Horizontal laser measurement system and method for airplane

A laser measurement system and level measurement technology, applied in the field of measurement, to achieve accurate measurement values, reduce measurement errors, and save manpower for measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

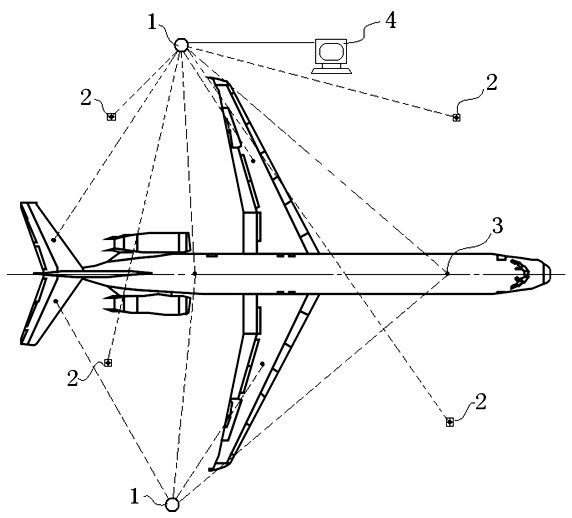

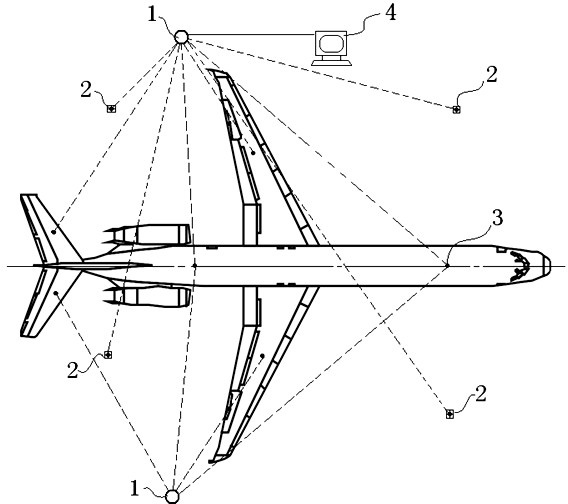

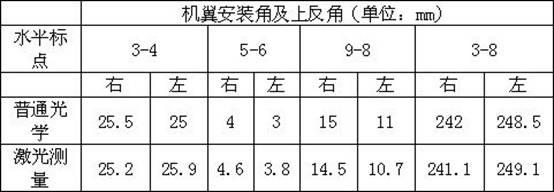

[0022] Example: The best embodiment of the present invention, aircraft horizontal laser measurement system, is made up of laser positioning device 1, horizontal reference coordinate point 2, horizontal measurement point 3 and computer 4, is provided with at least four horizontal reference coordinate points 2 around the aircraft, The horizontal reference coordinate point 2 is about 3-5 meters away from the fuselage, and there is no obstacle blocking the laser beam. A laser positioning device 1 is set on one side of the aircraft to be measured, and several horizontal measurement points 3 are set on the aircraft. The horizontal measurement points 3 are the measurement values required for leveling each aircraft, which are generally given when the aircraft is designed. quantity and location. The positions are generally distributed in positions such as the front section, the middle section, the vertical tail, the empennage and the wing of the fuselage, and the laser positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com