Performance and efficacy testing platform of heat exchanger

A test platform and heat exchanger technology, applied in the testing of machine/structural components, instruments, measuring devices, etc., can solve the problems of unfavorable installation testing, large space occupation, and high testing cost, and achieve stable and reliable test data. The effect of measuring demand and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

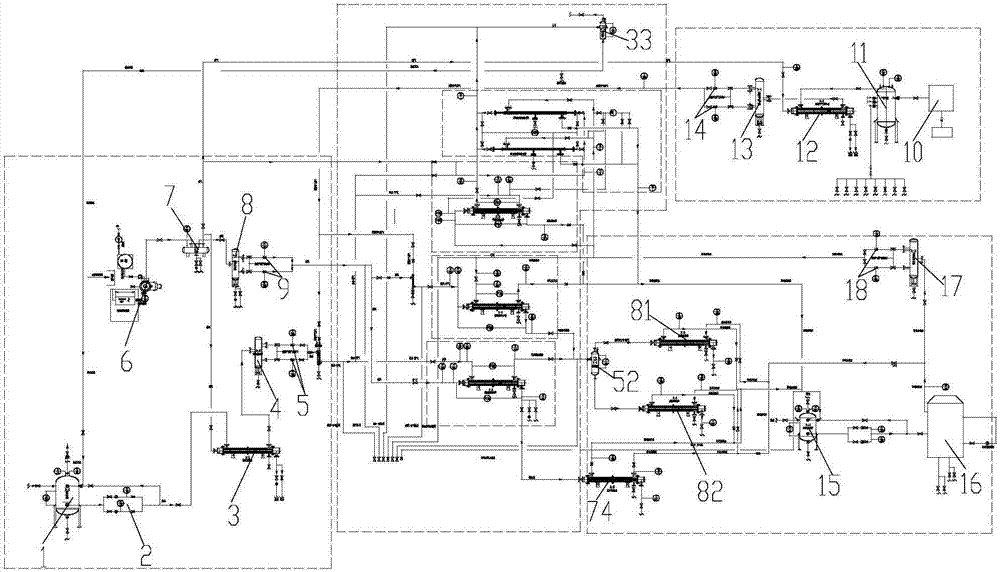

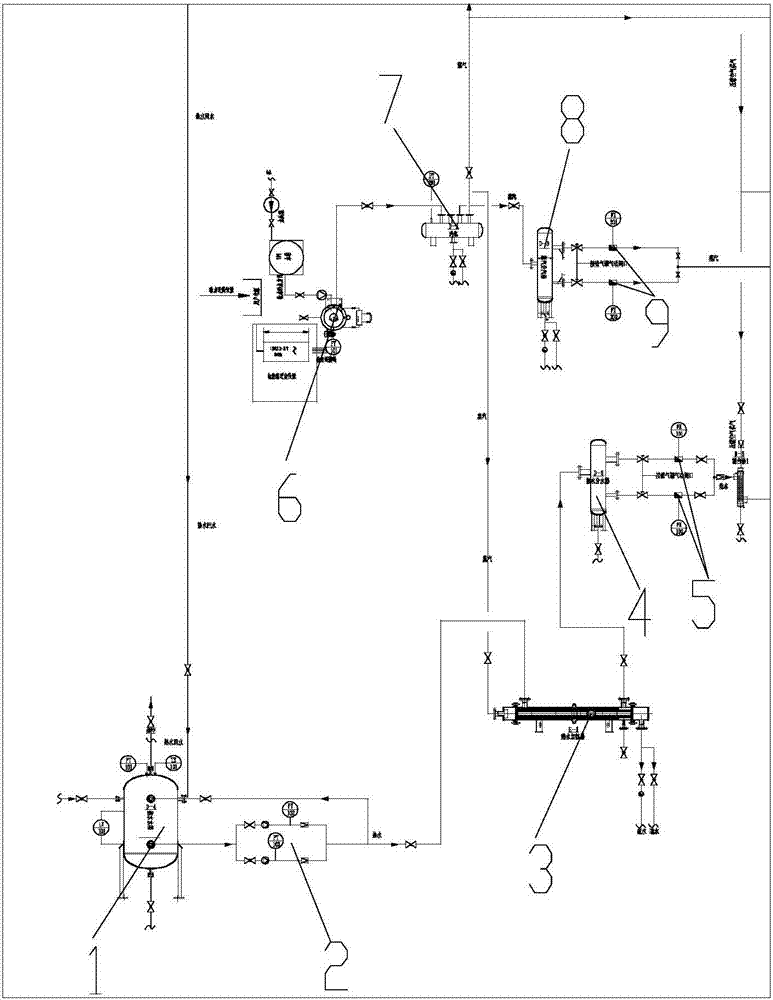

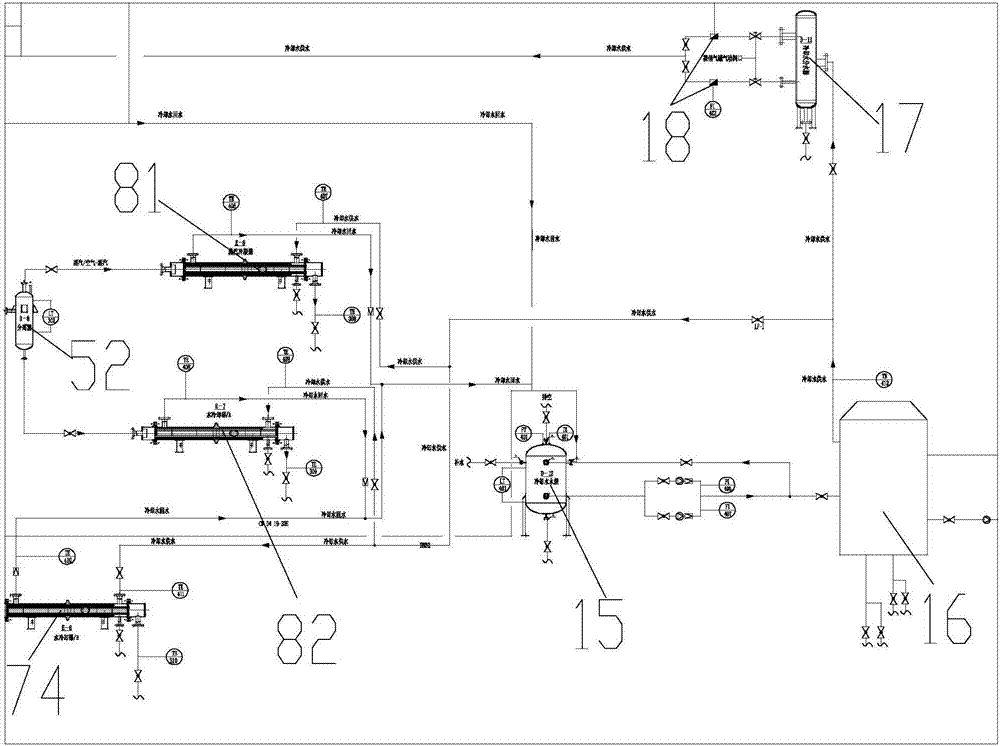

[0019] as attached Figure 1-9 The performance and energy efficiency test platform of a heat exchanger according to the present invention includes a heat source part, a steam source part, a first mixer 19, a second mixer 20, an air source part, a cold source part, a shell-and-tube Heat exchanger 30, first separator 33, shell-and-tube heat exchanger test assembly, condensing heat exchanger 51, boiling heat exchanger 71, first water cooler 74, second separator 52, steam condenser 81 and the second water cooler 82; the heat source part is composed of a hot water tank 1, a hot water circulation pump 2, a hot water heater 3, a hot water separator 4 and a heat source vortex flowmeter 5 connected in sequence; The heat source vortex flowmeter 5 links to each other with the first mixer 19; the steam source part is composed of an electric heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com