Product traceability method of electronic assembly process based on RFID tags

A technology of RFID tags and assembly process, which is applied in the direction of cooperative operation devices, data processing applications, instruments, etc., can solve the problems of different information structures, complex production process of electronic assembly workshop, and complex information types in assembly process, etc., to achieve improvement. Integrity and inaccuracy, guarantee the effect of visual control and traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

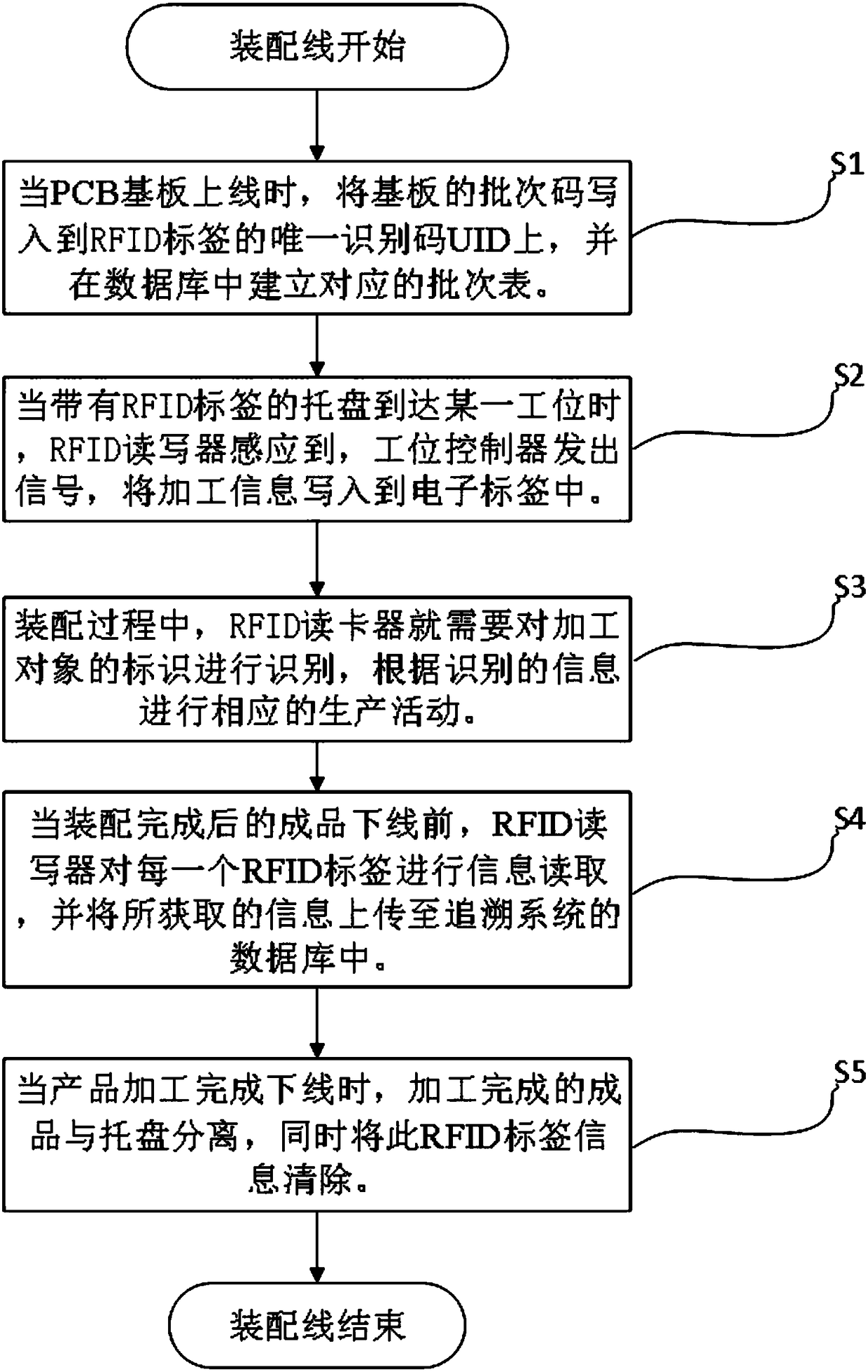

[0026] combine figure 1 , which is a flow chart of the RFID tag-based electronic assembly process product traceability method of the present invention; the present invention is a RFID tag-based electronic assembly process product traceability method, comprising the following steps:

[0027] S1: At the beginning of the production line, when the PCB substrate is on the line, write the batch code of the batch substrate into the unique identification code UID of the RFID tag, and establish a corresponding batch table in the product traceability system database;

[0028] S2: During assembly, when the pallet with the RFID tag arrives at a certain station, the RFID reader on the station first senses the arrival of the tag, and then the station controller on the station sends out a signal , write ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com