Plant source volatile organic matter test method

A technology of volatile organic compounds and testing methods, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as incomplete sample analysis, complex instrument structure, and broadened chromatographic peaks, so as to reduce analysis costs and avoid moisture interference , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of sampling tubes:

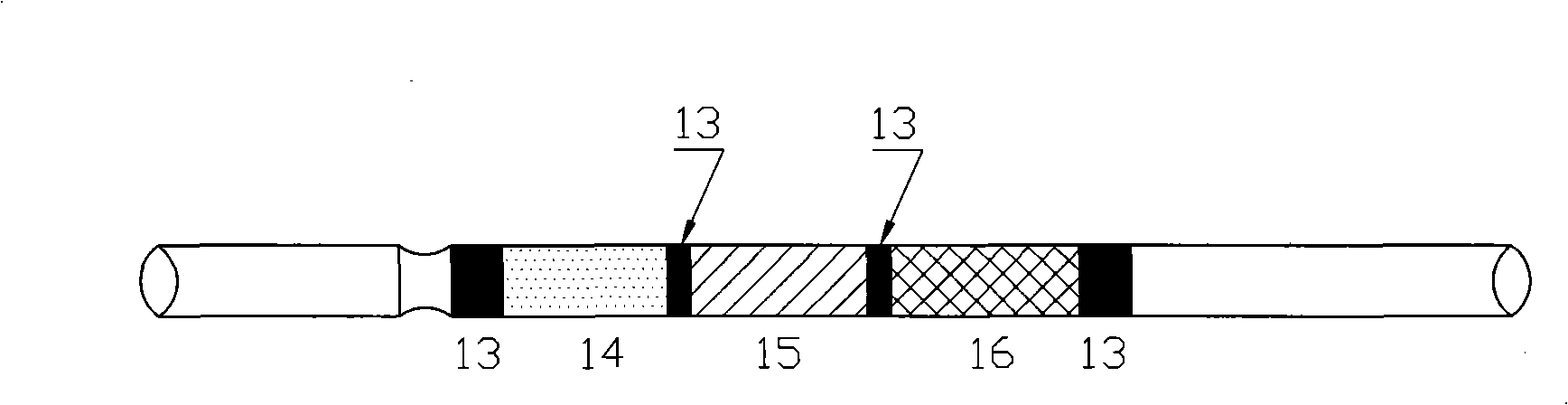

[0028] 1) Filling of the sampling tube: Tenax-TA, Carboxen 1000 and Carbosieve SIII were 60 mg, 35 mg, and 35 mg in turn, of which: Tenax-TA, Carboxen 1000 and Carbosieve SIII (purchased in Shanghai, Anpu Company) were adsorbed The agent is filled in a 115 mm × Φ6 mm (outer diameter) glass sampling tube, and the two ends of the sampling tube are filled with 5 mm quartz fibers 13, 14 of which are Tenax-TA fillers, 15 are Carboxen 1000 fillers, and 16 are Carbosieve SIII fillers.

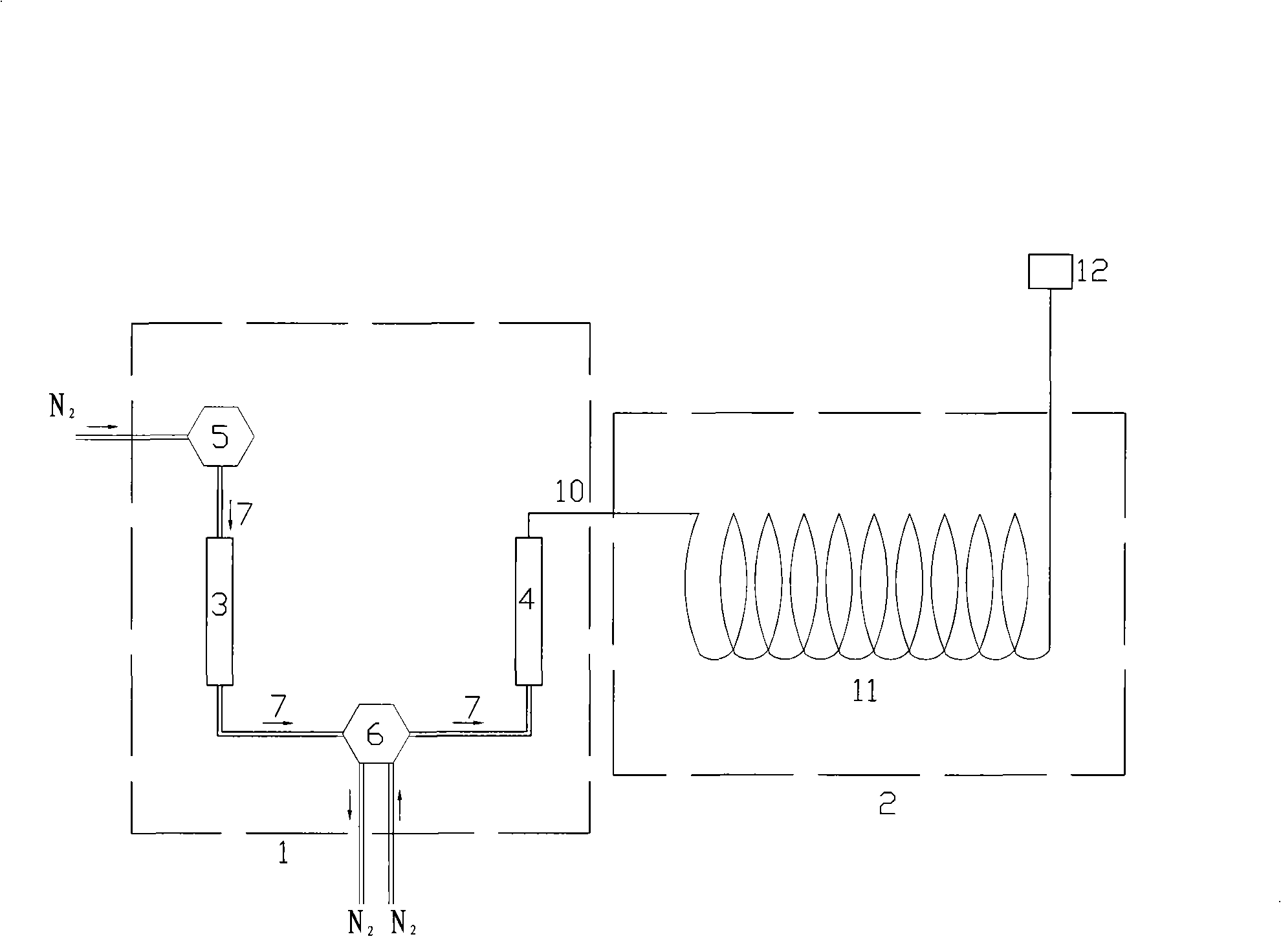

[0029] One end of the sampling tube is straight, and the front end of the other end has a groove, and the part of the sampling tube with the groove is connected to the inlet end of the carrier gas of the thermal desorption instrument (see figure 1 , figure 2 ).

[0030] 2) Aging of the sampling tube: put the filled sampling tube into the thermal desorption instrument, make it age at 250°C for 1 hour, then rapidly raise the temperature to 300°C for 1 hour, and...

Embodiment 2

[0038] Describe the performance of the secondary thermal desorber.

[0039] Take Δ3-carene, a representative compound of plant-derived volatile organic compounds, as an example. Get the Δ3-carene whose concentration is 0.1 mg / ml, and the solvent is 1 microliter of standard solution of methanol, and operate according to the measurement steps of Example 1 to obtain the analysis results (see Figure 3A ); Then, the adsorption tube is operated according to the measurement steps of Example 1 without regeneration and sample introduction, and the analysis results are obtained (see Figure 3B ), a total of 2 chromatograms were obtained. Comparing the two spectral lines A and B in Fig. 3, it can be seen that the analysis efficiency of the secondary thermal analyzer for plant-derived volatile organic compounds can reach more than 96%, reaching the level of a secondary thermal analyzer with a cold trap. structure effect.

Embodiment 3

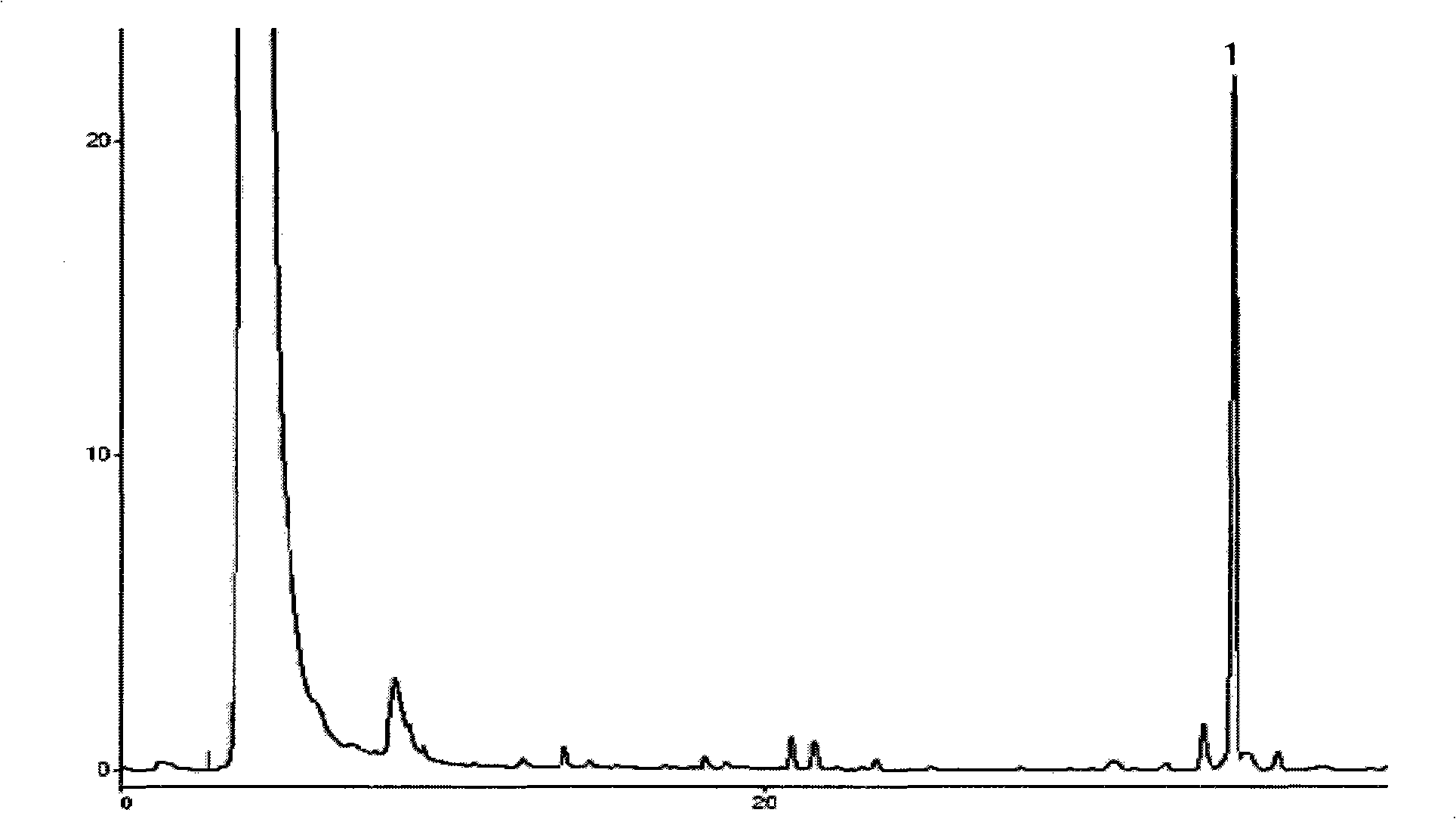

[0041] Camphene, α-pinene, β-pinene, Δ3-carene, d-limonene, α-terpinene and ocimene are the most representative compounds in plant-derived volatile organic compounds. Take 1 microliter of the mixed standard solution containing the above compounds, the concentration of camphene in the mixed standard solution is 0.01 mg / ml, and the concentration of other compounds is 0.1 mg / ml. Operation by the assay step of embodiment 1, obtain analysis result (referring to Figure 4 ) to obtain a chromatogram, it can be seen from the figure that the second thermal desorption sample injection can keep the capillary chromatographic column with a high separation ability of the chromatographic peaks, and achieve the effect of having a secondary structure of a cold trap. Among them, peak 2 to peak 8 are 2.α-pinene, 3. camphene, 4.β-pinene, 5.Δ3-carene, 6.α-terpinene, 7.d-limonene, 8. ocimene. Figure 4 It is the chromatogram of terpene standard sample analysis in embodiment 4. The analysis condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com