Novel bottle cap with inner and outer double anti-fake codes and manufacturing method of novel bottle cap

A technology of anti-counterfeiting codes and bottle caps, which is applied in the direction of capping with auxiliary devices, sealing parts with auxiliary devices, closing, etc., which can solve the problems of damaging the rights and interests of wineries and consumers, disrupting market order, and making counterfeit products. Achieve the effect of simple operation of anti-counterfeiting settings, realization of information management, and strong anti-counterfeiting functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

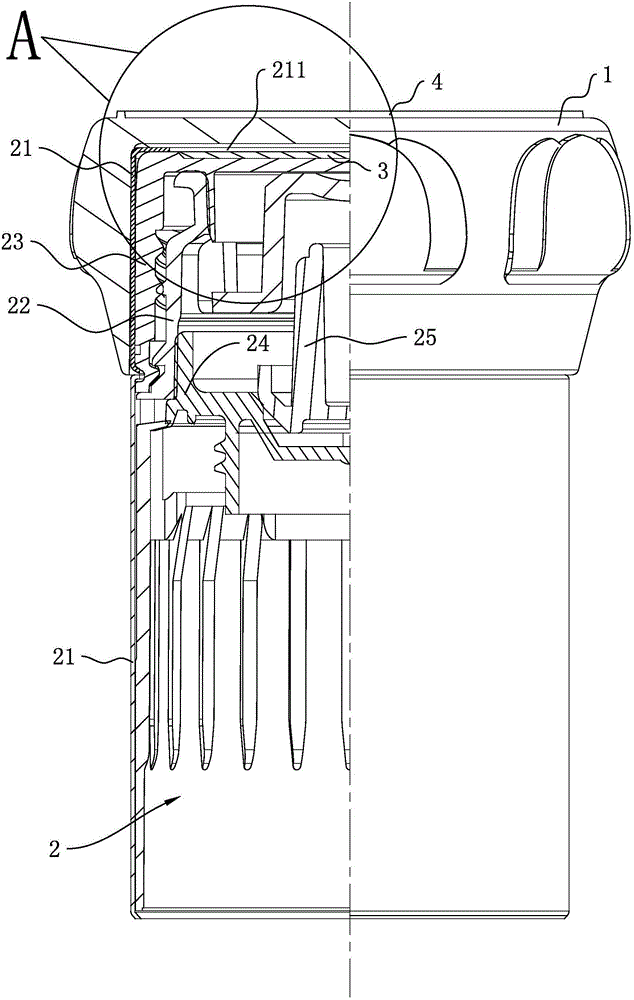

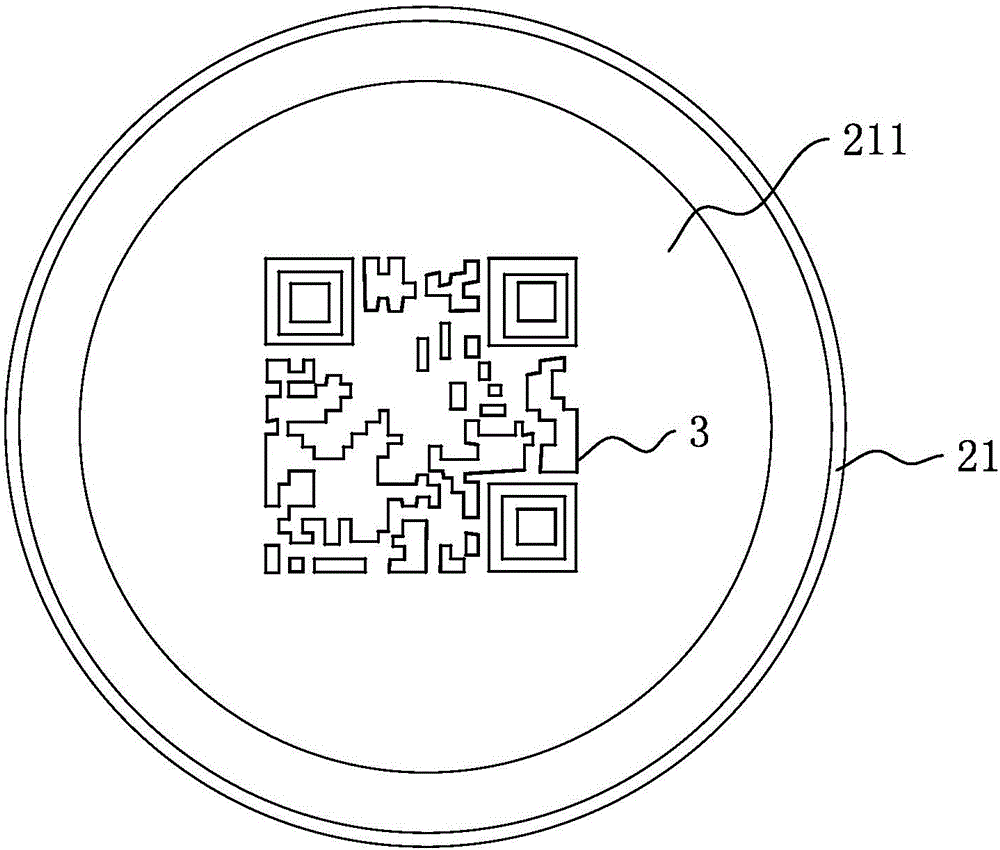

[0036] Such as figure 1 , figure 2 , Figure 5 As shown, the novel bottle cap with internal and external double anti-counterfeiting codes of the present invention includes an outer cap 1 and an inner cap part 2 inside the outer cap 1 . The inner cover part 2 includes an aluminum cylinder 21 , an inner sleeve 22 , a transparent cover 23 , an inner plug 24 and a check valve 25 . An opening is provided on the top of the inner cover part 2, and an anti-counterfeiting query code 3 for recording encrypted data is provided in the opening, and the outer cover 1 can completely cover the opening. Specifically, the upper part of the aluminum cylinder 21 protrudes into the outer cover 1 and is in surface contact with the outer cover 1 , and the lower part protrudes out of the outer cover 1 . The top of the aluminum cylinder 21 is provided with a hole 211, and the inner sleeve 22 is also provided in the aluminum cylinder 21. A transparent cover 23 is provided between the inner sleeve 2...

Embodiment 2

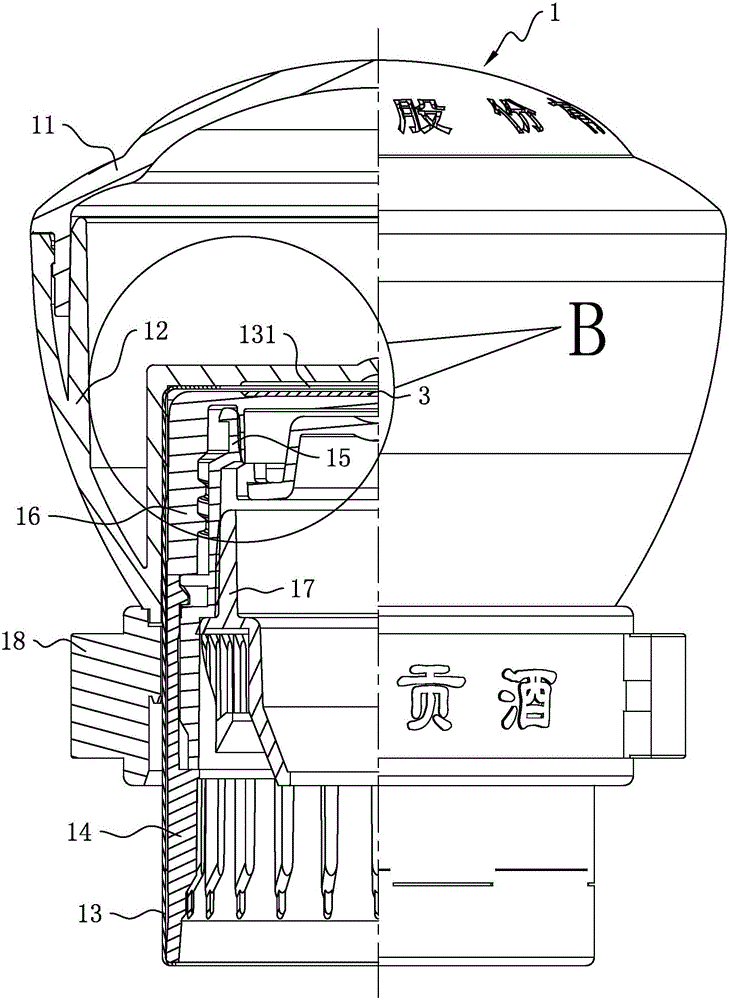

[0046] Such as image 3 , Figure 4 , Figure 6 Shown, outer cover 1 comprises upper crown-shaped cover 11, lower crown-shaped cover 12, and information query code 4 (omitted among the figures) can be arranged on the outer top wall of upper crown-shaped cover 11 or the outer side wall of lower crown-shaped cover 12 One place, or two places at the same time. The inner cover part 2 includes an aluminum sleeve 13, the upper part of the aluminum sleeve 13 extends into the lower crown 12 and is in contact with the lower crown 12, the top of the aluminum sleeve 13 is provided with a through hole 131, and the aluminum sleeve 13 also has a There is an outer jacket 14, an inner sleeve 15 is arranged inside the outer sleeve 14, a transparent cover 16 is provided between the inner sleeve 15 and the aluminum sleeve 13, the transparent cover 16 is located in the lower crown cover 12, and an anti-counterfeiting query code is arranged on the top of the transparent cover 16 3. An inner plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com