Method and device for measuring breakthrough pressure of porous medium material

A technology of porous media and measuring devices, which is applied in measuring devices, suspension and porous material analysis, soil material testing, etc. It can solve the problem of inaccurate measurement of breakthrough pressure of low-permeability porous media materials, too large breakthrough pressure value, and liquid discharge low quantity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A multi-method integrated porous media material breakthrough pressure and permeability coefficient measurement method at the same time, fast, efficient and accurate, the steps are as follows:

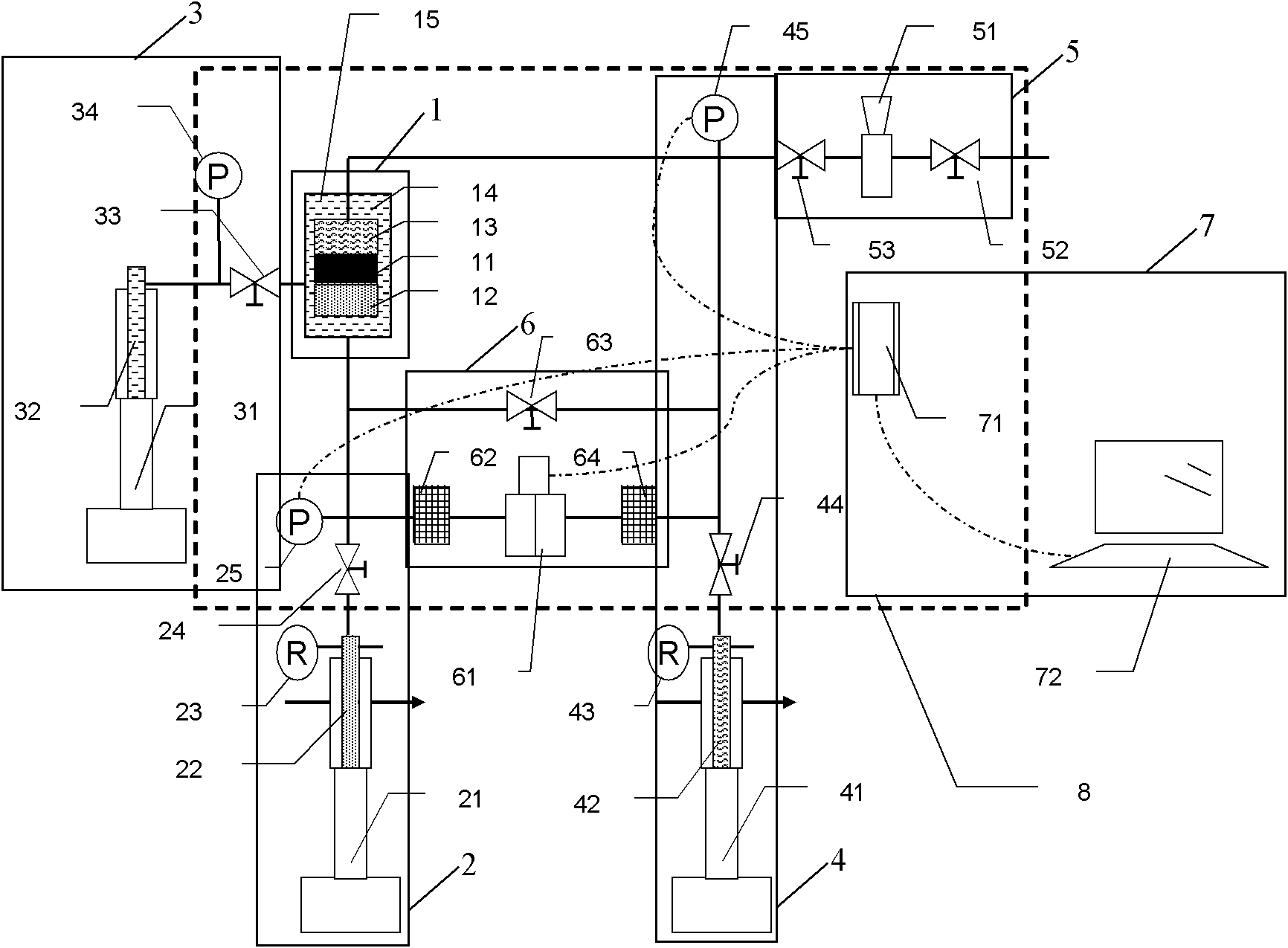

[0066] 1) According to figure 1 It can be seen that the saturated wet phase test piece 11 is placed in the holder 15, the entire measuring device is placed in the constant temperature control system 8, and the confining pressure medium is injected through the confining pressure injection system 3 to load the confining pressure stress on the tested piece 11;

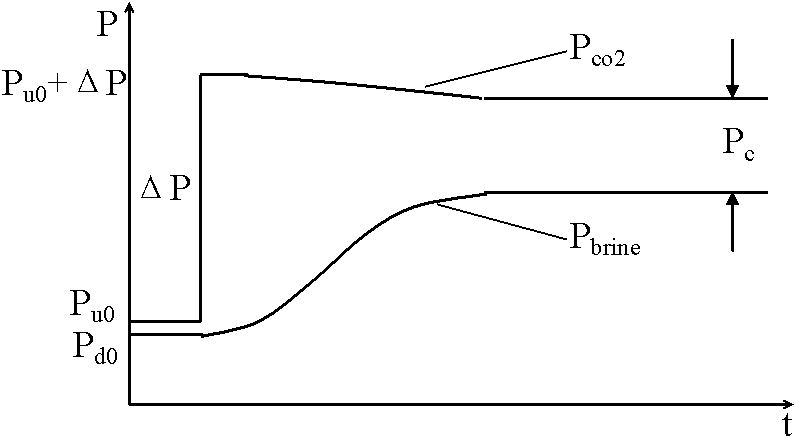

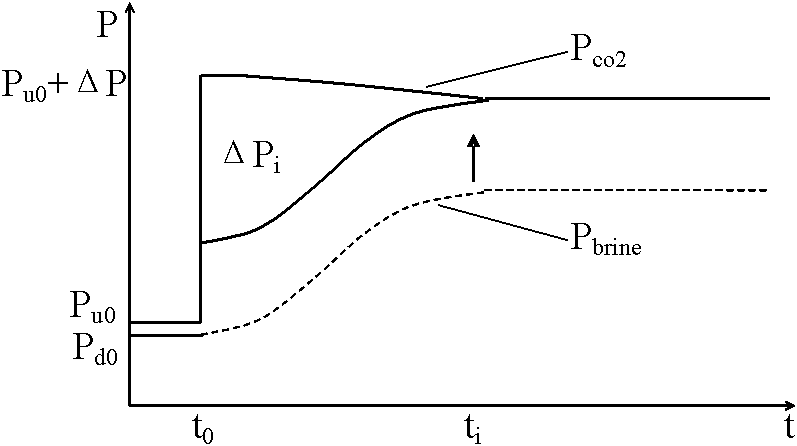

[0067] 2) Close the upstream vent valve 23, downstream vent valve 43 and back pressure vent valve 52, disconnect the communication valve 63, open the upstream control valve 24, downstream control valve 44 and back pressure control valve 53, and inject the system 2 through the upstream non-wetting phase Vacuum the upstream and downstream of the measuring device separately and simultaneously with the downstream wetting phase inject...

Embodiment 2

[0075] according to figure 1 It can be seen that the measurement of the breakthrough pressure of a porous media material (a multi-method integrated device for simultaneous, rapid, efficient and accurate measurement of the breakthrough pressure and permeability coefficient of the porous media material) includes the holder system 1. The upstream non-wetting phase The injection system 2, the confining pressure injection system 3, the downstream wetting phase injection system 4, the downstream back pressure system 5, the differential pressure monitoring system 6, the data acquisition and processing system 7, and the constant temperature control system 8, are characterized by: the gripper system 1 The holder 15 is connected to the confining pressure control valve 33 in the confining pressure injection system 3 through a pipeline, and its upstream is connected to the upstream control valve 24 and the upstream pressure gauge 25 in the upstream non-wetting phase injection system 2 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com