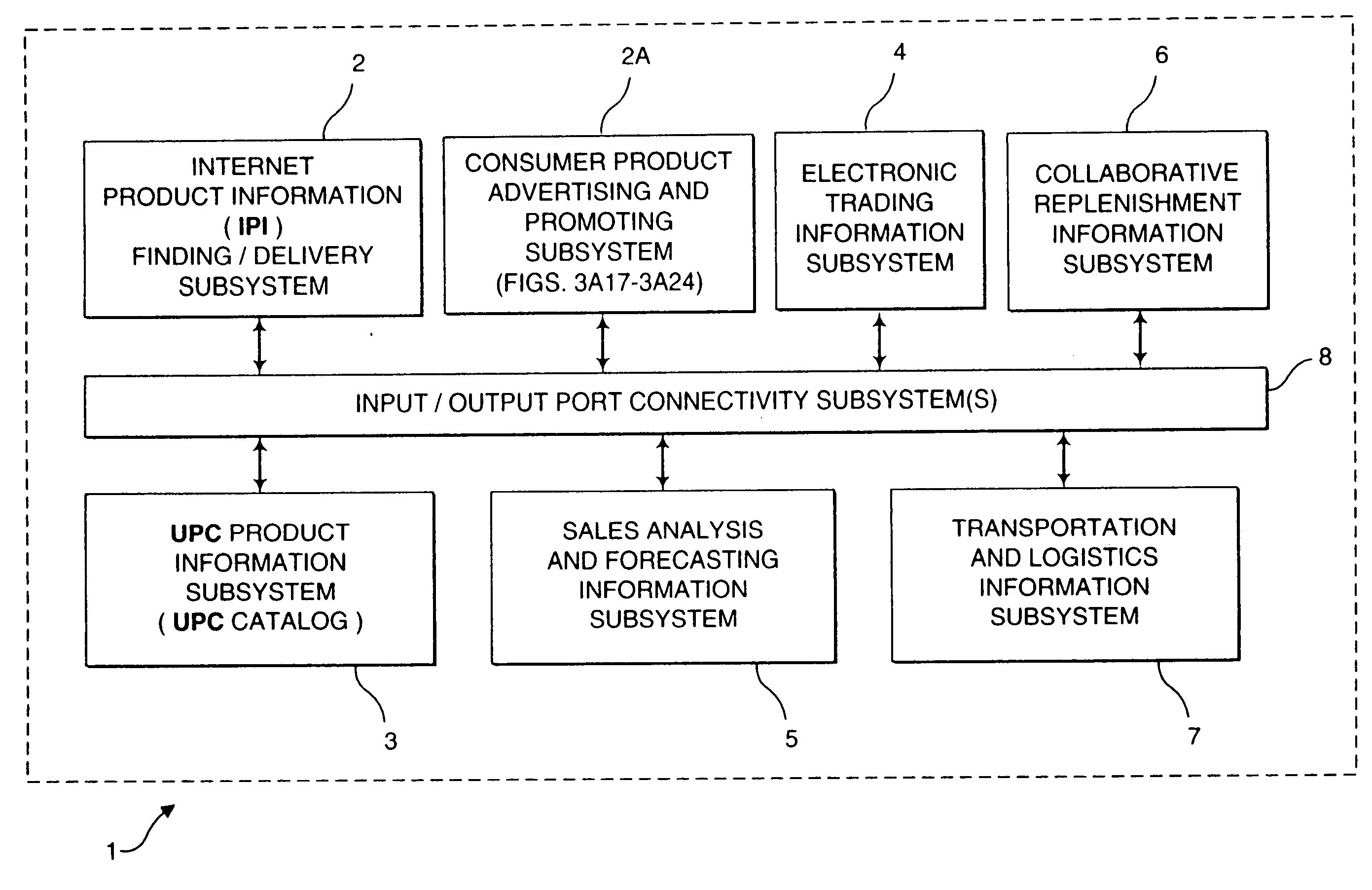

Internet-based method of and system for managing and serving consumer product advertisements to consumers in retail stores

InactiveUS20050251456A1Special data processing applicationsMarketingInformation resourceUniform resource locator

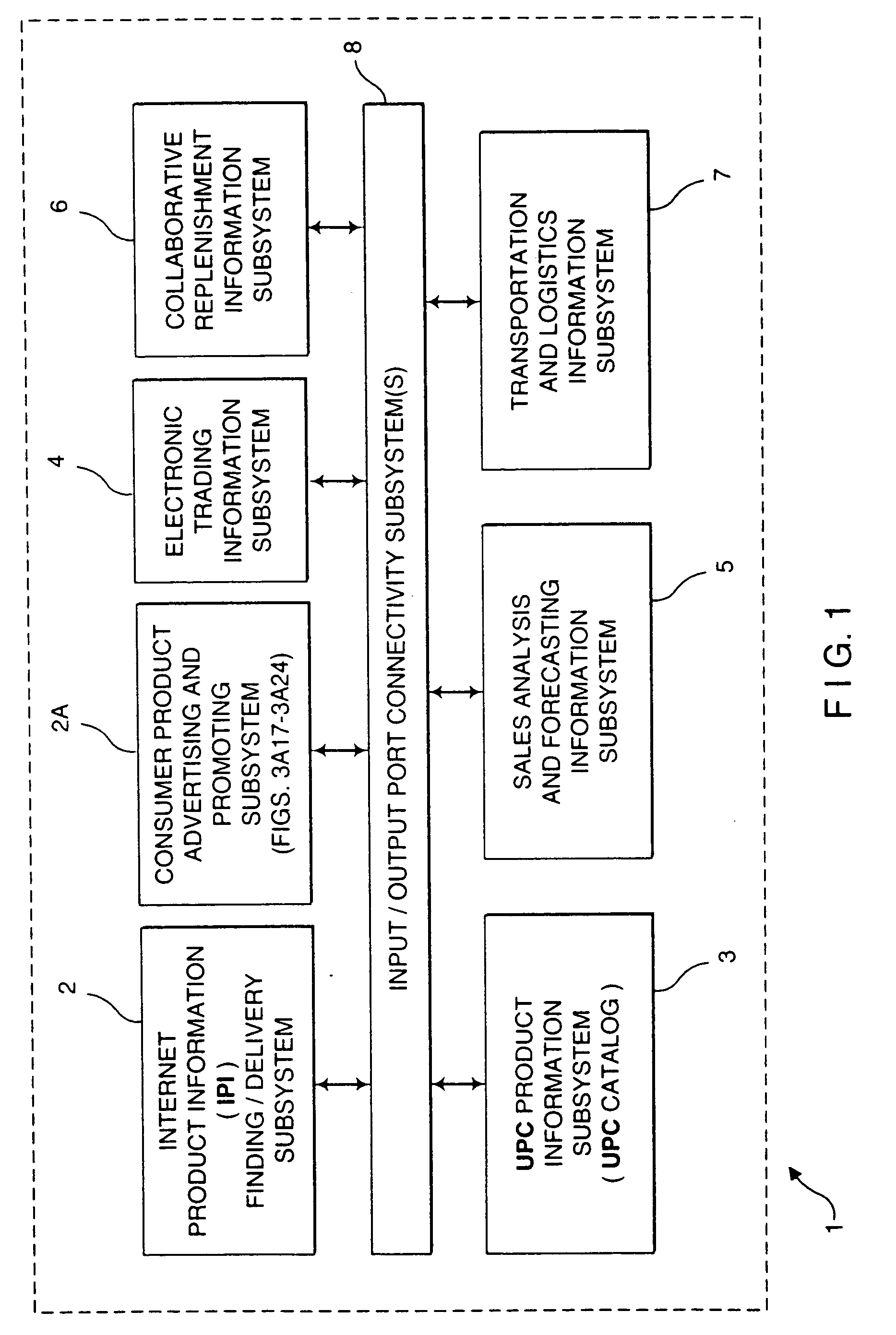

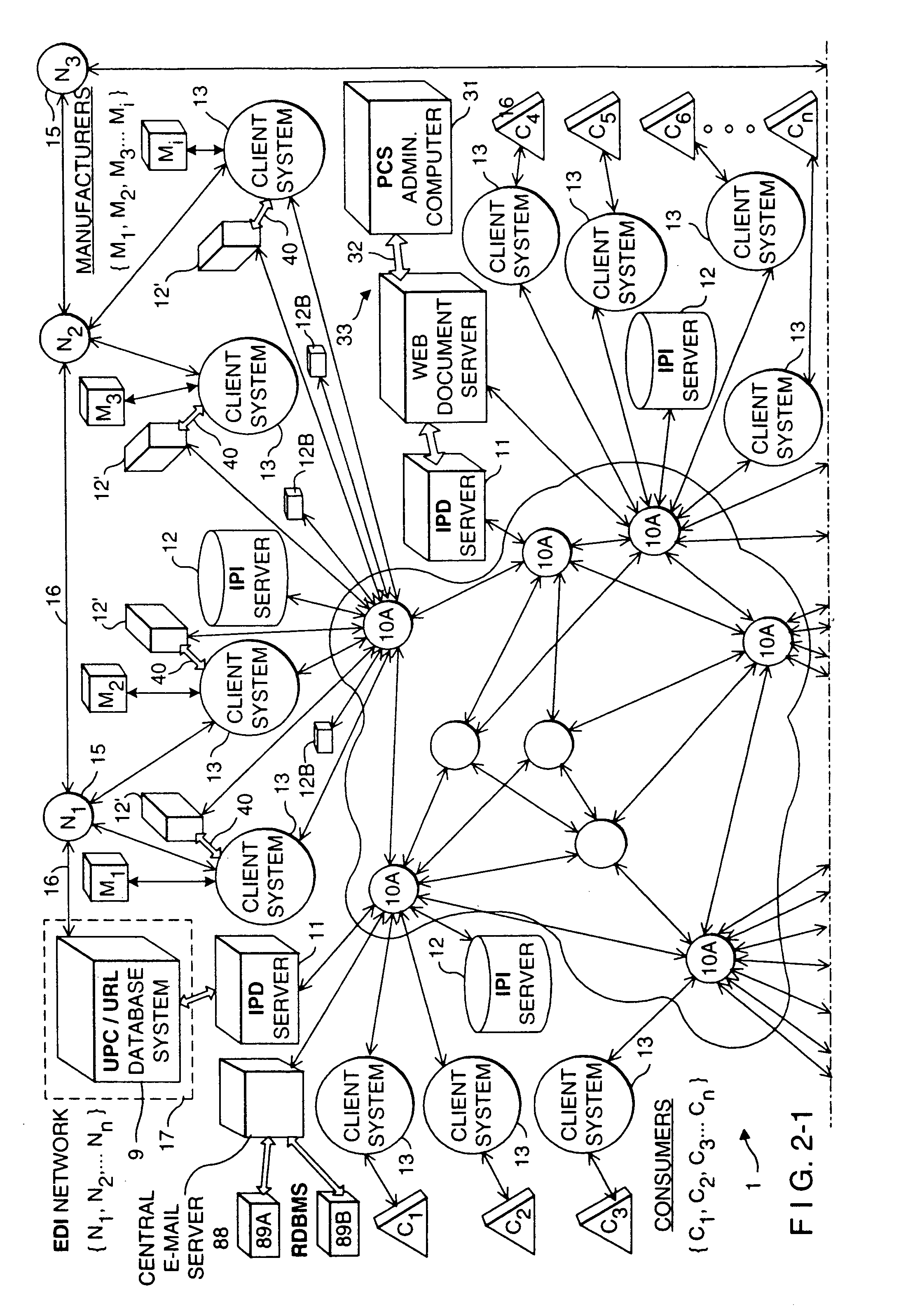

A retail-based consumer product information search and delivery system installed in a retail store environment and driven by a manufacturer-managed Internet-based consumer product information management and delivery network. The system comprises a subsystem of shelves for supporting one or more UPN-labeled products, and a plurality of product information kiosks operably connected to the Internet and mounted relative to the subsystem of shelves, and configured for reading UPN-encoded symbols on the UPN-labeled products and automatically displaying a plurality of URLs pointing to one or more information resources on the Internet that have been linked to the read UPN, by the manufacturer of the consumer product and / or an agent thereof. The manufacturer-managed Internet-based consumer product information management and delivery network enables manufacturers and / or their agents to manage and deliver manufacturer-specified product information resources to consumers having access to an Internet-enabled consumer product information kiosk installed within the retail store.

Owner:IPF

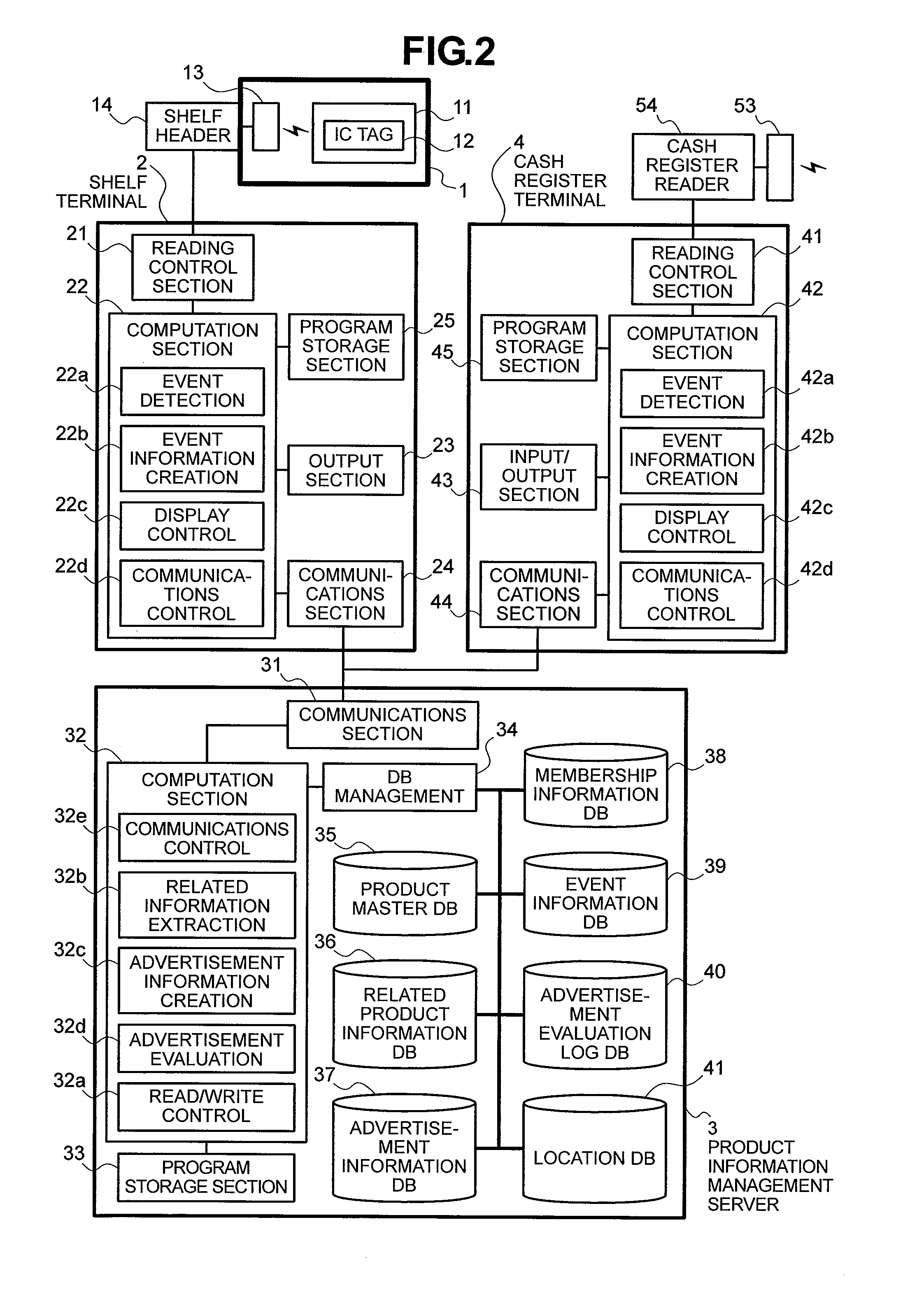

Product information provider system and method

InactiveUS20080215427A1Improve efficiencyIncrease salesAdvertisementsCo-operative working arrangementsProduct typeWorld Wide Web

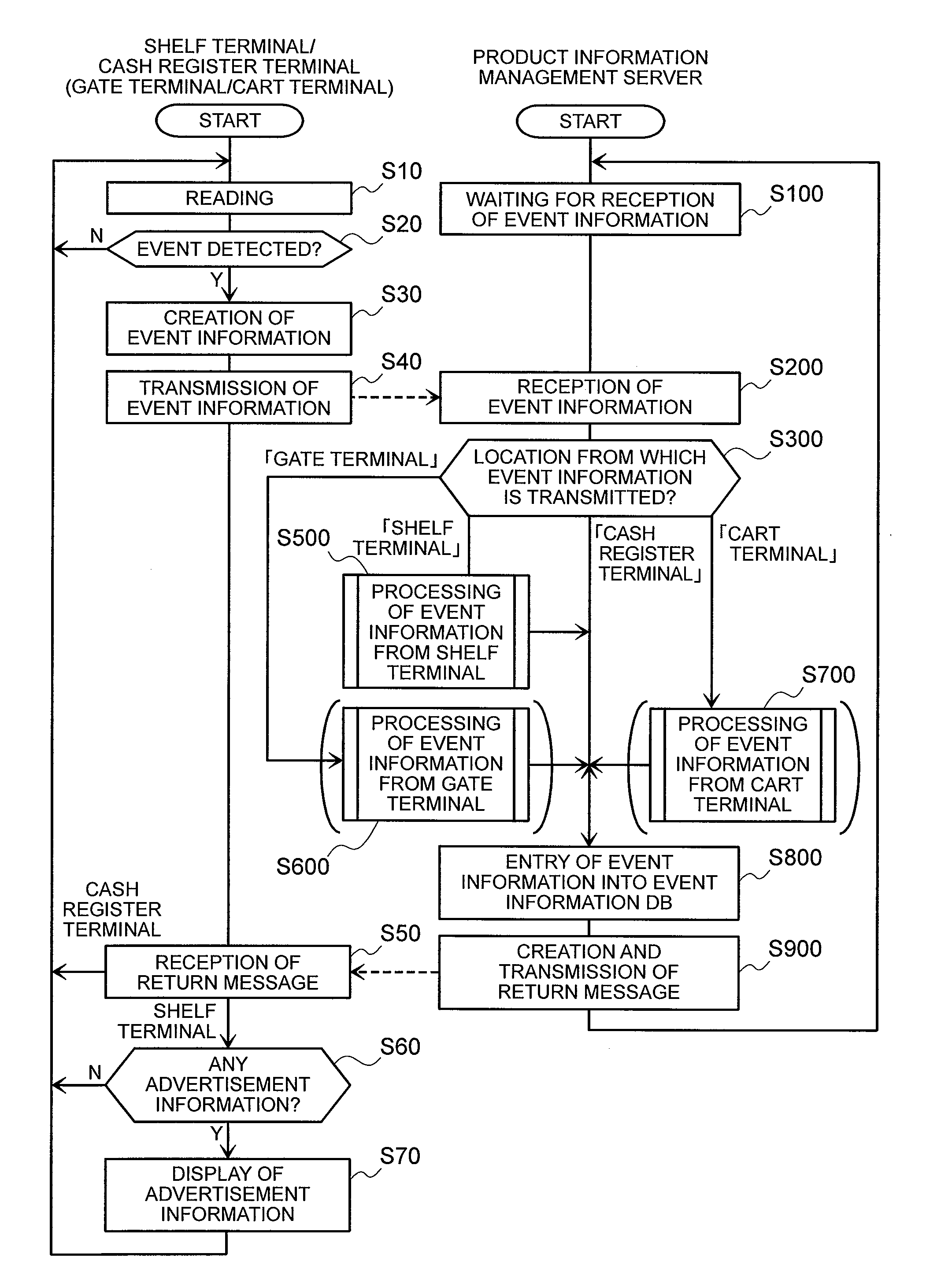

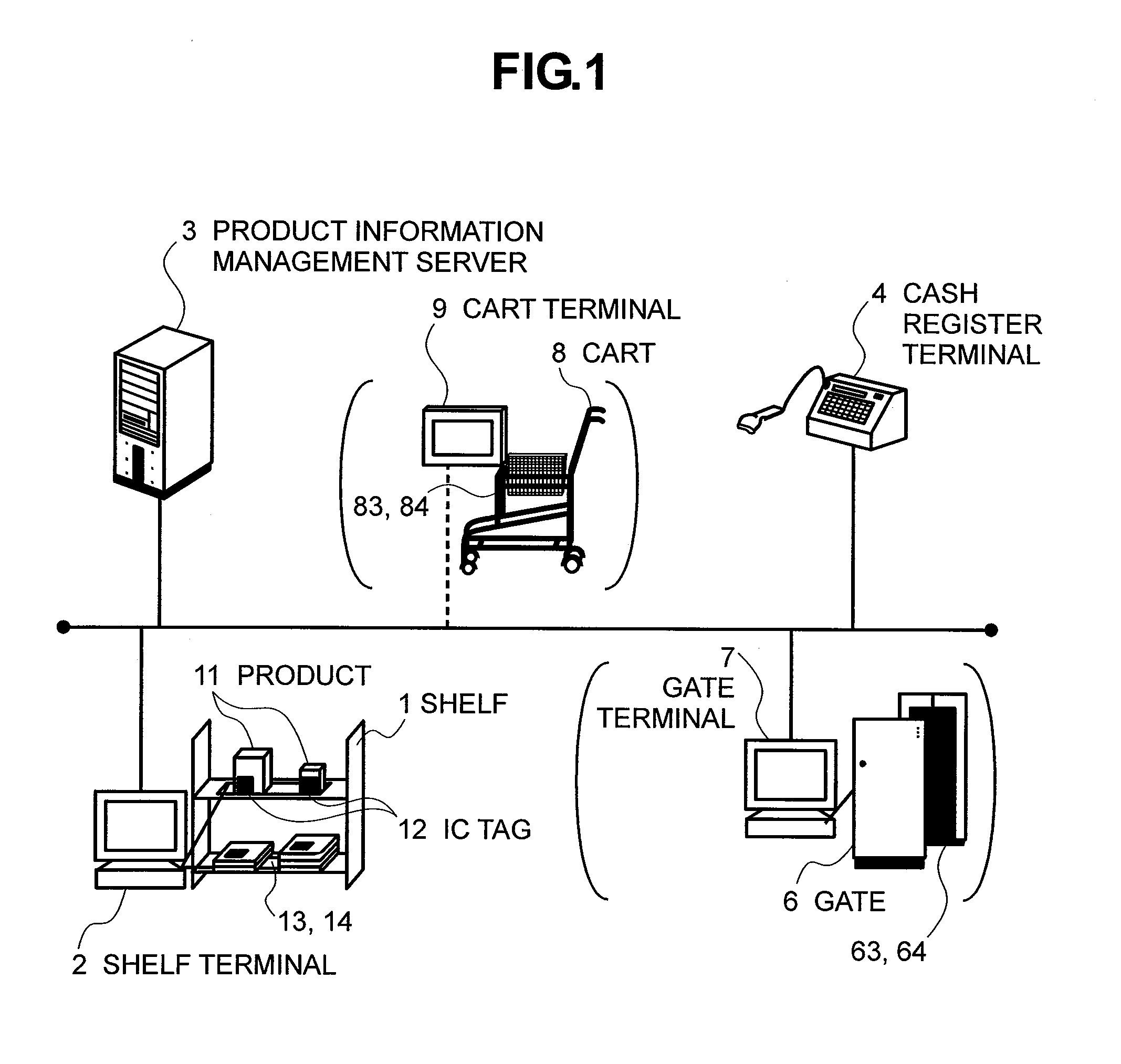

A shelf reader reads a product unique ID of an IC tag attached to a product on a shelf. In accordance with the reading result, a shelf terminal detects whether the product is taken out from the shelf or not, and forwards the detection result to a product information management server together with the product unique ID. In the product information management server, a related product information extraction section refers to a related product information database, and extracts any related product information including the type of the product taken out from the shelf. This related product information indicates a combination of a plurality of products that are considered preferable to purchase together. An advertisement information creation section creates advertisement information based on thus extracted related product information. The resulting advertisement information is forwarded to the shelf terminal, and then is displayed by an output section of the shelf terminal.

Owner:HITACHI LTD

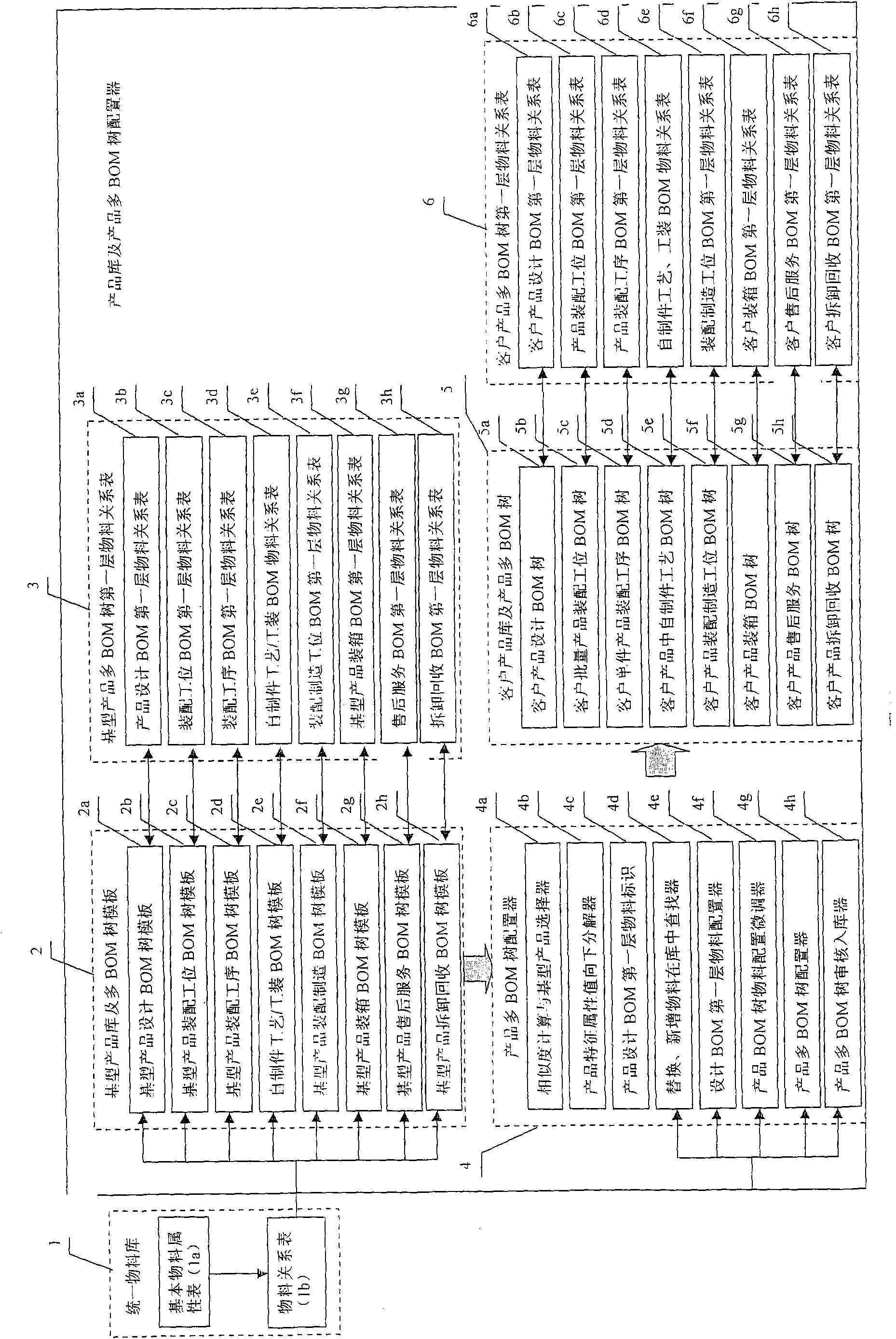

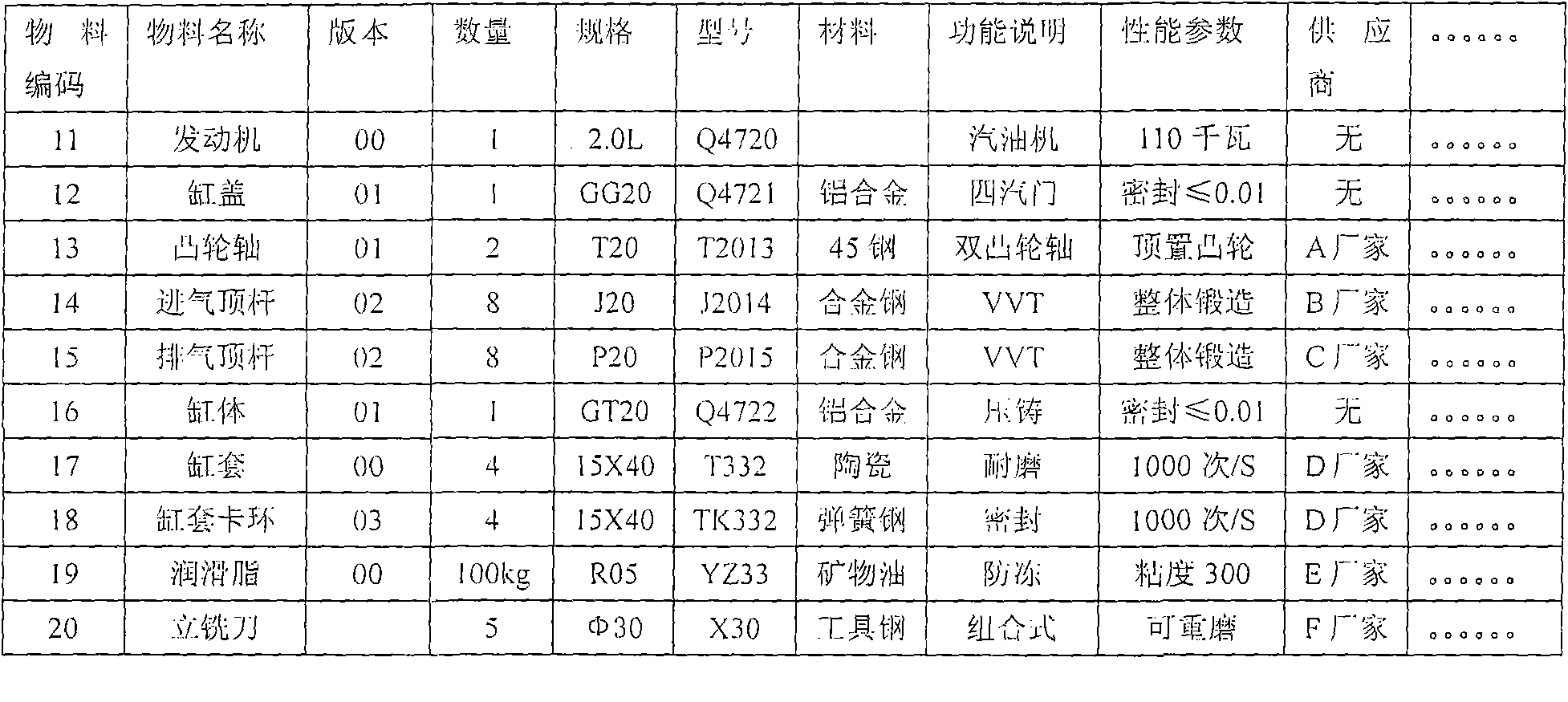

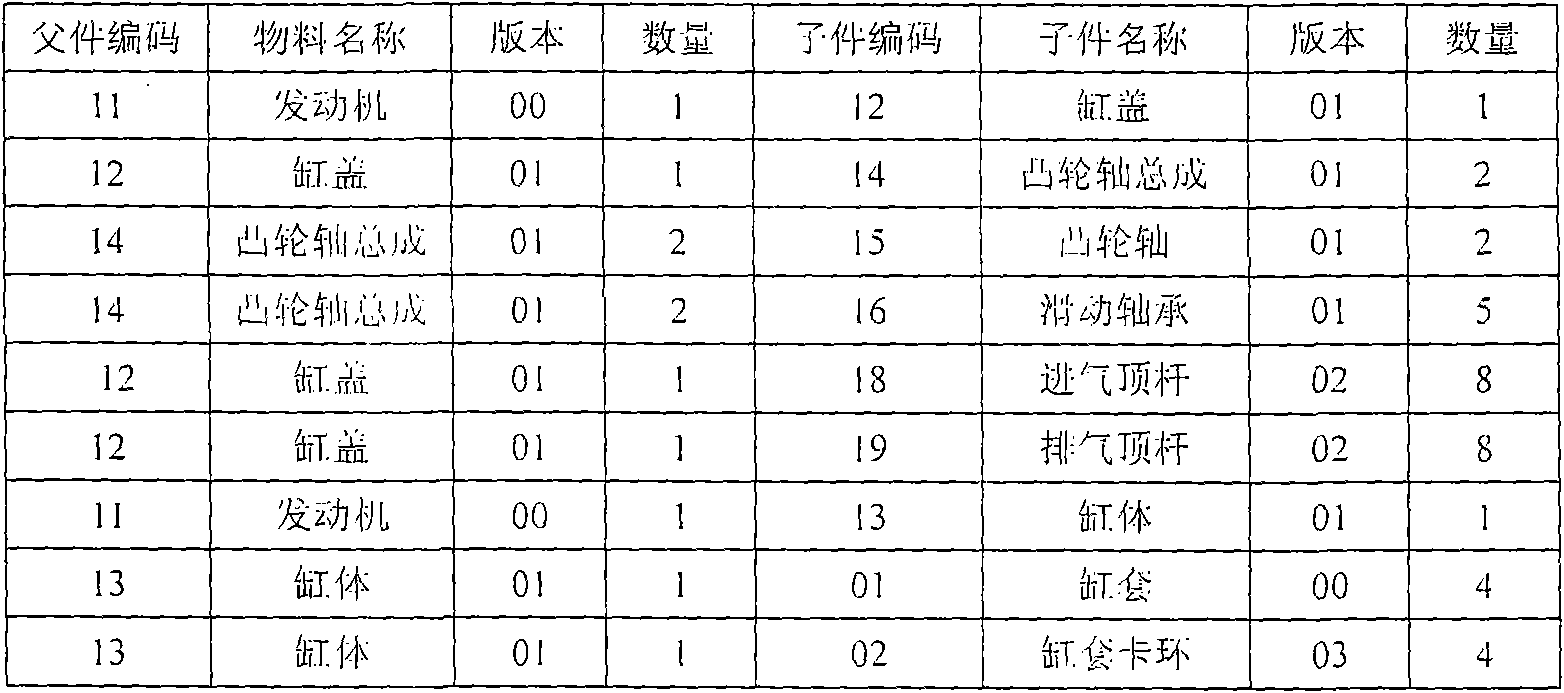

Method for configuring product multi-BOM tree based on base products

InactiveCN101937526AQuick configurationCost controlResourcesLogisticsProduct characteristicsProduct information management

The invention relates to a method for configuring a product multi-BOM tree based on base products, which is characterized by comprising the following steps of: establishment of a unified material library, a base product library and a product multi-BOM tree configurator; and selection of a base product design BOM and configuration of the product multi-BOM tree, which comprises the following processes of: decomposing client product feature attributes downwards; searching substituted and newly added materials; configuring first-layer materials of the product design BOM tree; finely adjusting the materials in the product BOM tree; and configuring the client product multi-BOM tree. The method has the obvious advantages of intuitively configuring the logic subordinate relationships among parts in the product at different stages of the life cycle, contributing to product information management, reducing the difficulty and workload of maintaining the consistency of information of the parts among different BOM tree structures and ensuring the effectiveness of data of each BOM tree structure of the product. The product multi-BOM tree configurator can be independently used and also can be embedded into a CAD / CAPP / PDM / ERP system.

Owner:重庆迈特科技有限责任公司

Automatic testing system for set-top box

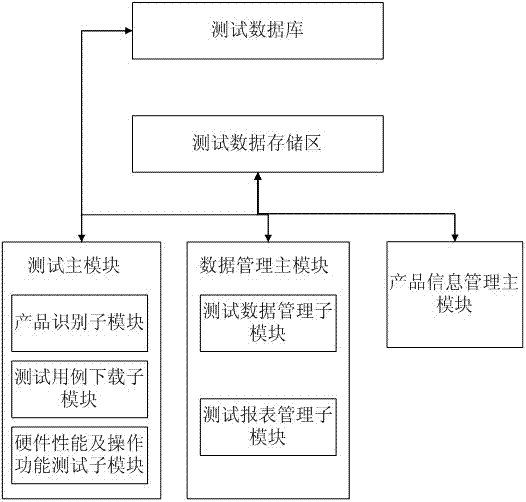

InactiveCN103079086ARealize fully intelligent automatic detectionImprove reliabilityTelevision systemsSelective content distributionExtensible markupData store

The invention discloses an automatic testing system for a set-top box. The automatic testing system comprises a testing database, a testing data storing area, a main testing module, a main data managing module, a main product information managing module and an interface layer, wherein the testing data storing area is used for storing testing data; the main testing module is used for identifying a product, downloading a testing case and testing hardware performance and operating functions; the main data managing module is used for managing testing data and managing testing reports; the main product information managing module is used for managing the serial number of the product and the information of a software version and a hardware version; and the interface layer is used for providing an expandable interface for each main module, and comprises a testing driving layer, a testing case layer, an XML (Extensible Markup Language) testing case managing layer and a testing applying layer. Due to the adoption of the automatic testing system, full-intelligence automatic detection of quality and function detection in the production process of the set-top box is realized, higher effectiveness and rapidness are realized, the reliability of testing is enhanced, the human cost is reduced, and the production cost is greatly saved.

Owner:UNIONMANTECH

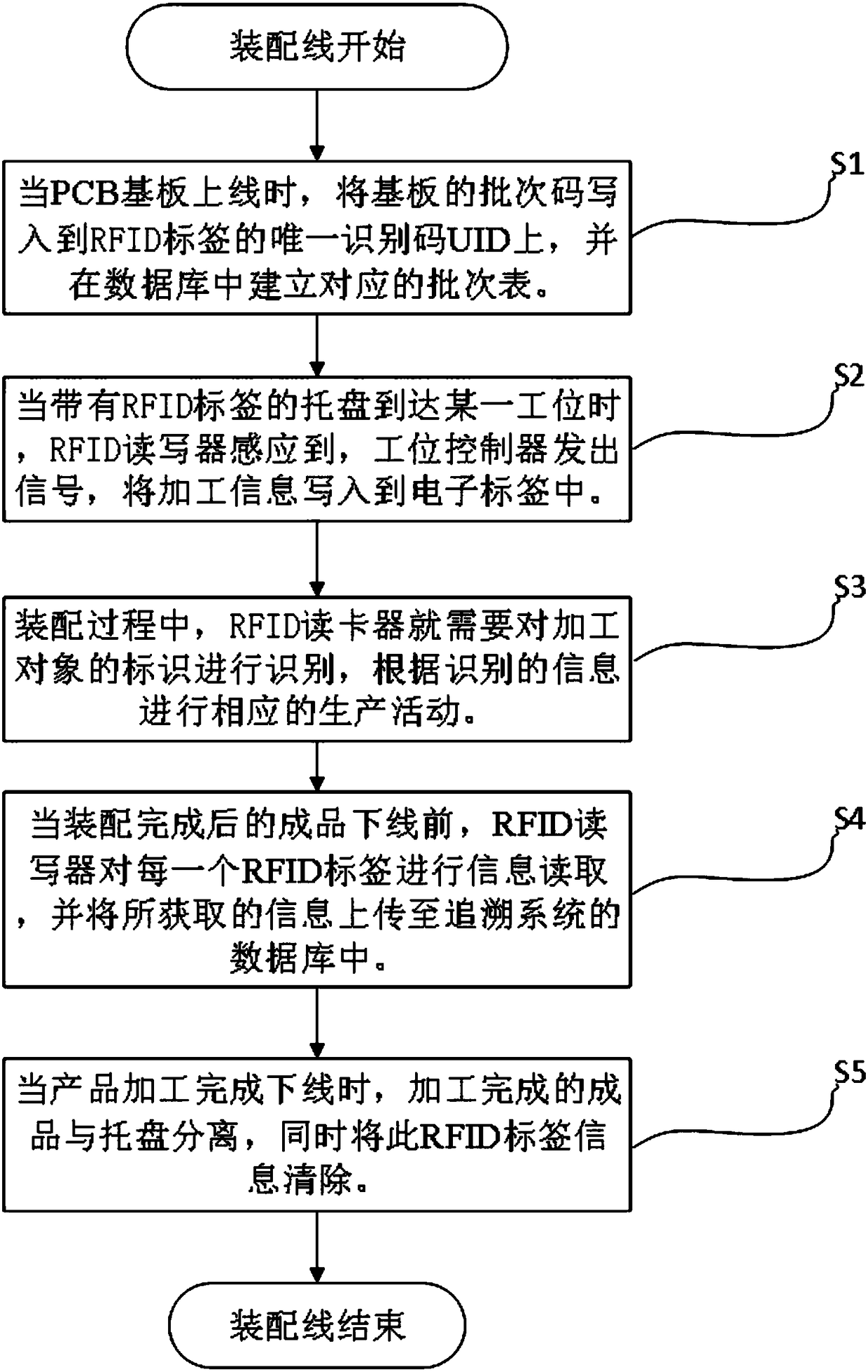

Product traceability method of electronic assembly process based on RFID tags

InactiveCN108182463ARealize all-round trackingImprove integrityCo-operative working arrangementsCommerceProduct traceabilityElectronic assemblies

The invention provides a product traceability method of an electronic assembly process based on RFID tags. By attaching RFID electronic tags to a tray carrying an electronic product and batch materials and providing a traceability system, the real-time tracking of each link of the electronic assembly process is achieved. By the set of traceability method, the problems of late information collection and incomplete data in the electronic assembly process be solved, quality-related assembly process information such as personnel, equipment, a production environment and processing parameters in theelectronic assembly process can be traced, a disadvantage that only the composition relationship between materials and components can be recorded in original product traceability is improved, thus the product traceability in the electronic assembly process is more comprehensive, detailed and efficient. The method can be widely applied to product information management and quality management in the electronic assembly industry.

Owner:NANJING UNIV OF SCI & TECH

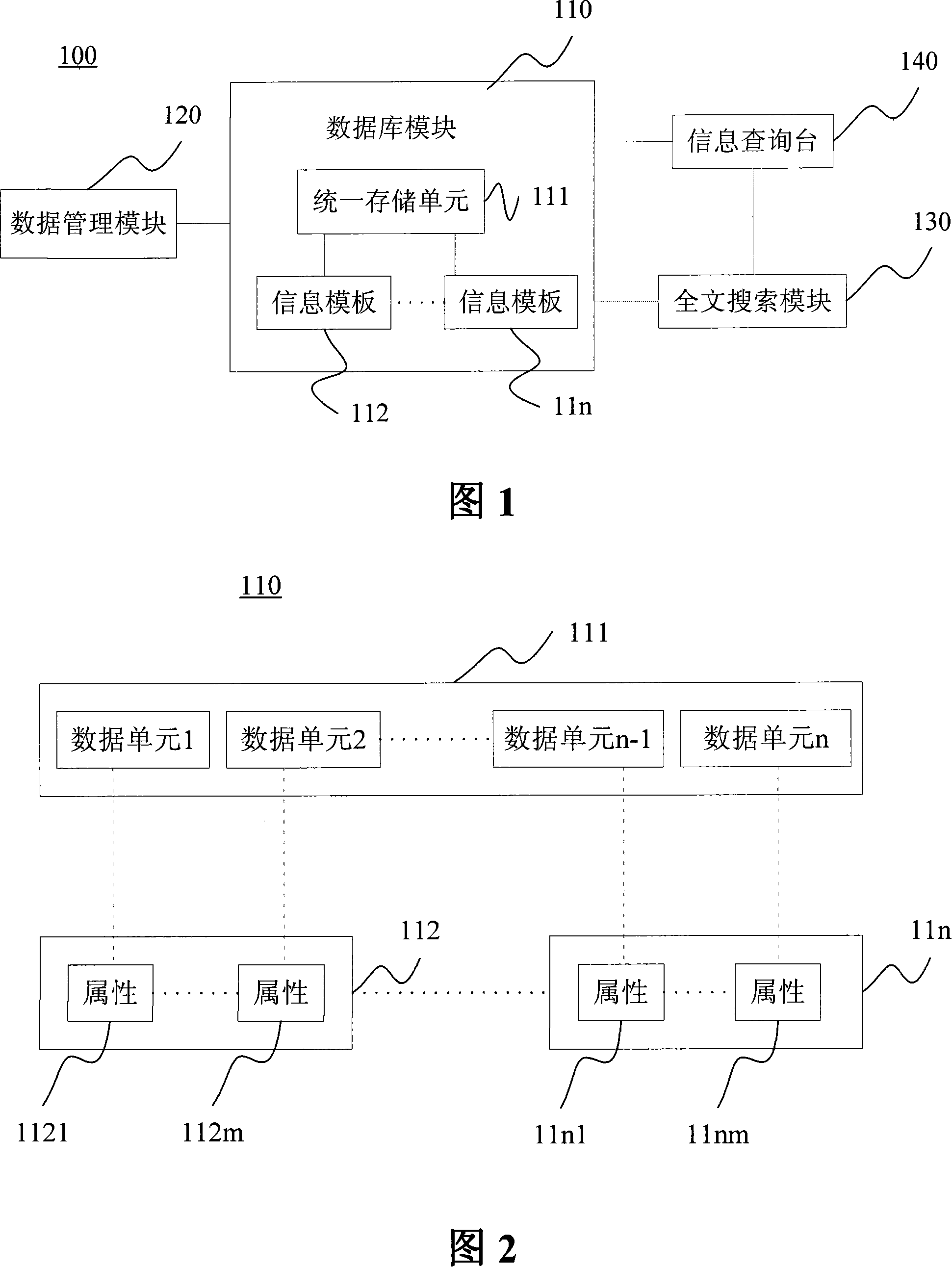

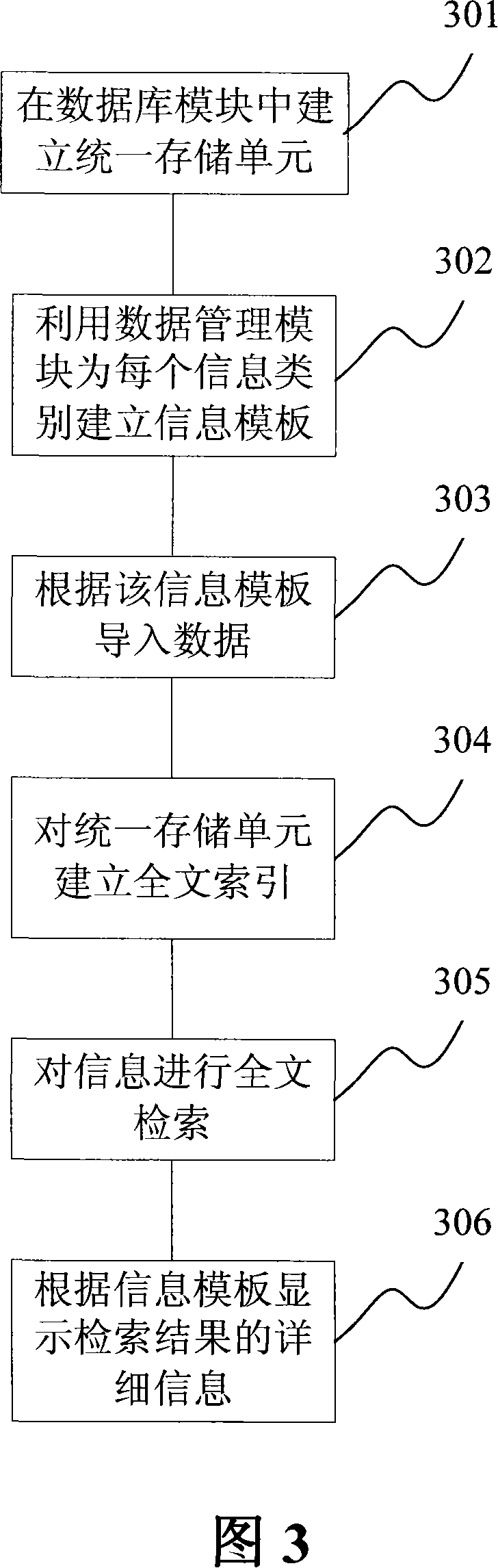

Information management system and information management method

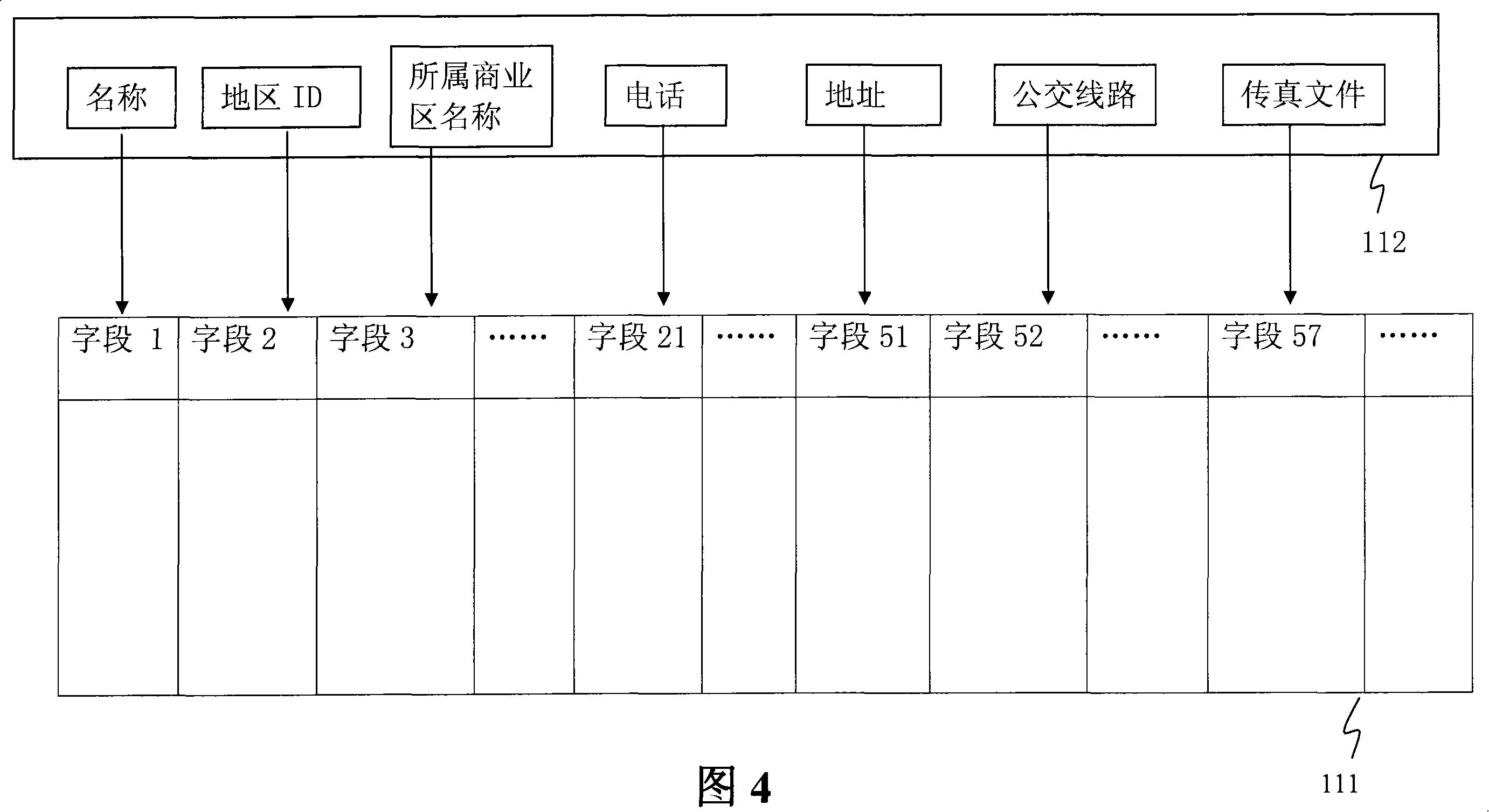

InactiveCN101141525ARealize individual needsMeet various needsSpecial service for subscribersData switching by path configurationPersonalizationInformation type

The present invention discloses an information management system and an information management method. The system comprises: a data base module which comprises a uniform storage unit and at least an information template; the uniform storage unit comprises a plurality of data units, used for storing the data information of a great variety of information categories; each information template is utilized to analyze the data information of an information category, each information template is defined into one or more property(s) of the information category, each property relates to a data unit, each property is defined with a storage rule for indicating the data validity of the data unit, and the data stored in the data unit is accorded with the storage rule; a data management module is used for creating the uniform storage unit and the information template, and importing the data into the uniform storage unit according to the information template. The present invention can realize the uniform storage and uniform management of different information. The individualized demands of different information categories are realized, and the seamless supporting for the new information is extended or added.

Owner:ZTE CORP

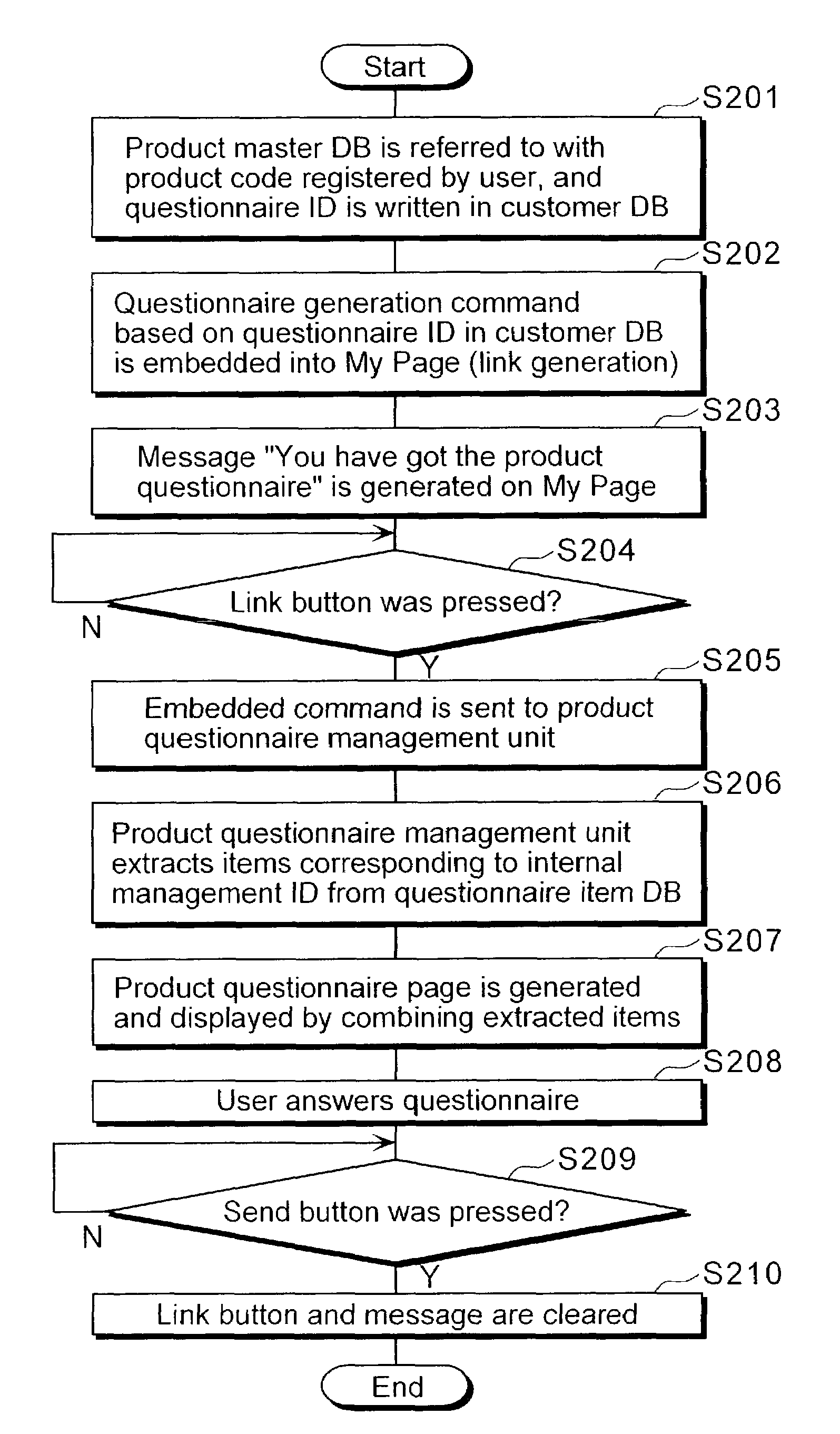

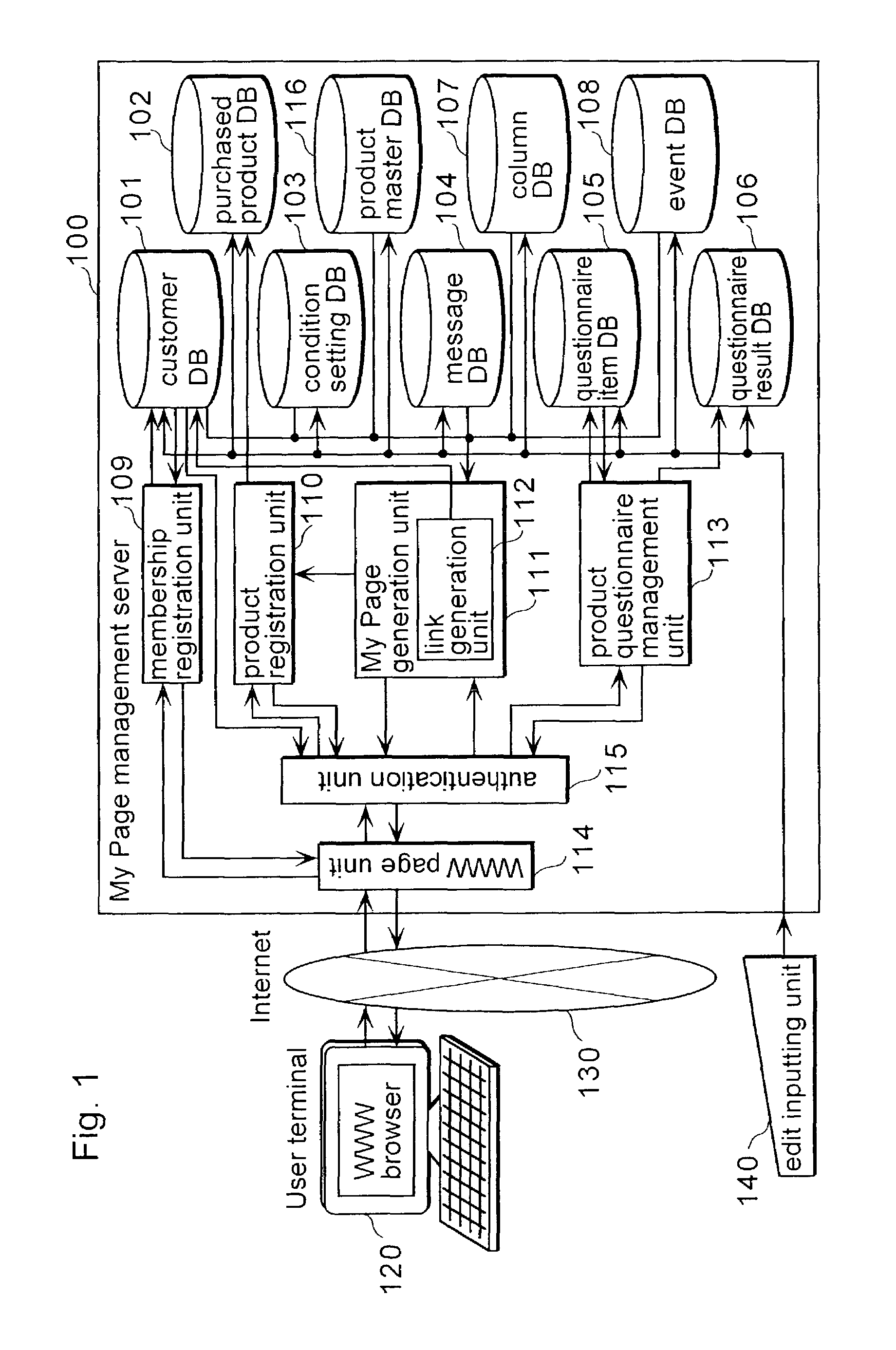

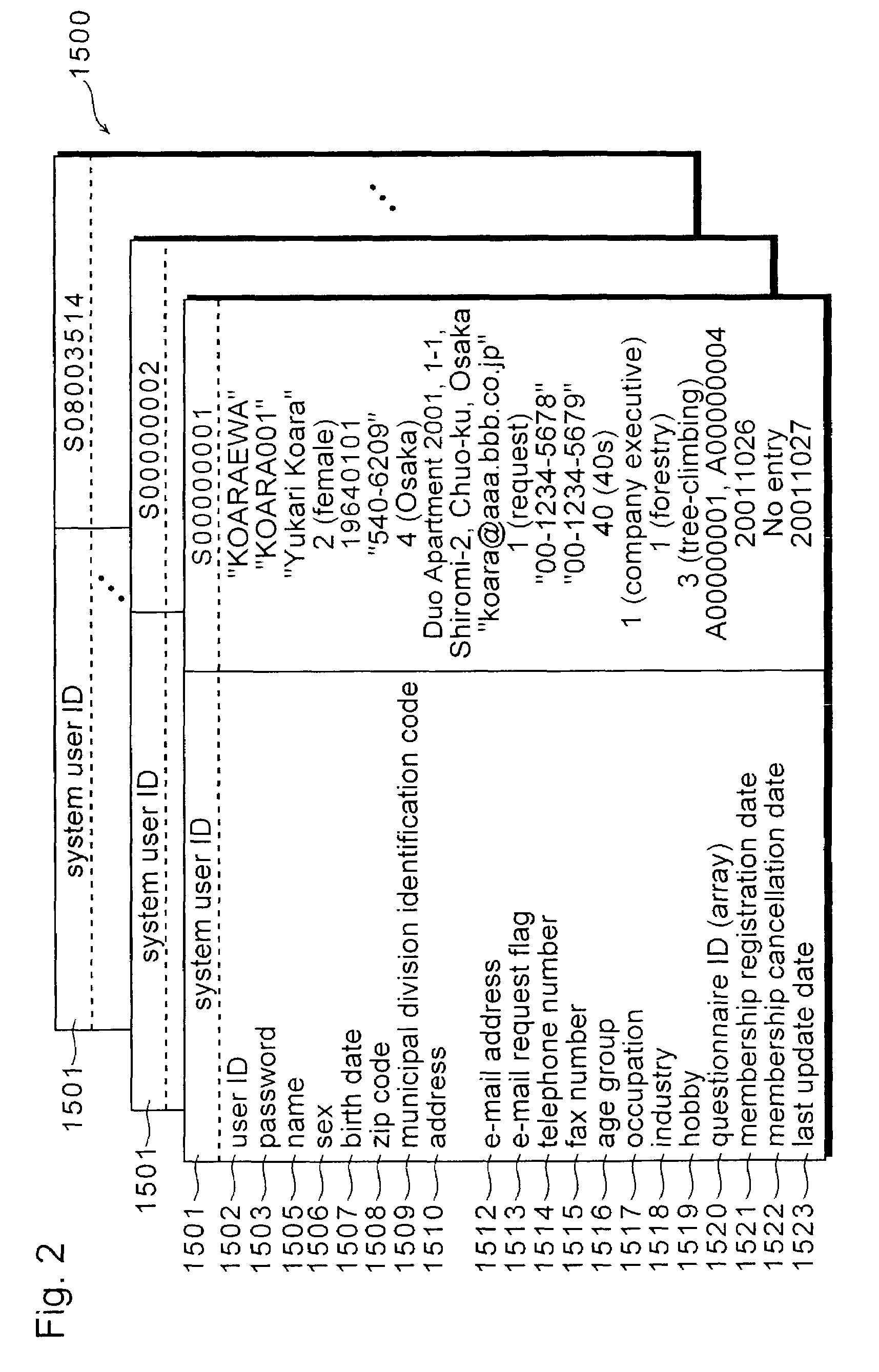

Product information management device

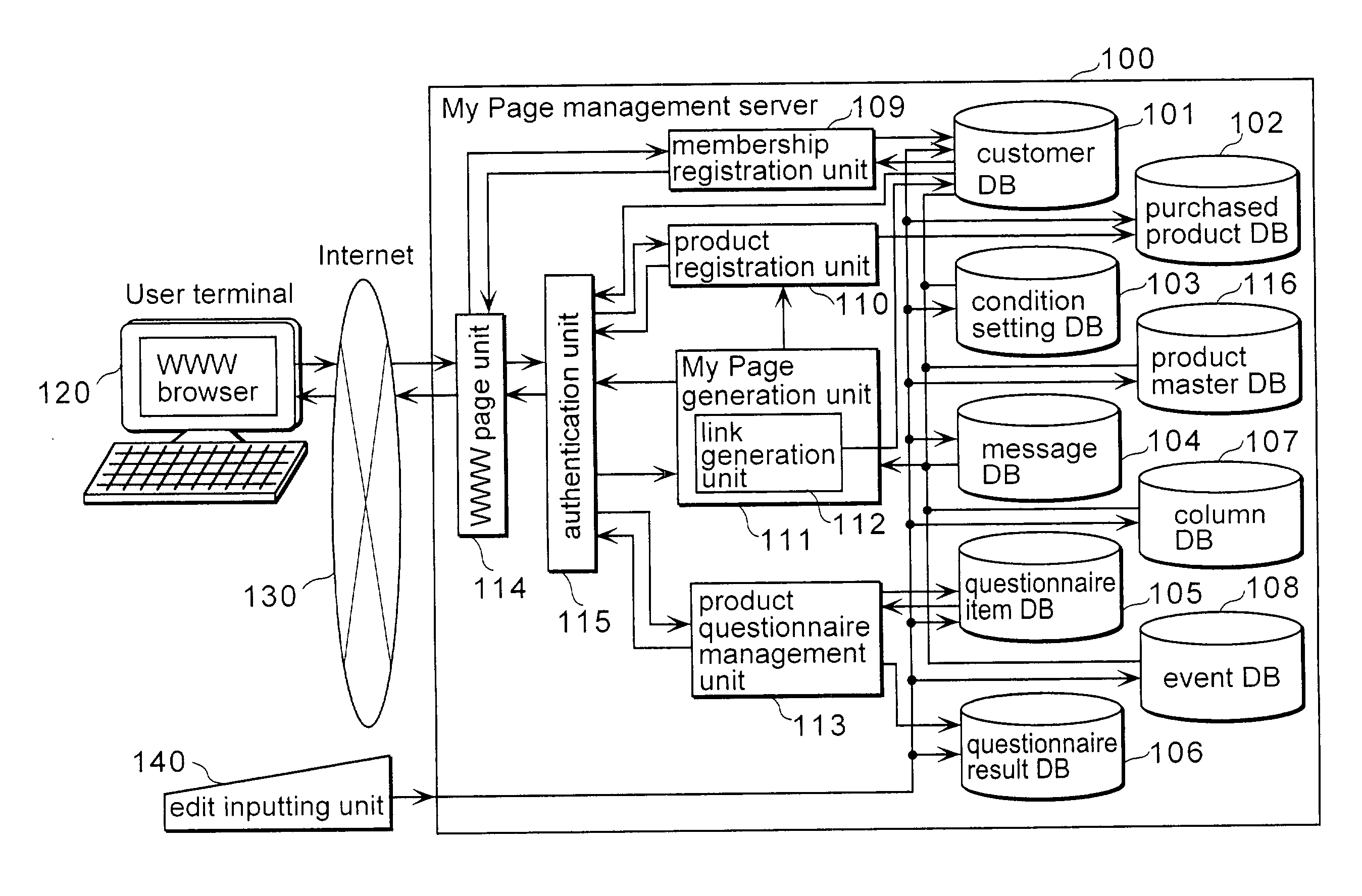

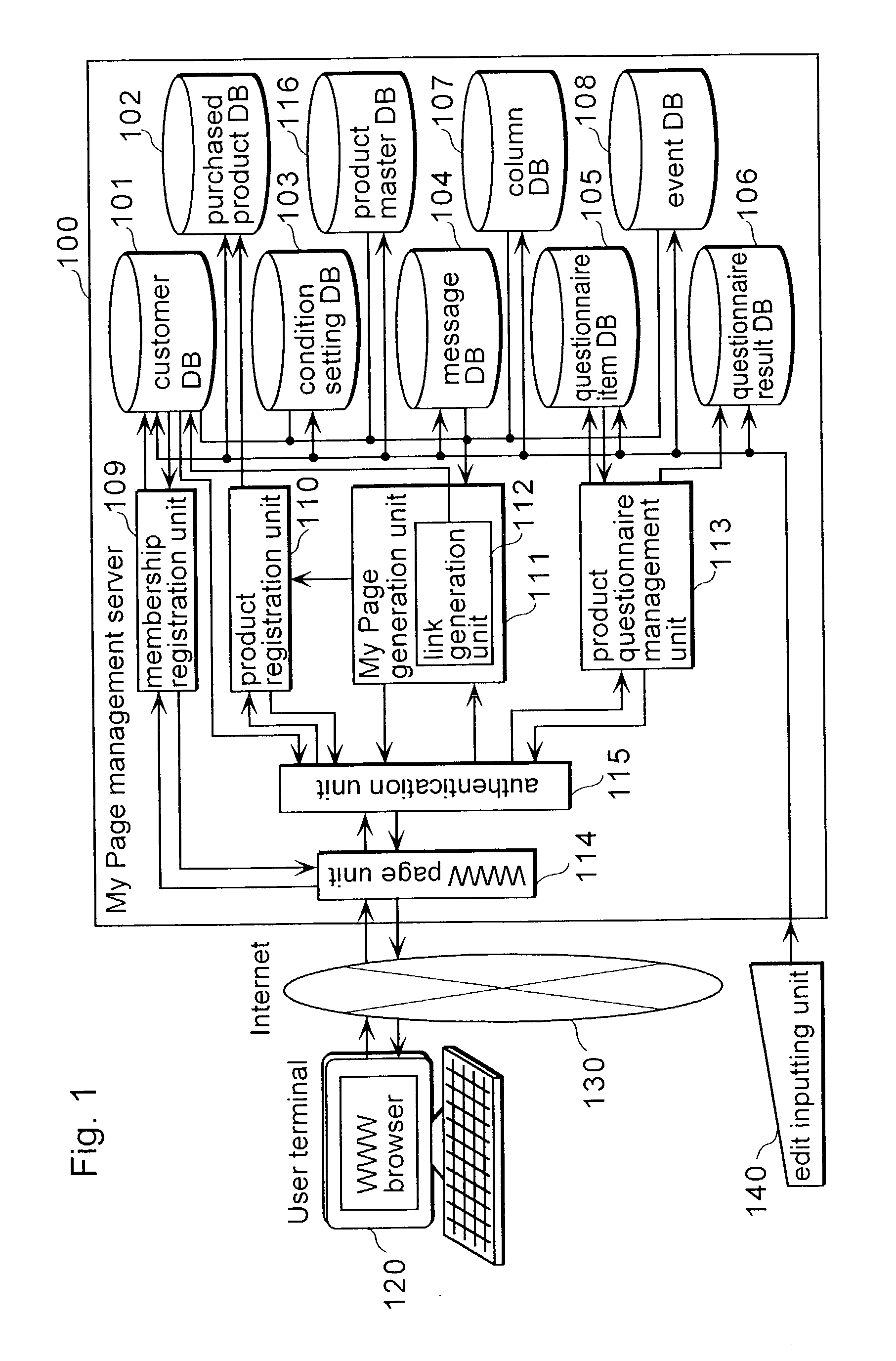

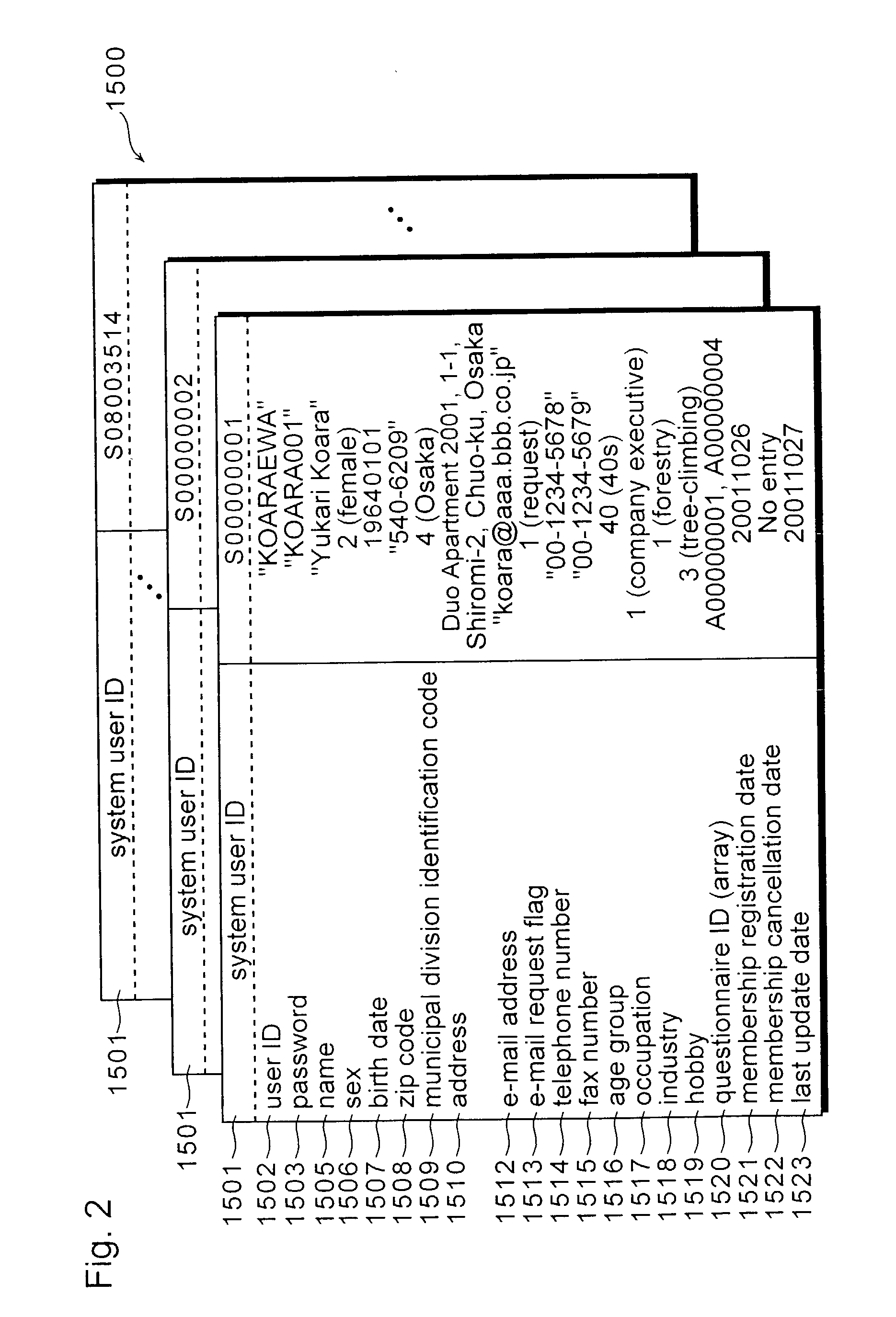

InactiveUS20030083962A1Increasing questionnaire collect rateUsabilityFinanceMultiple digital computer combinationsManagement unitWorld Wide Web

A My Page management server is a server that provides a personal world wide web (WWW) page named My Page for a user who has been registered as a member. The My Page management server includes a product registration unit that acquires information of a product which the user purchased, a link generation unit that generates, on the My Page, a link indicator which is linked to a product questionnaire about the product which the user purchased, based on the acquired information of the product, and a product questionnaire management unit that presents the linked product questionnaire to the user upon receiving a request for the product questionnaire from the user.

Owner:PANASONIC CORP

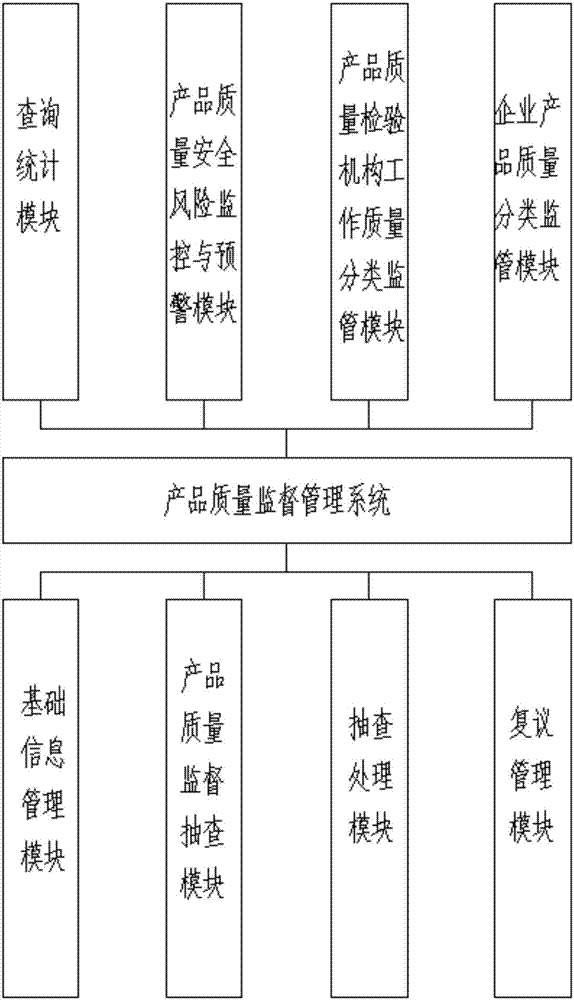

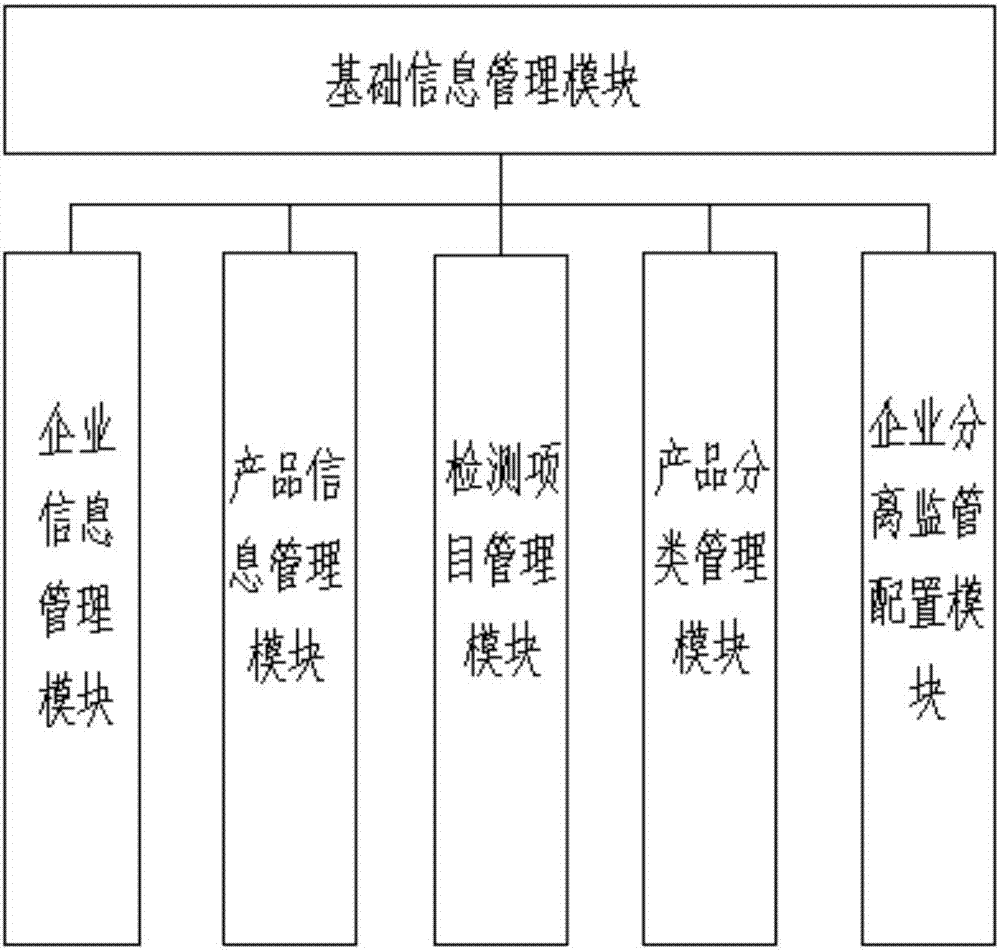

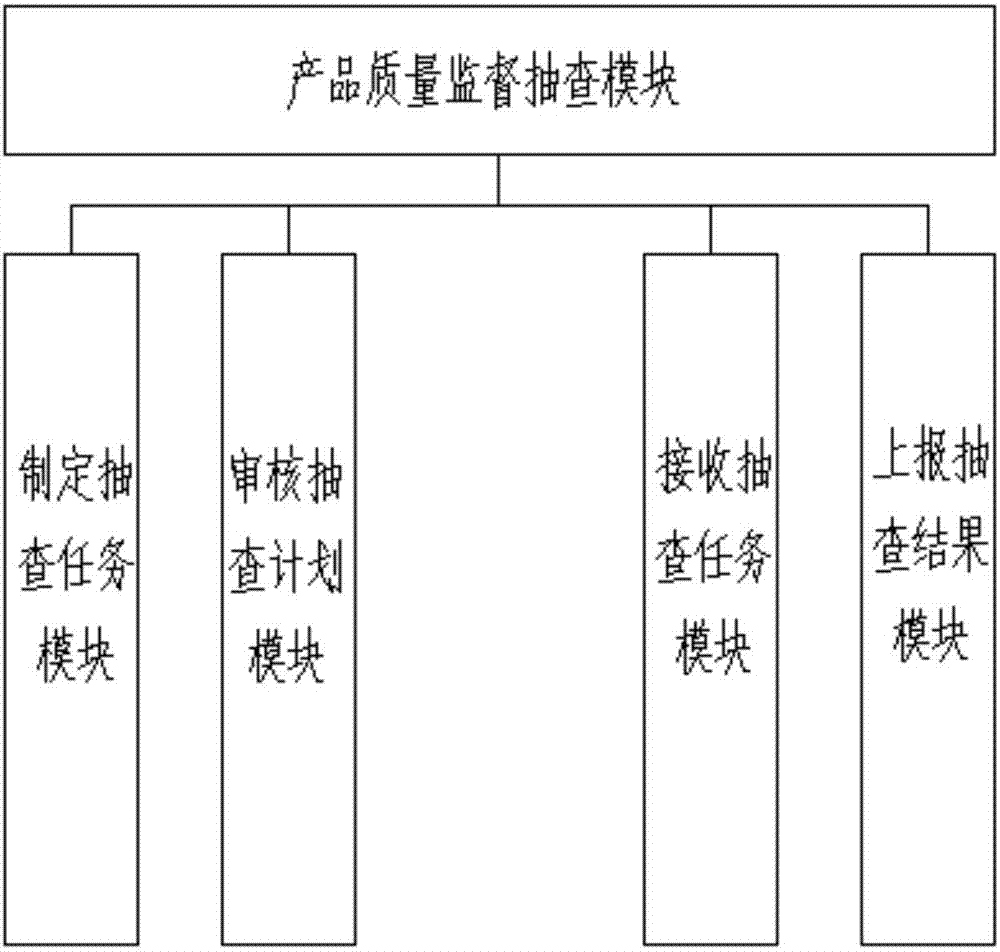

Product quality supervision and management system

InactiveCN107358416ANetworkingEasy to operateOffice automationCommerceProcess moduleProgram planning

The invention discloses a product quality supervision and management system. The system comprises a basic information management module used for enterprise information management and product information management and the like; a product quality supervision and spot check module used for making spot check tasks and checking spot check plans and the like; a spot check processing module used for issuing notifications and receiving rectification and reform notifications and the like; a reconsideration management module used for issuing re-inspection notifications, receiving the re-inspection notifications and reporting reconsideration results; a query statistics module used for querying various kinds of data; a product quality examination mechanism work quality classified supervision module used for examination mechanism information reporting and examination mechanism information query and the like; a product quality safety risk monitoring and early warning module used for product quality safety early warning, expert database review, early warning data analysis and check of high-quality product production demonstration zones; and an enterprise product quality classified supervision module used for classified supervision and template management and the like. The product quality supervision and management system can realize network and process operation, and improves work efficiency.

Owner:EASY BUSINESS DIGITAL TECH CO LTD

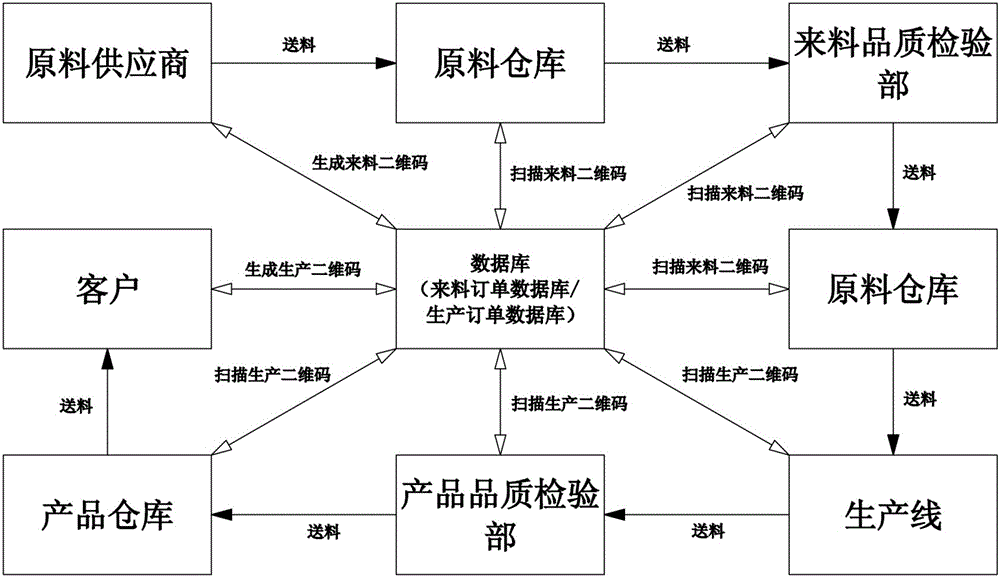

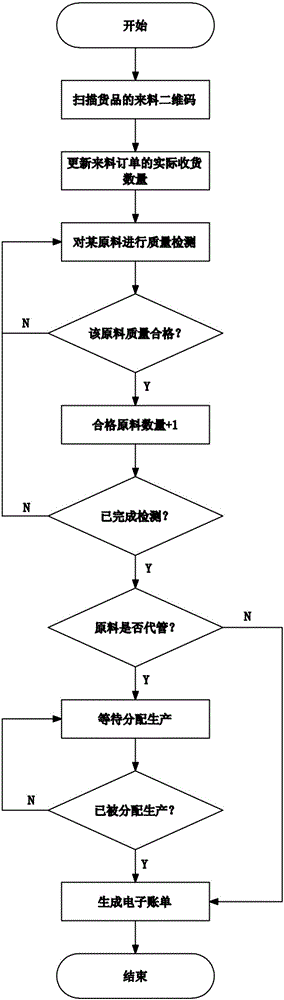

Information management system based on two-dimensional code technology

InactiveCN105139151ASimplified inventorySimplify workResourcesLogisticsInformation repositoryTransceiver

The invention discloses an information management system based on two-dimensional code technology. The information management system comprises a hardware part, an electronic system part and a network platform related to the electronic system. The hardware part comprises a server and a terminal device. The server is connected with the terminal device in a wired or wireless manner. The server is also connected with a text message receiving and sending device. The terminal device comprises a scanning device capable of scanning two-dimensional codes and a searching device capable of searching information. The electronic system comprises a supplied material order data base, a production order data base, a production responsible worker information base and system account numbers corresponding to different positions. All raw materials in the same supplied material order share one supplied material two-dimensional code generated by the system. All raw materials used in the all production orders are provided with specific production two-dimensional codes generated by the system.

Owner:FOSHAN ZHONGGEWEI ELECTRONICS

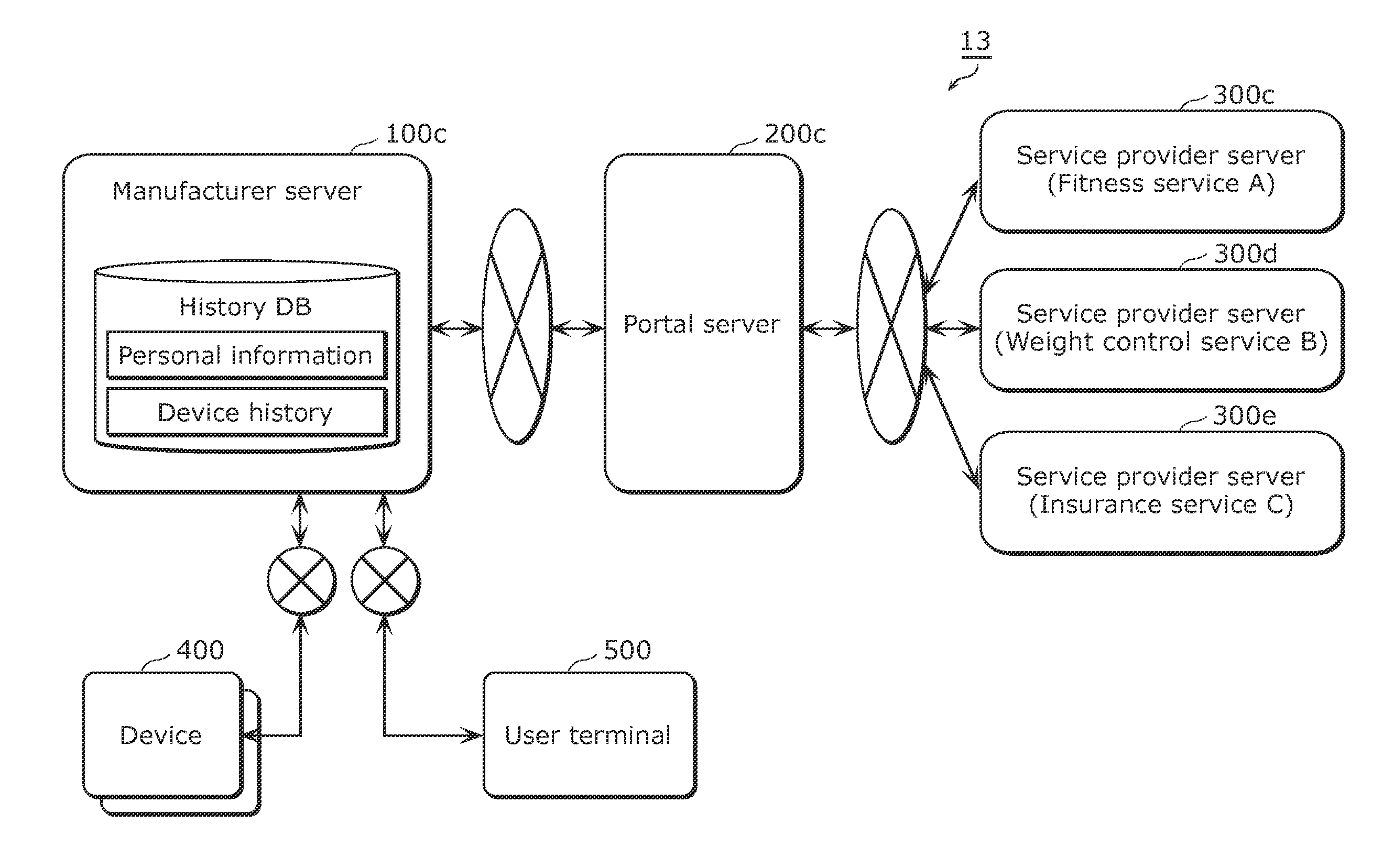

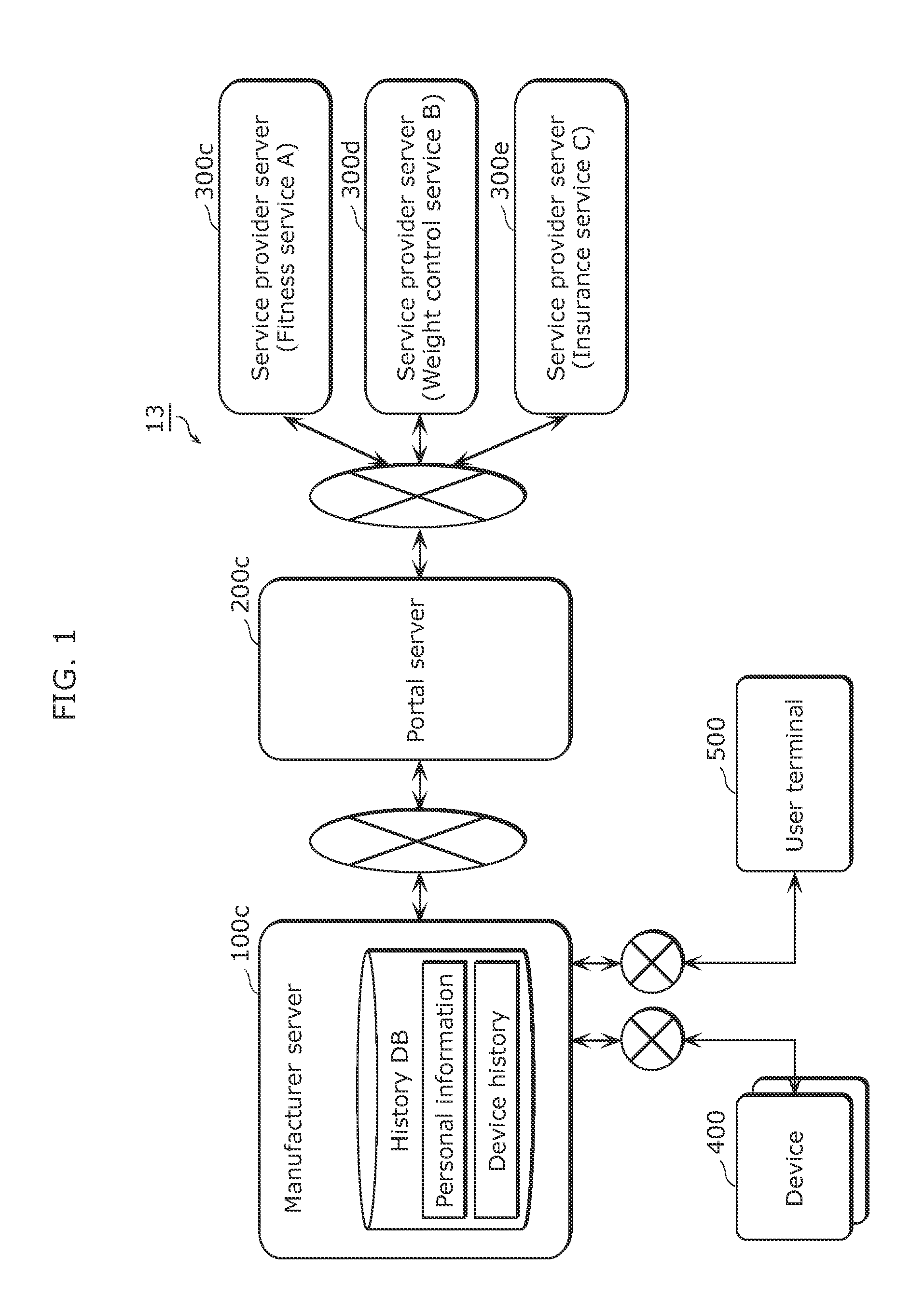

Information management method and information management system

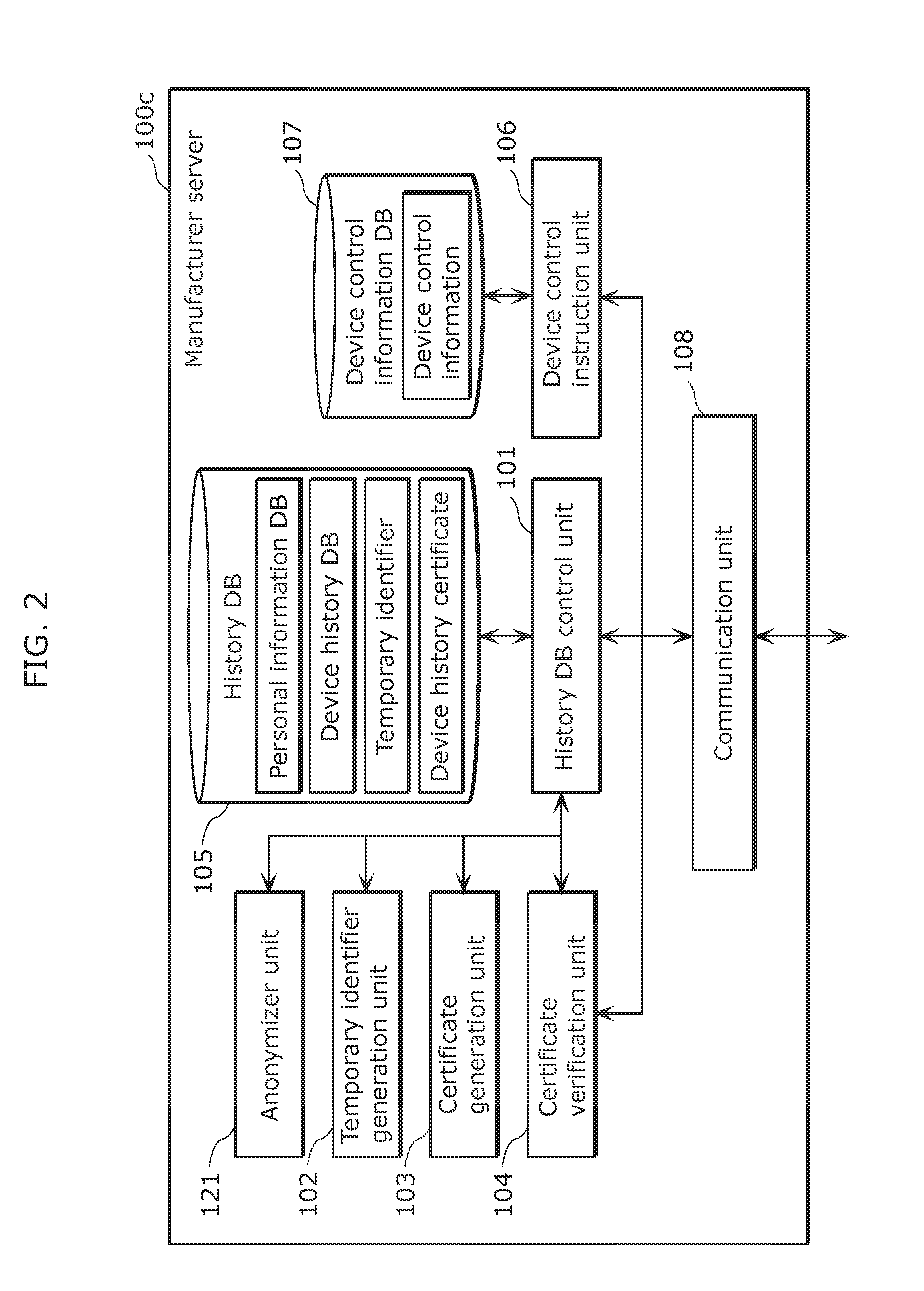

ActiveUS20140325592A1Securing anonymityDigital data protectionTransmissionInternet privacyService provision

An information management method includes: receiving, from a manufacturer server via a network, device history information indicating a history of an operation of a device used by a first user and first anonymized user information generated by anonymizing, according to a predetermined rule, first user information including attribute information which allows identification of the first user; receiving, from a service provider server different from the manufacturer server via the network, service history information indicating a history of service used by a second user and second anonymized user information generated by anonymizing, according to the predetermined rule, second user information including attribute information which allows identification of the second user; and associating the device history information and the service history information and managing them as composite information, when the first anonymized user information and the second anonymized user information are determined to be identical or similar.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

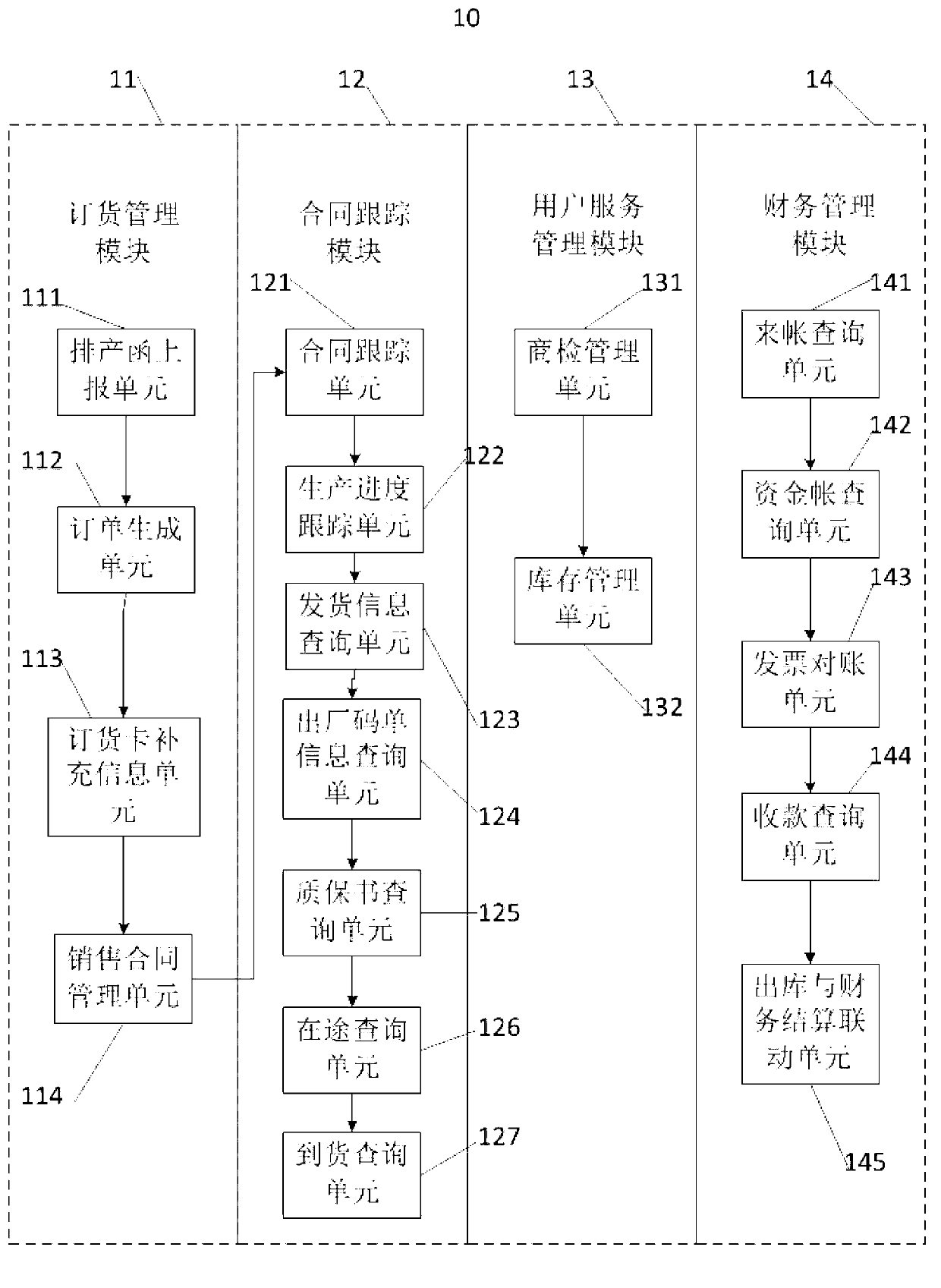

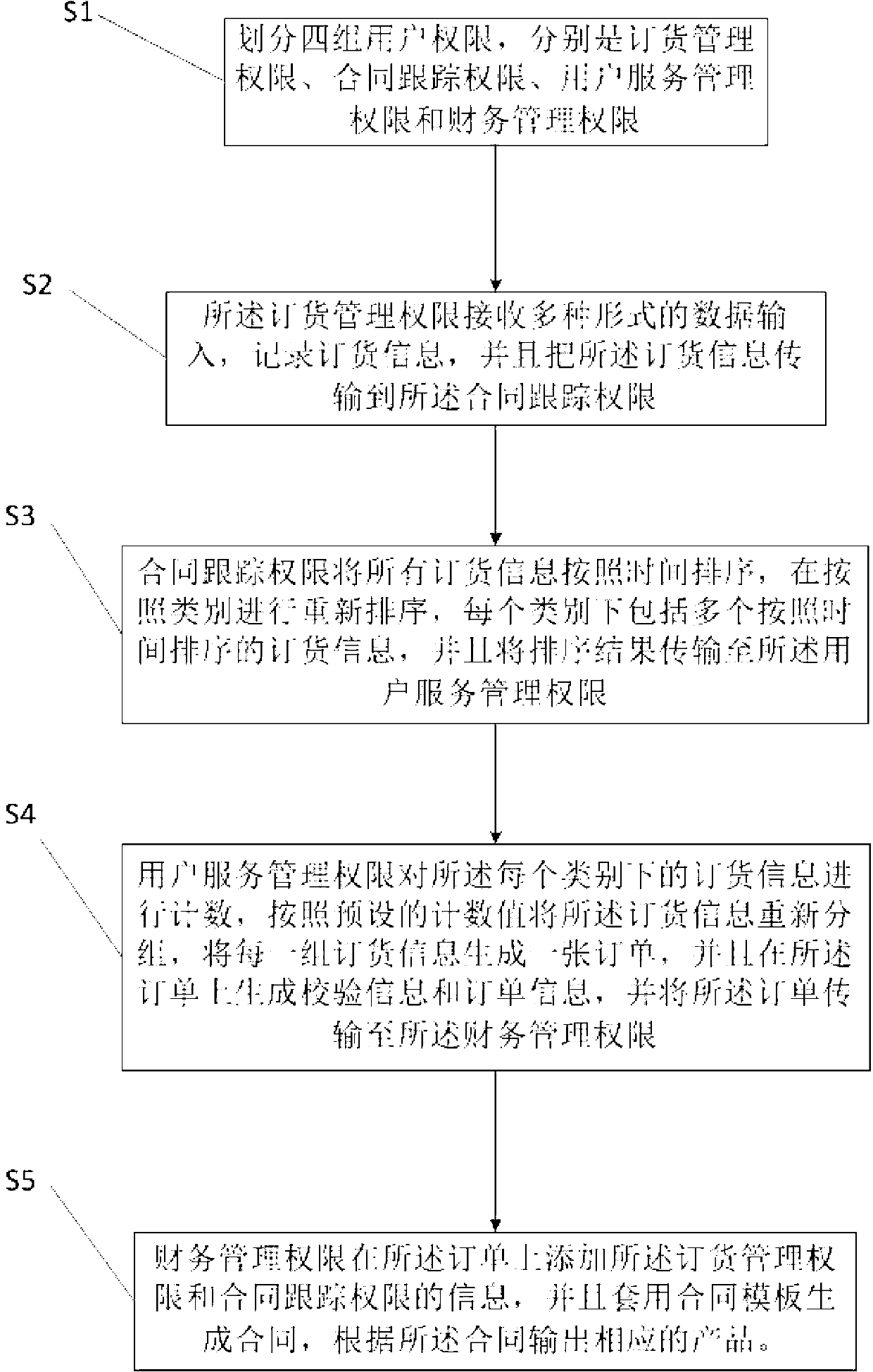

Information management system and information management method based on specific user supply chain coordination

InactiveCN103020806AAchieve sharingAchieve interactionLogisticsCommerceProduction scheduleInventory management

The invention discloses an information management system based on specific user supply chain coordination. The information management system based on specific user supply chain coordination comprises an ordering management module, a contract tracking module, a user service management module and a financial management module, wherein the ordering management module comprises a production scheduling letter reporting unit, an order generating unit, an order supplementary information unit and a sales contract management unit; the contract tracking module comprises a contract tracking unit, a production schedule tracking unit, a delivery information inquiry unit, a delivery weight note information inquiry unit, a quality certificate inquiry unit, an in-transit inquiry unit and an arrival inquiry unit; the user service management module comprises a commodity inspection management unit and a inventory management unit; and the financial management module comprises an account current inquiry unit, a fund account inquiry unit, an invoice account checking unit, a receipt inquiry unit and a delivery and financial settlement linkage unit. By the technical scheme, information sharing and interaction among specific users can be achieved, working strength of business personnel is lowered, and requirements on information consistency and transparency are met.

Owner:SHANGHAI BAOSTEEL TRADING

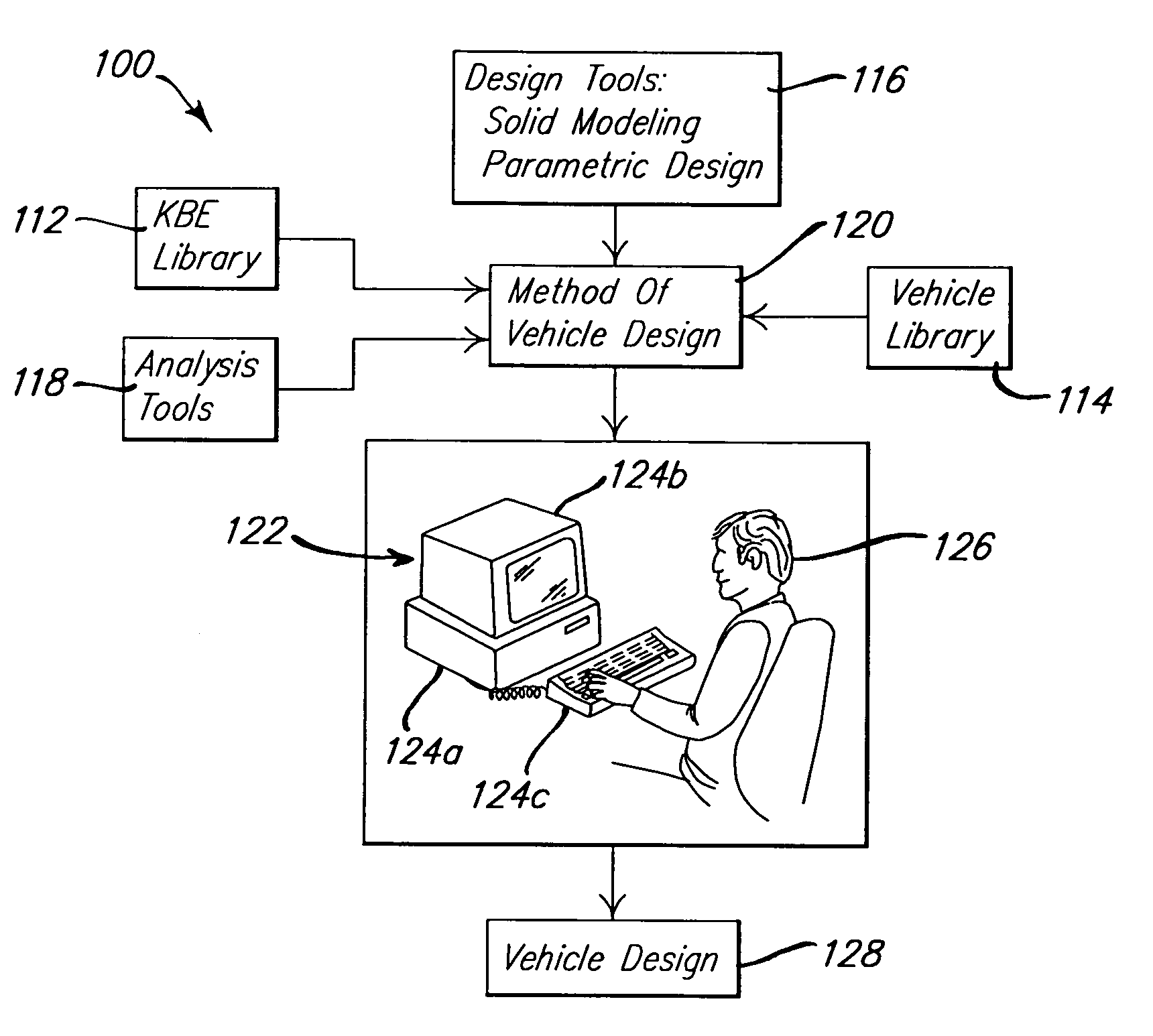

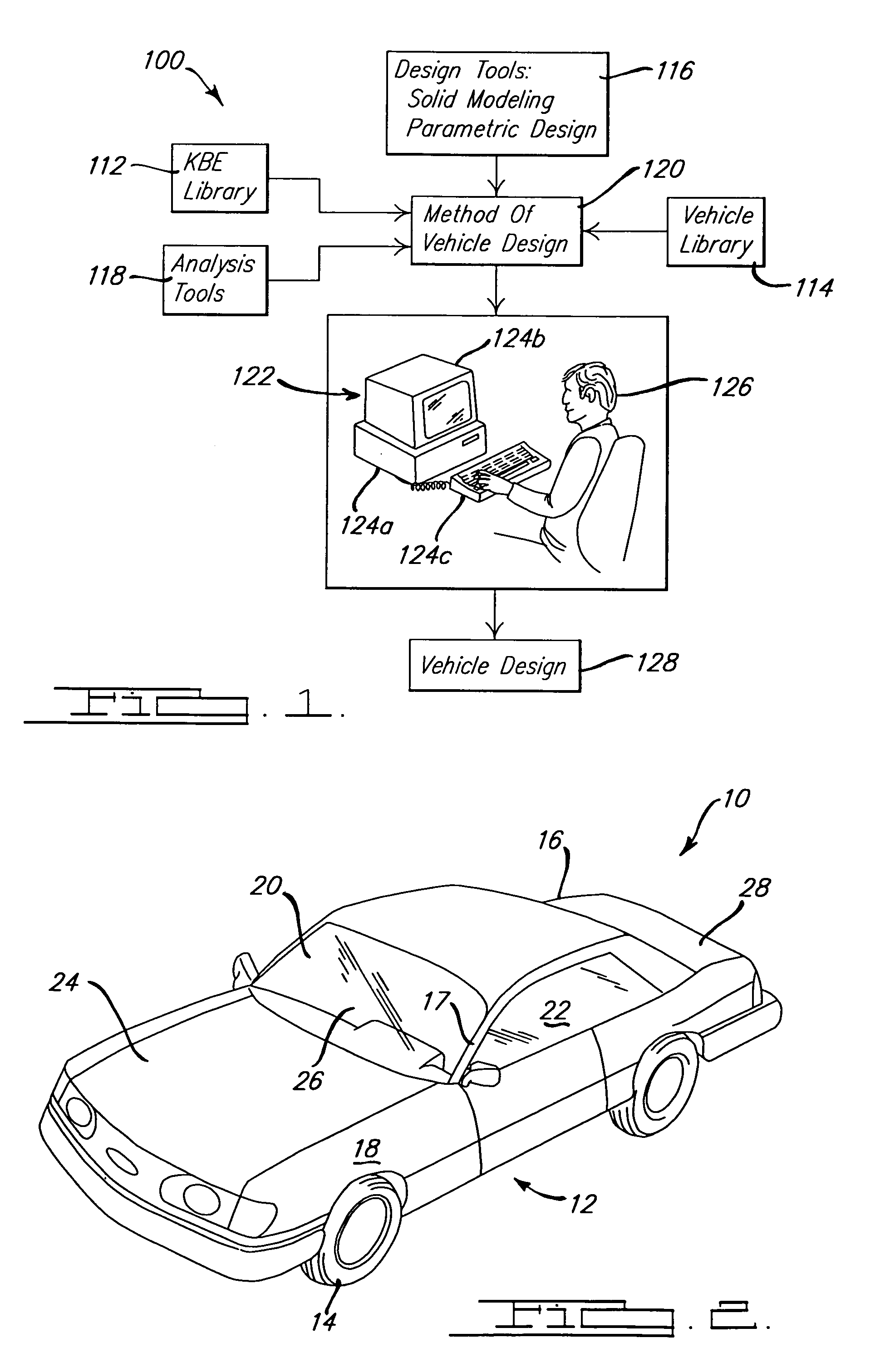

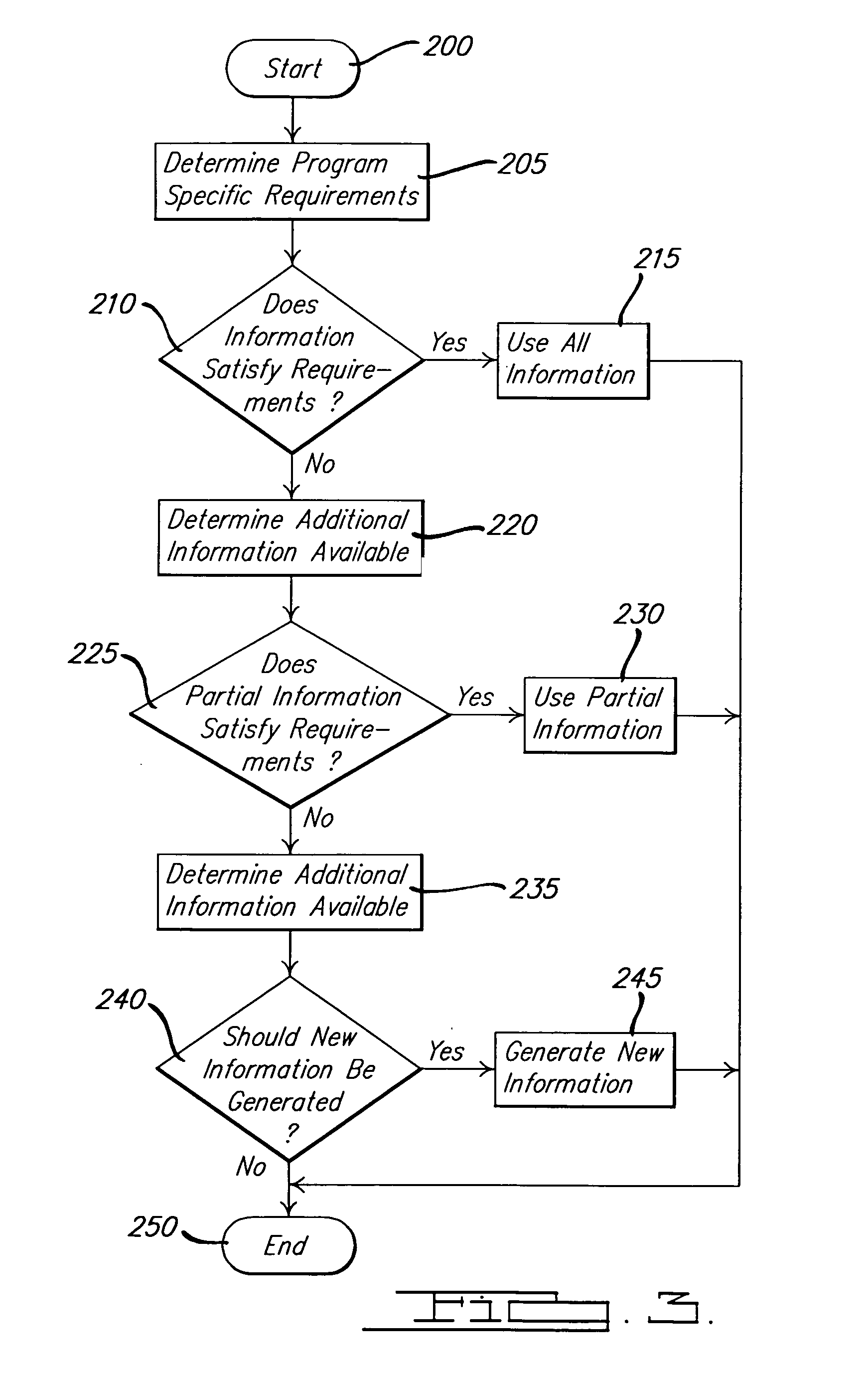

Method of integrating product information management with vehicle design

InactiveUS7158923B1Easy to appreciateInformed decision makingGeometric CADSpecial data processing applicationsComputerized systemLibrary science

A method of integrating product information management with vehicle design includes the steps of selecting a vehicle program requirement from a library stored in a memory of a computer system, wherein the library is accessed through an information portal on the computer system. The method also includes the steps of selecting an information database containing information related to the design of the vehicle from the library, wherein the information database is accessed through the information portal, and determining if the information from the information database correlates with the program requirement. The method further includes the steps of using the information from the information database in the design of the vehicle, if the information from the information database correlates with the program requirement.

Owner:FORD GLOBAL TECH LLC

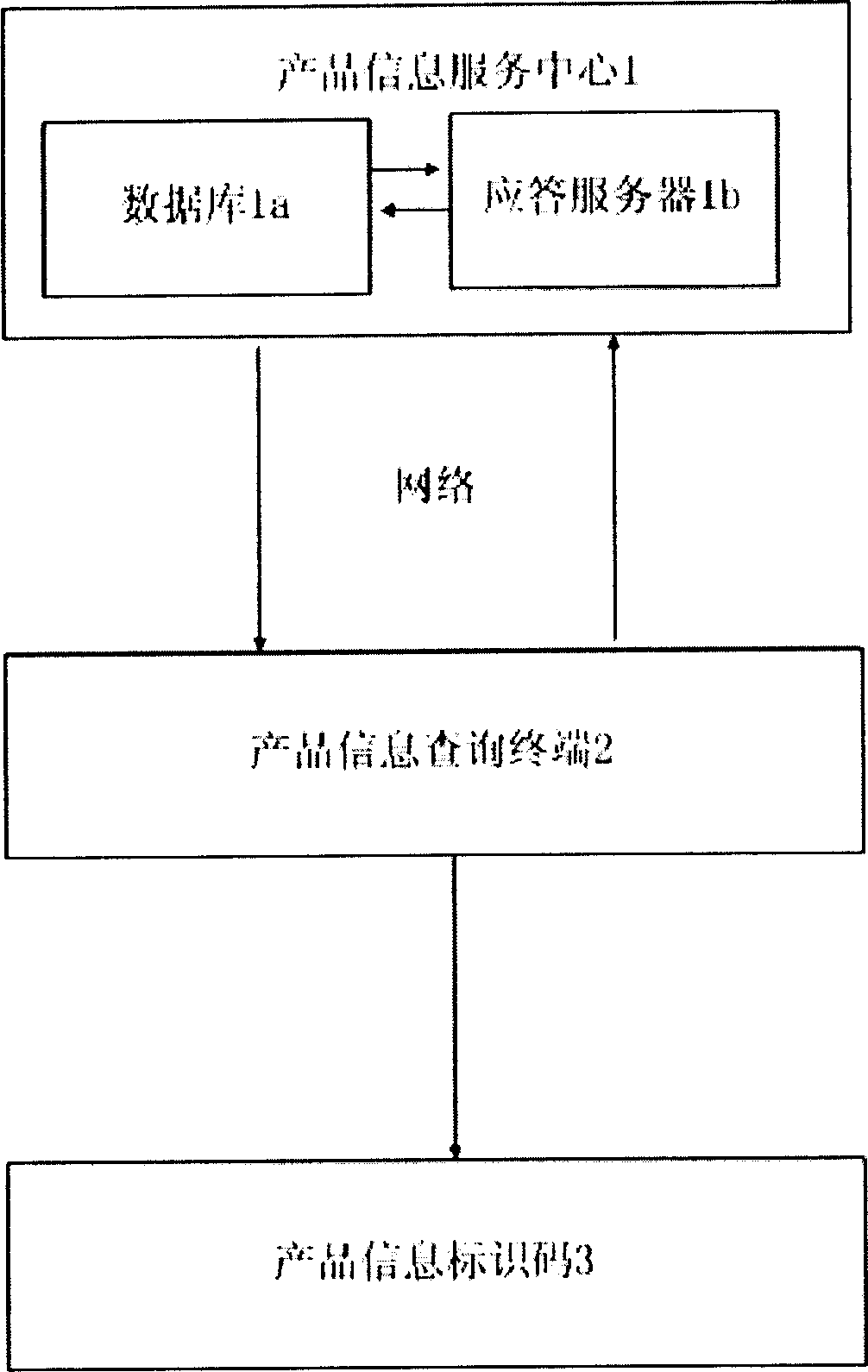

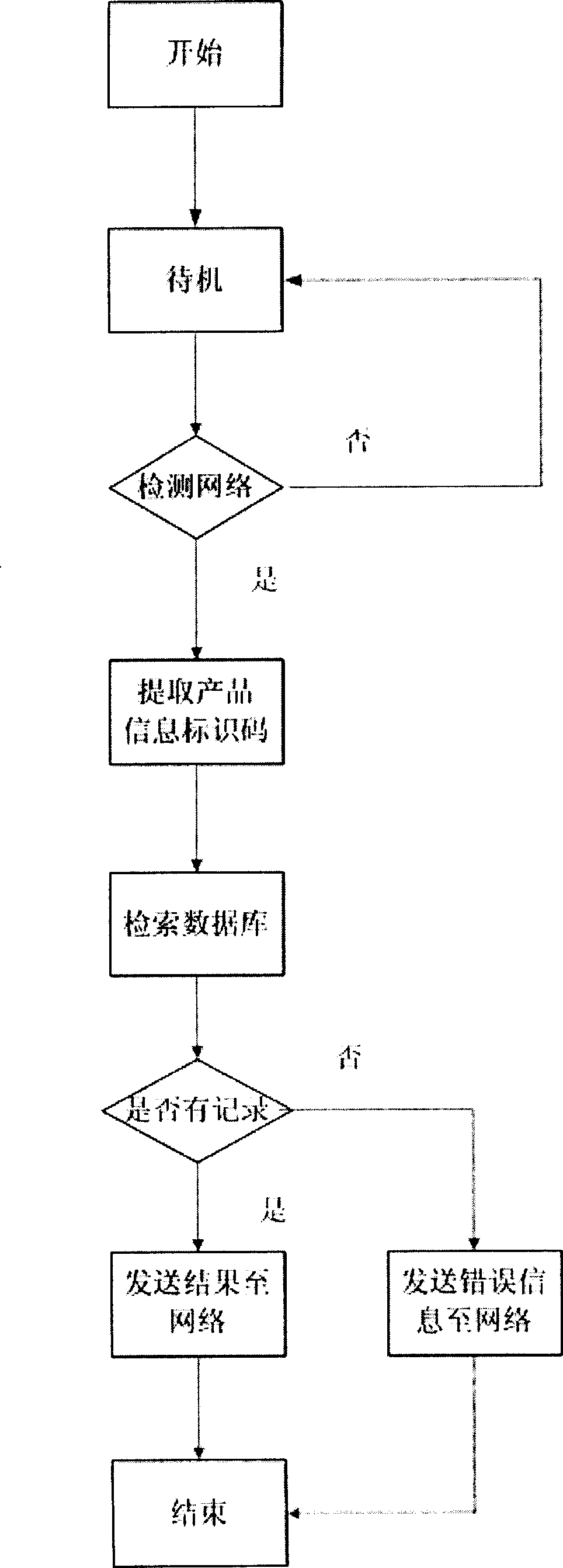

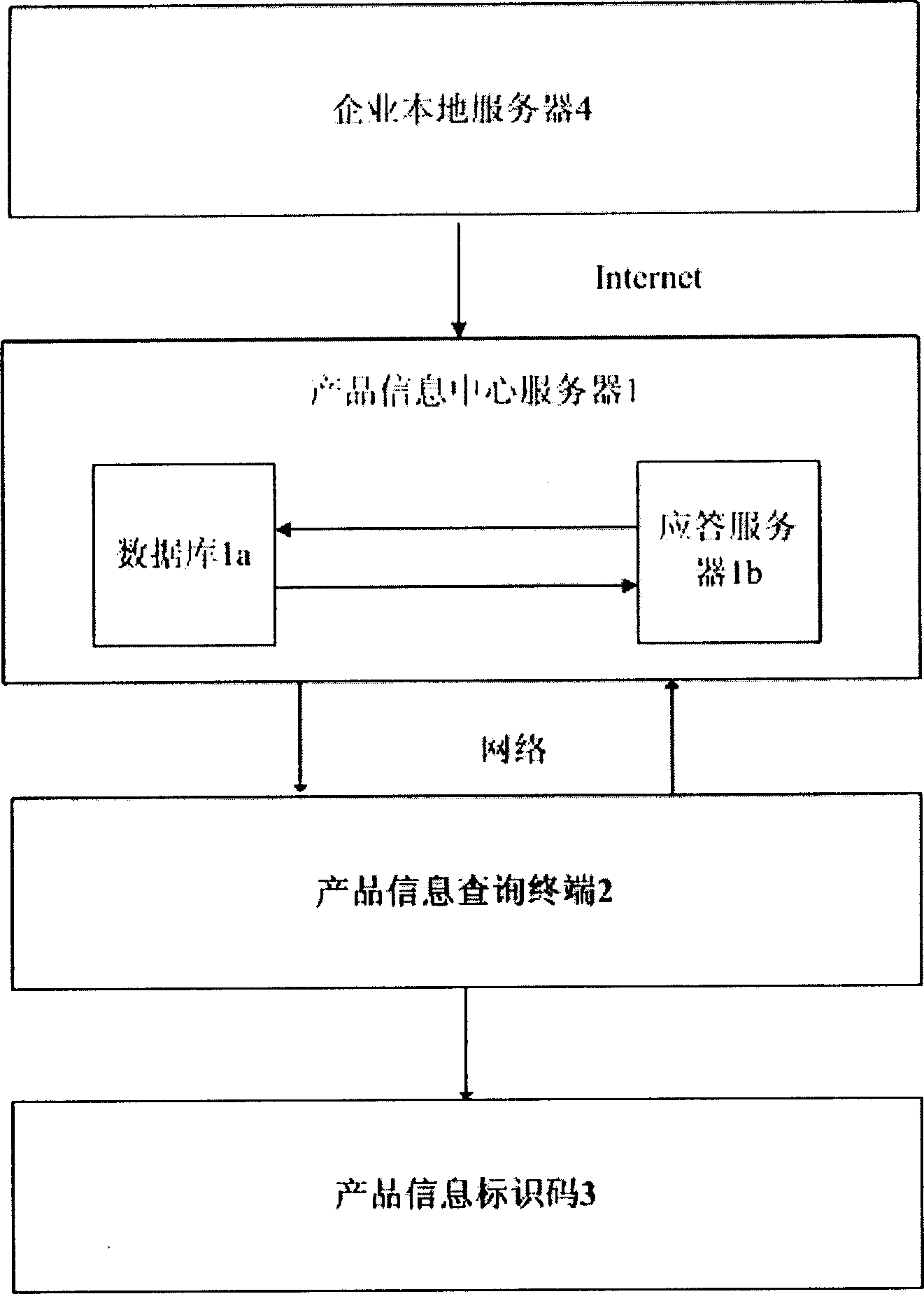

Product sale information management and inquiry system and method

InactiveCN1815496APrecise managementAccurate recordData switching by path configurationSpecial data processing applicationsLogistics managementComputer terminal

The system includes service unit of product information center, query terminal of product information, and ID code of product information. The service unit includes a database and responding server. The database is in use for managing and storing marketing information of product. The responding server is in use for answering query request from the query terminal of product information. ID code of product information is in use for identifying product information, which is one to one correspondence to marketing information in database. The invention can track, record and manage materials circulation for each piece of product as well as query whether a product has been changed in some degree in modes of gross exploration, selective examination inspection by using query terminal of product. The invention safeguards rights and privileges of corporations, legal dealers and customers.

Owner:东方惠科防伪技术有限责任公司

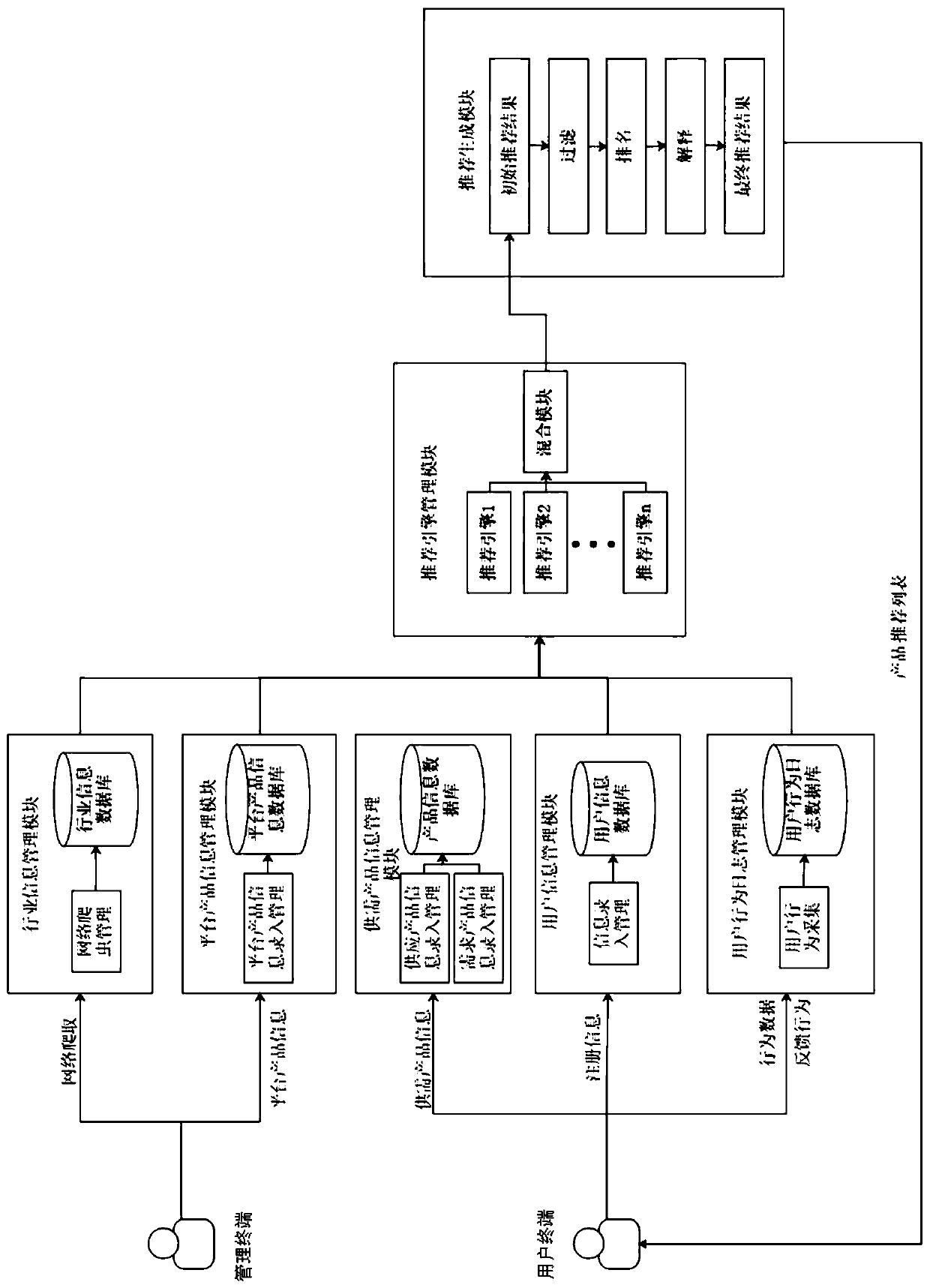

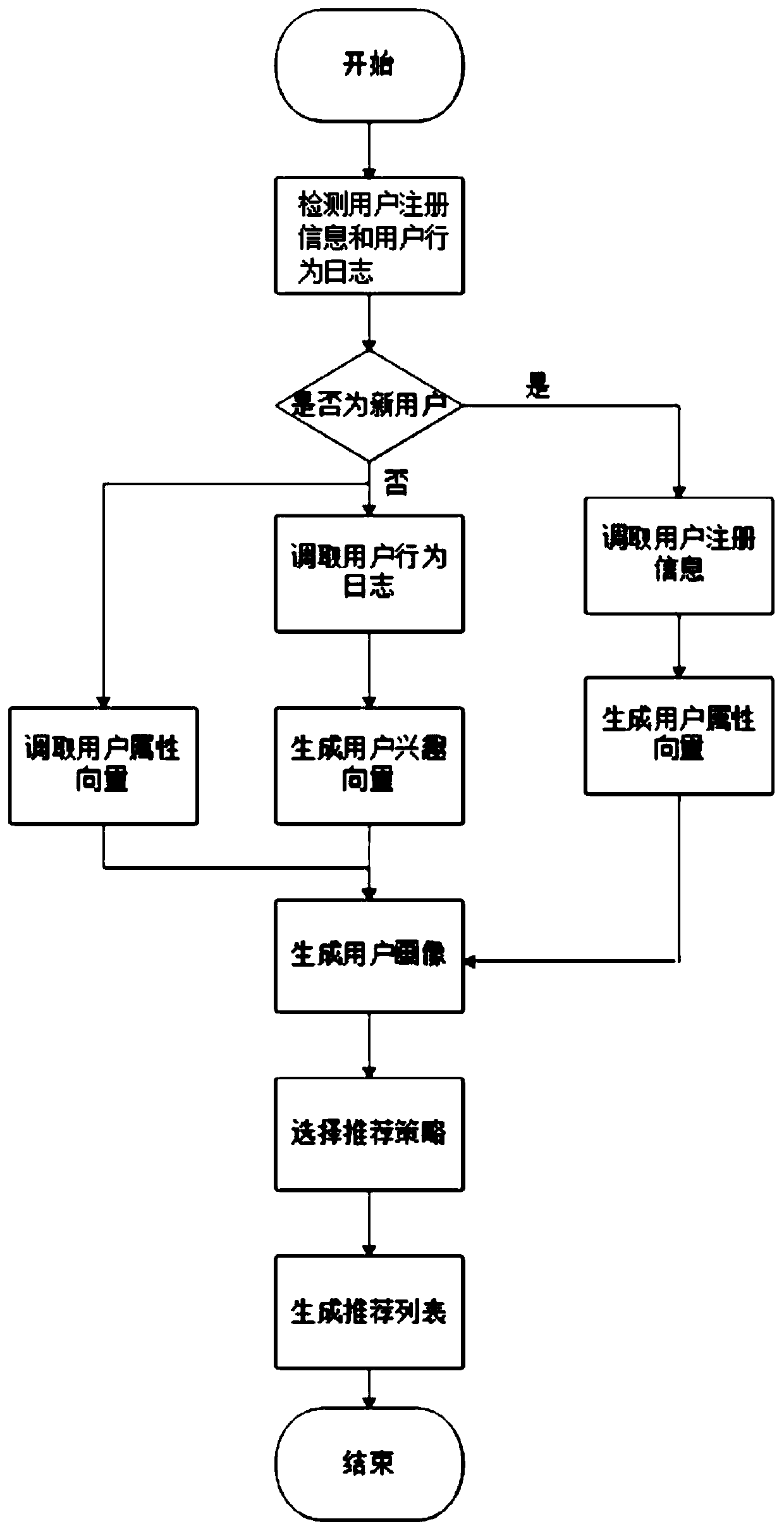

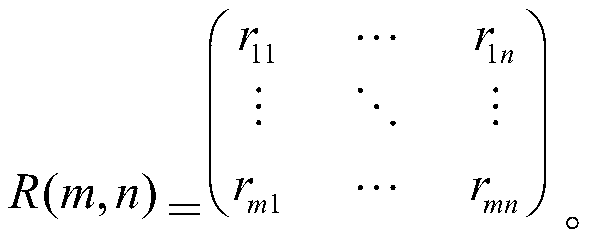

Industrial Internet product recommendation system and method

PendingCN110852852AImprove experienceIncrease stickinessWeb data indexingBuying/selling/leasing transactionsLog managementThe Internet

The invention relates to the technical field of computer application, and aims to provide an industrial Internet product recommendation system and method. The industrial Internet product recommendation system comprises a platform product information management module, a user information management module, a user behavior log management module, a recommendation engine management module, a recommendation generation module and a user terminal. The invention also discloses an industrial Internet product recommendation method, which comprises the following steps of detecting user registration information and a user behavior log in real time, judging whether the user is a new user or not, if so, calling the user registration information and generating a user attribute vector, and then generatinga user portrait according to the attribute vector; if not, calling the user behavior log and generating a user interest vector, and then generating a user portrait in combination with the user attribute vector; selecting a recommendation strategy; generating a product recommendation list. The user experience can be improved, the cooperation opportunity of the user and the platform is increased, and the user stickiness is enhanced.

Owner:成都航天科工大数据研究院有限公司

Pharmaceutical adjuvant automatic production line control system

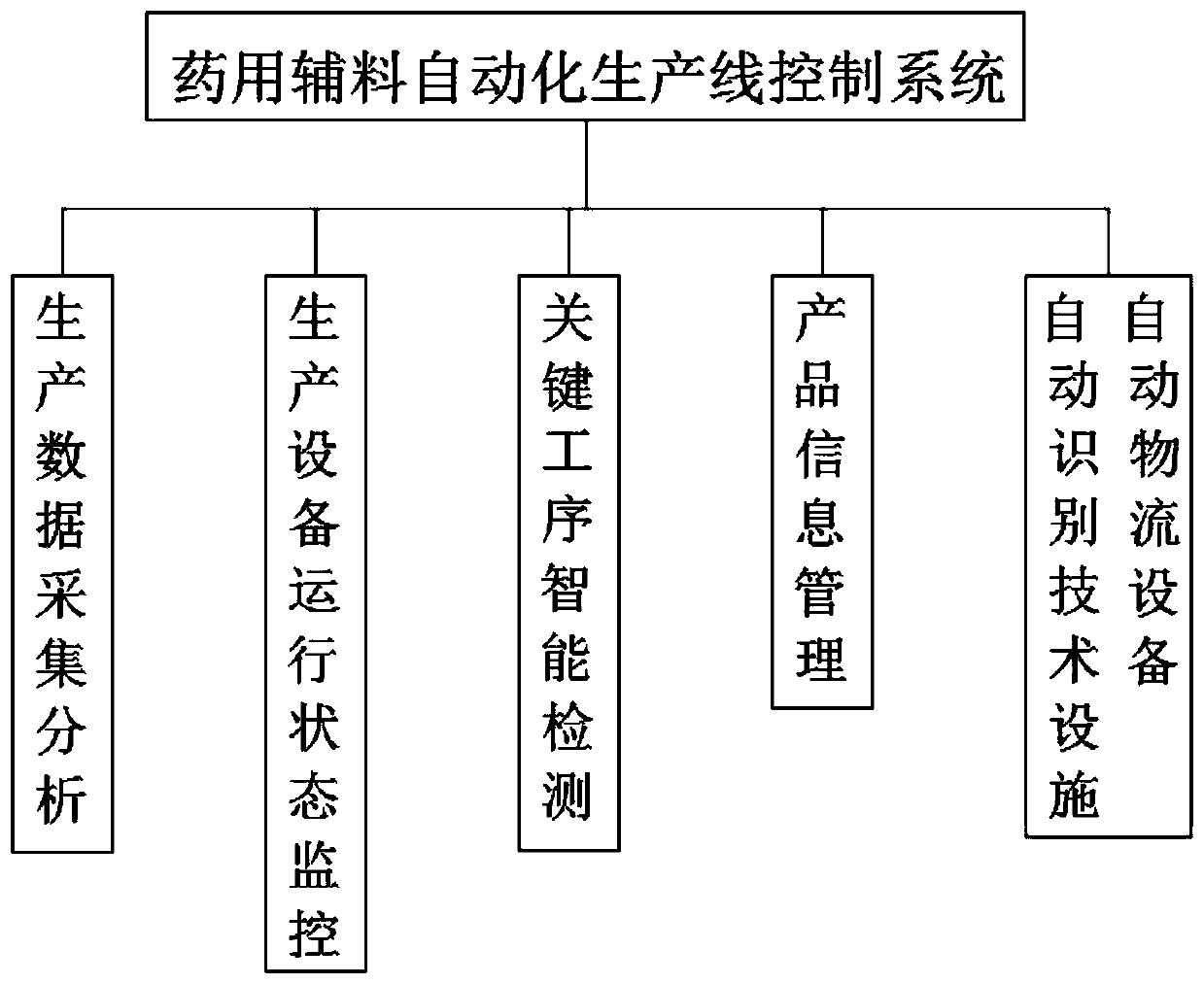

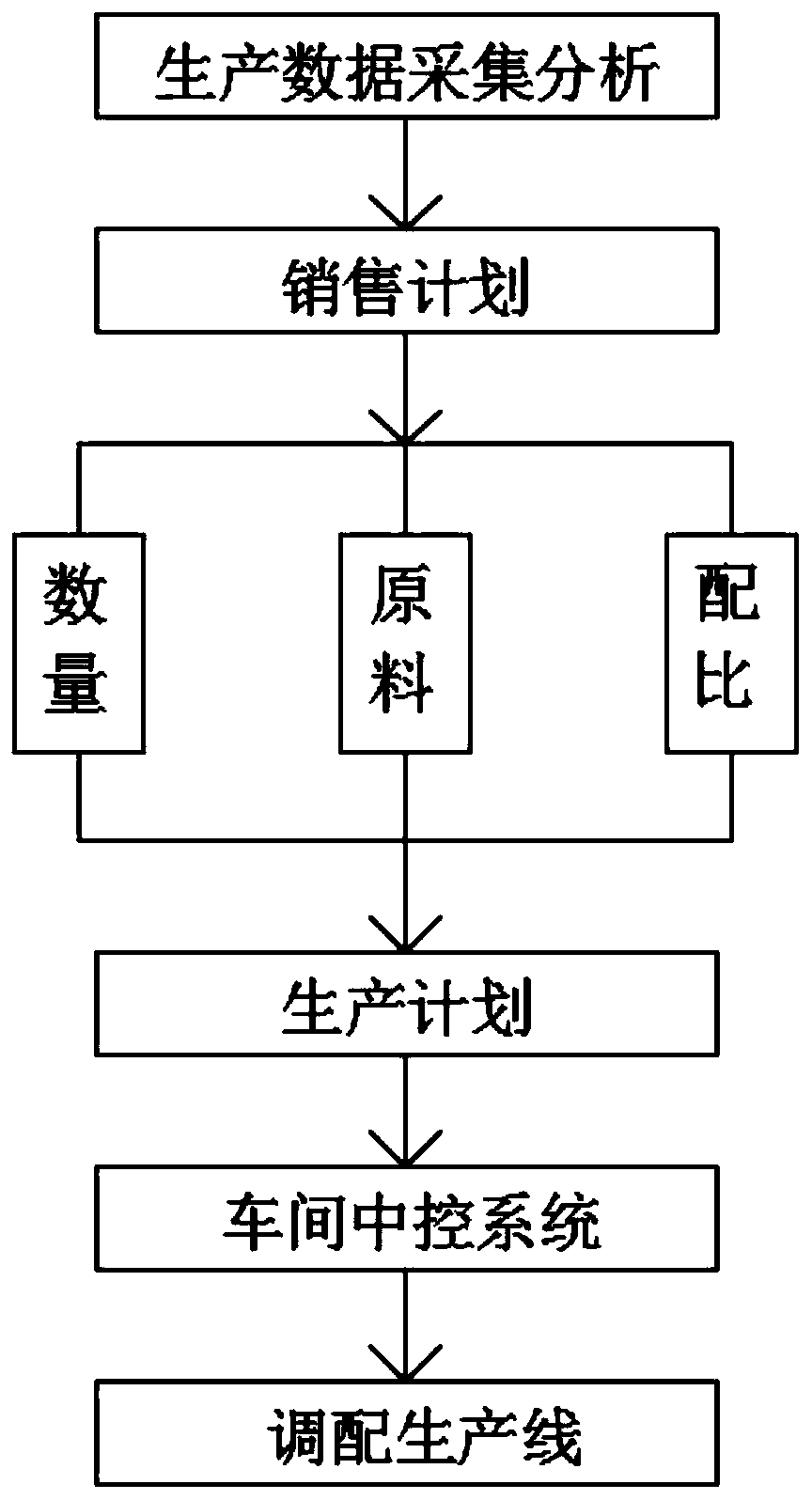

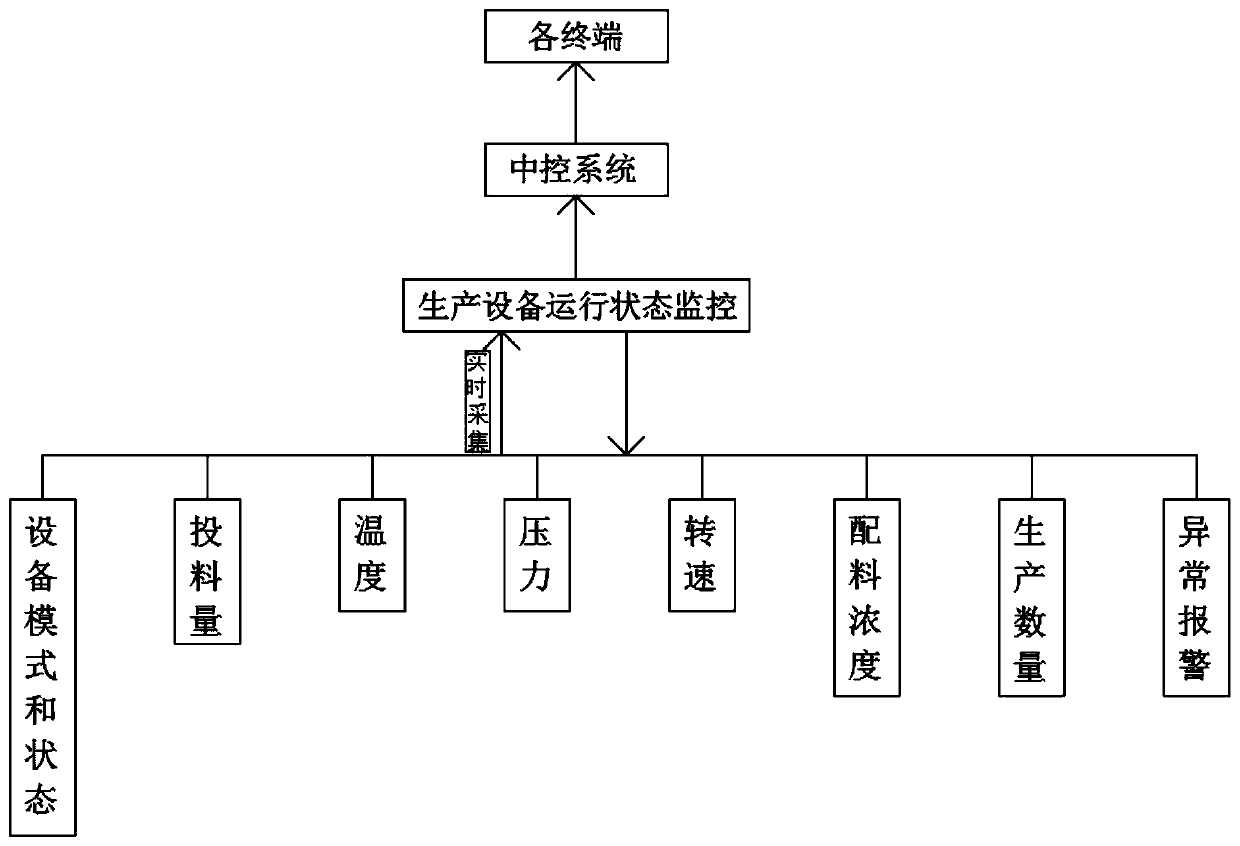

PendingCN111459105AEasy to controlEasy to storeTotal factory controlProgramme total factory controlData acquisitionPharmaceutical Aids

The invention discloses a pharmaceutical adjuvant automatic production line control system and relates to the field of pharmaceutical adjuvant production. The system comprises production data acquisition and analysis, production equipment operation state monitoring, key process intelligent quality detection, product information management, and automatic identification technical facility and automatic logistics equipment use; according to the production data acquisition and analysis, a production plan is automatically generated according to the content of a sales plan. According to the system of the invention, overall control is carried out based on the automatic production line control system; a production plan is automatically generated according to the sales plan and issued to a workshopcentral control system; the central control system plans a and deploys a production line; equipment operation states are collected in real time and fed back to the central control system; the centralcontrol system performs analysis and then processes the information and sends a result to each terminal; production conditions are collected and transmitted to the central control system in real timein a production process; an alarm is automatically given when reaction parameters deviate from a set standard; automatic or manual adjustment is performed in a PLC system to perform exception removal; and therefore, the real-time feedback rate can be increased, production quality can be controlled more easily, and production efficiency can be improved.

Owner:ANHUI SUNHERE PHARMA EXCIPIENTS

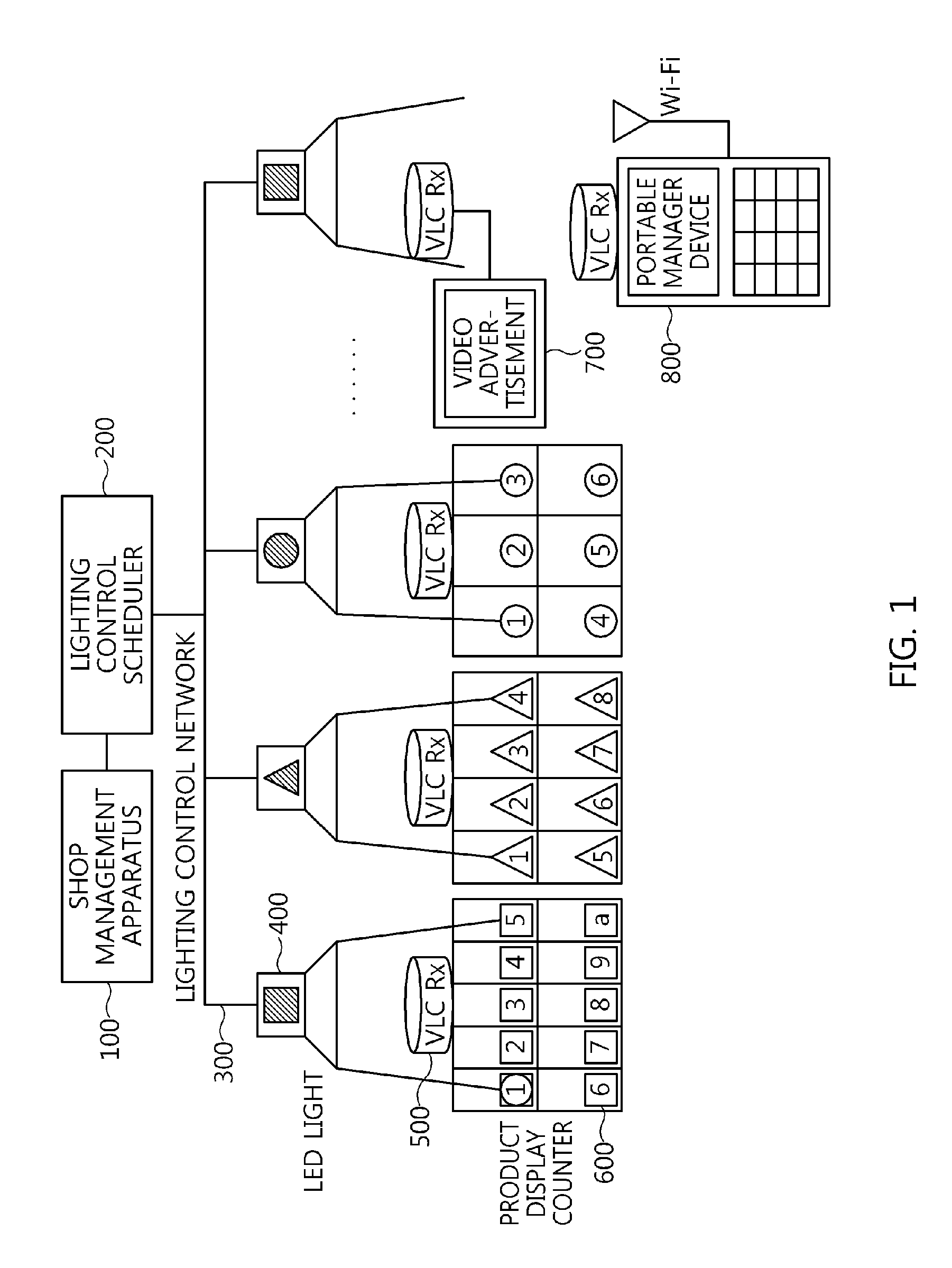

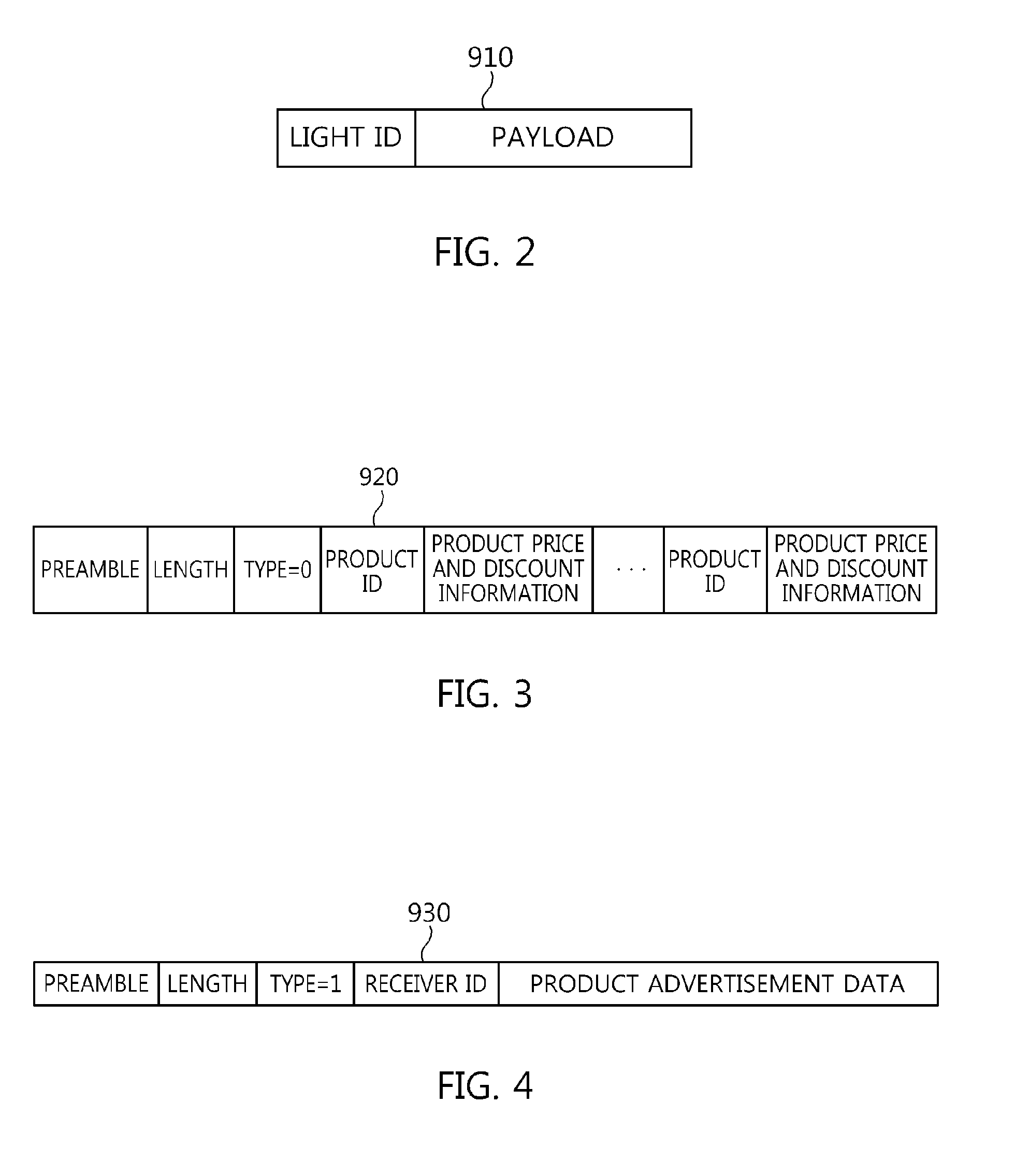

Apparatus and method for managing shop using lighting network and visible light communication

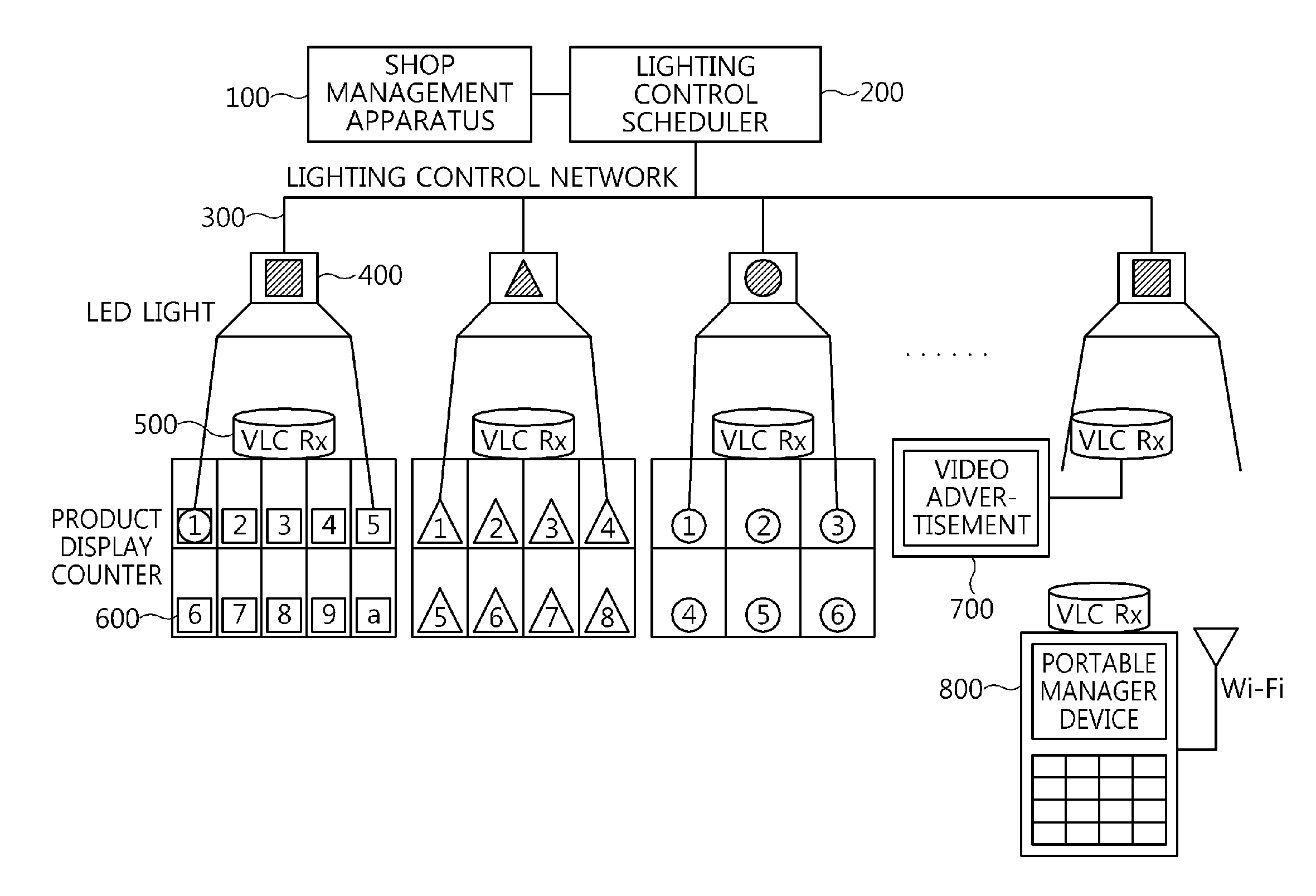

InactiveUS20150262103A1Television system detailsElectroluminescent light sourcesManagement unitIlluminance

A shop management apparatus and method are disclosed therein. The apparatus includes an input unit, a product information management unit, a communication unit, and a shop management unit. The input unit receives product information and discount event information within a shop. The product information management unit compares the product information and the discount event information with previously stored information, sends changed product information and changed discount event information, acquired based on a result of the comparison, to a lighting control scheduler, and receives a corresponding reception Ack message. The communication unit receives VLC data and illuminance information for each light ID, corresponding to the product information and the discount event information, from a portable manager device. The shop management unit checks an error of the VLC data, checks the illuminance of a corresponding LED light within the shop based on the illuminance information, and then manages the shop.

Owner:ELECTRONICS & TELECOMM RES INST

Product information management device

InactiveUS7246086B2Easy for to collect product informationUsabilityFinanceMultiple digital computer combinationsManagement unitWorld Wide Web

Owner:PANASONIC CORP

Facility agriculture agricultural product information management system and construction method thereof

InactiveCN108229982ASatisfy retrospective inquiriesMeet the needs of retrospectively querying the relevant information of agricultural productsMeasurement devicesCo-operative working arrangementsThe InternetWater quality

The invention relates to a facility agriculture agricultural product information management system and a construction method thereof. The system comprises a cloud server, the cloud server is respectively connected with a client-side query system, an agricultural product information collection pool and a monitoring system, the client-side query system comprises an interchanger, a firewall, Internet, an authority authentication server and a query client-side which are connected sequentially, the interchanger bidirectionally communicates with the cloud server, the agricultural product informationcollection pool comprises a forbidden pesticide recording system, a basic information tie-in system, a water quality detection device, a temperature and humidity sensor, a soil detection device, a camera, an air detection device, a pesticide detection device and a chemical fertilizer detection device which are all connected with the cloud server. The facility agriculture agricultural product information management system and the construction method thereof have the advantages of whole-process monitoring and tracing, can meet the condition that a monitoring center monitors the whole process from production to sales of the agricultural products, meet the requirements of customers to trace and inquire relevant information of the agricultural products, and can also meet the inquiries about temperature, humidity, air quality and the like of the growing environment of the agricultural products needed by buyers.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

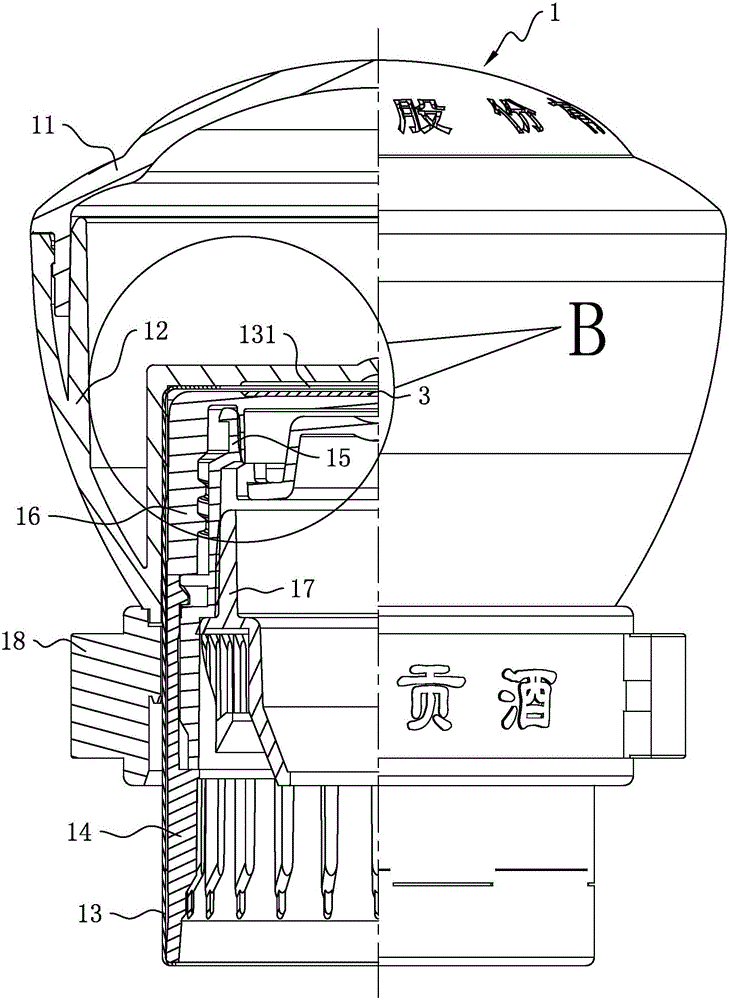

Wine product information management system

ActiveCN107481421AImprove economyEasy to operateApparatus for dispensing fluids/granular materialsCommerceData miningIndustrial engineering

The invention discloses a wine product information management system. The wine product information management system comprises an information generating system, an information matching system and a wine product identification code, wherein the information generating system is used for inputting wine product information to a server and generating the unique wine product identification code, the wine product identification code is placed on a vessel, and the vessel is used for storing the wine corresponding to the wine product information; the information matching system is used for reading the wine product identification code, matching the wine product identification code with the wine product information in the server, and judging whether or not to send an authorization signal according to the matching result; a seal cover which controls opening and closing through the authorization signal is arranged on the vessel. The wine product information management system has the advantages of good anti-fake effect, low running effect and high safety, and can organically integrate purchase and delivery of wine products, warehousing storage locations, operative personnel management and online wine quality monitoring to conduct management.

Owner:康兆君

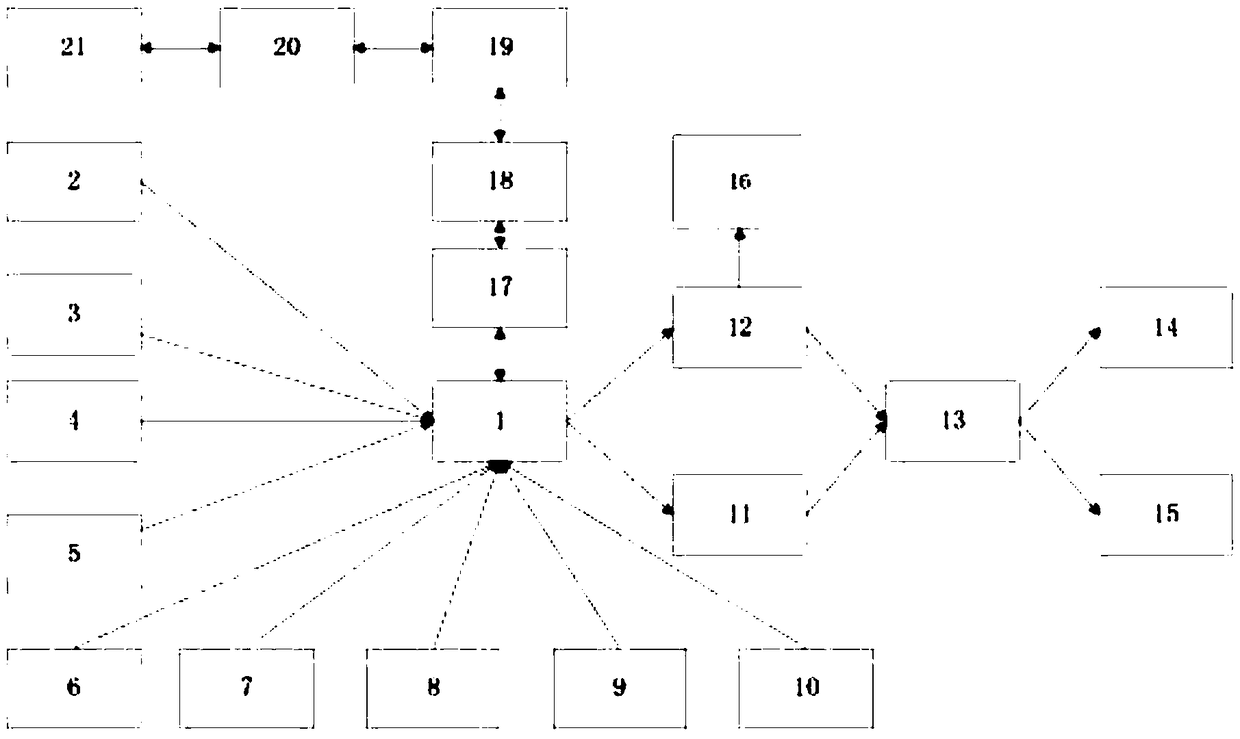

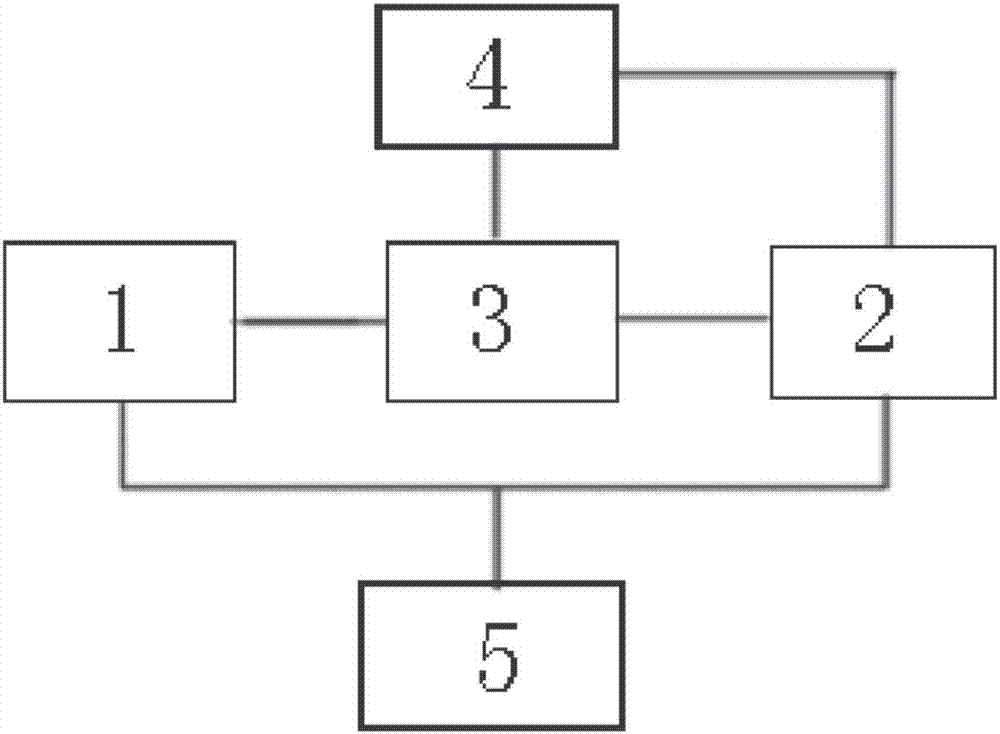

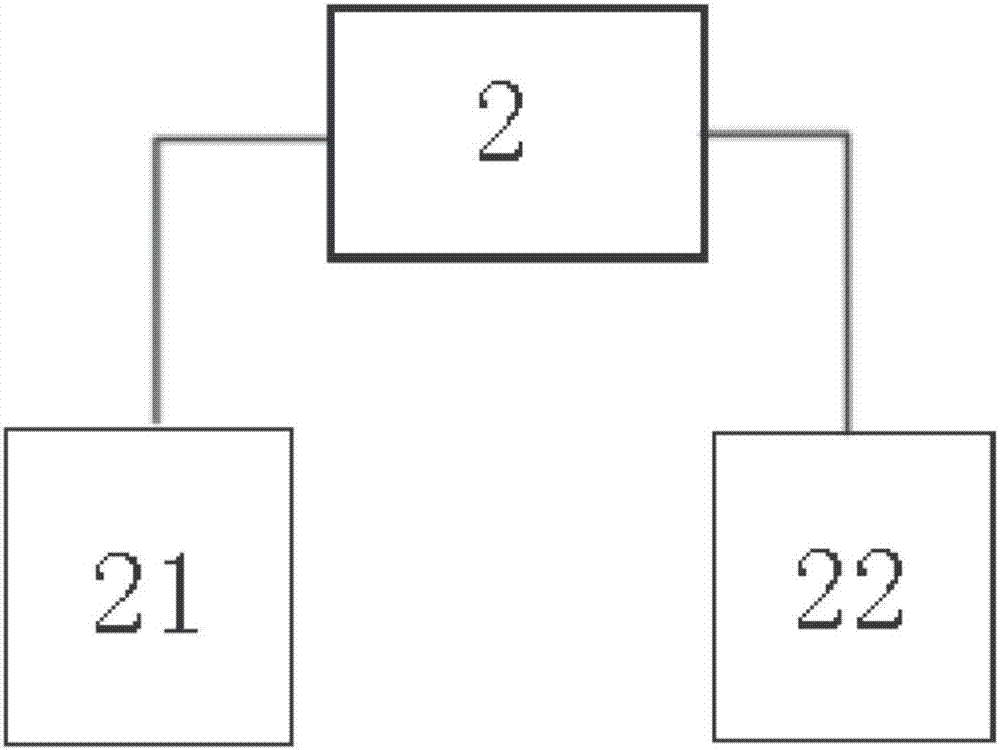

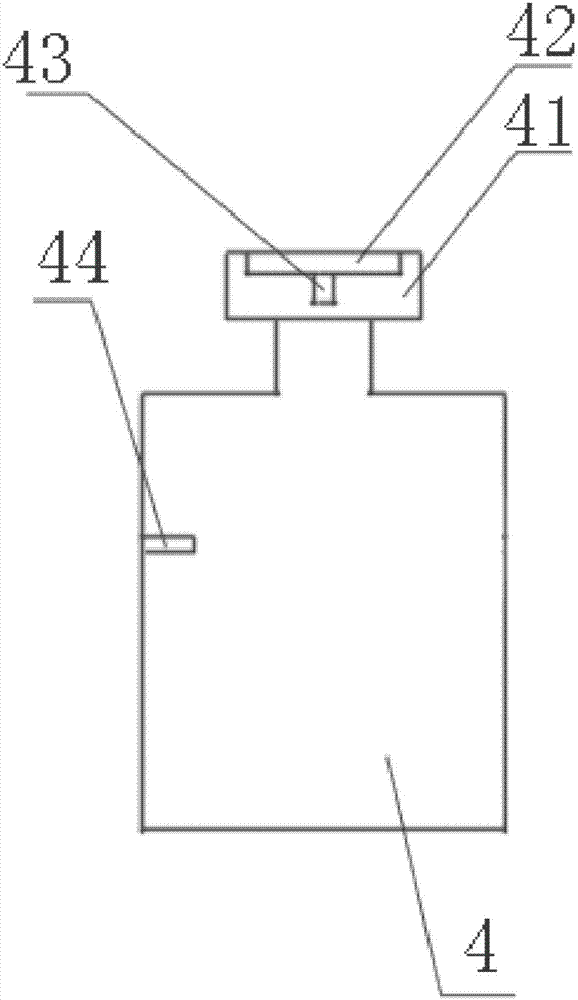

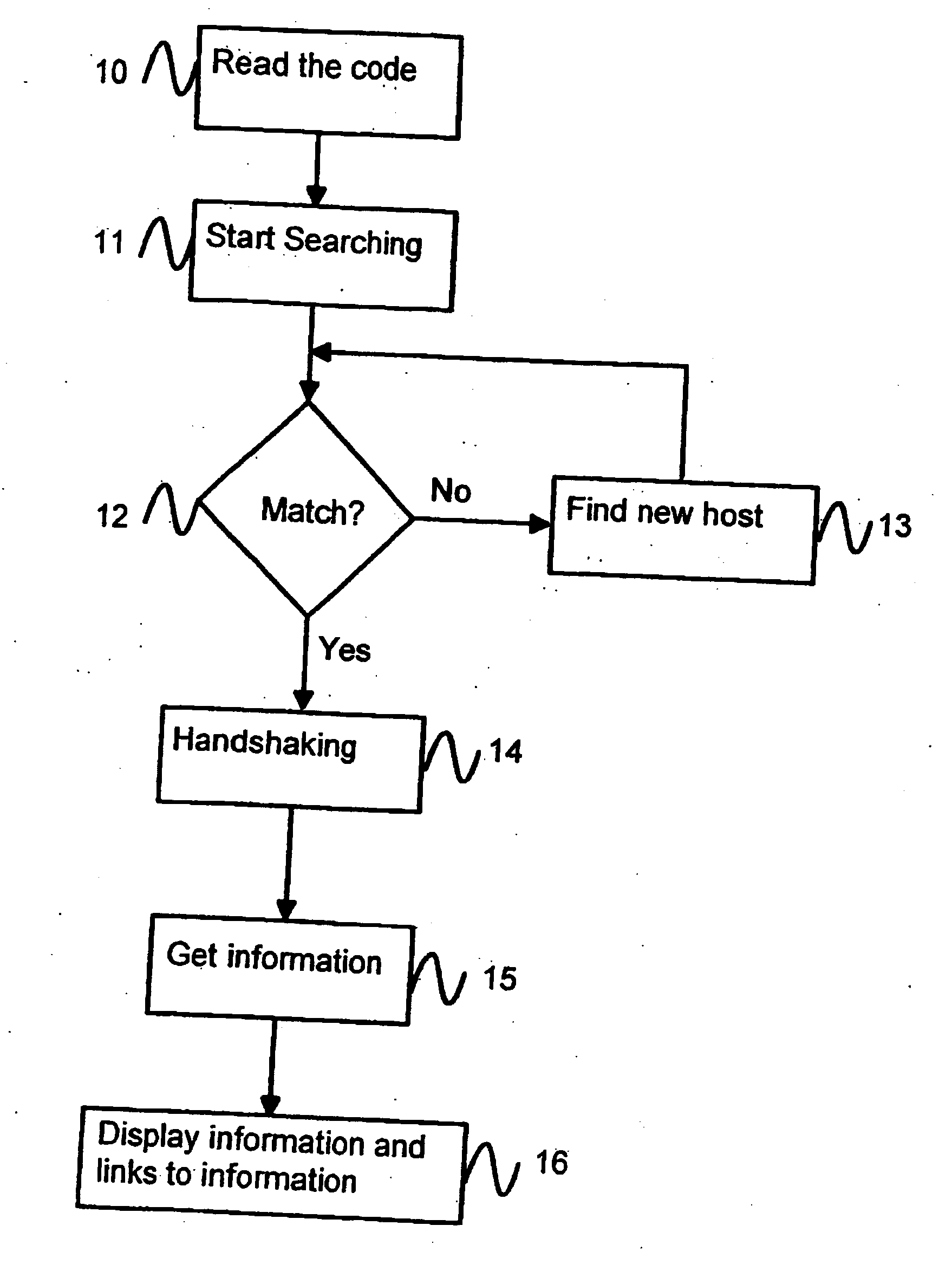

Distributed product information management

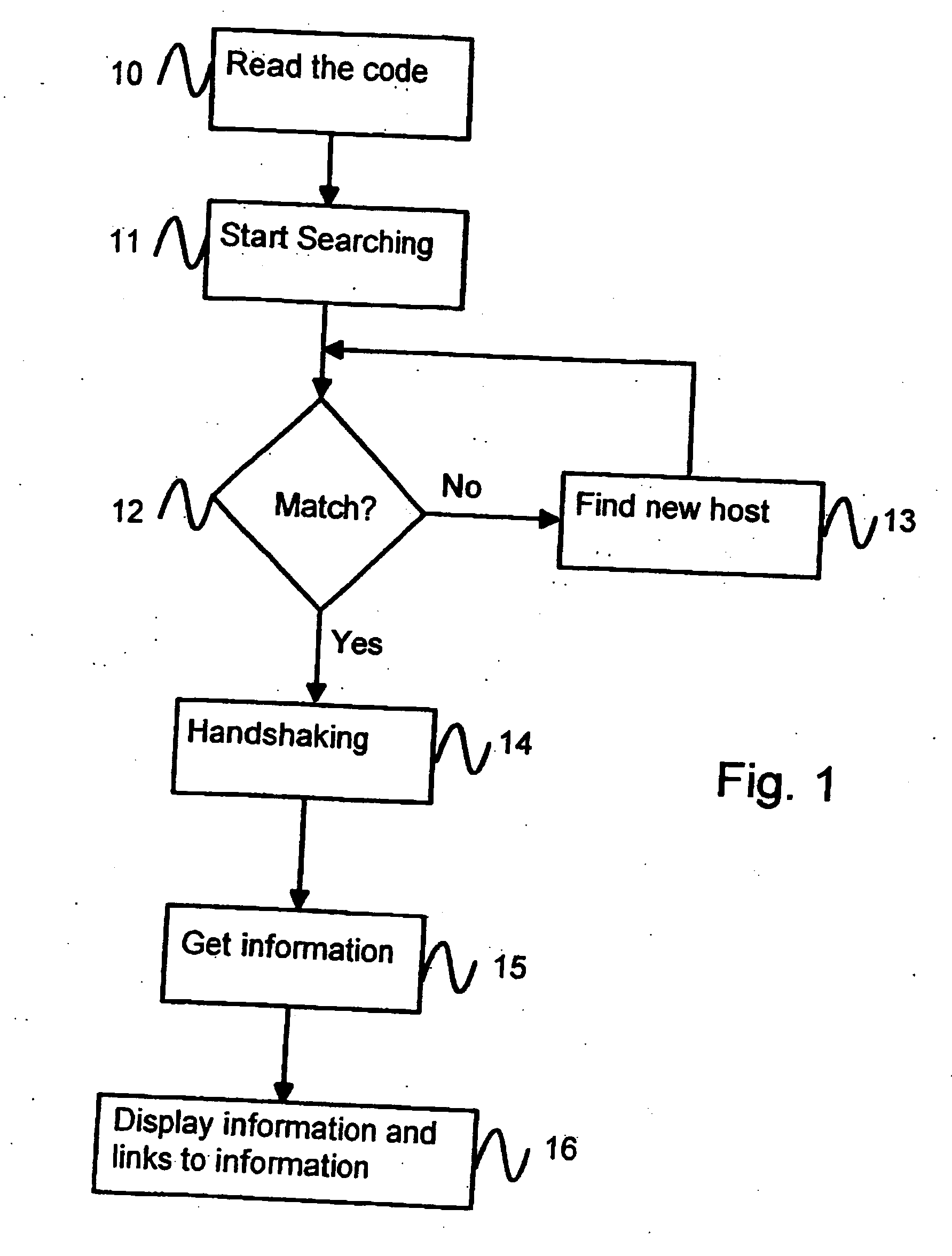

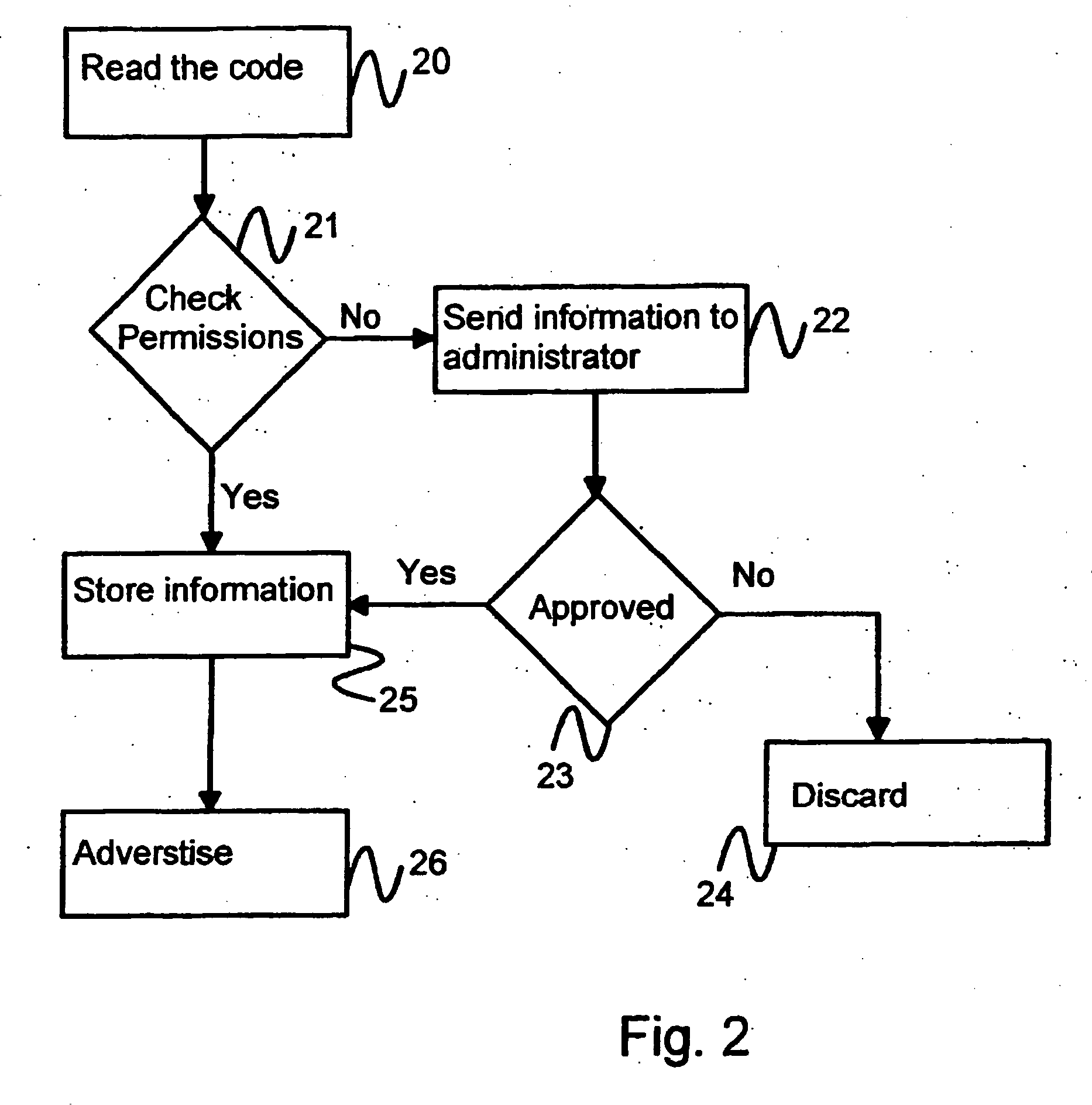

InactiveUS20060212425A1Effective wayWeb data indexingBuying/selling/leasing transactionsWorld Wide WebHost machine

The present invention discloses a method and a system for managing distributed product information. The products ( 30 ) are equipped with unique product information code ( 31 ). Unique codes indicate information stored to information hosts ( 34, 36, 38 ). The hosts are aware of other hosts and if the host does not have any information about requested product the request is directed to the next host. The product information comprises links to all hosts having information about requested product. When ever a new product code is added to the host it will advertise the code to the other hosts having information relating to the same product code.

Owner:ELISA

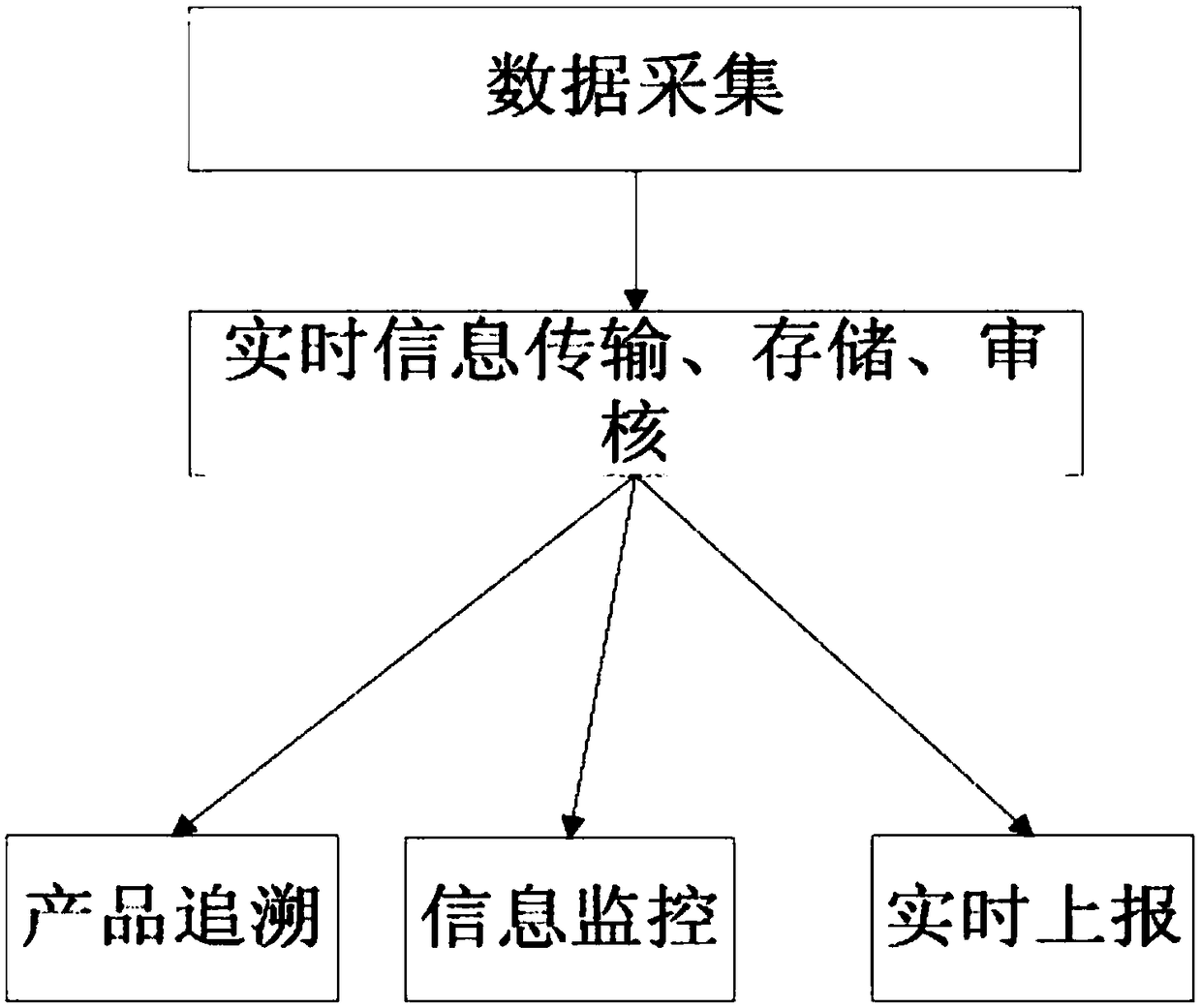

Internet-of-things-based collection and alarm system for real product state

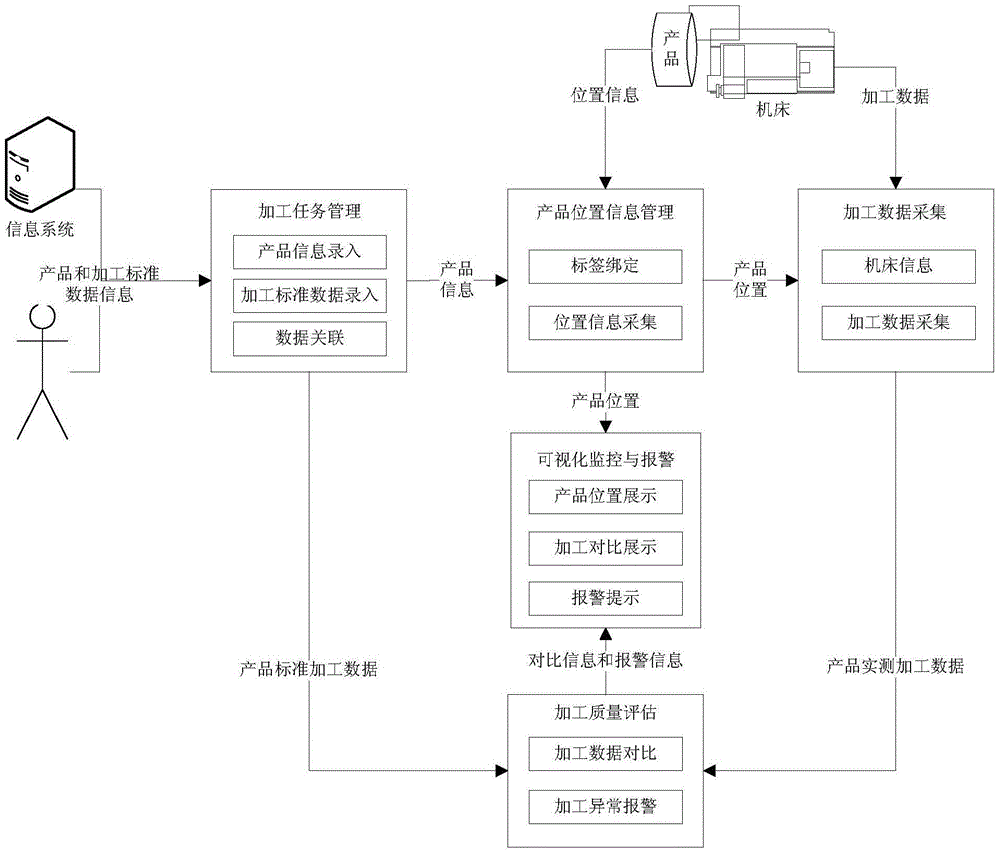

ActiveCN105425743AReal-time searchImprove efficiencyMemory record carrier reading problemsTotal factory controlVisual monitoringData acquisition

The invention provides an internet-of-things-based collection and alarm system for a real product state. The system is composed of a product information management module, a position information acquisition module, a processing data acquisition module, a quality evaluation module and a visual monitoring and alarm module. A product identification number, production information, and processing standard data are recorded into the product information management module; the position information acquisition module collects production and position information based on binding of the product with an RFID tag; the processing data acquisition module collects processing data in real time when the product is processed on a machine tool; the quality evaluation module searches corresponding processing standard data of a corresponding processed product according to the position of the machine tool and carries out comparison and determination on the processing standard data and actually measured data, and alarming is carried out when a deviation degrees exceeds a threshold value; and the product position and alarm prompting information are displayed for a product processing worker by the visual monitoring and alarm module. Therefore, collection efficiency of the product position information during the production process is improved; the product quality is evaluated during the processing process; the wrong operation is stopped based on alarming; and the economic losses are reduced.

Owner:BEIJING SATELLITE MFG FACTORY

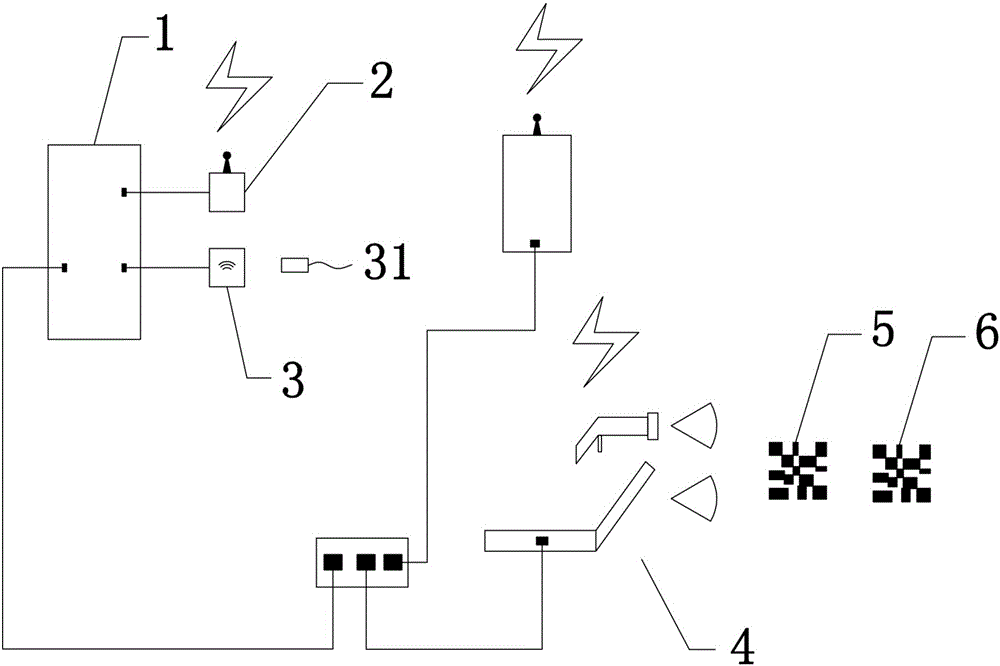

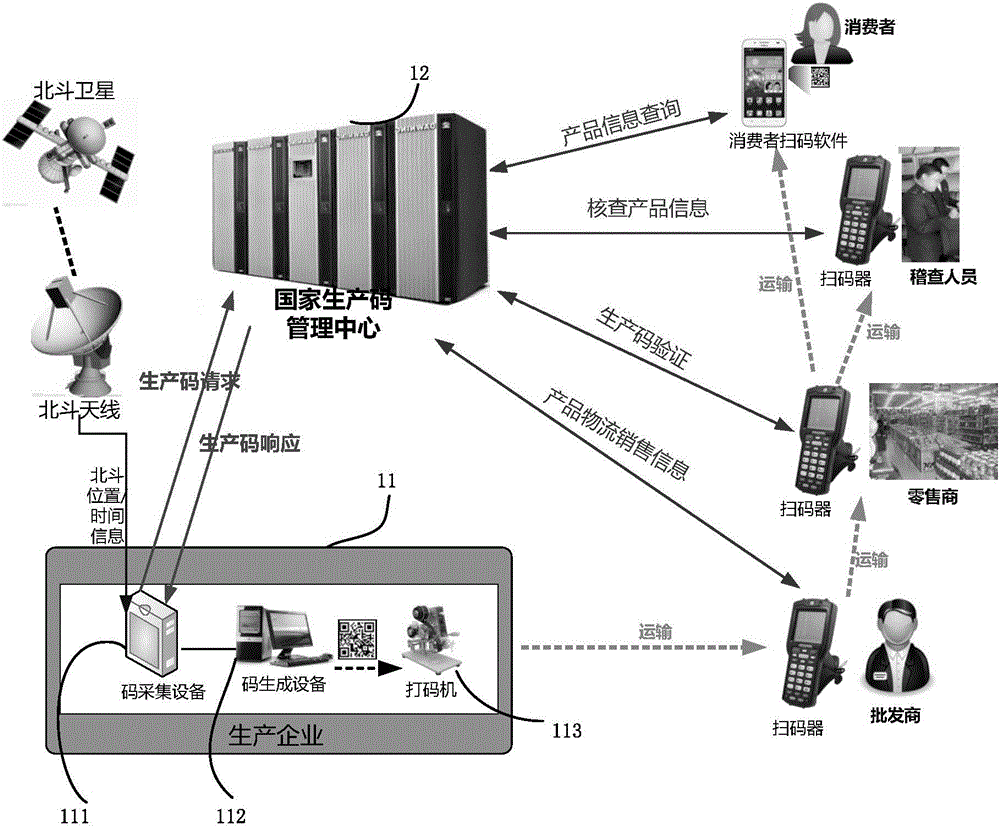

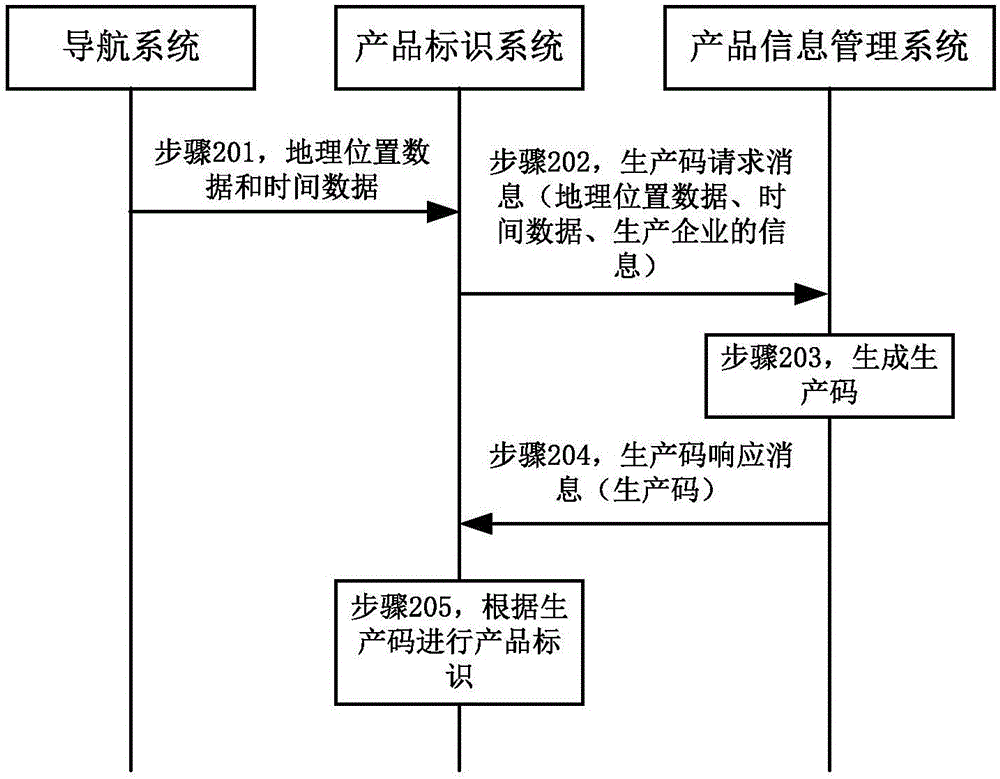

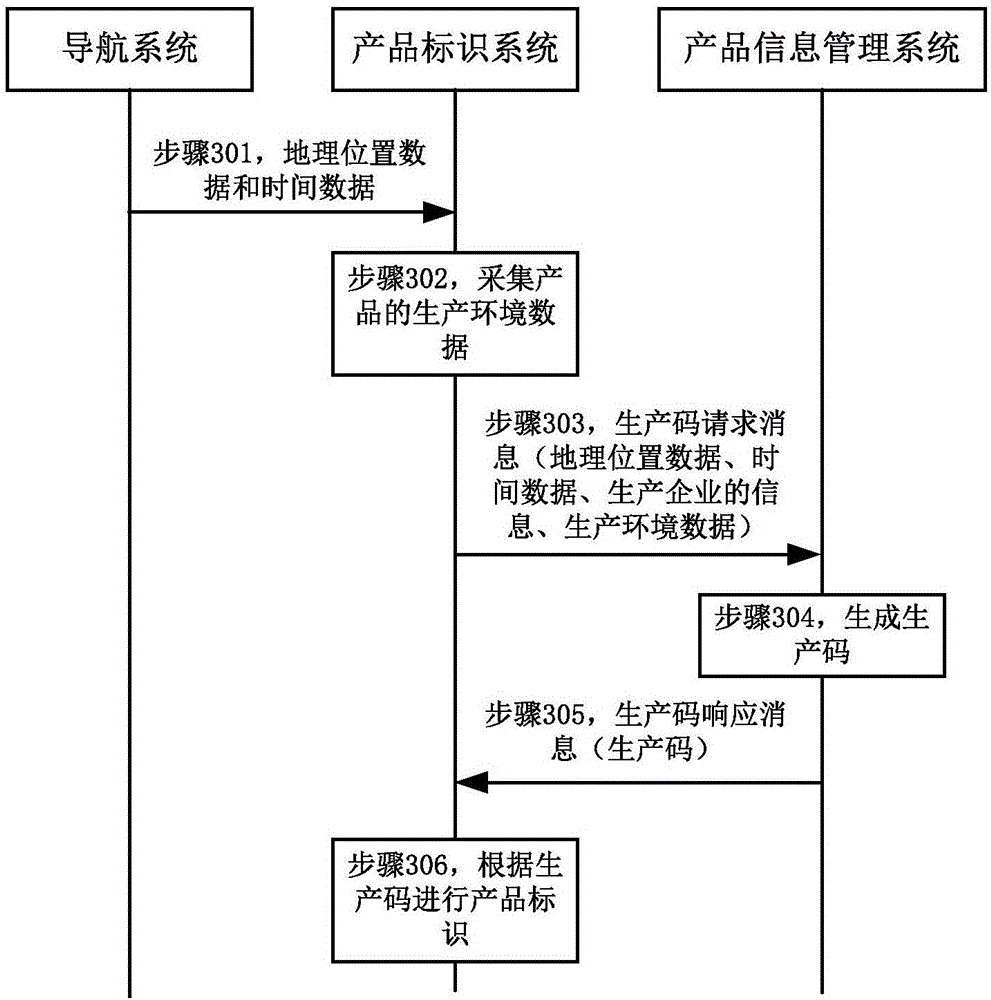

Product identification methods, product identification systems and product information management systems

Embodiments of the present invention relate to product identification methods, product identification systems and product information management systems. The method comprises the steps that when the product identification system of a manufacturing enterprise determines that products need to be identified, the product identification system acquires geographical position data and time data of the products from a navigation system; the product identification system sends a production code request message to the product information management system, wherein the production code request message carries the geographical position data, the time data and information of the manufacturing enterprise, and the production code request message is used for indicating the product information management system to generate a unique production code for identifying the product according to the geographical position data, the time data and the information of the manufacturing enterprise; the product identification system receives a production code response message sent by the product information management system, wherein the production code response message carries the production code; and the product identification system performs product identification on the product according to the production code. According to the methods provided by embodiments of the present invention, fake and shoddy products can be identified effectively.

Owner:北京雅恩科技有限公司

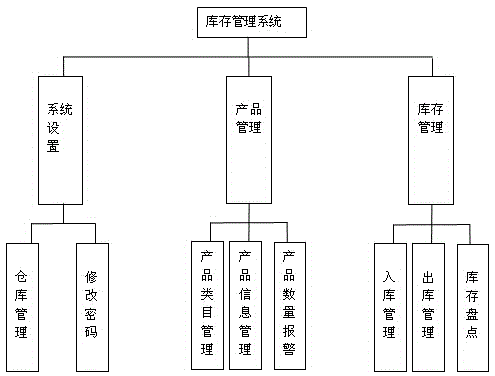

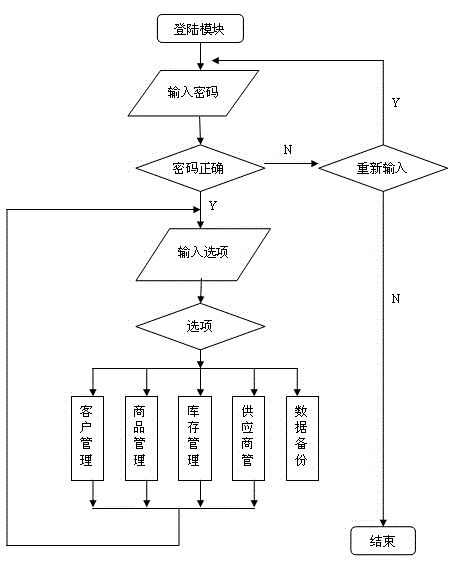

Commodity inventory management information system

InactiveCN104318414AImprove resource utilizationImprove accuracyLogisticsSpecial data processing applicationsInformation processingData stream

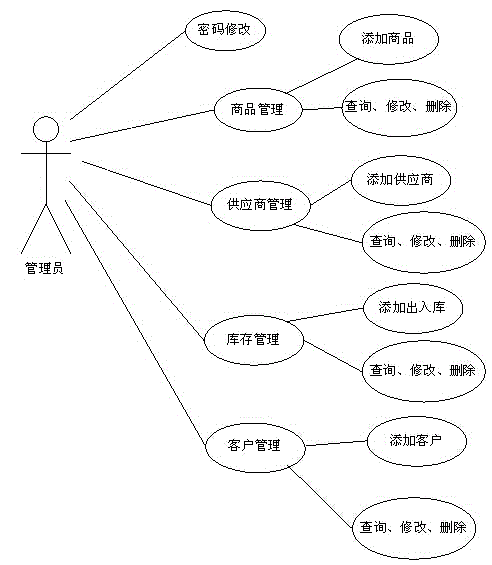

The invention discloses a commodity inventory management information system, and relates to the computer management system. The commodity inventory management information system uses a Browser / Server structure as an overall structure of the commodity inventory management information system, and is provided with a system setup unit, a product management unit and an inventory management unit, wherein the system setup unit comprises a store management module and a password change module, the product management unit comprises a product category management module, a product information management module and a product quantity alarm module, the inventory management module comprises a warehousing management module, a warehouse exit management module and an inventory verification module, and data flows, data elements, data storage, data processing and external items of all the above modules are described through a data dictionary, corresponding database lists are built, and the database lists are connected with a database through a JDBC (java database connectivity) technology of the Java language. The commodity inventory management information system can avoid commodity business management randomness, improves accuracy and speed of commodity information processing, and accurately and timely grasps internal market information and other external information of a company so as to improve decision ability of company leaders.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

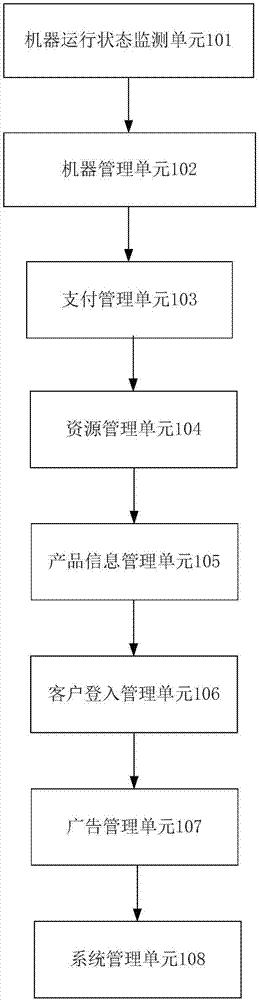

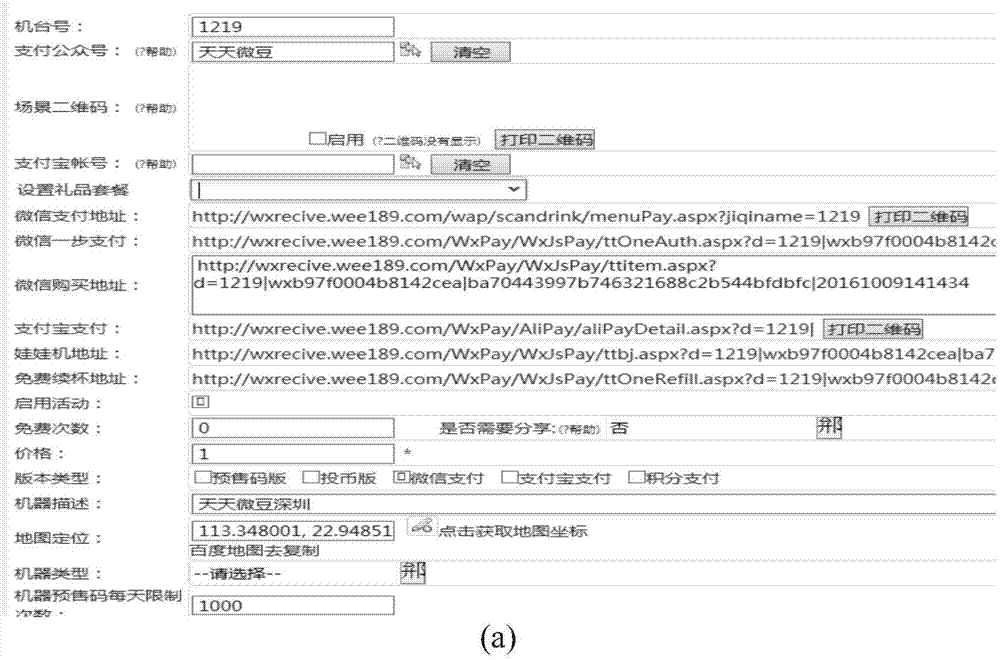

Management system of vending machines

InactiveCN107330595AAchieve management controlEfficient managementCoin-freed apparatus detailsPayment architectureUser needsPayment

A management system of vending machines disclosed by the present invention comprises a machine operation state monitoring unit used for monitoring the accumulated income of the machines, the total order number and the total machine number, and providing a financial statement according to the monitored data; a machine management unit used for users to edit and manage the setting of the machines; a payment management unit used for providing the payment accounts of the users needed to bind at a background and managing the payment accounts; a product information management unit used for setting the pictures of the products, the serial port commands of the products and the prices of the products according to the demands to manage the information of the products. According to the present invention, the management control of the vending machines can be realized, the conditions of the vending machines, such as the complete machine conditions, the sale conditions, the purchase-sale-stock conditions, etc., can be managed.

Owner:招财猫(广州)高新科技有限公司

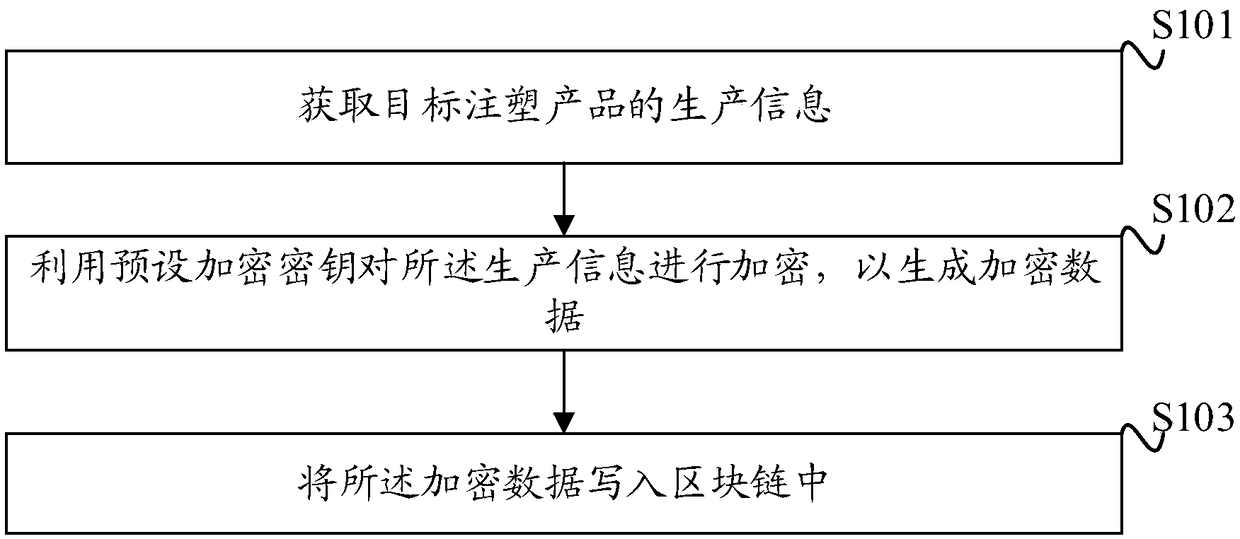

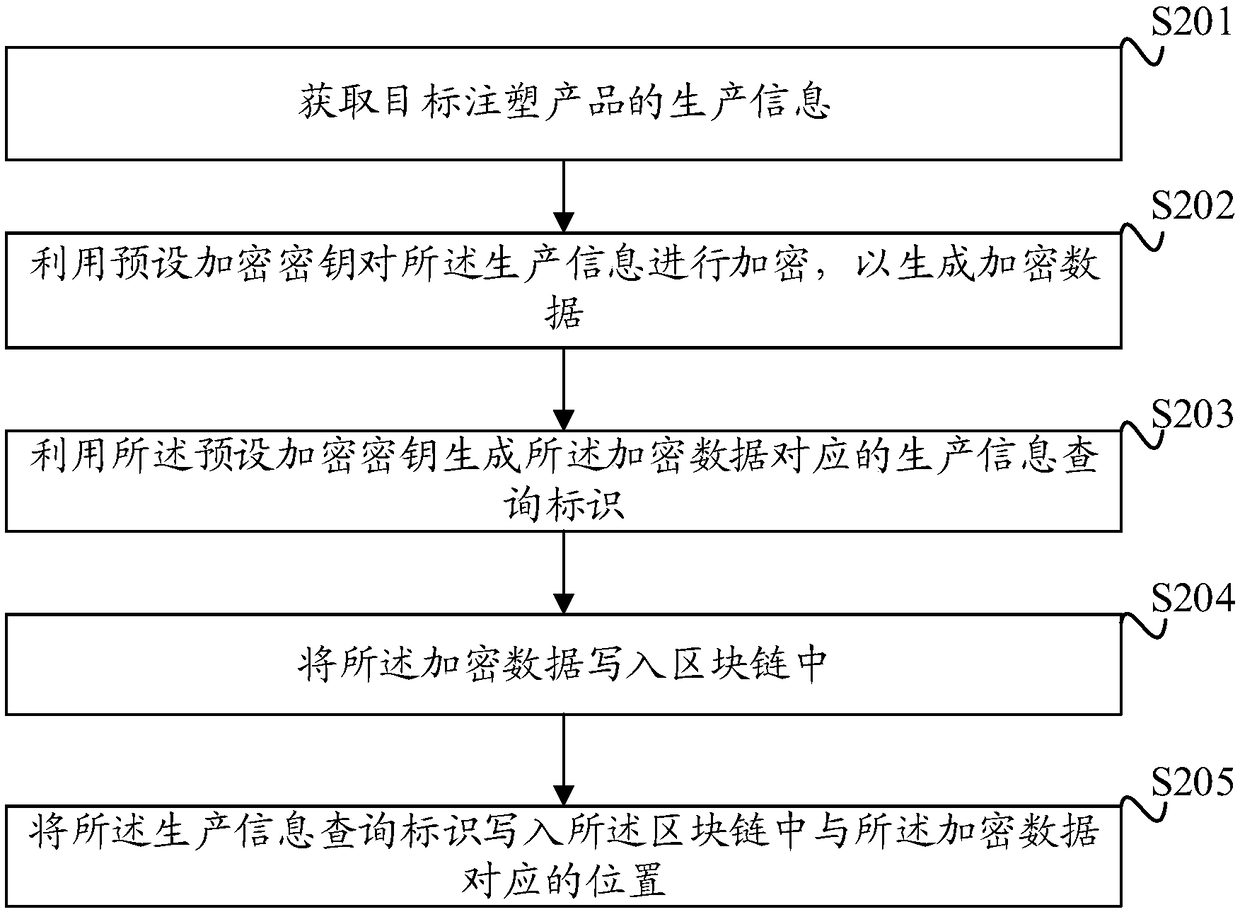

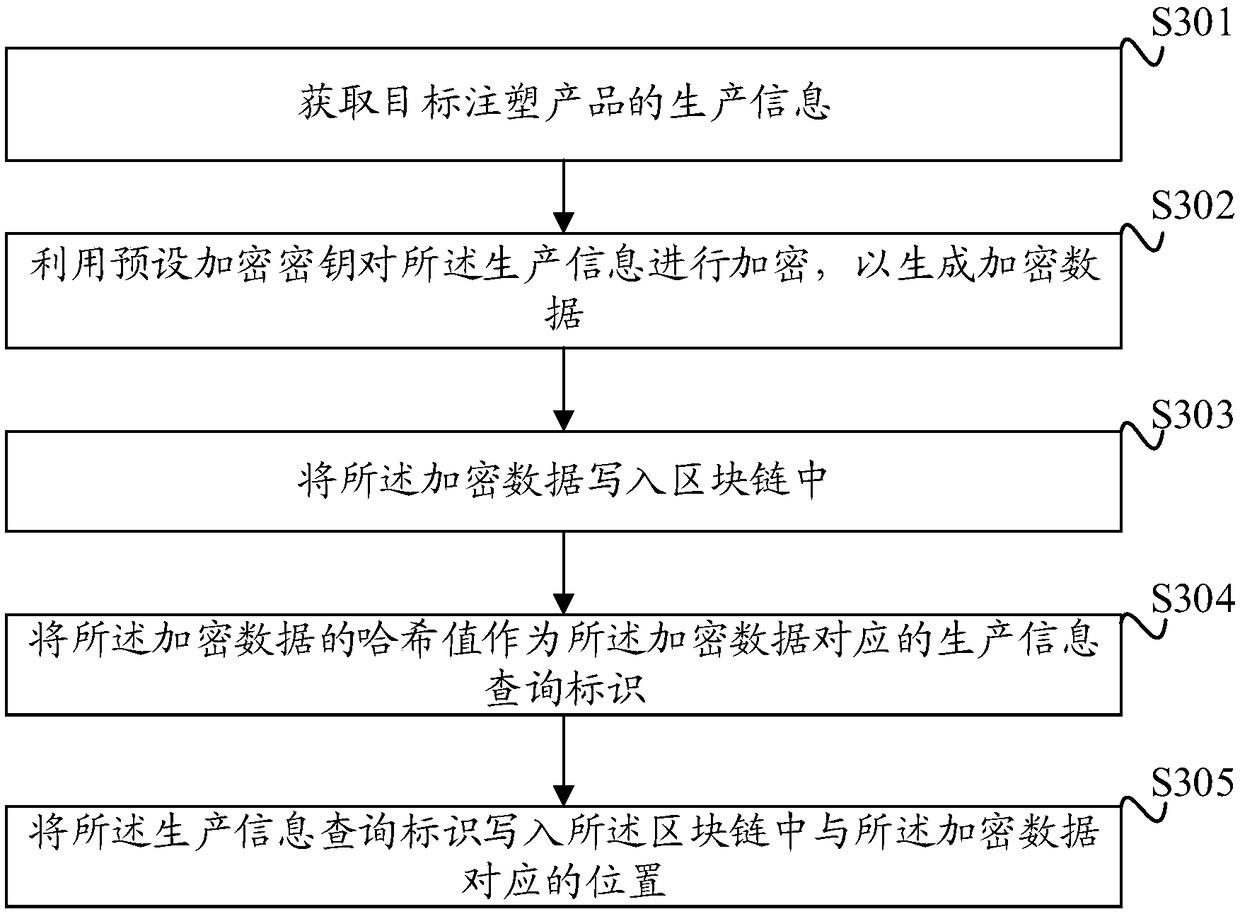

Block-chain-based injection molding product information management method, server, and injection molding machine

InactiveCN109271801AAvoid lossPrevent leakageDigital data protectionOther databases indexingDependabilityInjection molding machine

The invention discloses a block-chain-based injection molding product production information management method and device, a server and an injection molding machine, relates to the technical field ofblock chains, and is used for solving the problem of data leakage or loss caused by the server being damaged when the injection molding machine molding parameters are stored by the server in a unifiedmode. The method comprises: obtaining production information of a target product, and encrypting the production information by using a preset encryption key to generate encrypted data, further writing the encrypted data into the block chain, as can be seen from the above, the production information is encrypted, and stored in the block chain, the properties of incapability of information tampering and extremely high stability and reliability peculiar to a block chain technology are fully utilized, thus the encrypted production information is stored in the block chain, stable and safe storagecan be guaranteed, the problem of information loss or leakage caused by server damage after all the production information is stored in the server in the prior art is avoided, and the information security is improved.

Owner:NINGBO TECHMATION

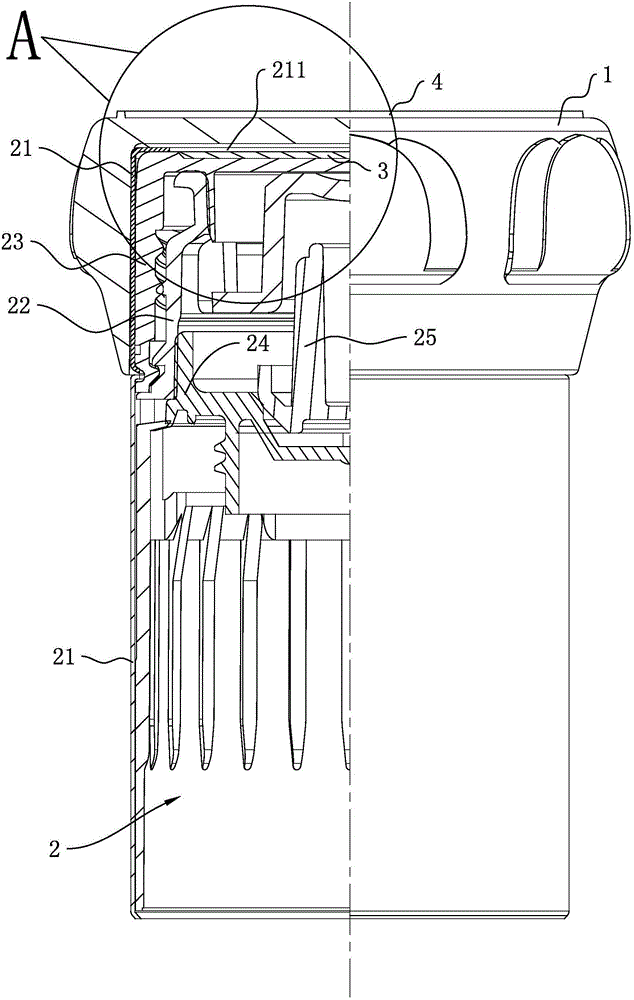

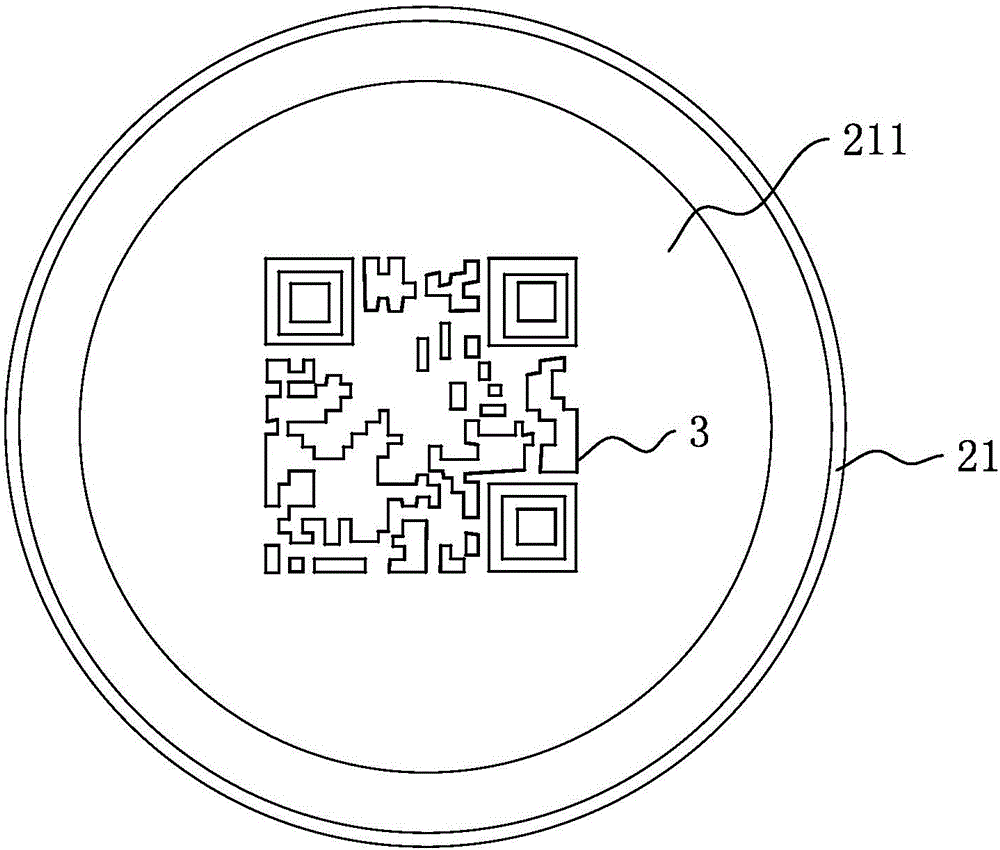

Novel bottle cap with inner and outer double anti-fake codes and manufacturing method of novel bottle cap

ActiveCN105691883ASimple structureStrong anti-counterfeiting functionClosure with auxillary devicesEngineeringBottle cap

The invention provides a novel bottle cap with inner and outer double anti-fake codes and a manufacturing method of the novel bottle cap. The bottle cap comprises an outer cap body and an inner cap part located in the outer cap body. An opening part is formed in the top of the inner cap part. The opening part is internally provided with the anti-fake inquiry code used for recording encrypt data. The opening part can be completely shielded by the outer cap body. The outer portion of the outer cap body is provided with the information inquiry code used for recording product information. The anti-fake inquiry code and the information inquiry code are in corresponding relevance. The invention further provides the manufacturing method of the bottle cap. The manufacturing method includes the steps that firstly, the anti-fake inquiry code and the information inquiry code are arranged on the bottle cap forming parts; then the double codes are scanned; and finally, the bottle cap is assembled. The bottle cap manufactured through the method is simple in structure, low in manufacturing cost, good in anti-fake effect and capable of facilitating achieving of product information management.

Owner:海普智联科技(德阳)有限公司

Online flash auction marketing system based on WeChat platform

InactiveCN108280675AFast saleQuick saleBuying/selling/leasing transactionsMarketingLibrary scienceAuthentication

The invention provides an online flash auction marketing system based on a WeChat platform. The online flash auction marketing system based on the WeChat platform is characterized in that the online flash auction marketing system is developed based on the WeChat platform and comprises a plurality of modules which are operated in coordination, such as a background management module, an authentication module, a promotional product information management module, an order management module, a flash auction management module and a cheating decision module. The online flash auction marketing systemhas the advantages of providing fast and efficient product promotion and sale, enhancing participation enthusiasm of shopping users, and being fast, convenient and low in cost.

Owner:广东所能网络有限公司

Enterprise internal information system

InactiveCN102708457AIntelligent managementFlexible managementResourcesUser PrivilegeNetwork connection

The invention discloses an enterprise internal information system, which comprises a backstage management module and a system management module, wherein the backstage management module comprises a product information management module, a client information management module, a crew information management module, a production plan management module, a research and development project management module and other shared information modules; and the system management module comprises an information security protective module and a user authority management module, and the modules are connected through networks and perform data operations through a client side. The enterprise internal information system builds enterprise internal networks, establishes a software date base of enterprise internal basic information, achieves information sharing and communication among departments inside the enterprise, performs standard management on various kinds of information, facilitates data statistics and analysis, and can improve stability, timeliness, safety and flexibility of enterprise internal management.

Owner:SUZHOU BAISIMAI INFORMATION CONSULTING

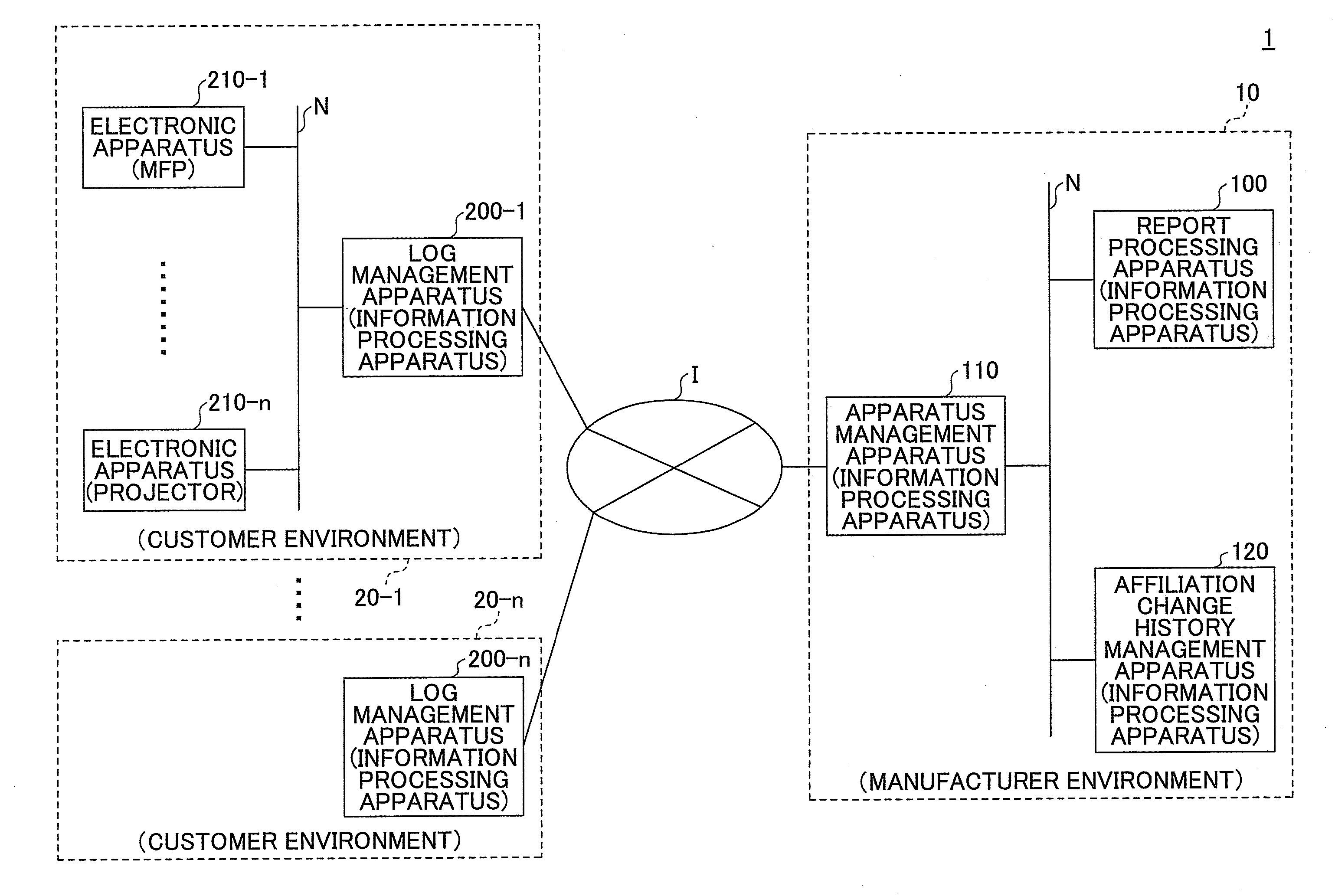

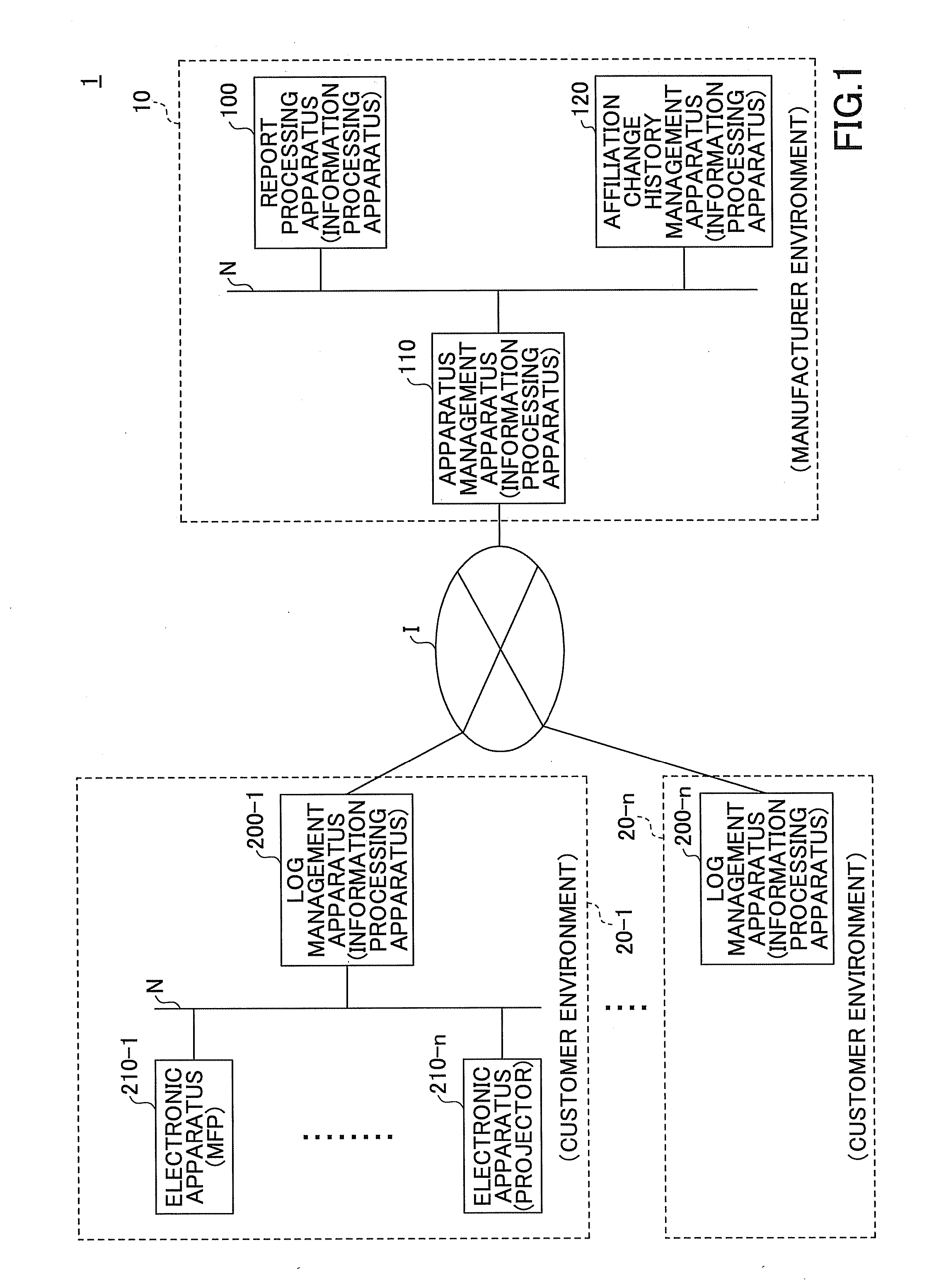

Information management system and information processing apparatus

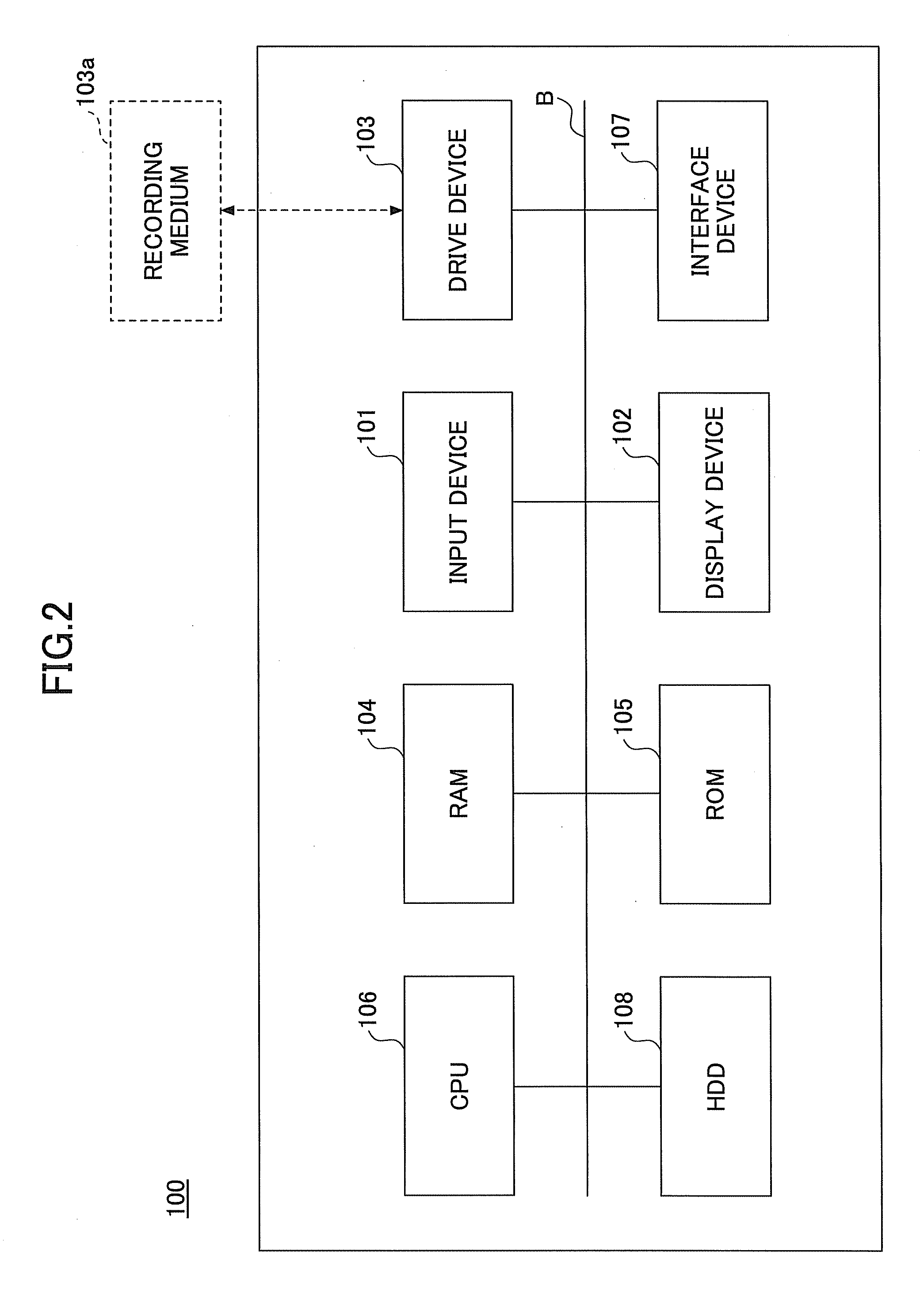

InactiveUS20130054844A1Eliminate the problemInput/output processes for data processingInformation processingStorage cell

An information management system includes: a first storage unit to retain history information, acquired from an electronic apparatus, indicating use history of the electronic apparatus, and a second storage unit to retain transition information indicating transition of an operation environment of the electronic apparatus in an installation site of the electronic apparatus; and an information processing apparatus to output a report indicating a use status of the electronic apparatus. The information processing apparatus includes: an acquisition part to acquire said transition information from the second storage unit and acquire said history information from the first storage unit; a creation part to create report data which aggregates apparatus use status for each affiliation area to which the electronic belongs during a designated report period based on the transition information and the history information; and an output part to output the report data created by the creation part.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com