Patents

Literature

137results about How to "The measured value is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

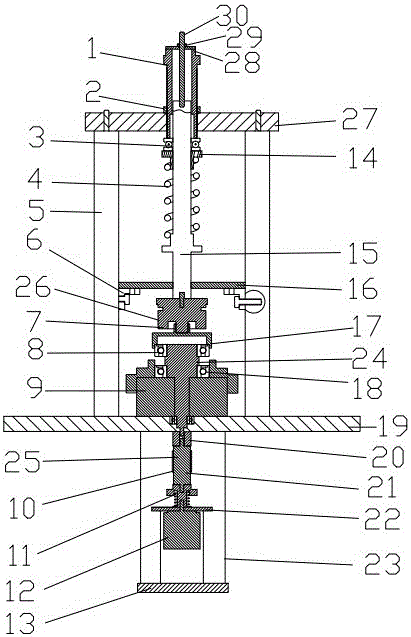

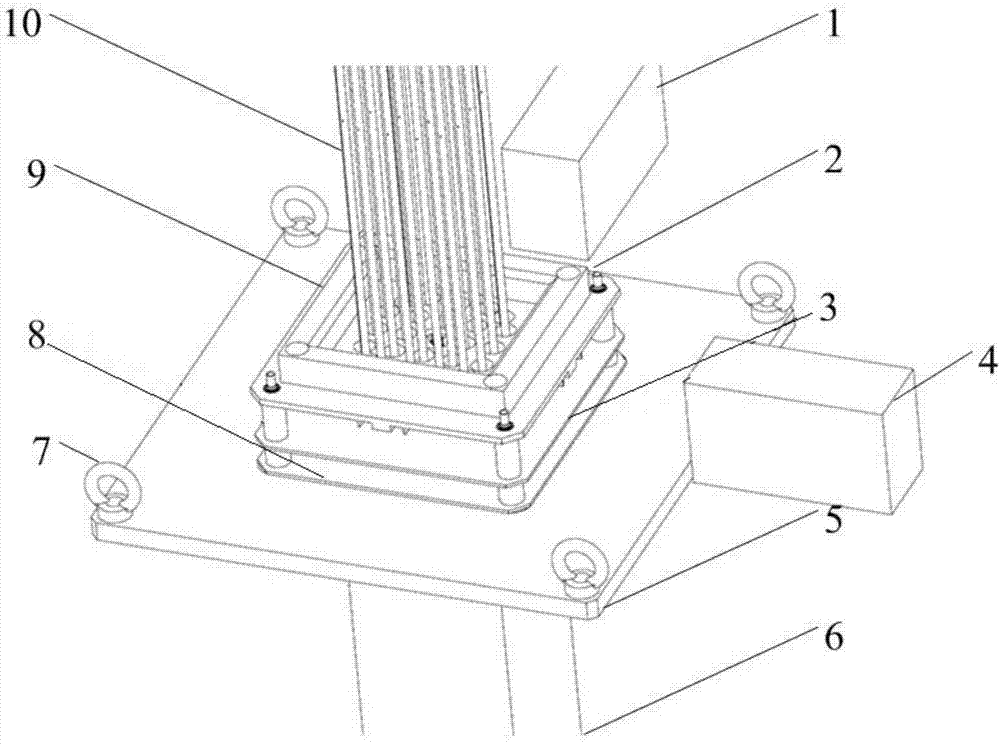

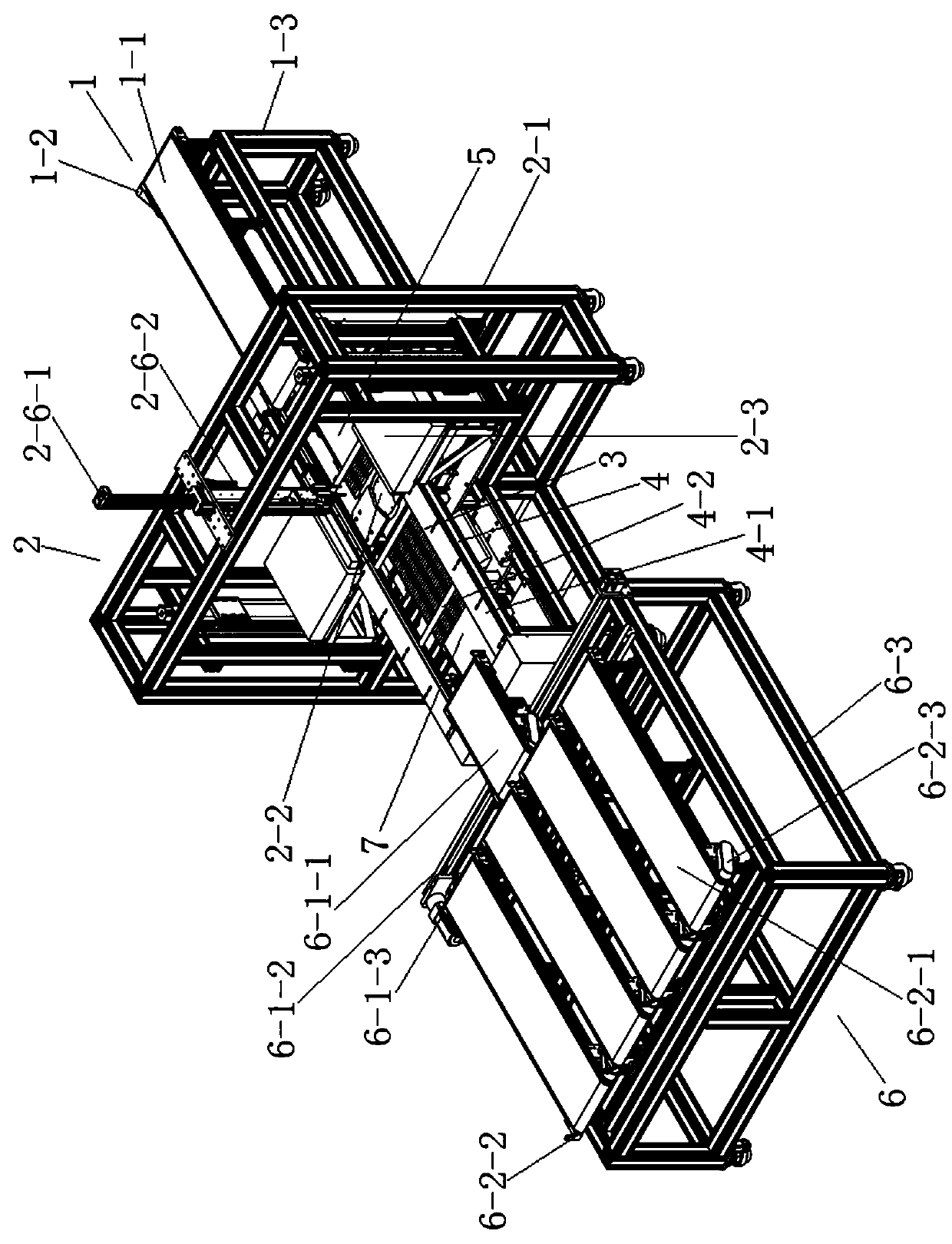

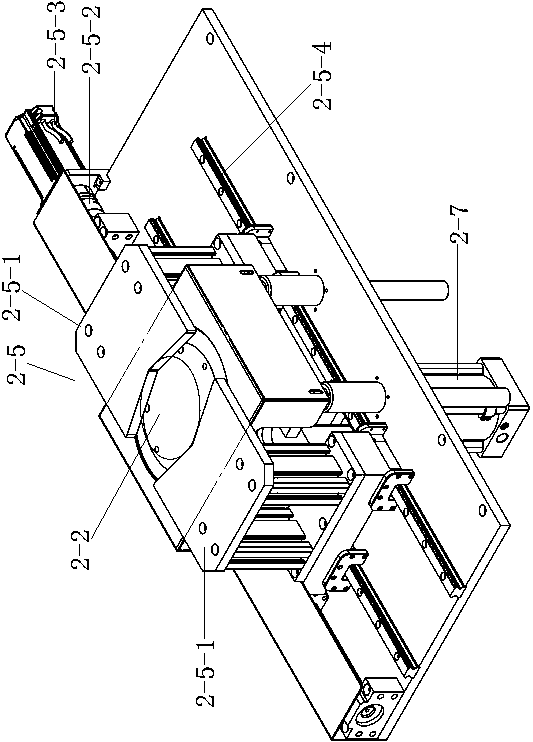

Rock-soil mechanics direct shear experimental system

InactiveCN1641336AKeep constantUniform deformationMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesSoil mechanicsElectric machinery

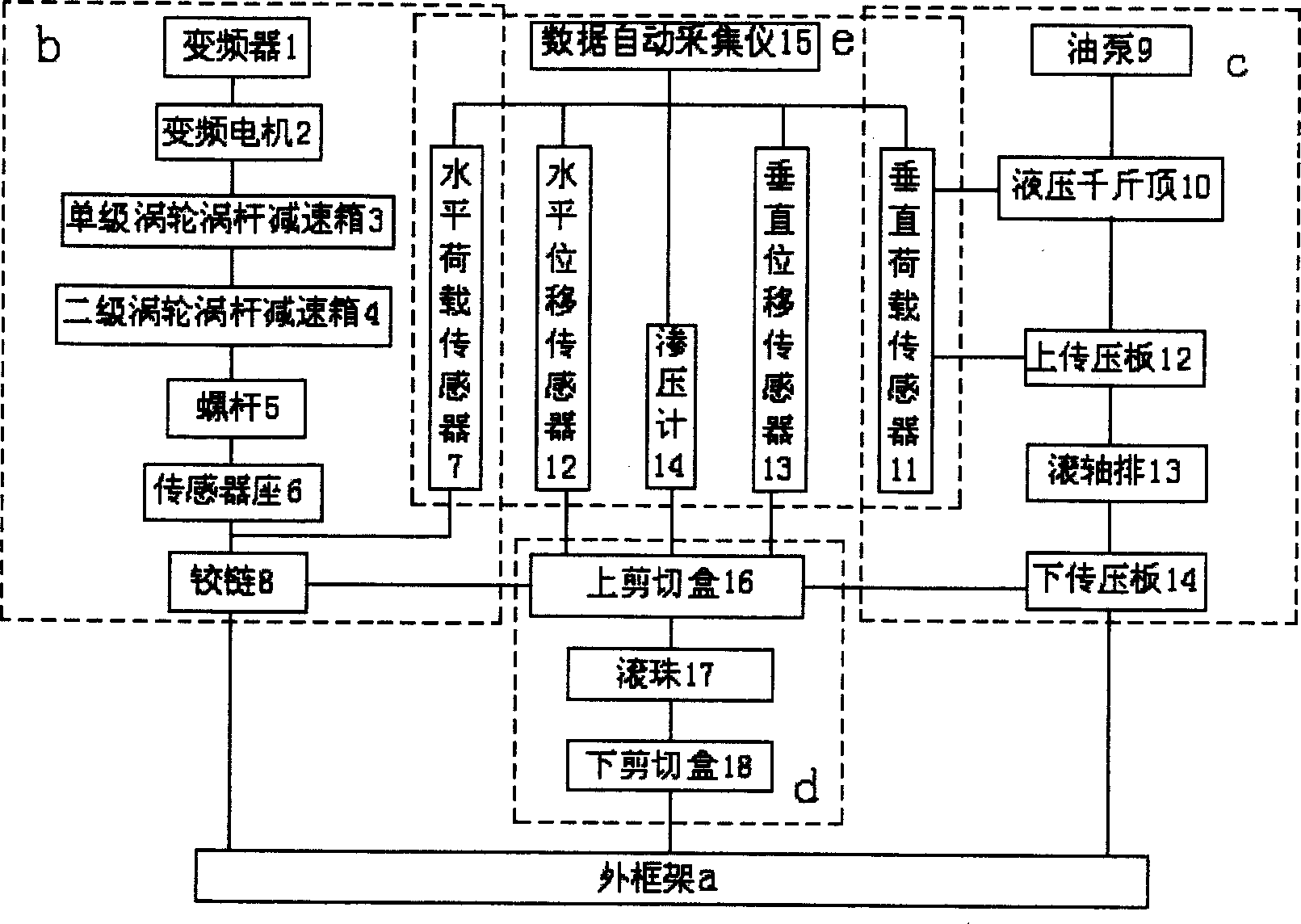

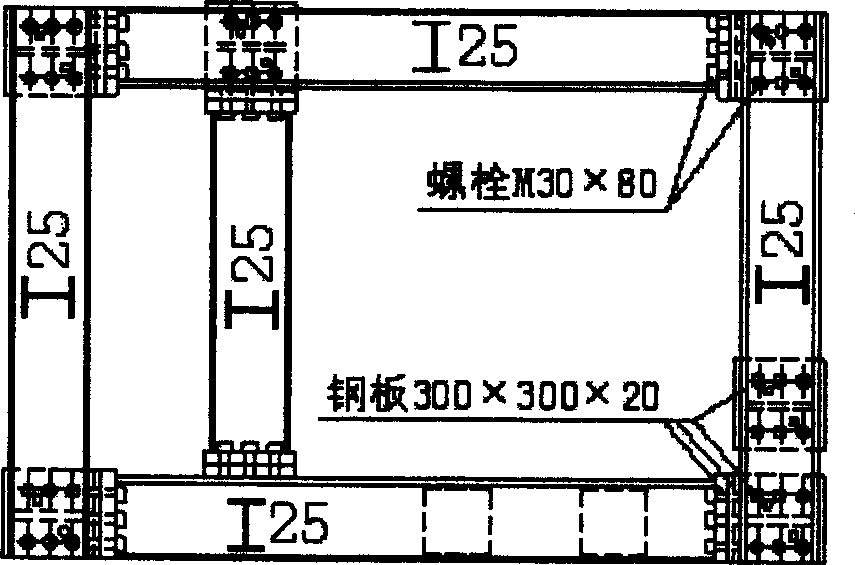

The invention discloses a straight cut testing system for rock and earth mechanics, relating to a cutting system. The invention is composed of outer frame, horizontal loading system, vertical loading system, cut box, and measuring system; the horizontal loading system, the vertical loading system, the cut box and the cut box are fixed on the outer frame, respectively; the horizontal loading system, the vertical loading system and the measuring system are connected with the cut box, respectively. The invention has high measuring accuracy and good stability; all the data are automatically collected, thus reducing artificial reading error; it adopts variable frequency electric motor so as to reduce the manufacturing cost on the premise of assuring a stable cutting speed; all the parts are removable, convenient to transport and install. It can be used in determining peak values and remaining shearing strength of fine earth, coarse earth and soft rock and provide strength parameter for engineering design and rock and earth stability.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

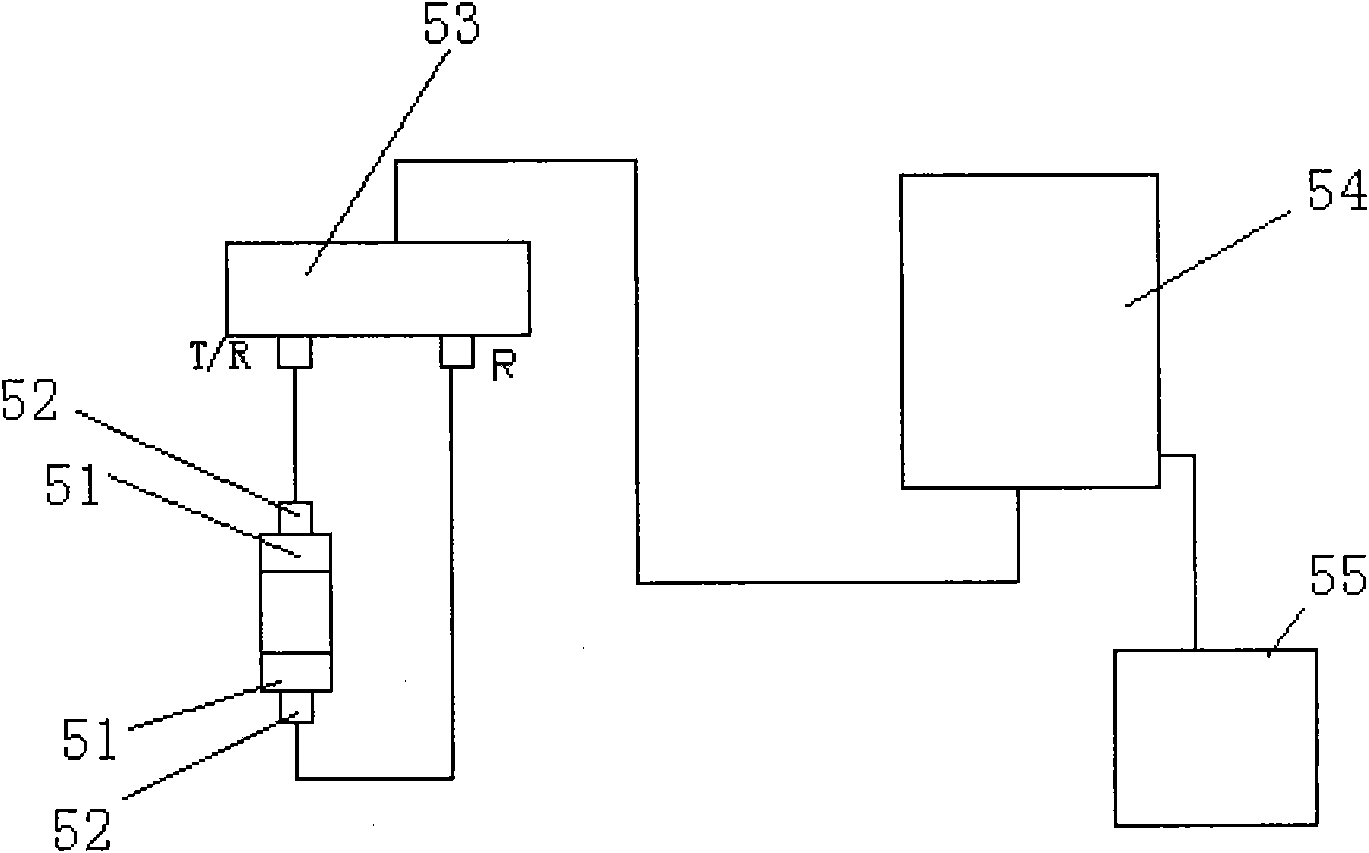

Device and method for simulating generation of gas hydrate and measuring physical property parameters thereof

ActiveCN101936833AAccurate physical parametersAccurate Acoustic Property DataAnalysing fluids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationRefrigeration compressorEngineering

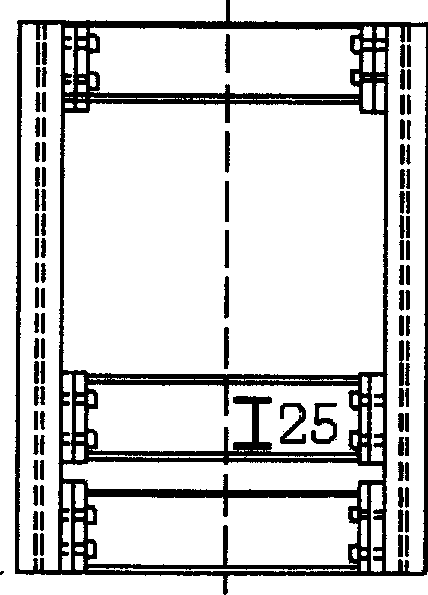

The invention relates to a device and a method for simulating generation of a gas hydrate and measuring physical property parameters thereof. The device is characterized by comprising a high-pressure reactor which is respectively connected with a high-pressure gas distribution system, a temperature measuring system, a pressure measuring system and an ultrasonic sound velocity measuring system, wherein the high-pressure reactor is arranged in a cold bath tank connected with a refrigeration compressor; a handle slide rod is slidingly inserted at the top of the high-pressure reactor; the ultrasonic sound velocity measuring system comprises two ultrasound probes respectively arranged at the bottom of the handle slide rod and the bottom in the high-pressure reactor, and the two ultrasound probes are respectively connected with an acoustoelectric transducer; one acoustoelectric transducer is connected with the transmitting end of an ultrasonic signal transmitter-receiver through a lead, while the other acoustoelectric transducer is connected with the receiving end of the ultrasonic signal transmitter-receiver through a lead; the ultrasonic signal transmitter-receiver is connected with an oscilloscope, and the output end of the oscilloscope is connected with a computer acquisition system; and a gas hydrate sound wave acquisition and analysis module is preset in the computer acquisition system.

Owner:CHINA NAT OFFSHORE OIL CORP +1

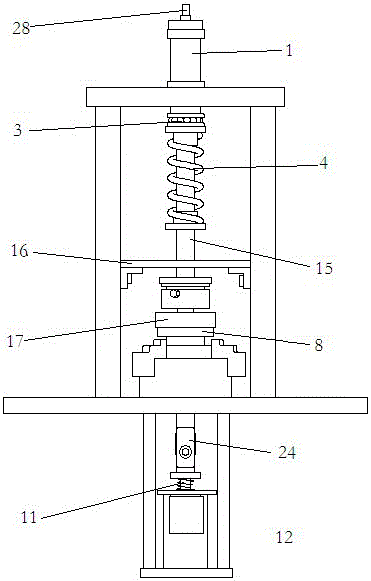

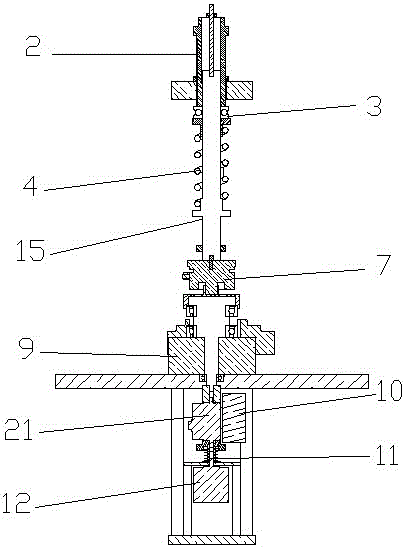

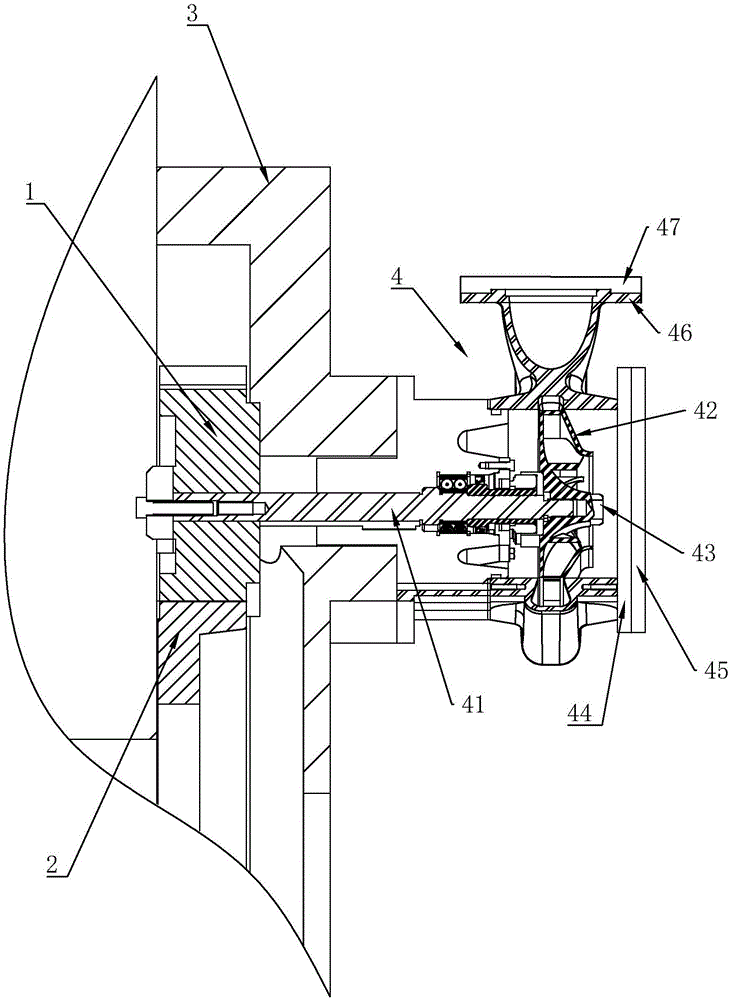

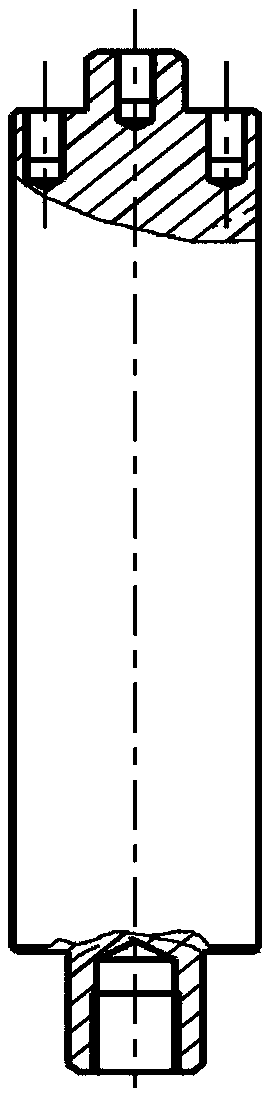

Bearing rotation torque test device

Provided is a bearing rotation torque test device. The center shaft of an axial loading member is connected with a thrust bearing and a spring spacer. A micro-load rod matches a pressure sensor connected with an axial loading sleeve. A measuring member is formed through clearance fit between the inner holes of two identical upper and lower detection bearings and a test shaft. The lower end of the test shaft is connected with an elastic coupler. The outer diameter of the upper detection bearing matches the axial loading sleeve mounted on the pressure sensor, and the outer diameter of the lower detection bearing matches a three-claw chuck mounted on a test bench. The shaft of a stepper motor is additionally equipped with a torque overload device, so damage to a torque sensor by detection overload is avoided. The thrust bearing, the spring spacer and the elastic coupler are provided with an aligning function, so the concentricity of the device is guaranteed. After loading, the three-claw chuck is released. The bearings are undirected, and are completely unaffected by tilting load and other pressures. The test values are more accurate. The trouble of detection tool replacement for test of bearings of different specifications is reduced. The problem that inaccurate values, poor repeatability and poor practicability are caused by loading deformation of the detection bearings is solved completely.

Owner:CIXING GROUP

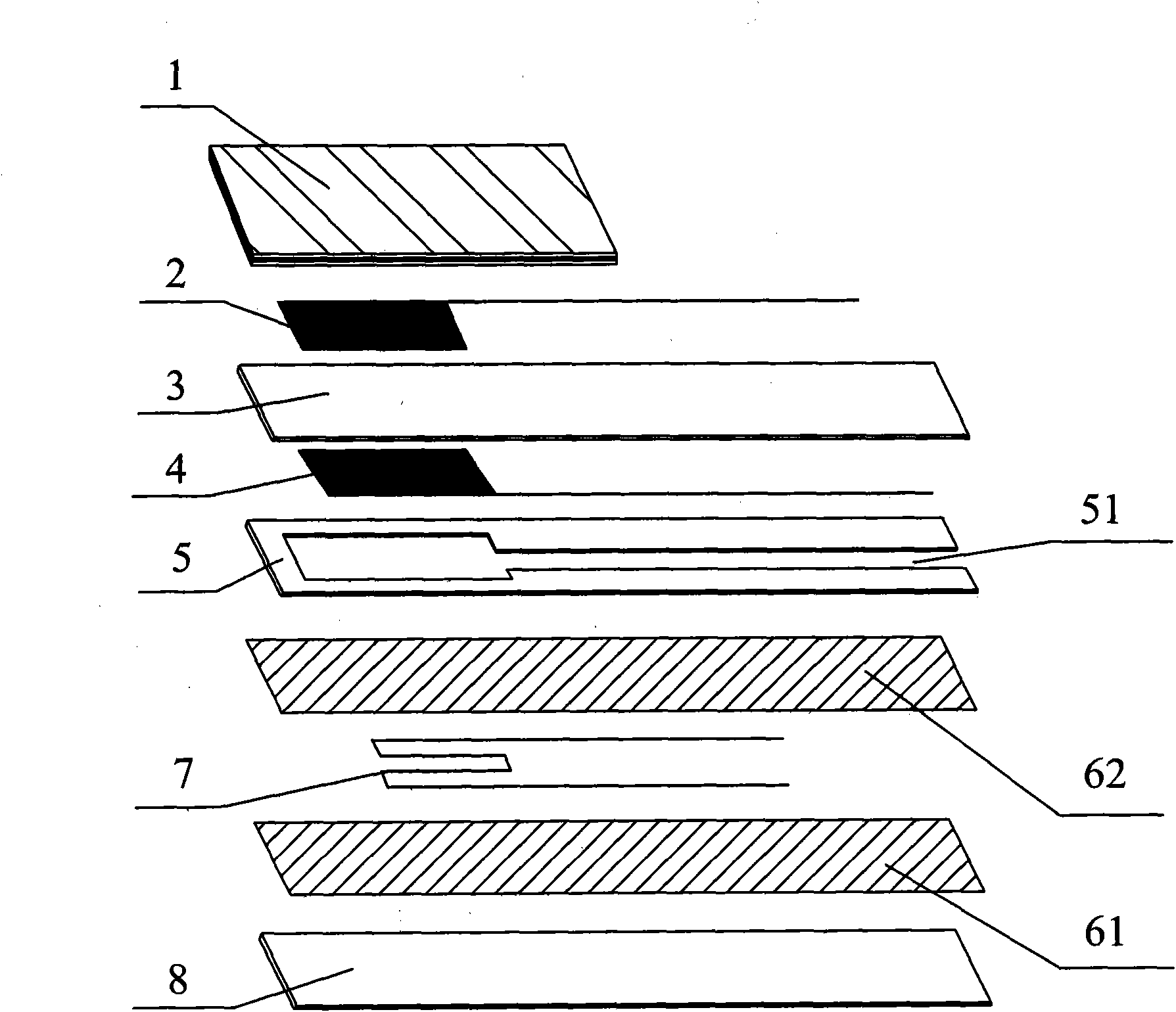

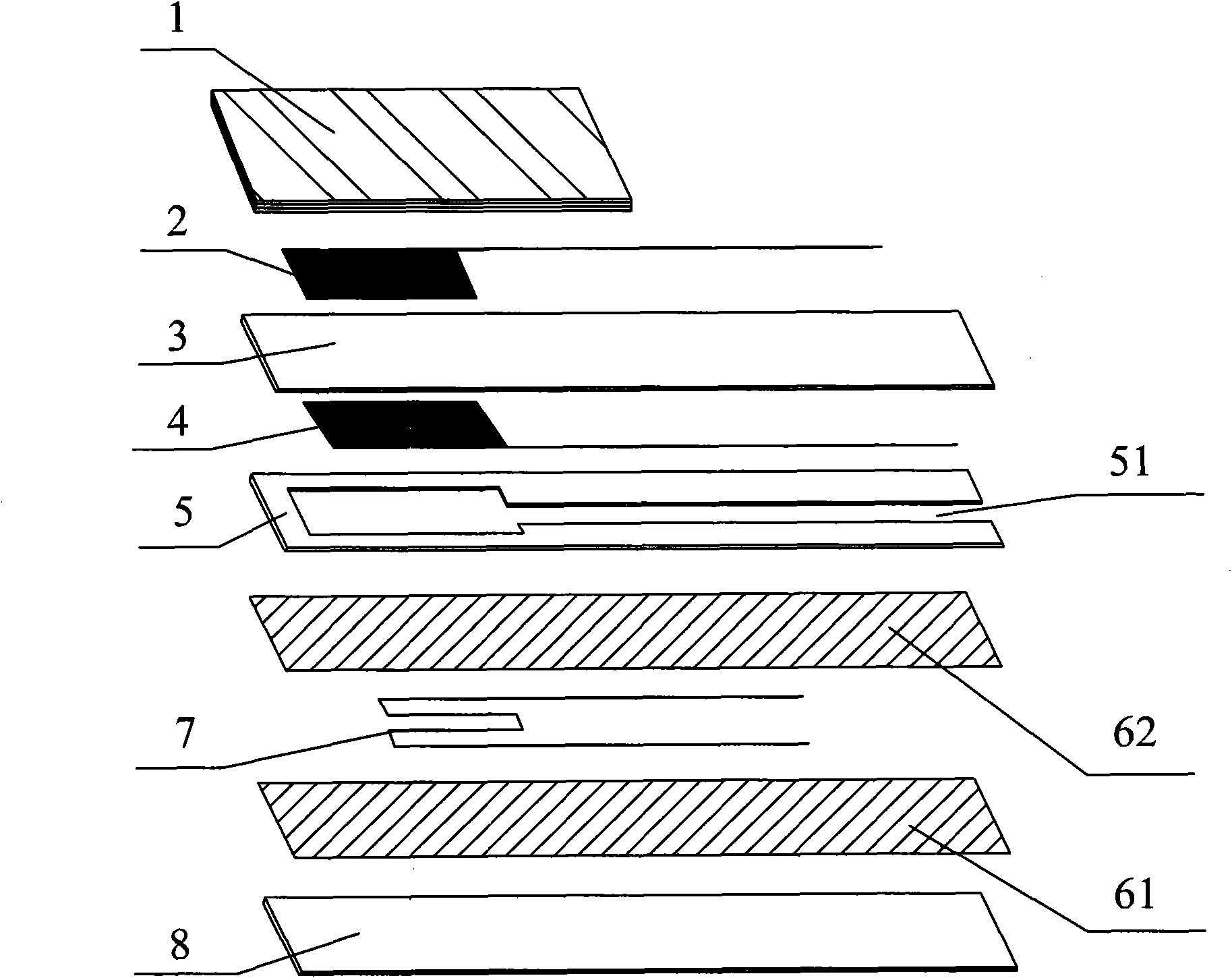

Chip type oxygen sensor and preparation method thereof

ActiveCN102109488AReduced exhaust transfer timeThe measured value is accurateLayered productsMaterial analysis by electric/magnetic meansThermal shockPorous layer

The invention provides a chip type oxygen sensor and a preparation method thereof. A porous protection layer of the chip type oxygen sensor comprises a transition layer, a porous layer and a compact layer; holes are formed on all the layers, so that the bottom of the porous protection layer is communicated with the top of the porous protection layer; the transition layer contains zirconium oxide and magnesia alumina spinels, the average hole diameter of the transition layer ranges from 0.1 mu.m to 2.5 mu.m, and the porosity of the transition layer ranges from 20 percent to 40 percent; the porous layer contains zirconium oxide, magnesia alumina spinels and noble metal, the average hole diameter of the porous layer ranges from 0.1 mu.m to 3.5 mu.m, and the porosity of the porous layer ranges from 30 percent to 50 percent; and the compact layer contains zirconium oxide, the average hole diameter of the compact layer ranges from 2 mu.m to 3 mu.m, and the porosity of the compact layer ranges from 20 percent to 40 percent. Compared with the prior art, the chip type oxygen sensor has the advantages of high sensitivity and thermal shock resistance and long service life.

Owner:BYD CO LTD

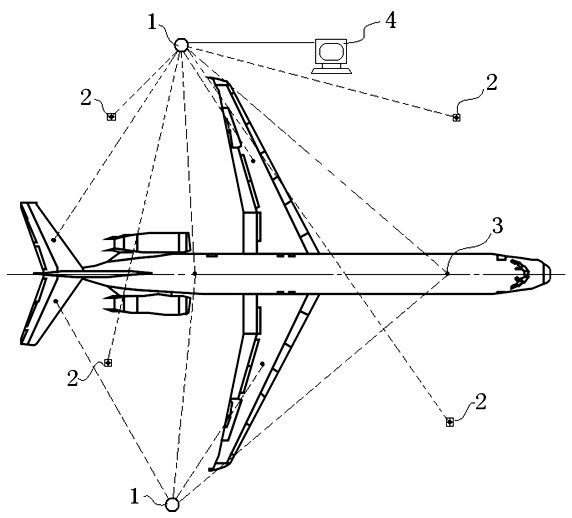

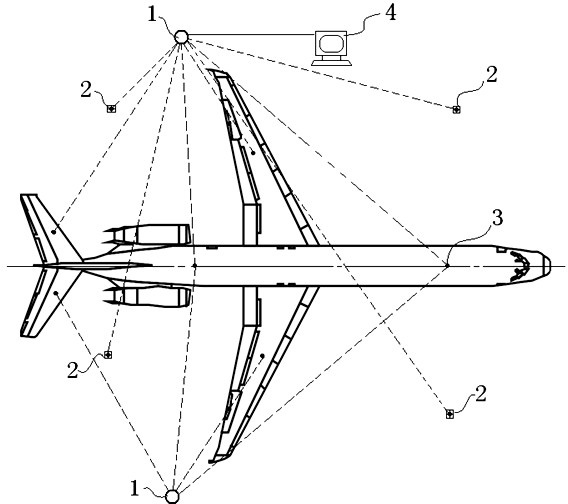

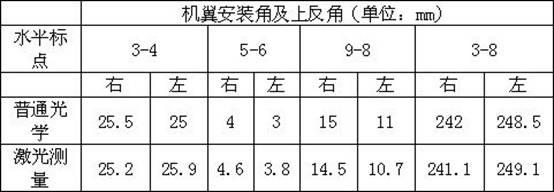

Horizontal laser measurement system and method for airplane

InactiveCN102519430ASave human effortImprove work efficiencyIncline measurementEngineeringLaser tracker

The invention discloses a horizontal laser measurement system and a method for an airplane. The horizontal laser measurement system is composed of a laser locating device, a horizontal reference coordinate point and a horizontal measurement point. The horizontal laser measurement system is characterized in that: at least four horizontal reference coordinate points are arranged around the airplane; the laser locating device is arranged at one side of the airplane; a plurality of horizontal measuring points are arranged on the airplane; and the laser locating device is connected with a computer. In a measuring process, the value of each measuring point is produced by a laser tracker according to the laser reflection principle, so that the measurement error caused by manual operation is reduced, and the measurement value is more accurate.

Owner:JIANGXI HONGDU AVIATION IND GRP

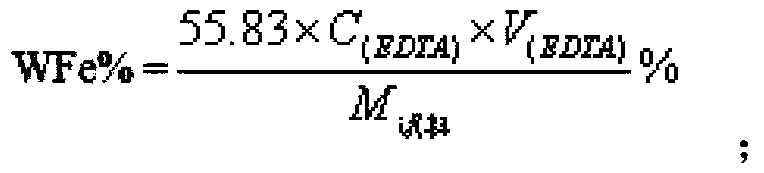

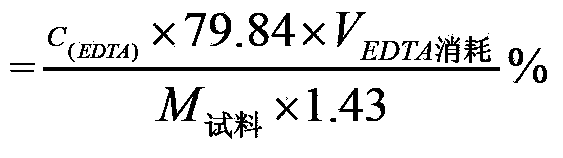

Method for detecting total iron content of steel slag

ActiveCN103411968AReduce system errorEliminate the effects ofMaterial analysis by observing effect on chemical indicatorSlagDecomposition

The invention relates to the field of detection, in particular to the field of steel slag detection and more particularly relates to a method for detecting the total iron content of steel slag. Aim at the problems of inaccurate detection to the content of total iron in steel slag and high detection cost at present, the invention innovatively provides the method for detecting the total iron content of the steel slag. The method comprises three main procedures of sample preparation by breaking, decomposition and element content measurement. Through the adoption of the method, the total iron content of the steel slag can be economically, quickly, effectively and accurately measured.

Owner:宝武环科南京资源利用有限公司

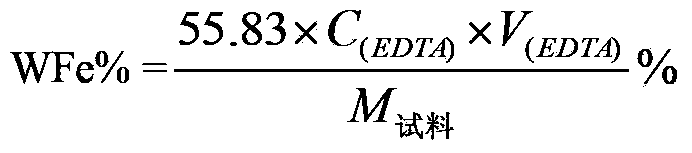

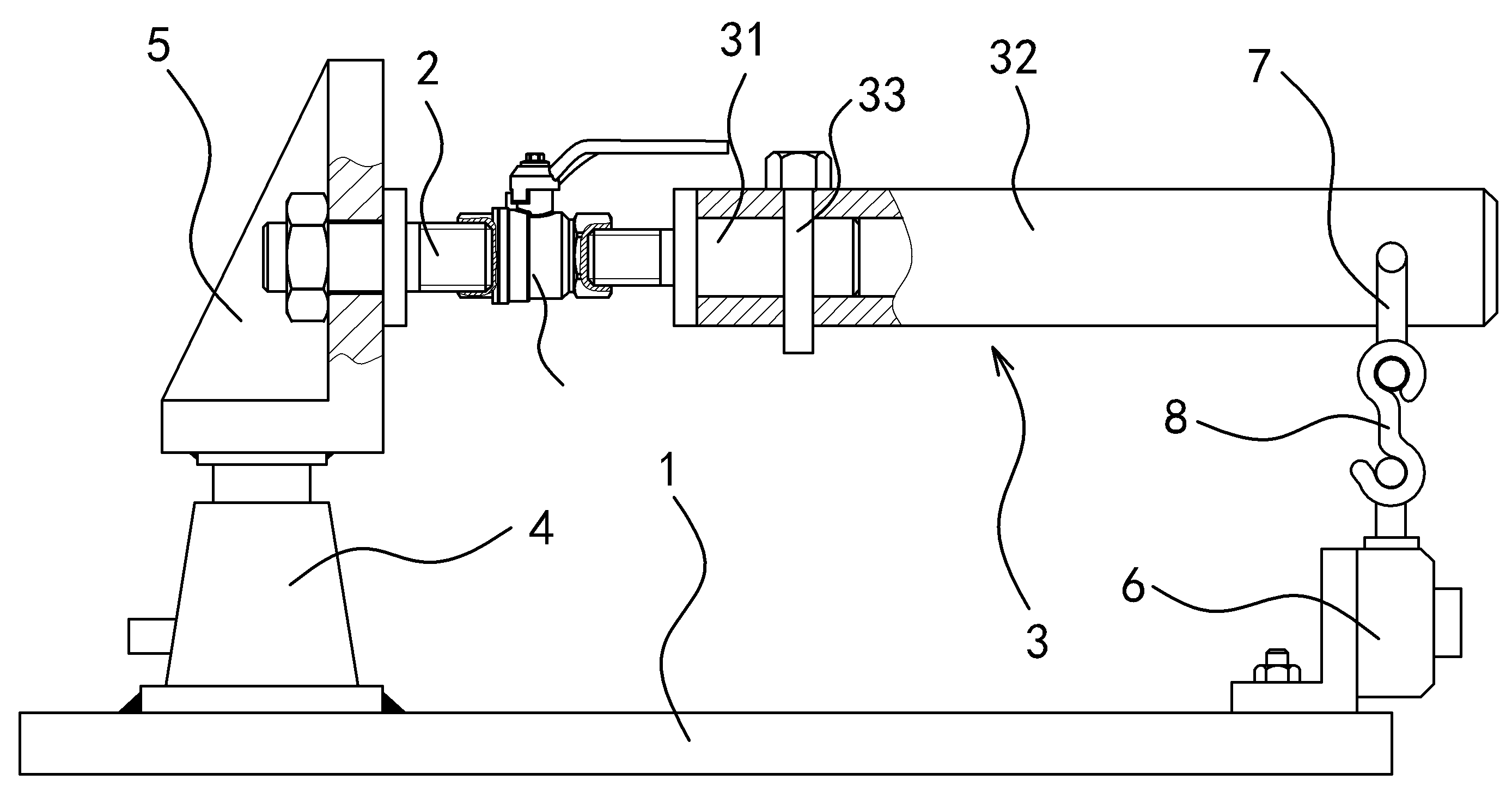

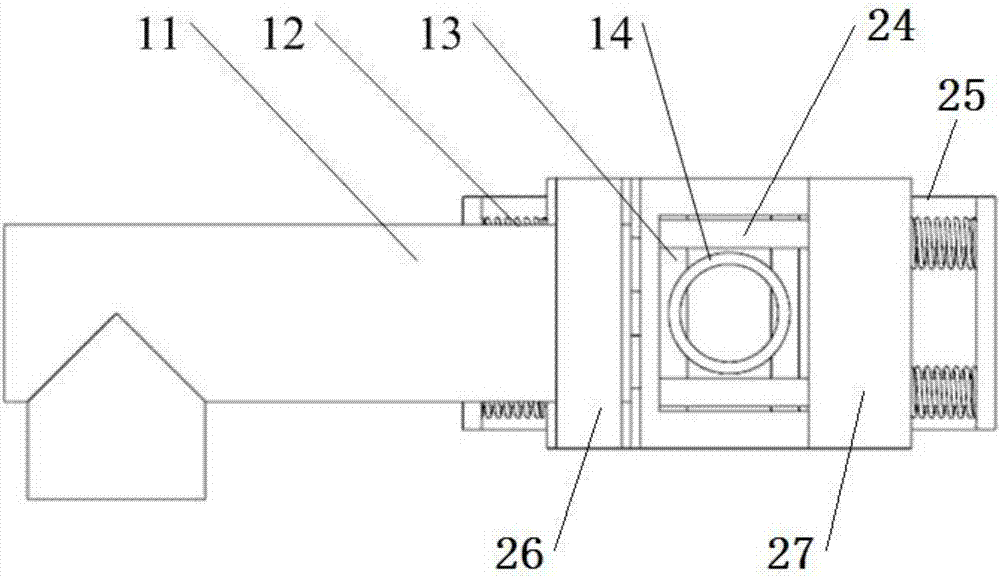

Bending resistance test device for valve

InactiveCN101813575ASimple structureSmall footprintStructural/machines measurementFlexural strengthEngineering

The invention provides a bending resistance test device for a valve, belonging to the technical field of machinery and solving the problems of difficult operation of the bending resistance of the traditional valve, high cost and potential safety hazard existing in operation. The bending resistance test device for the valve comprises a base, a connecting rod 1 and a connecting rod 2, wherein a force applying mechanism is fixed on the base, one end of the connecting rod 1 can be connected with one end of the valve and the other end can be fixedly connected with the force applying mechanism, the force applying mechanism can ensure the connecting rod 1 to bear a radial action force when the force applying mechanism is operated; and one end of the connecting rod 2 can be connected with the other end of the valve, and a force measurer capable of measuring a radial force-loading value of the connecting rod 2 is arranged between the other end of the connecting rod 2 and the base. The bending resistance test device for the valve has the advantages of simple structure, small occupation space, convenient operation and accurate measurement values.

Owner:ZHEJIANG WORLD BRASS

Chip type oxygen sensor and preparation method thereof

ActiveCN102109486AHigh sensitivityExtended service lifeMaterial analysis by electric/magnetic meansProtection layerYttrium

The invention provides a chip type oxygen sensor and a preparation method thereof. A porous protection layer of the chip type oxygen sensor comprises a transition layer, a porous layer and an absorption layer; holes are formed on all the layers, so that the bottom of the porous protection layer is communicated with the top of the porous protection layer; the holes on the transition layer with thediameters ranging from 0.1mu.m to 1.5 mu.m account for above 80 percent of the total holes on the transition layer; the holes on the porous layer with the diameters ranging from 0.3 mu.m to 8 mu.m account for above 80 percent of the total holes on the porous layer; the holes on the absorption layer with the diameters ranging from 0.1 mu.m to 2 mu.m account for above 80 percent of the total holes on the absorption layer; the transition layer contains zirconium oxide with stable yttrium oxide and magnesia-alumina spinels; the porous layer contains zirconium oxide, magnesia-alumina spinels and noble metal; and the absorption layer contains magnesium oxide, calcium oxide, aluminum oxide, magnesium sulfate and barium oxide. Compared with the prior art, the chip type oxygen sensor has the advantages of high sensitivity and thermal shock resistance and long service life.

Owner:BYD CO LTD

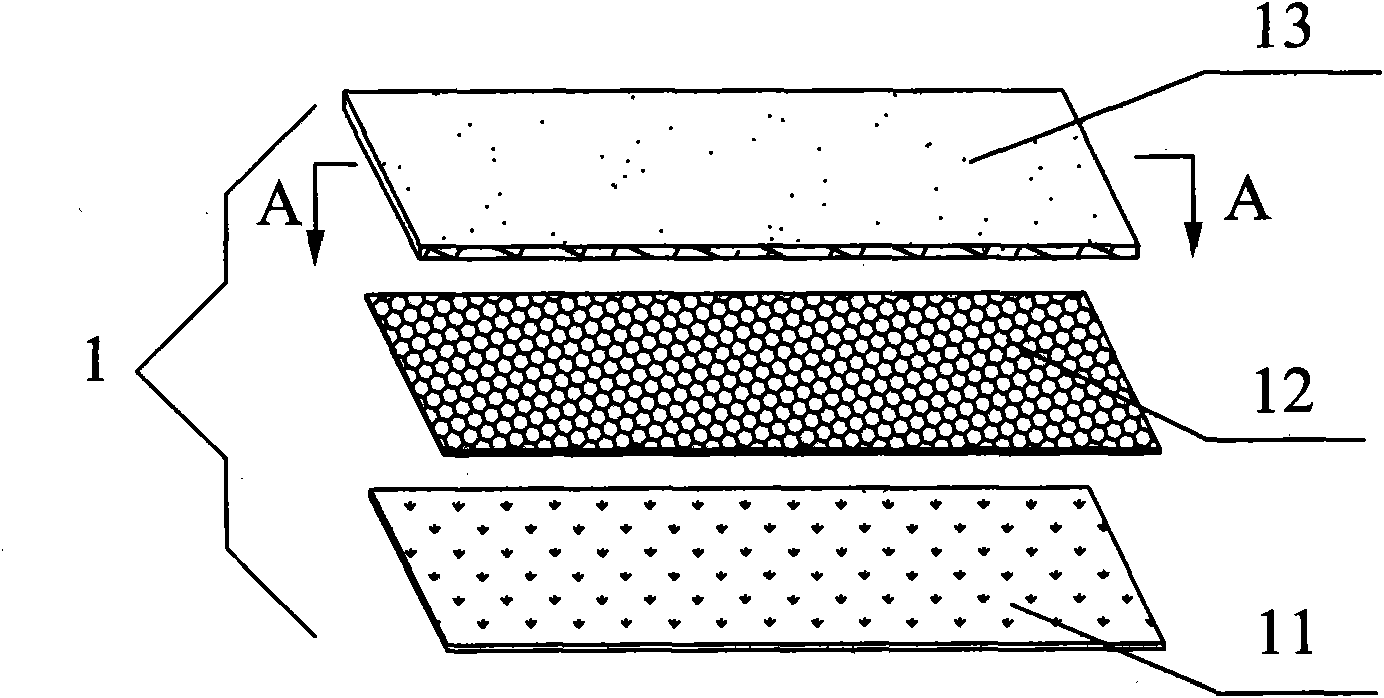

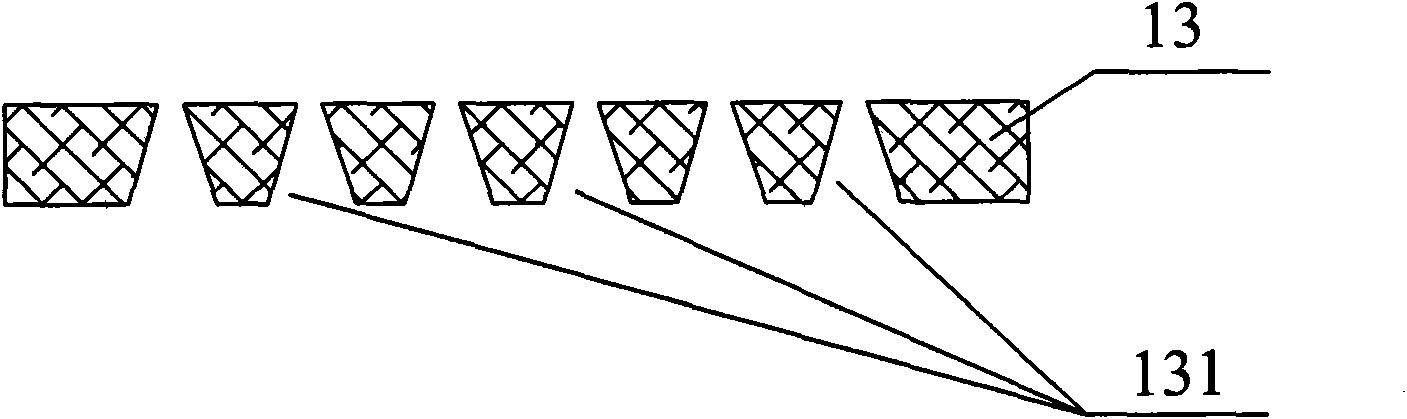

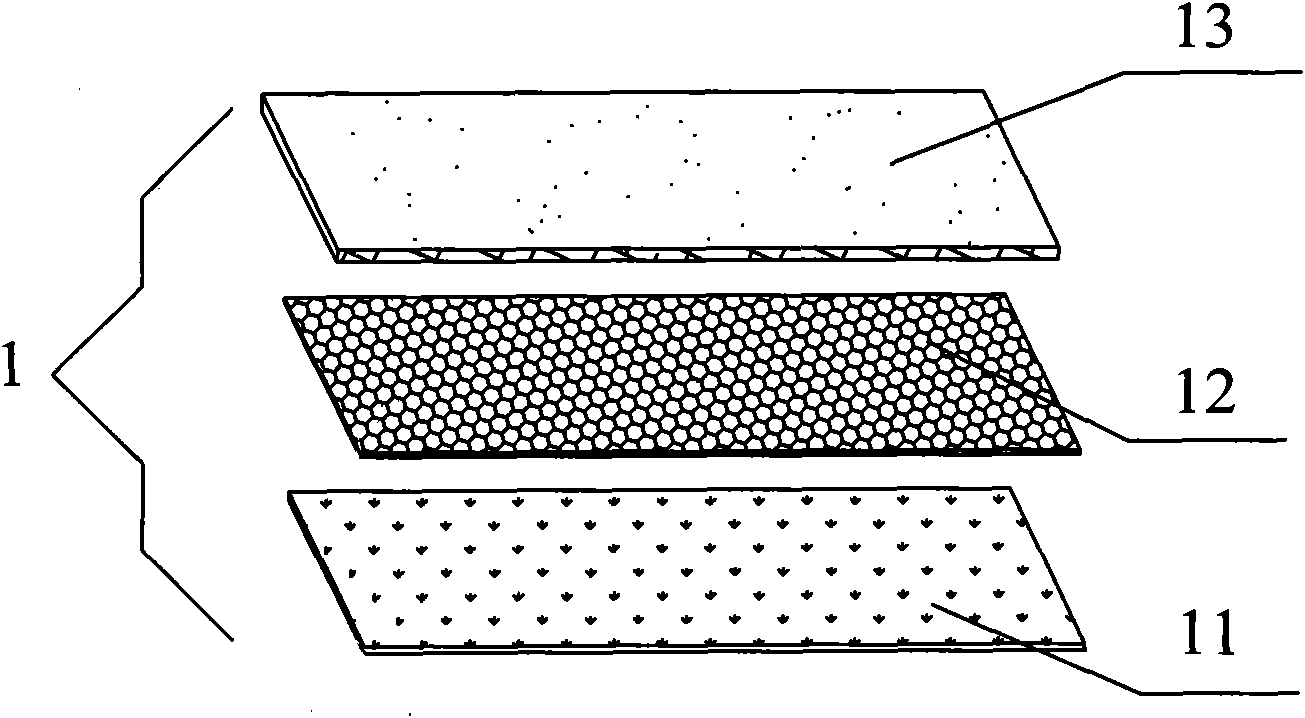

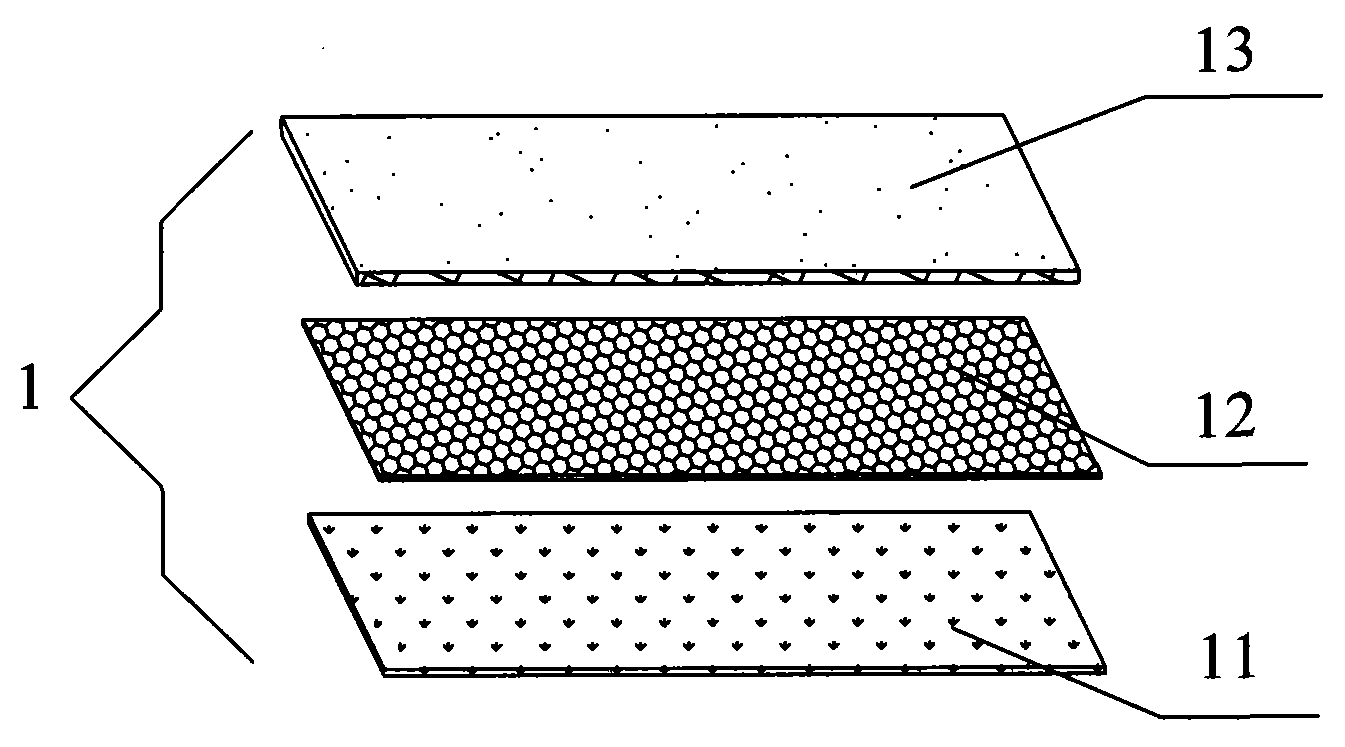

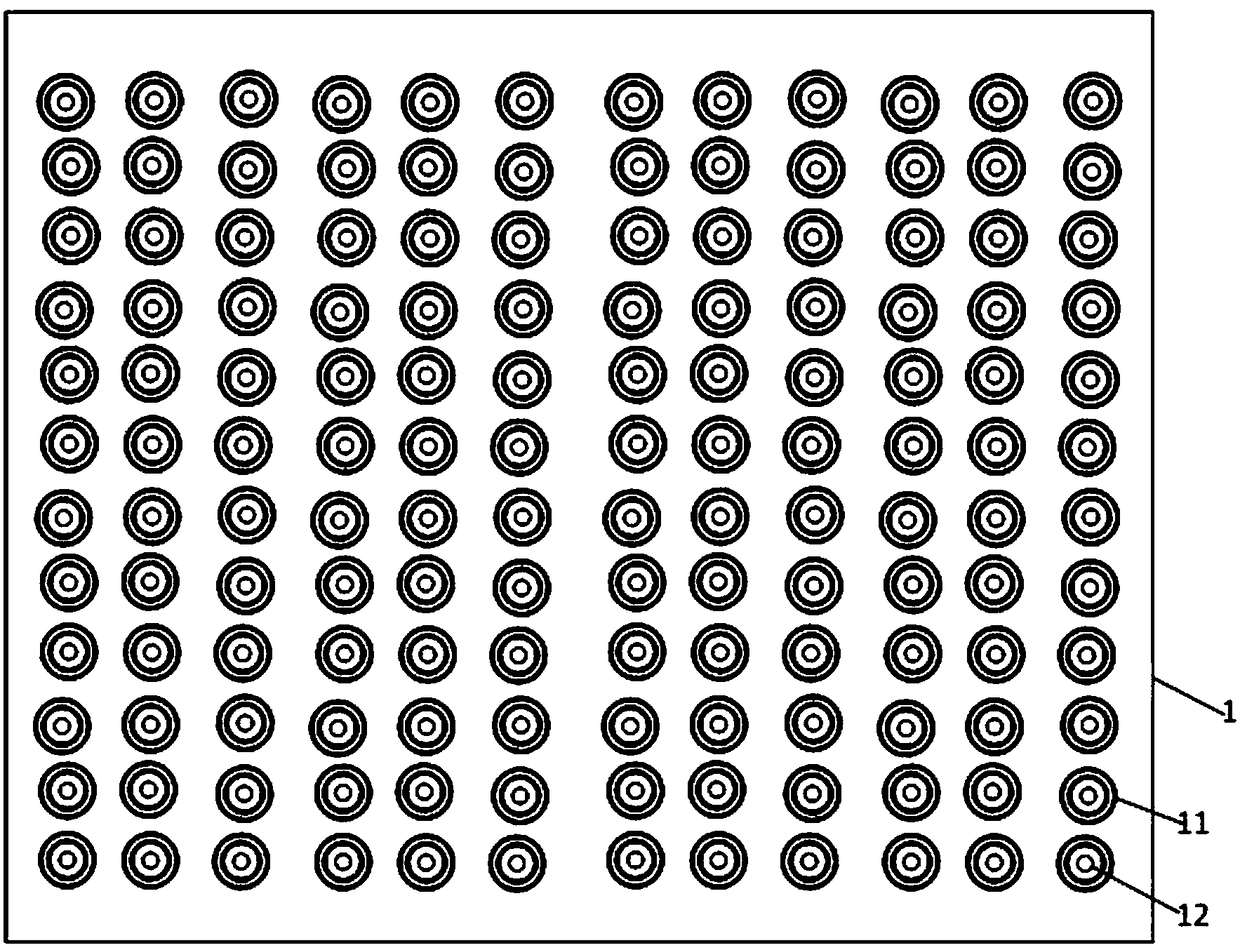

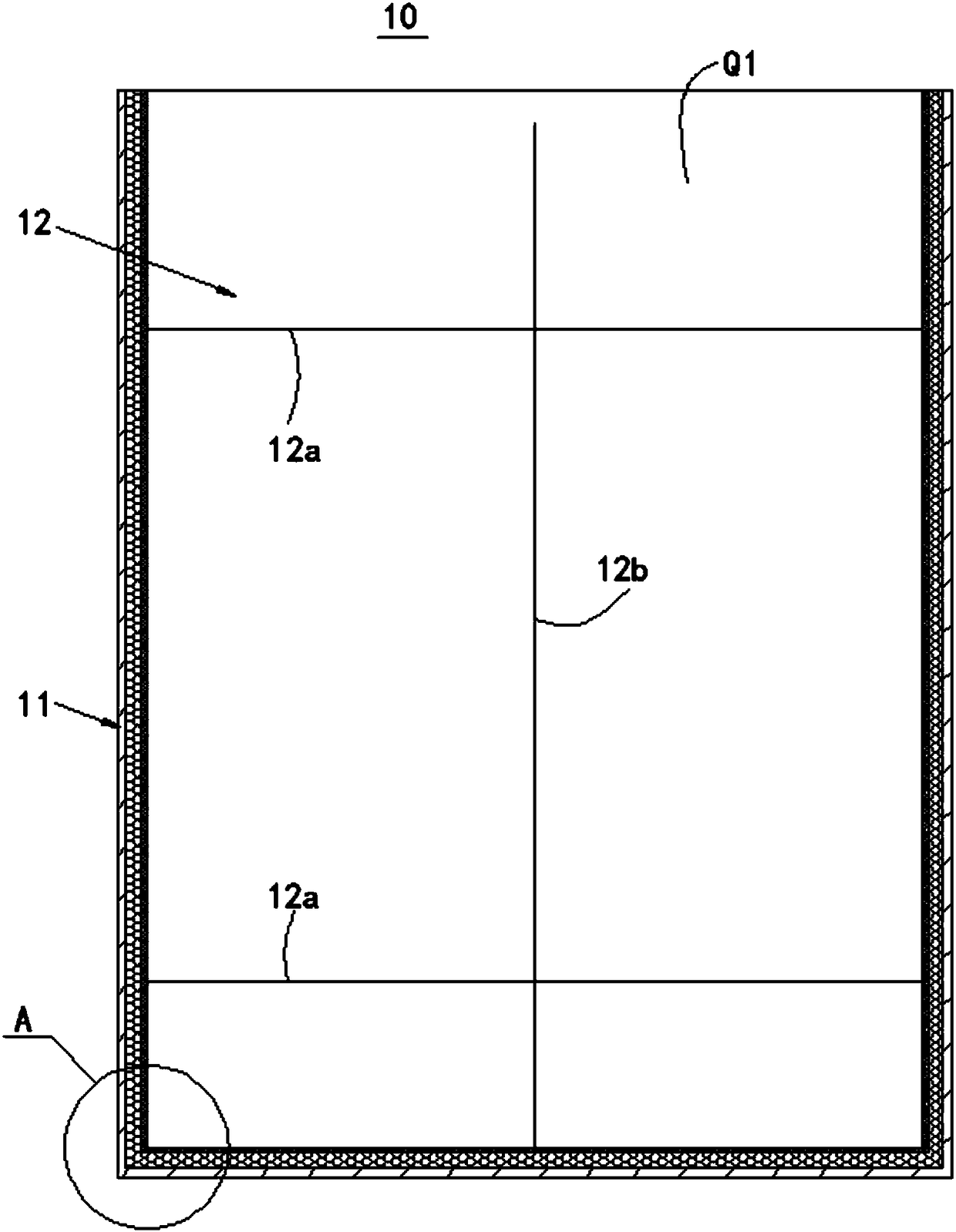

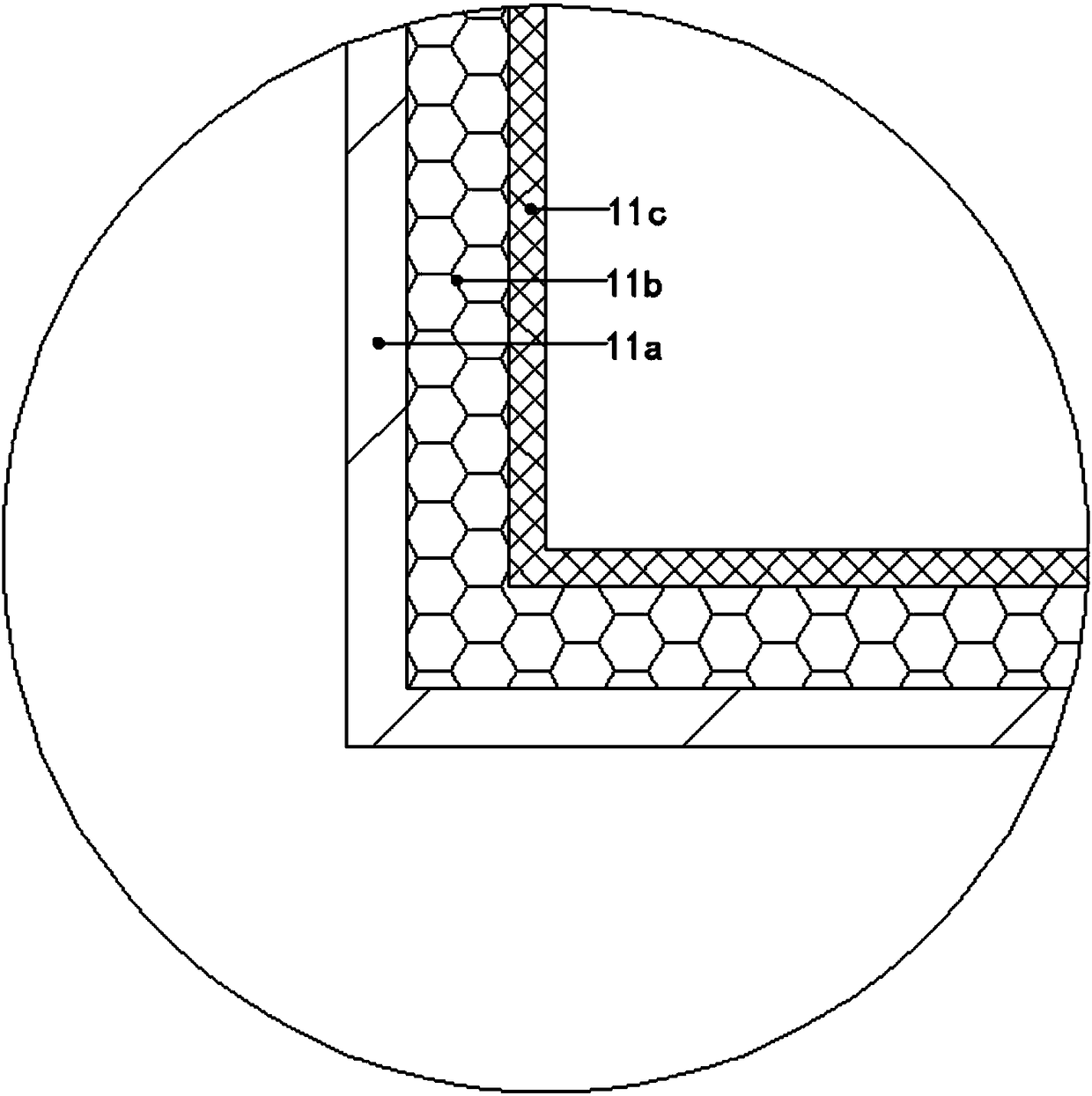

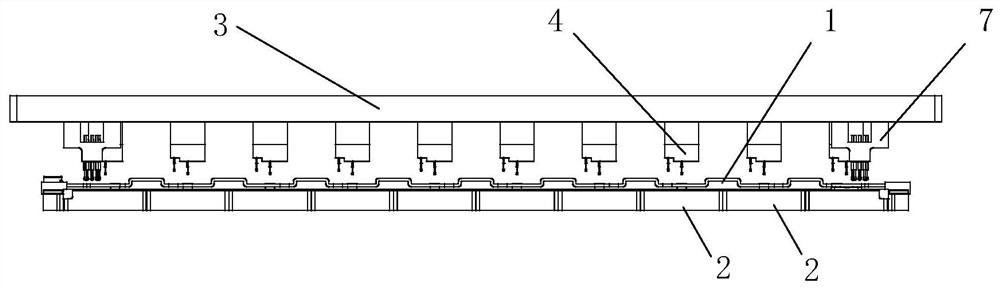

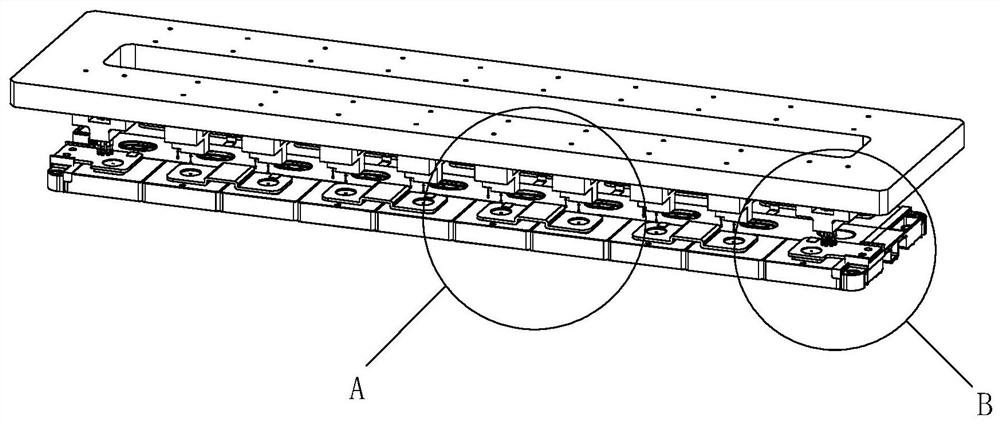

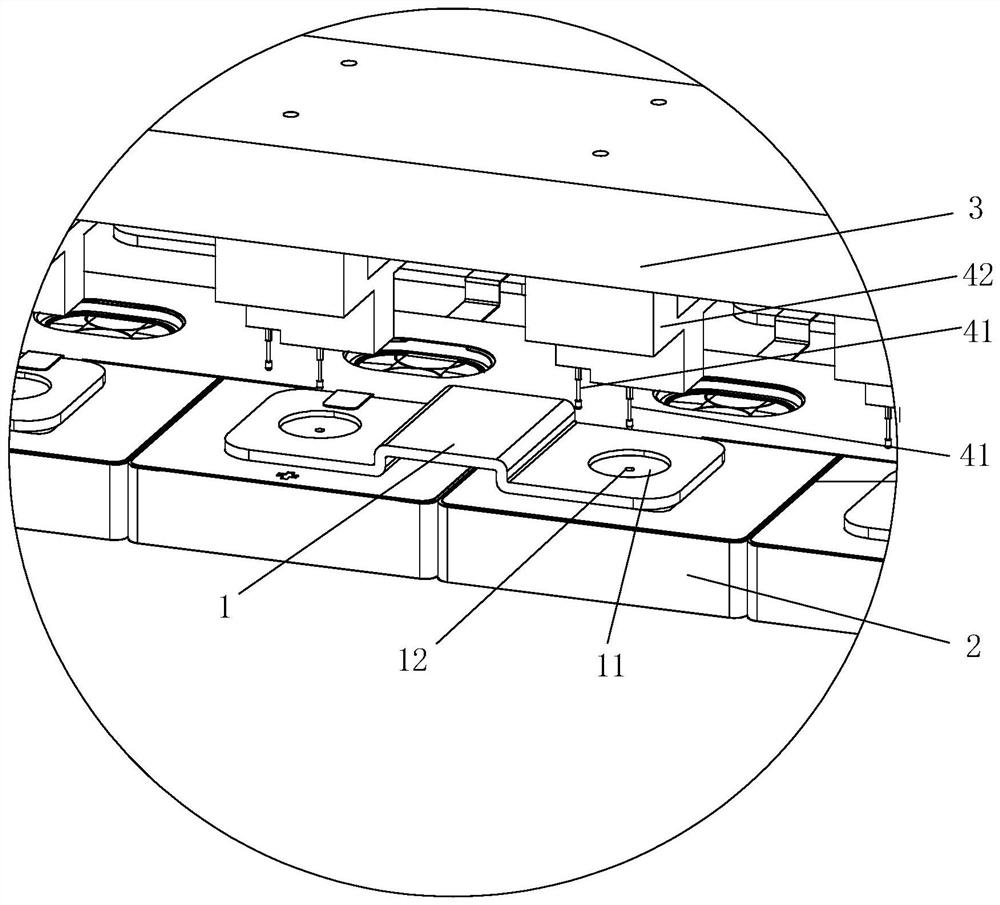

Precast concrete member surface roughness quantitative detection device

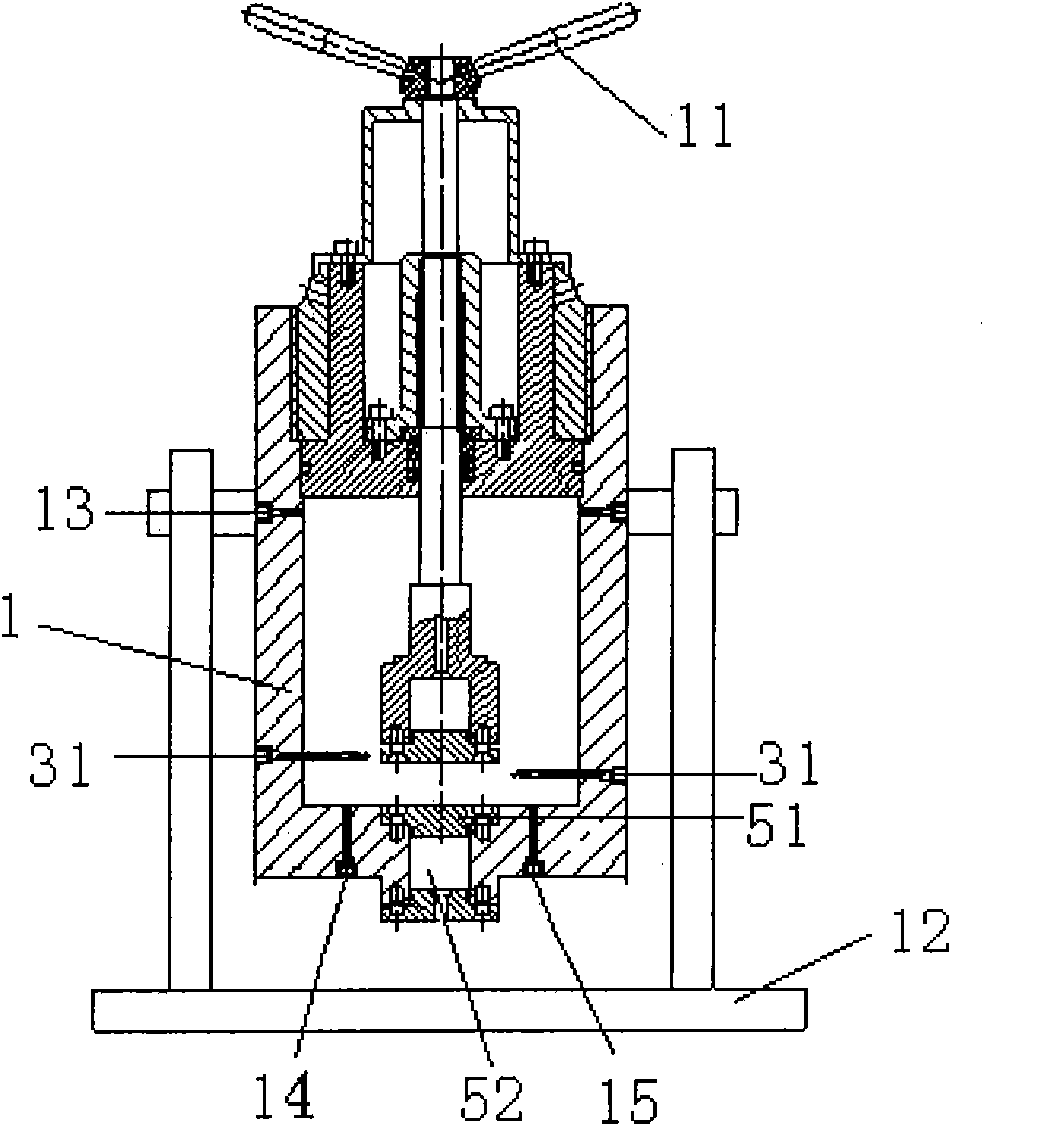

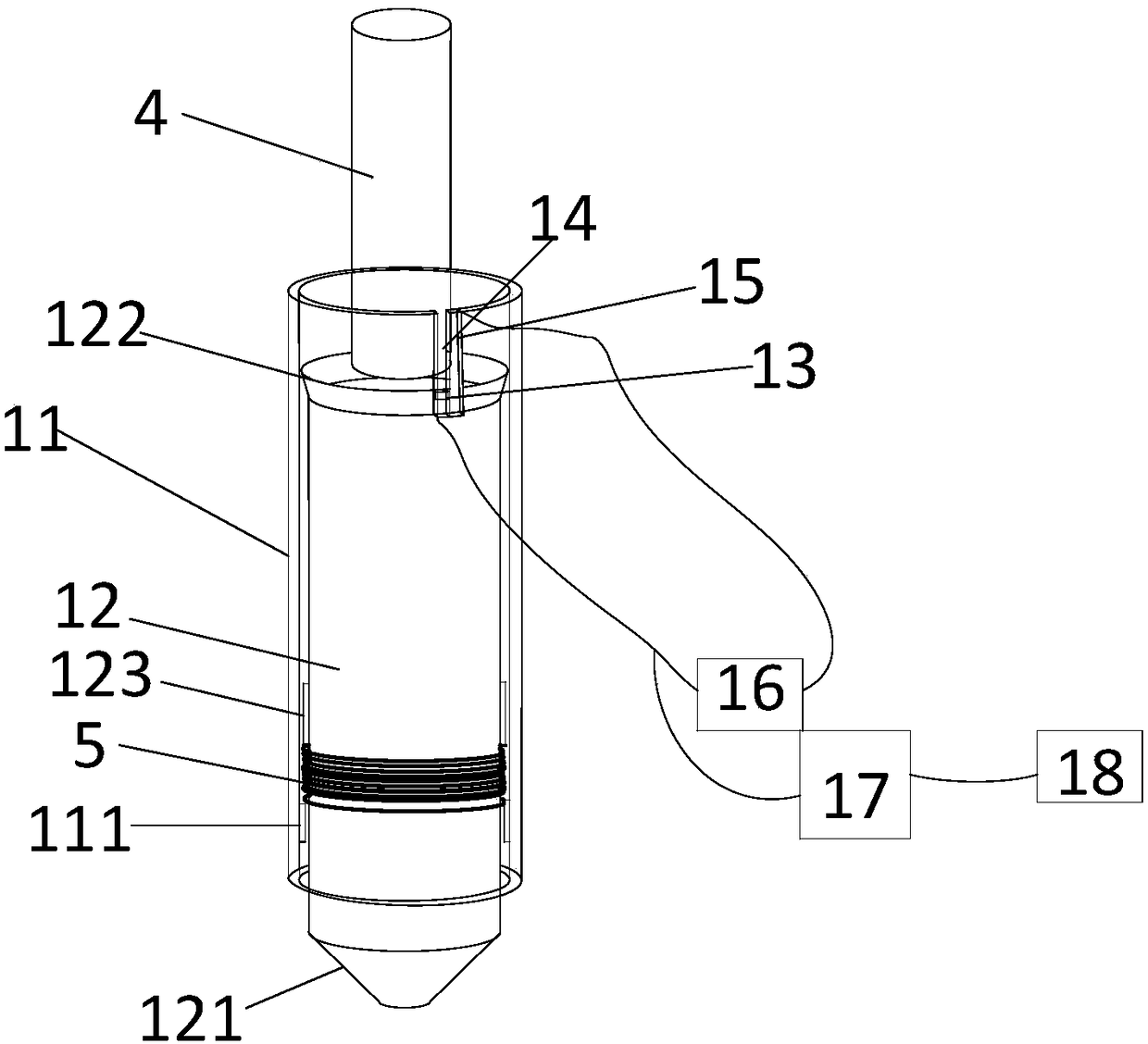

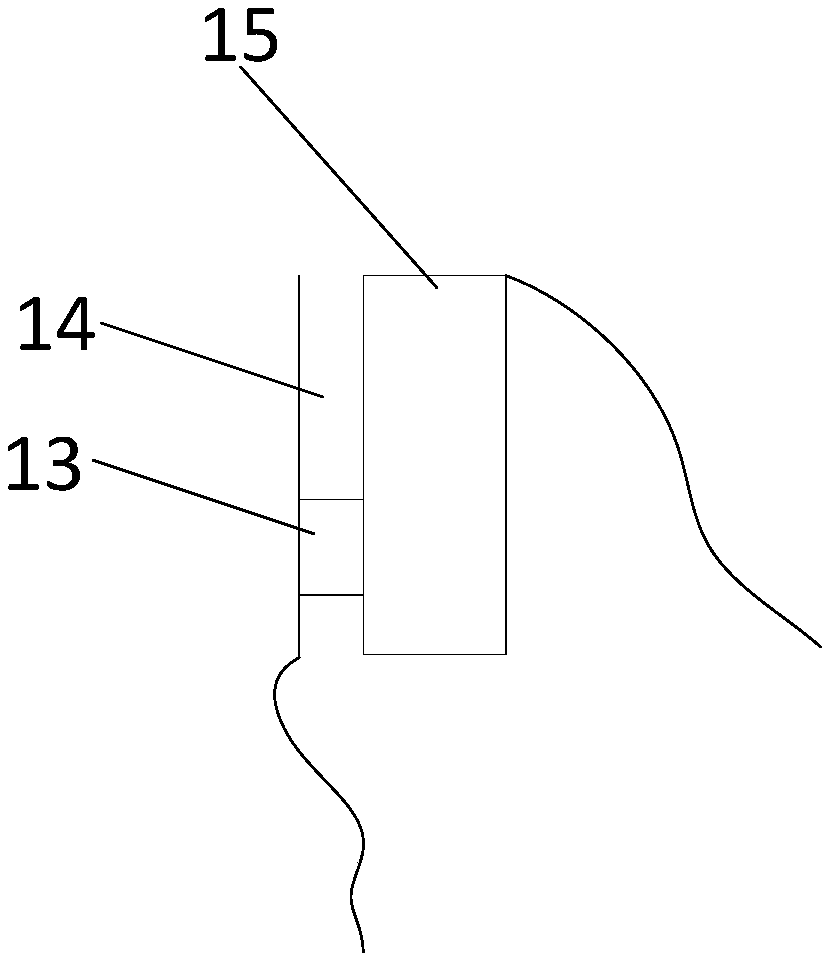

ActiveCN108519048AReduced measurement timeThe measured value is accurateElectric/magnetic roughness/irregularity measurementsSurface roughnessEngineering

The invention discloses a precast concrete member surface roughness quantitative detection device. The device includes a shell (1), a lifting driver (2) and a squeezing board (3), the shell (1) is provided with a through hole (11), a detection needle (12), a conductive protrusion (13), a groove (14), a sliding resistor (15), a constant voltage power supply (16) and a current collector (17), and the bottom of the squeezing board (3) is provided with a plurality of elastic rods (4). The method provided by the invention can automatically and rapidly obtain a numerical value of the surface roughness of a prefabricated structural member.

Owner:刘明亮

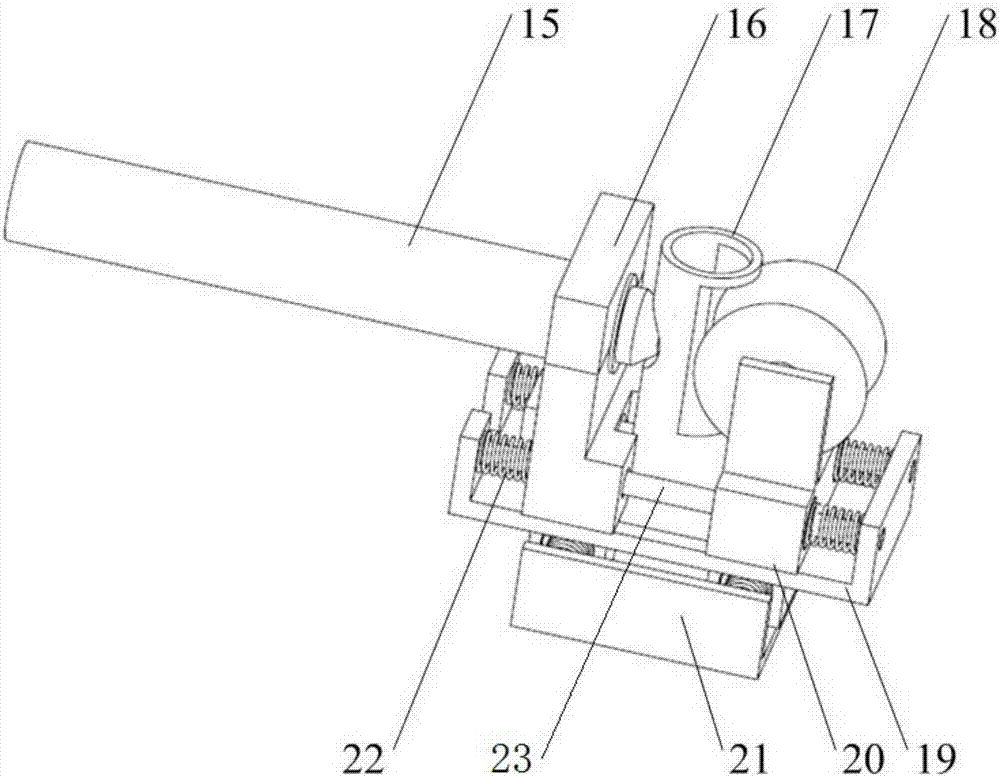

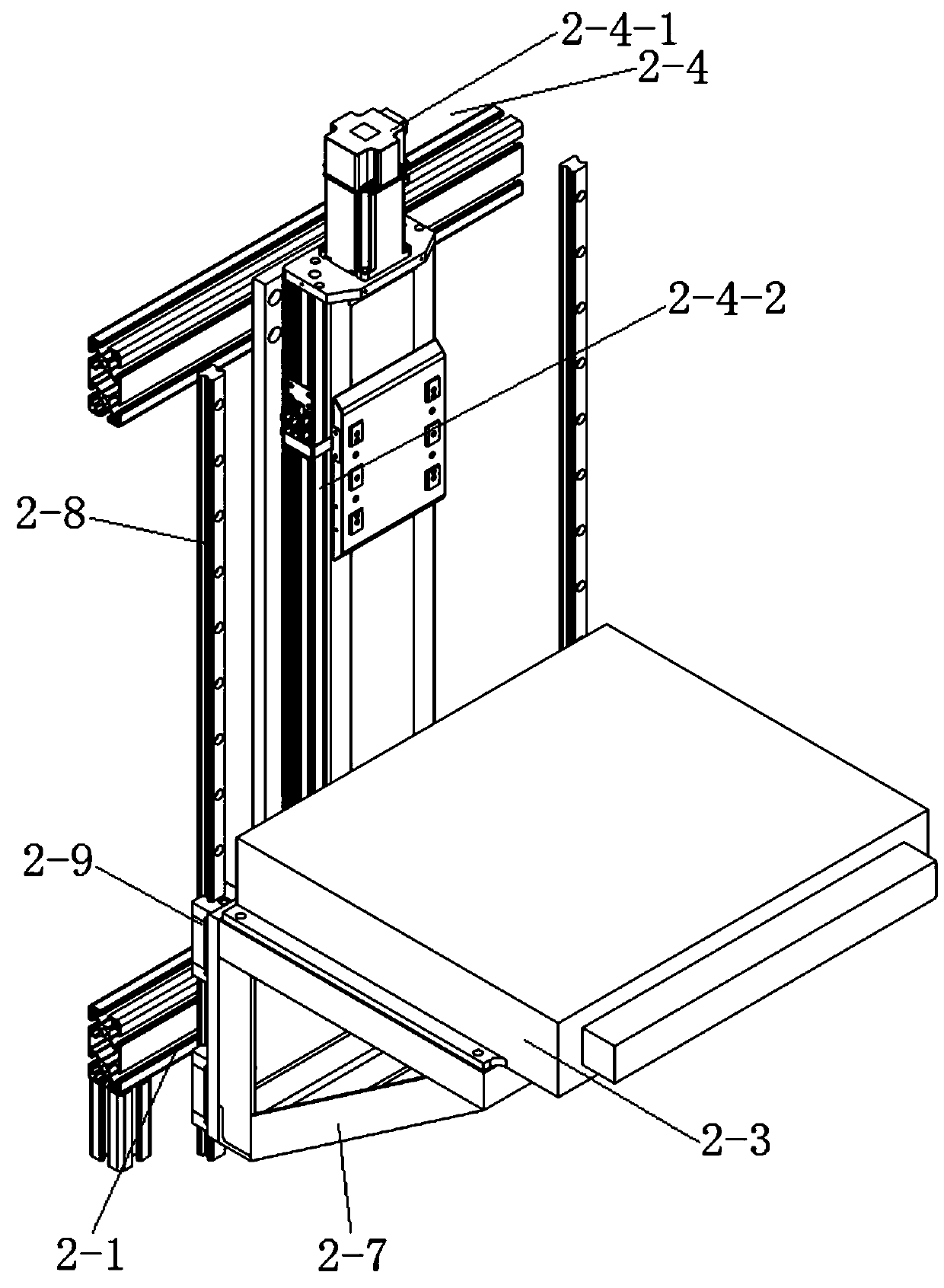

Low-temperature ultrasonic vibration fatigue experiment system

ActiveCN105510443AAccurate cycleThe measured value is accurateAnalysing solids using sonic/ultrasonic/infrasonic wavesReciprocating motionTransducer

The invention discloses a low-temperature ultrasonic vibration fatigue experiment system. The low-temperature ultrasonic vibration fatigue experiment system comprises a piezoelectric transducer and an ultrasonic signal generator. The electric energy input end of the piezoelectric transducer is electrically connected with the alternating current signal output end of the ultrasonic signal generator, and the mechanical vibration output end of the piezoelectric transducer is connected with a test piece. A cryogenic box is further included and is of a closed box body structure, the test piece is located in the cryogenic box, a cooler is further arranged in the cryogenic box, a cooling device is further arranged outside the cryogenic box, and the cooling device is connected with the cooler through a pipeline. The cooler is of a spiral-coil-shaped structure, and the reciprocating direction of the test piece is located on the axis of the spiral-coil-shaped structure. A convection fan arranged in the cryogenic box is further included, and the axis of the convection fan is collinear with the axis of the spiral-coil-shaped structure. According to the system, a low-temperature vibration fatigue loading experiment can be efficiently conducted on the test piece.

Owner:SICHUAN UNIV

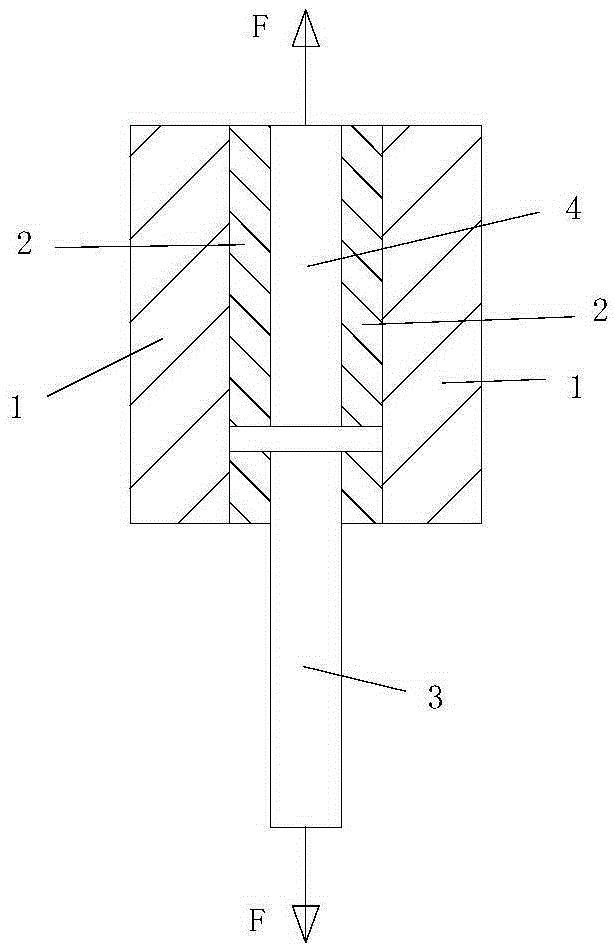

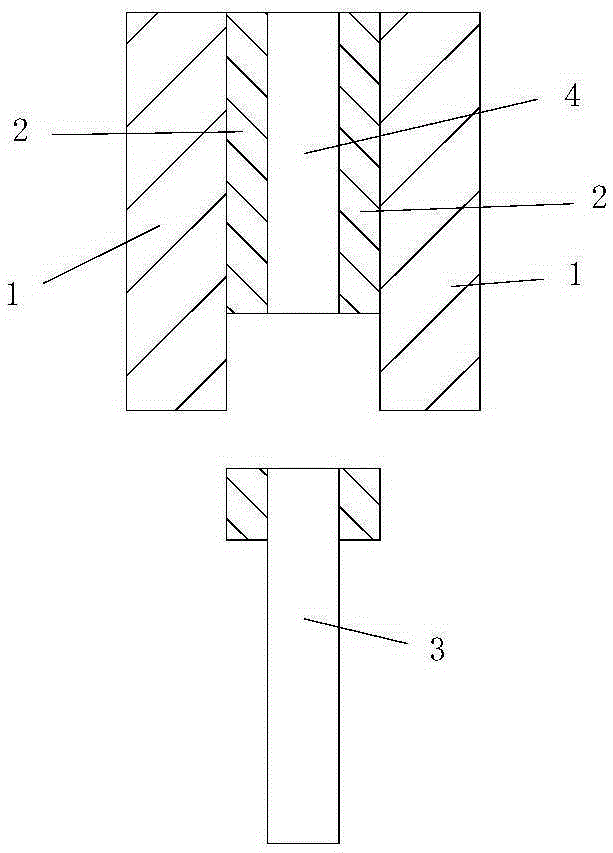

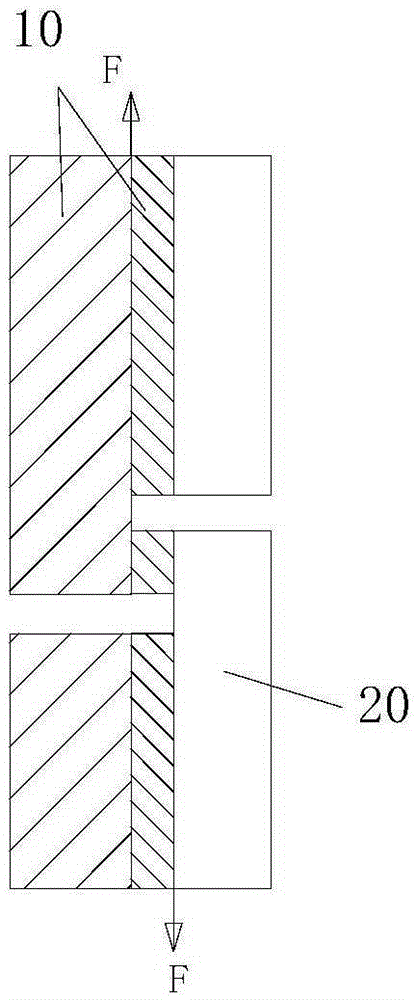

Method for detecting interface bonding strength of composite materials

ActiveCN106680200ALess distracting factorsThe measured value is accurateUsing mechanical meansMaterial analysisThin metalAlloy

The invention discloses a method for detecting the interface bonding strength of composite materials. The method comprises the following steps: preparing two composite materials to be detected, an aluminum plate to be soldered and a filler; arranging the two composite materials to be detected, the aluminum plate to be soldered and the filler to form a three-layer structure: placing the aluminum plate to be soldered and the filler between the two composite materials in parallel, and allowing a part of the aluminum plate to be soldered to stretch out of the two composite materials; arranging the two composite materials in a thin metal layer facing manner; soldering the two composite materials, the aluminum plate to be soldered and the filler to obtain a soldered member; and drawing the soldered member until the soldered member is pulled and broken, recording the value of measured force, and calculating the thin metal layer and substrate interface bonding strength, wherein the thin metal layers of the composite materials, between the aluminum plate to be soldered and the filler, are removed. A sample produced through double side soldering is adopted to detect in order to make two forces applied to the thin metal layers be applied in the same plane and make the steel base and the aluminum alloy layer of the broken sample have no bended angles, so the measured value is accurate.

Owner:YINBANG CLAD MATERIAL

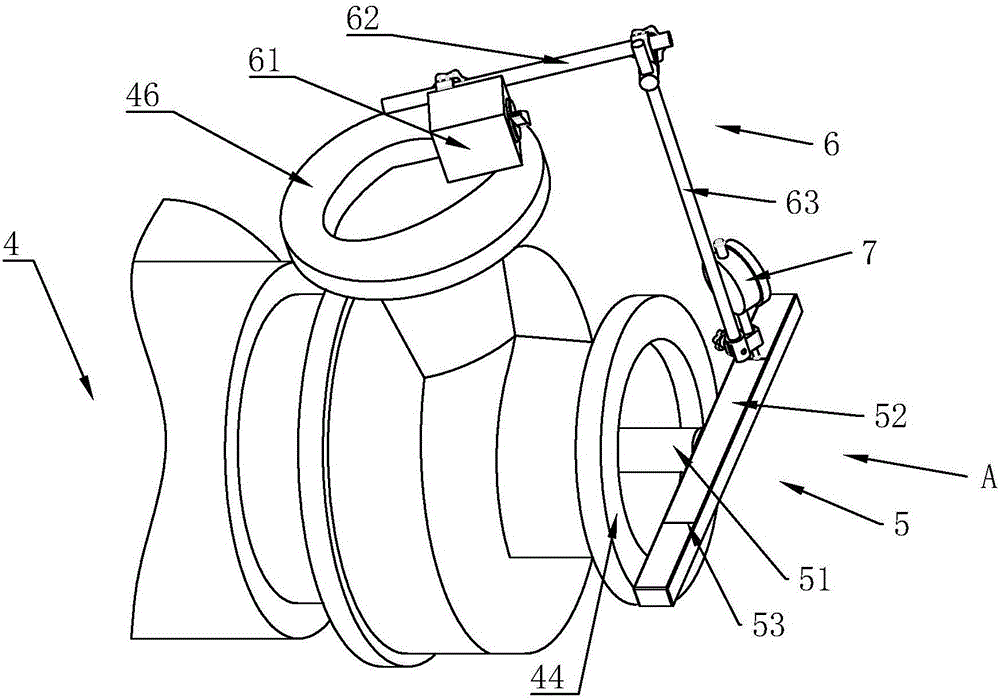

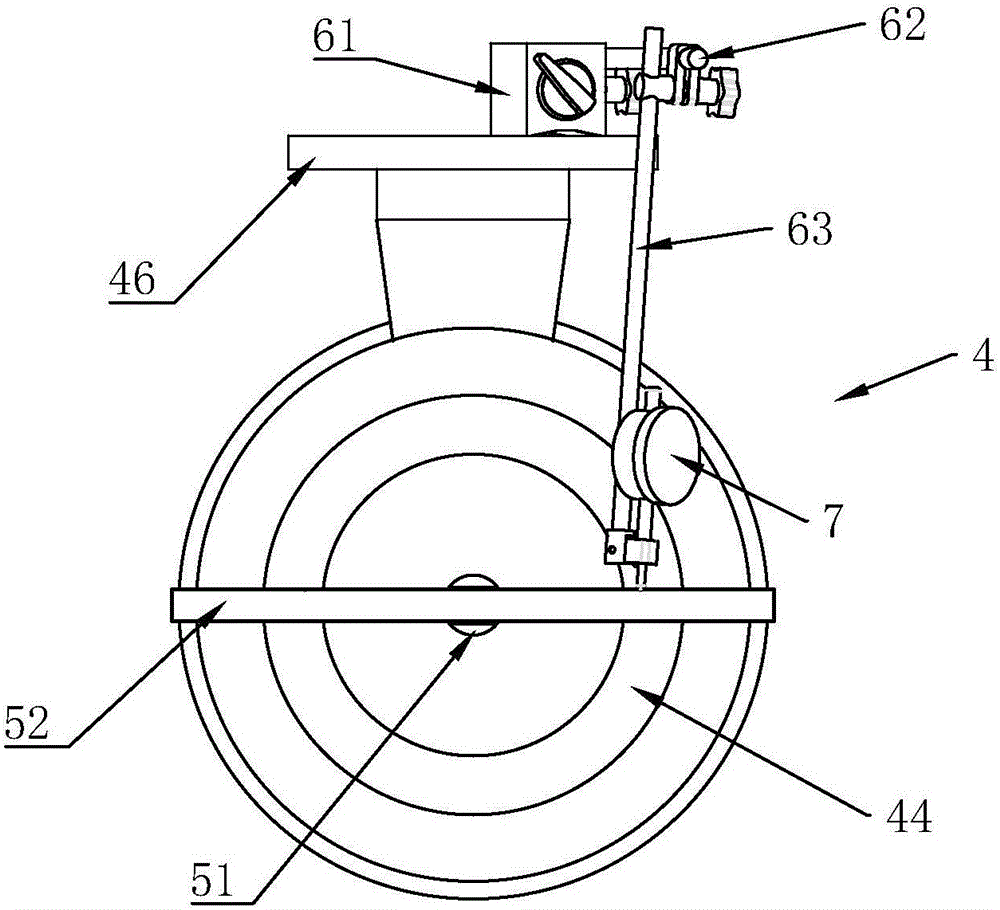

Measuring technology of gear clearance between water pump gear and crankshaft gear

ActiveCN105841586ARealize coaxial rotationEnables indirect measurementsMechanical clearance measurementsGear wheelEngineering

The invention discloses a measuring technology of a gear clearance between a water pump gear and a crankshaft gear. The measuring technology includes the following steps that: the water pump gear is assembled on the rotation shaft of a water pump, a water pump turbine is installed on the rotation shaft through a fastening nut on the water pump turbine, and the water pump is assembled to an engine, and the water pump gear and the crankshaft gear are engaged with each other; the crankshaft of the crankshaft gear is fixedly installed; a first sealing flange at the inlet of the water pump is disassembled, a measurement fixture is concentrically connected onto the fastening nut, the measurement fixture is provided with two scribed lines, and the distance between the two scribed lines is the reference circle diameter of the water pump gear; a second sealing flange at the outlet of the water pump is provided with a supporting mechanism provided with a dial indicator, and the pushing pin of the dial indicator abuts against one of the scribed lines; the dial indicator is zeroed; and the water pump gear is rotated towards the direction of the dial indicator. The measuring technology is simple in measuring process and easy in operation, and can assist in shortening measuring time and improving working efficiency. The measurement of the gear clearance between the water pump gear and the crankshaft gear can be realized through the dial indicator, and measuring accuracy is high.

Owner:WEICHAI HEAVY MACHINERY

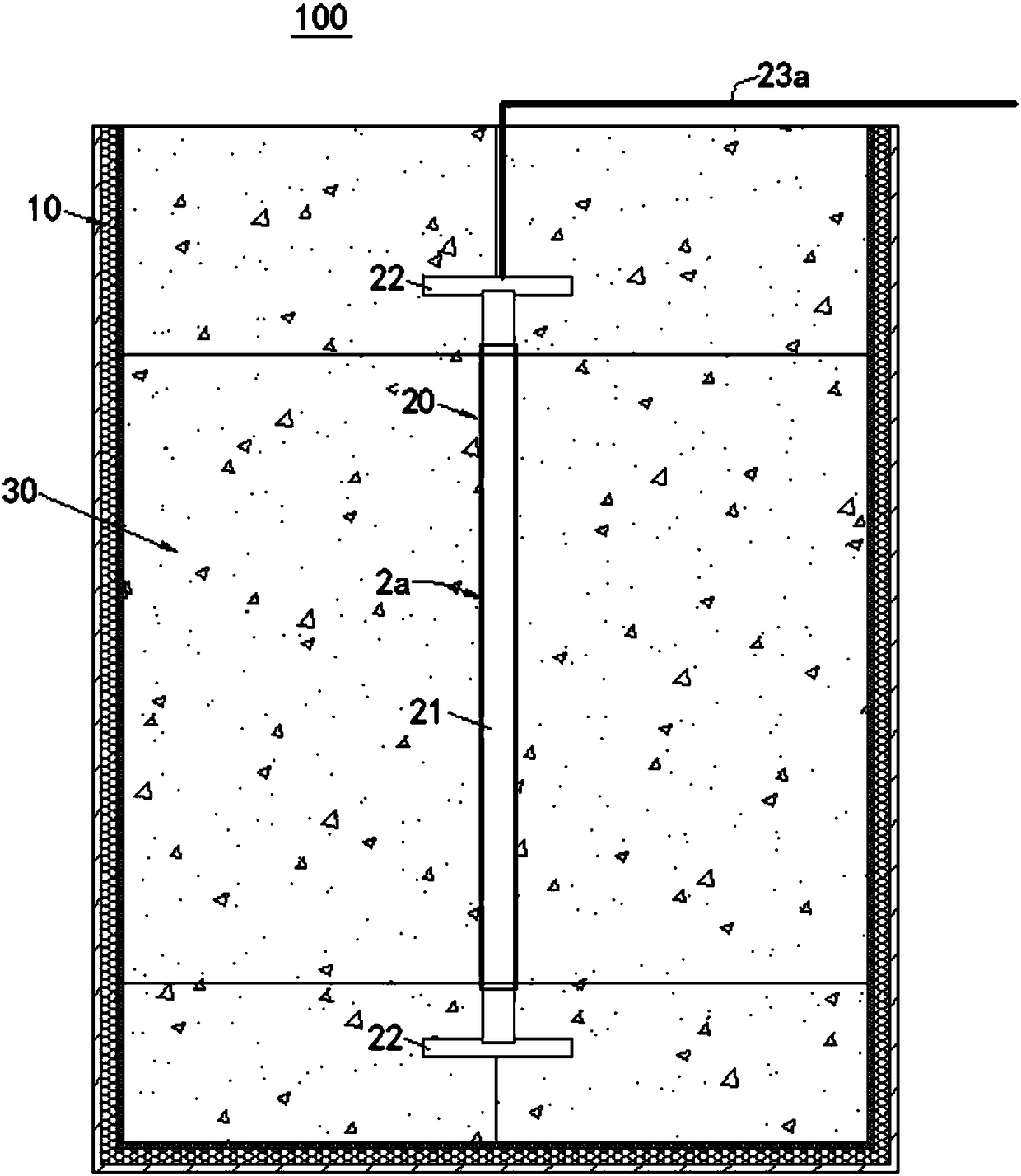

Fully-graded concrete stress-free strain measuring device and measuring method

InactiveCN108593896AThe measured value is accurateAvoid or minimize the influence of external stressMaterial testing goodsStress freeStrain measurement

The invention relates to the field of concrete technical parameter measurement, and aims at solving the problem of low precision of the existing concrete strain measurement and providing a fully-graded concrete stress-free strain measuring device and measuring method. The fully-graded concrete stress-free strain measuring method comprises the following steps of preserving a cylindrical pit with the bottom surface diameter being D and the depth being L in a concrete dam construction cabin surface; after the final setting of peripheral concrete, putting a stress-free barrel into the pit; installing a strain meter into an inner cavity of the stress-free barrel; casting fully-graded concrete into an inner cavity of the stress-free barrel, wherein the casting height h1 is smaller than the depthL1 of an inner cavity of the stress-free barrel; after the initial setting of the concrete in the stress-free barrel, taking the initial value of the strain meter; casting a next cabin of concrete; covering the stress-free barrel; continuously monitoring the strain meter value; analyzing the stress-free strain of the fully-graded concrete. The device and the method provided by the invention havethe beneficial effects that the external stress influence can be enabled to be effectively avoided or possibly reduced, so that the measuring value of the strain meter is sufficiently accurate.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

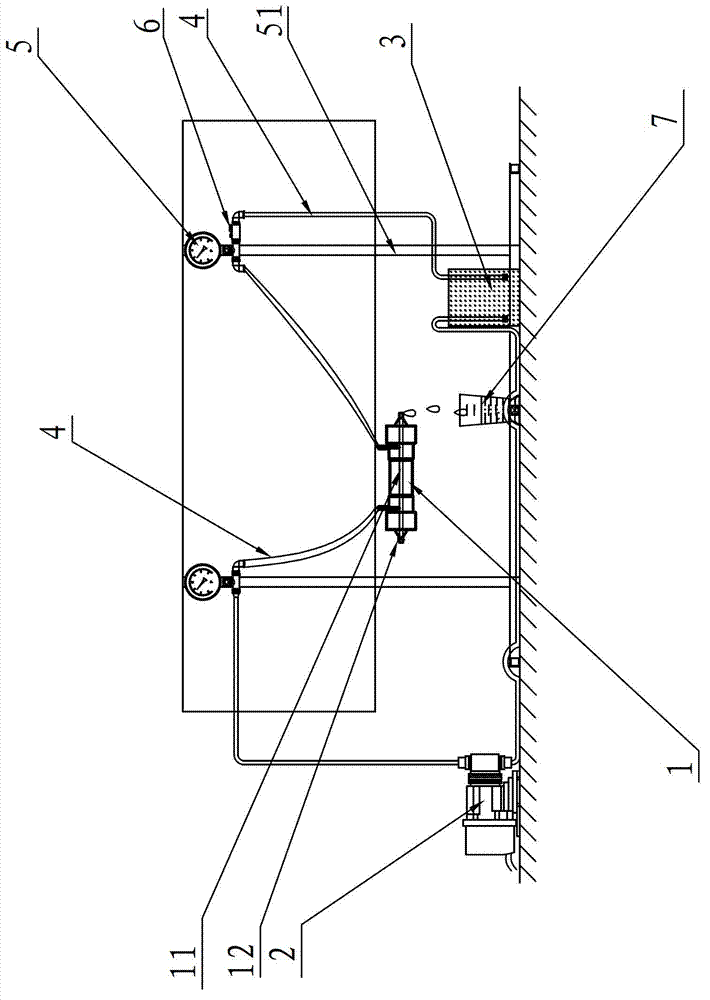

Device for testing antifouling property of hollow-fibre membrane

ActiveCN102961970AGuaranteed uptimeEasy to measureSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a device for testing antifouling property of a hollow-fibre membrane. The device comprises an end cap, and a hollow hole arranged in the end cap, wherein a charging pump and a feed liquid circulating barrel for forming a circulation loop are connected with two ends of the hollow hole; a plurality of connecting pipes are arranged at the two ends of the hollow hole, and between the charging pump and the feed liquid circulating barrel; a pressure gauge is arranged on each connecting pipe, and valves are also arranged at two ends of the hollow hole on the end cap. By adopting the device for testing the antifouling property of the hollow-fibre membrane, the fibre membrane to be tested is arranged inside the hollow hole in a testing process, and liquid inside the feed liquid circulating barrel is driven to flow circularly through the charging pump; a work scene of the fibre membrane in actual operation can be simulated by controlling the entire internal pressure of the device, and the antifouling property is test. Therefore, the device is simple in operational process, convenient and fast in measurement process, and accurate in measured numerical value. Thus, the device disclosed by the invention is applied to the field of an experiment test.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Determination method for potential well deep distribution of methane adsorption by coal

ActiveCN106918532AThe measured value is accurateThe calculated value is accurateMaterial analysisPotential wellRate parameter

The invention relates to a determination method for potential well deep distribution of methane adsorption by coal, which relates to a method for evaluating methane reserves in a coal reservoir, due to characteristic of uneven potential well depth of methane adsorption by raw coal body, multi-measuring point adsorption measurements under adsorption pressure and different constant temperature conditions can be carried out on a block coal sample; by using a Langmuir equation based on adsorption kinetics, the adsorption rate parameter b under different constant temperature conditions and the corresponding temperature T enable fitting calculation to obtain a proportion constant bm, the methane adsorption quantity under each constant temperature condition and adsorption pressure are subjected to segment fitting, quantity of different depths of potential wells can be calculated, and a potential well distribution histogram in a certain depth scope can be drafted. The method can be used for realizing accurate calculation of methane adsorption capability under different temperature and pressure conditions on the coal body, and can be used for accurately evaluating the coal bed gas content of the coal reservoir.

Owner:TAIYUAN UNIV OF TECH

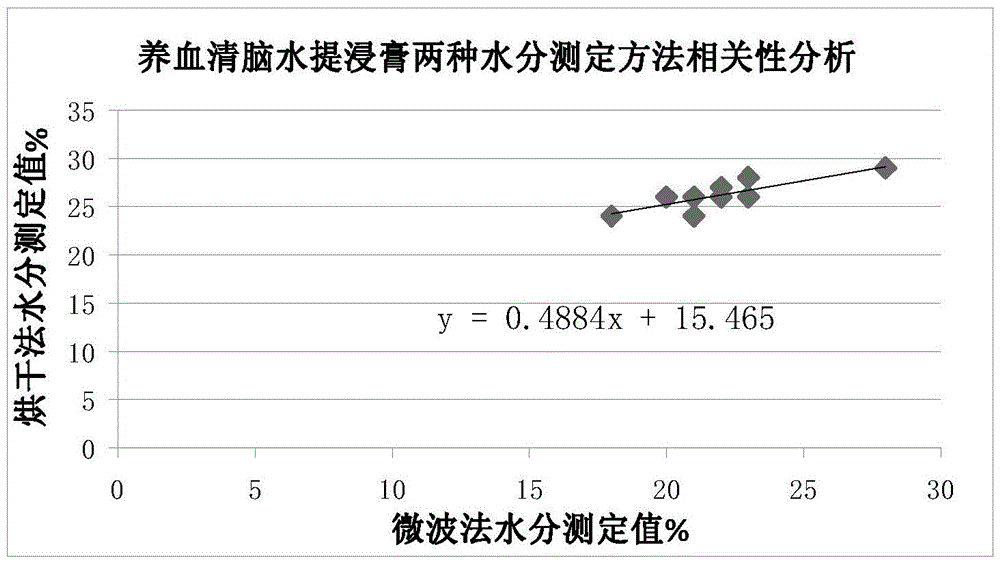

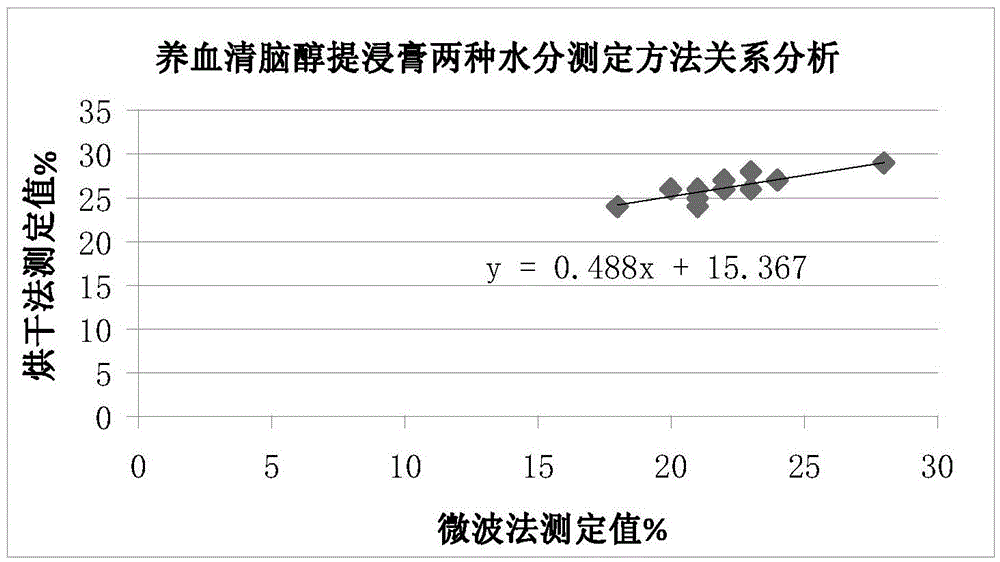

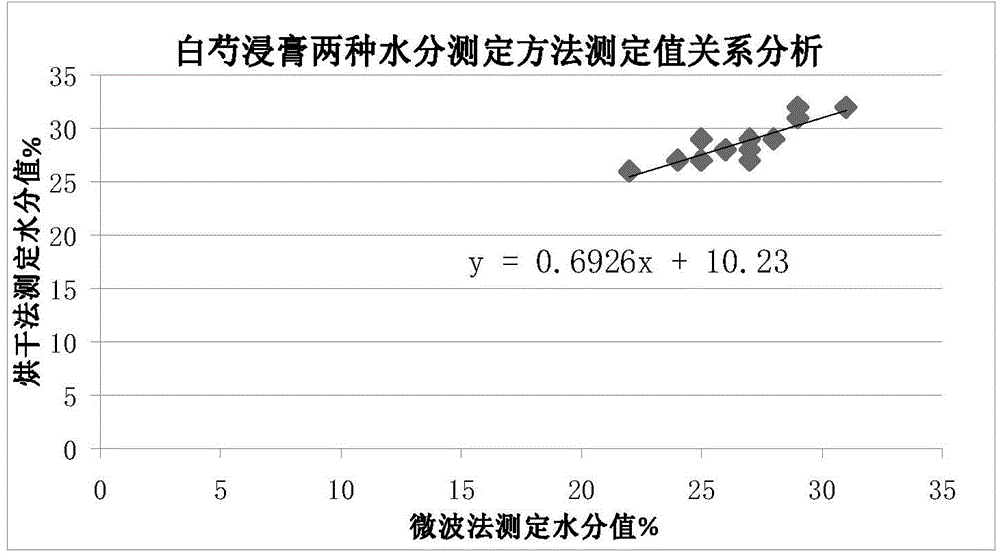

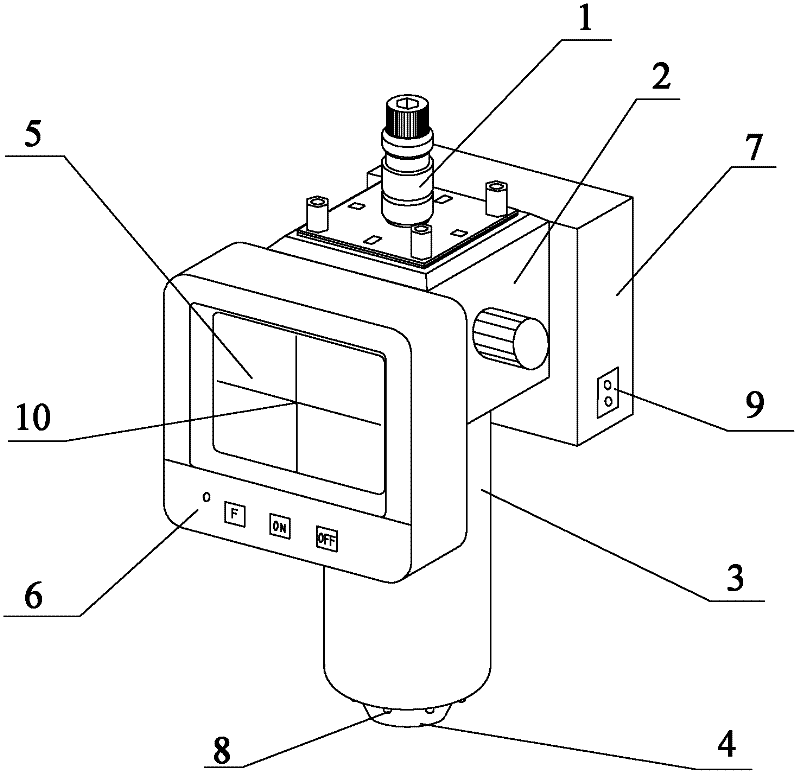

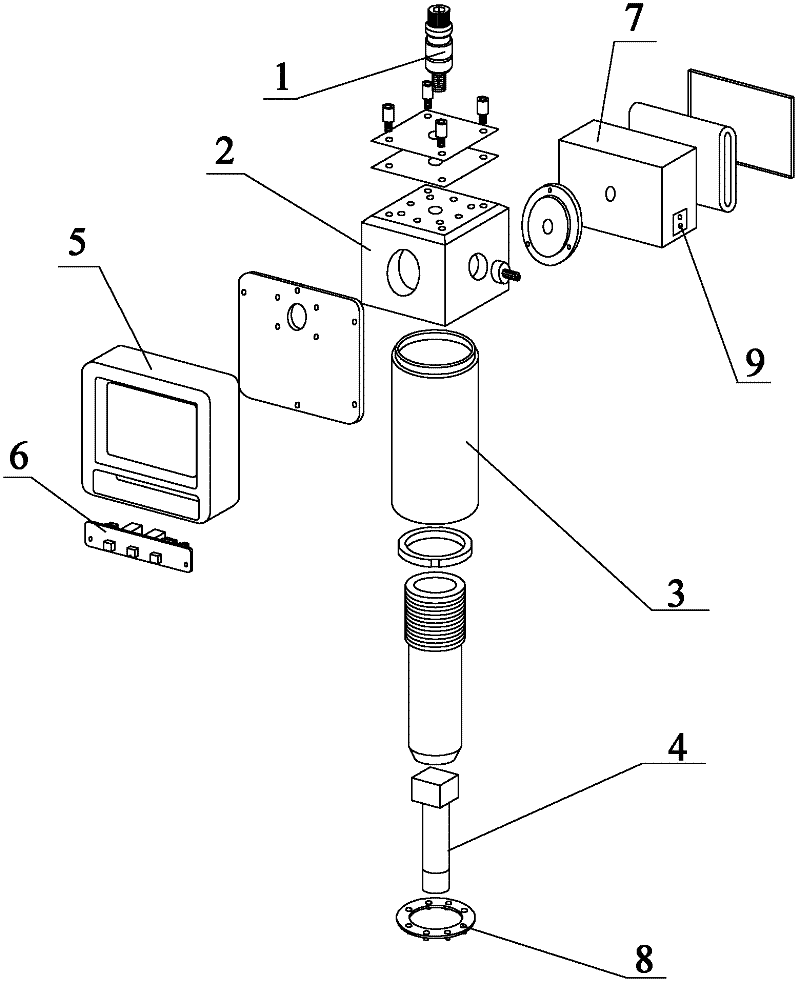

Rapid microwave moisture measurement method for fluid extract and extract

InactiveCN105021634ASolve the problems existing in the process of measuring the water content of the extractThe measured value is accurateMoisture content investigation using microwavesGlass fiberMicrowave

The invention relates to a rapid microwave moisture measurement method for a fluid extract and an extract. The method comprises the following steps: 1, taking two pieces of glass fiber papers, putting the glass fiber papers on a balance of a microwave moisture measurement apparatus and weighing in a peeling manner, taking an extract sample and putting the extract sample on one piece of glass fiber paper, covering with the other piece of glass fiber paper and flattening, then putting the papers back to the balance, covering with a detection pool, beginning to detect and recording a measurement value; 2, substituting the measurement value of the microwave moisture measurement apparatus into a data model, and calculating the moisture value according to the formula that the moisture value of the extract is equal to X * the measurement value of the microwave moisture measurement apparatus + Y, wherein X and Y are relationship parameters of moisture measurement by microwaves and moisture measurement by a drying method.

Owner:TIANJIN TASLY MORDEN TCM RESOURCES

An online video multiplier workpiece detector

InactiveCN102284889APrecise positioningThe measured value is accurateMeasurement/indication equipmentsCcd cameraMachine tool

The invention discloses an online video magnification workpiece detector. A rapid positioning mandrel is connected above the main frame of the instrument, and a camera mounting body is installed below the main frame of the instrument, and a CCD industrial sensor with a magnification lens is installed inside. Camera, the display screen of the CCD industrial camera is installed in front of the main frame of the instrument, and the quick positioning mandrel above the main frame of the instrument is set coaxially and concentrically with the magnification lens of the CCD industrial camera installed in the camera installation body. The present invention is directly installed on the fast positioning fixture of the spindle of the numerical control and digital display processing machine tool, and the measured workpiece on the workbench is directly photographed with the lens of the CCD industrial camera, and the video image is enlarged and transmitted to the display screen, and is set in the center of the display screen. Some cross marks are used to position the detection reference of the workpiece to be tested, and then the moving table drives the invention to move to each detection position of the workpiece to be tested, and the cross marks are used for comparison and measurement, and the accurate information is obtained from the digital display table of the processing machine tool. measured value.

Owner:杨志光

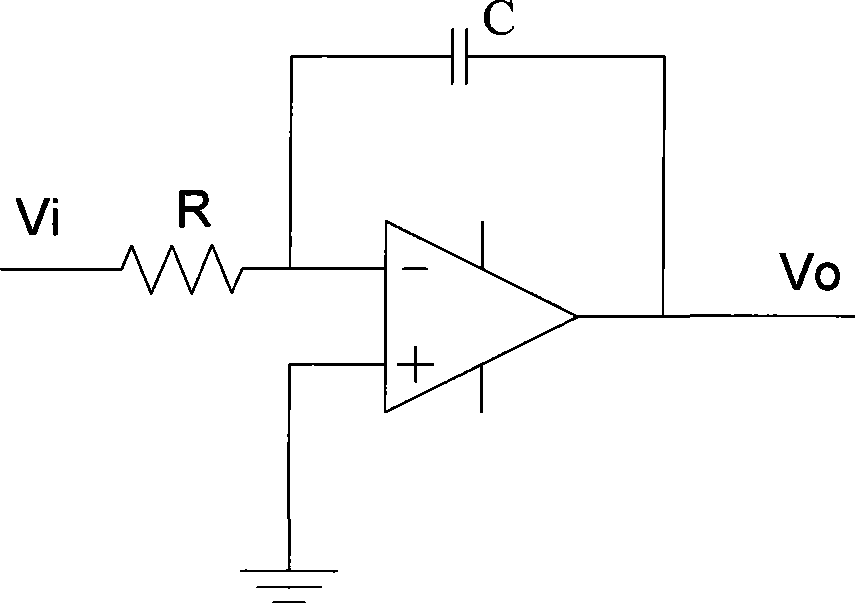

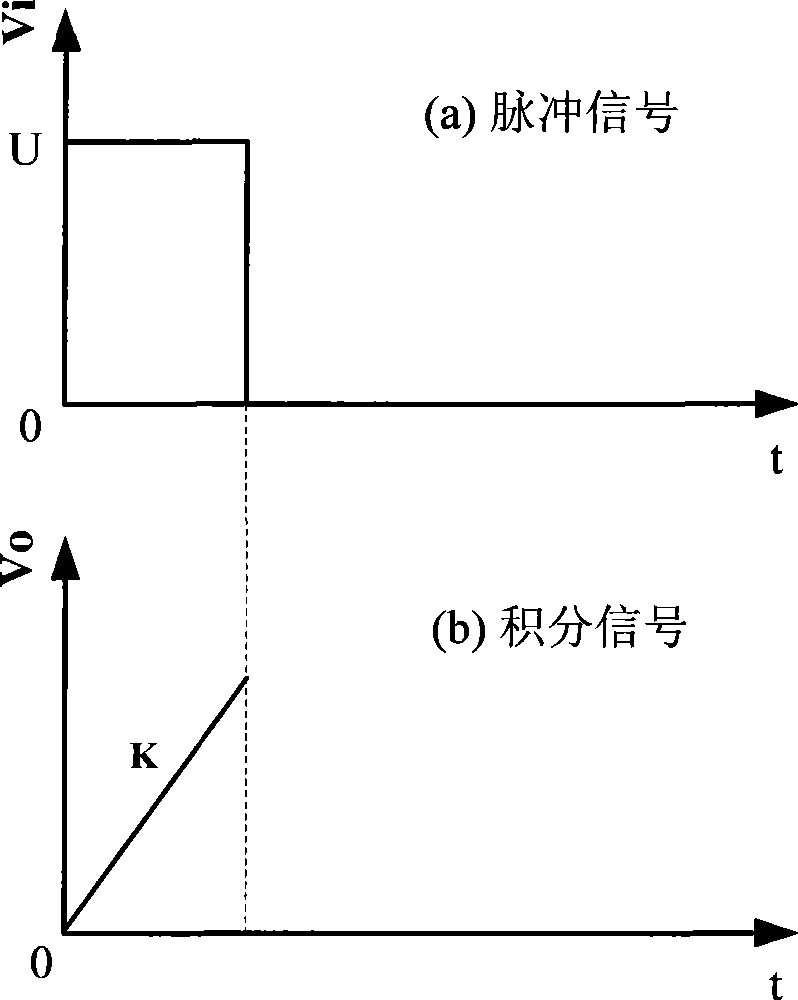

Integral time constant calibration method

InactiveCN101482910AEasy to useEasy to operateComputing operations for integration/differentiationCapacitanceElectrical resistance and conductance

The invention discloses an integral time constant calibration method which is characterized by comprising following steps: (1) a pulse signal with an amplitude of U is given to an input end of an integrator, and the integrator integrates the pulse signal to obtain an integral output curve; (2) according to the formula, after a time T, an integral output voltage is that V=(U / RC)T+U, wherein R is an integrator resistance, C is an integrator capacitance, T is an integral time, and U is an integrator initial voltage, thereby the integral slope K can be calculated by the integral output curve; (3) the slope of the integral output curve is that K=(V to U) / T=(U / RC), thereby an integral time constant is that t=RC=U / K, wherein U is the amplitude of the pulse signal, K is the slope of the integral output curve, U and K can be calculated by the formula, and the integral time constant t can be calculated by substituting U and K. The method of the invention has simple operation and clear steps, the according formulas are all known physical formulas, and no special devices are needed in the method of the invention. And the method of the invention has rapid measurement process and accurate measured value, and is convenient for technicist to use.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Device and method for measuring diameter of dense pipe bundle and thickness of oxide film on site

ActiveCN107274941AThe measured value is accurateAvoid radiation damageNuclear energy generationNuclear monitoringDiameter measurementBiomedical engineering

The invention discloses a device and a method for measuring the diameter of a dense pipe bundle and the thickness of an oxide film on site. The device comprises a plurality of rod diameter measurement units and a plurality of oxide film thickness measurement unit which are mounted on a measurement rack, wherein the rod diameter measurement units are all arranged in the same horizontal plane; the oxide film thickness measurement units are all arranged in the same horizontal plane; a channel, through which a sample supply pipe passes, is arranged inside each of each rod diameter measurement unit and each oxide film thickness measurement unit; the channel of each rod diameter measurement unit is correspondingly coaxial with the channel of each oxide film thickness measurement unit. By classification of the dense pipe bundle, the device can directly and precisely measure the diameter of the dense pipe bundle and the thickness of the oxide film at any position in the whole stroke on the site; in the measurement process, direct contact with a human body is avoided; a sensor is configured to measure tiny changes of the diameter and the thickness of the oxide film, so that the detection is safer, more efficient and more reliable; in case of failure of a certain measurement unit, the device still can complete the measurement work.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

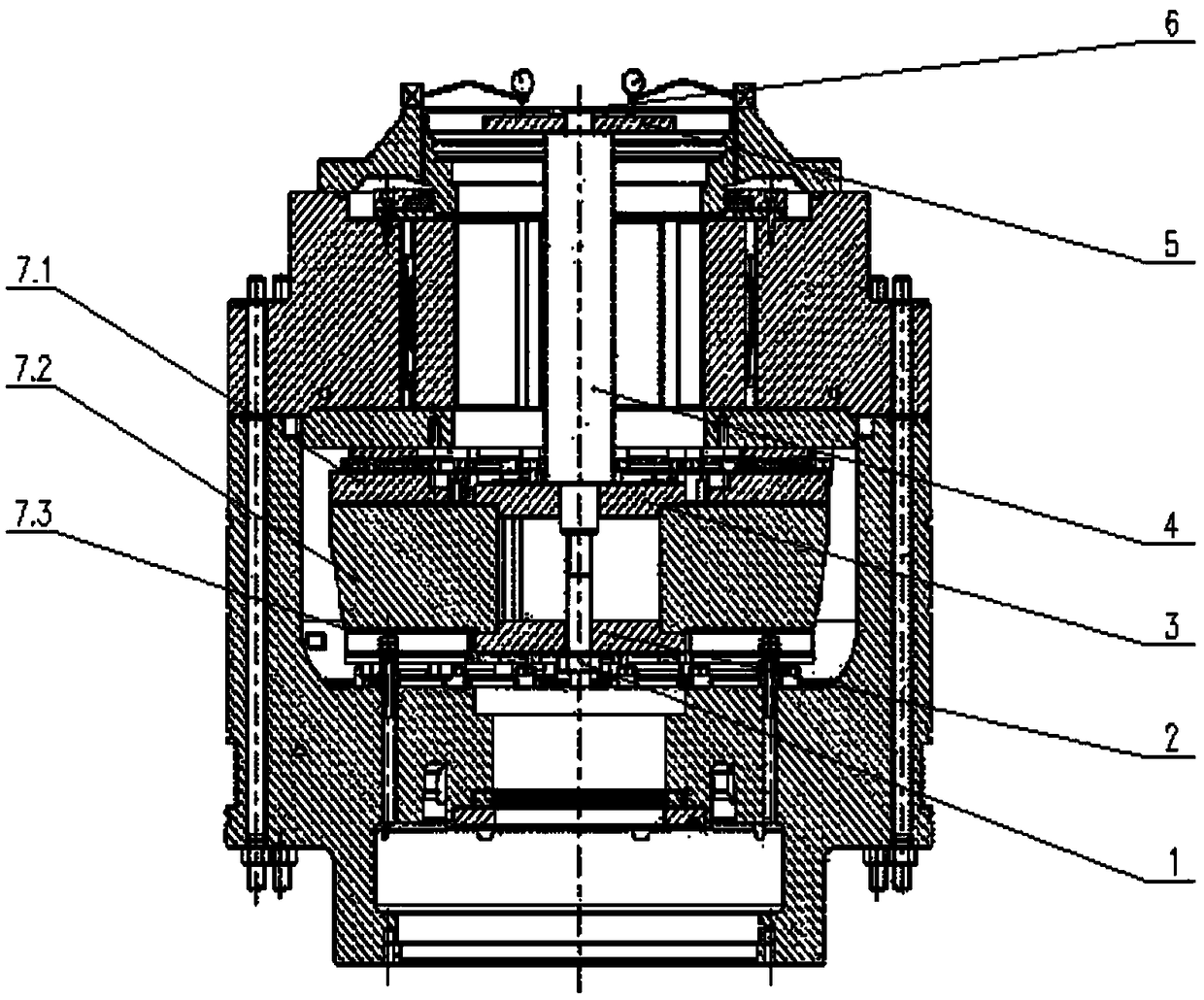

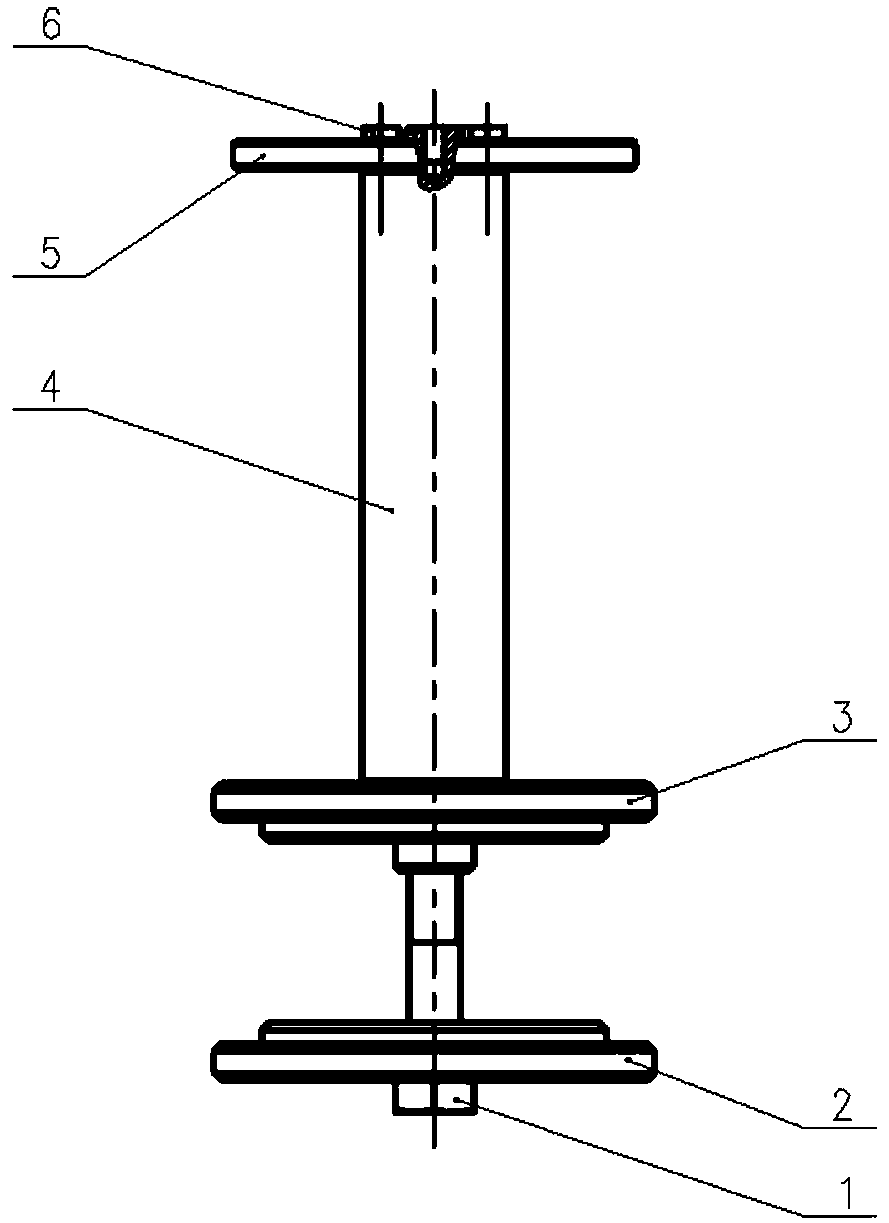

Mounting clearance measuring device of reactor coolant pump thrust plate

PendingCN109405714ASimple structureSave human effortMechanical clearance measurementsEngineeringControllability

The invention relates to a mounting clearance measuring device of a reactor coolant pump thrust plate. An upper pressure plate (3) is mounted on a tool shaft (4); a bolt (1) is assembled with a threaded hole formed below the tool shaft (4) through a lower pressure plate (2); and a thrust plate (7.2) is installed between the upper pressure plate (3) and the lower pressure plate (2). An axial clearance plate (5) is installed above the tool shaft (4) by hexagon head screws (6). A lifting lug is installed in the threaded hole above the tool shaft (4). A dial indicator is mounted on the plane of the axial clearance plate (5). Therefore, the clearance between the thrust plate and the main thrust tile can be measured quickly and accurately. The time spent in the whole process is reduced; the controllability is high; the manpower is reduced; the operation becomes simple; and the device is convenient to mount or dismount. The device is manufactured conveniently; and the cost is saved.

Owner:HARBIN ELECTRIC POWER EQUIP

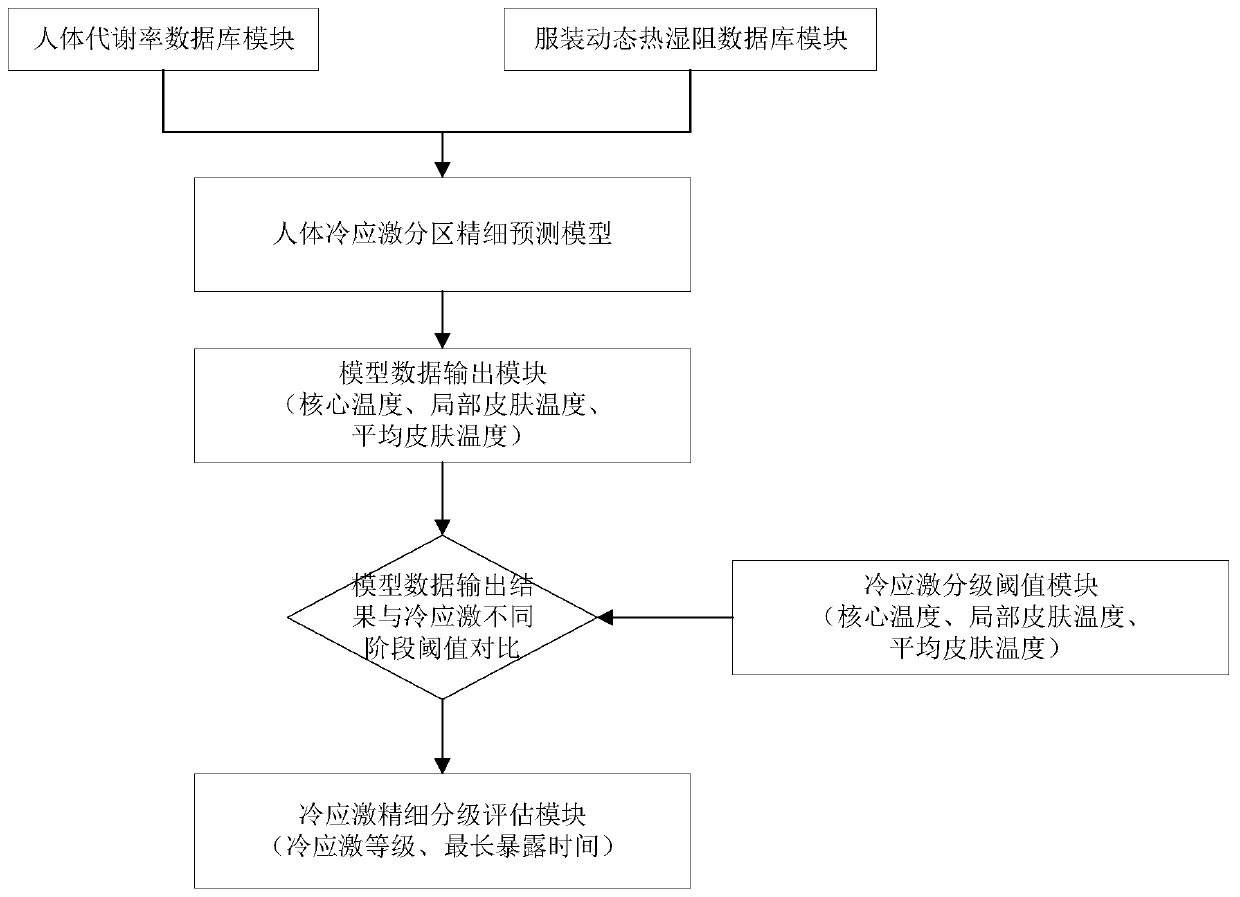

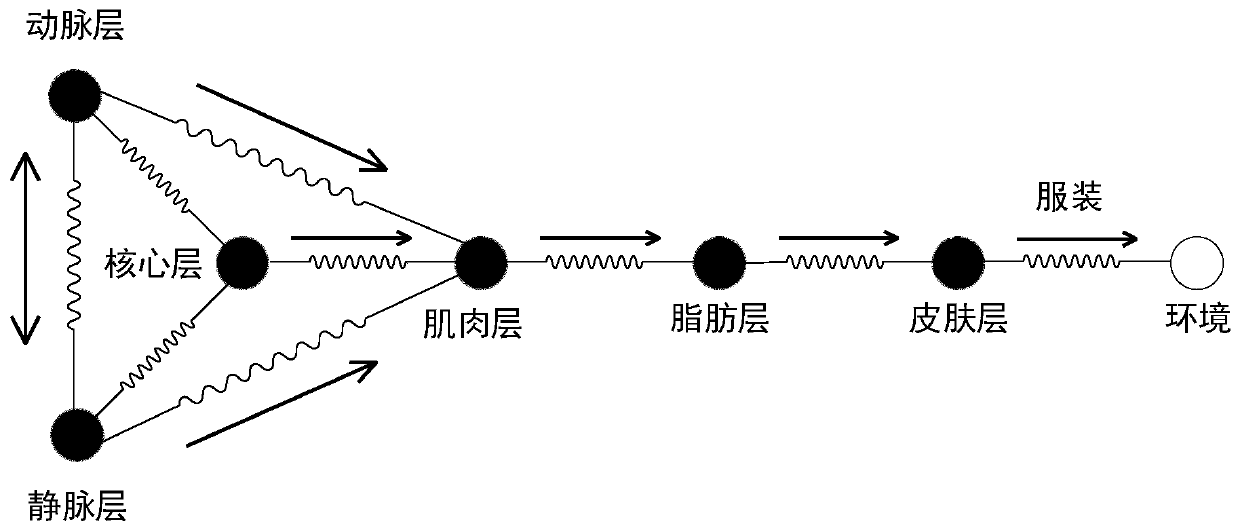

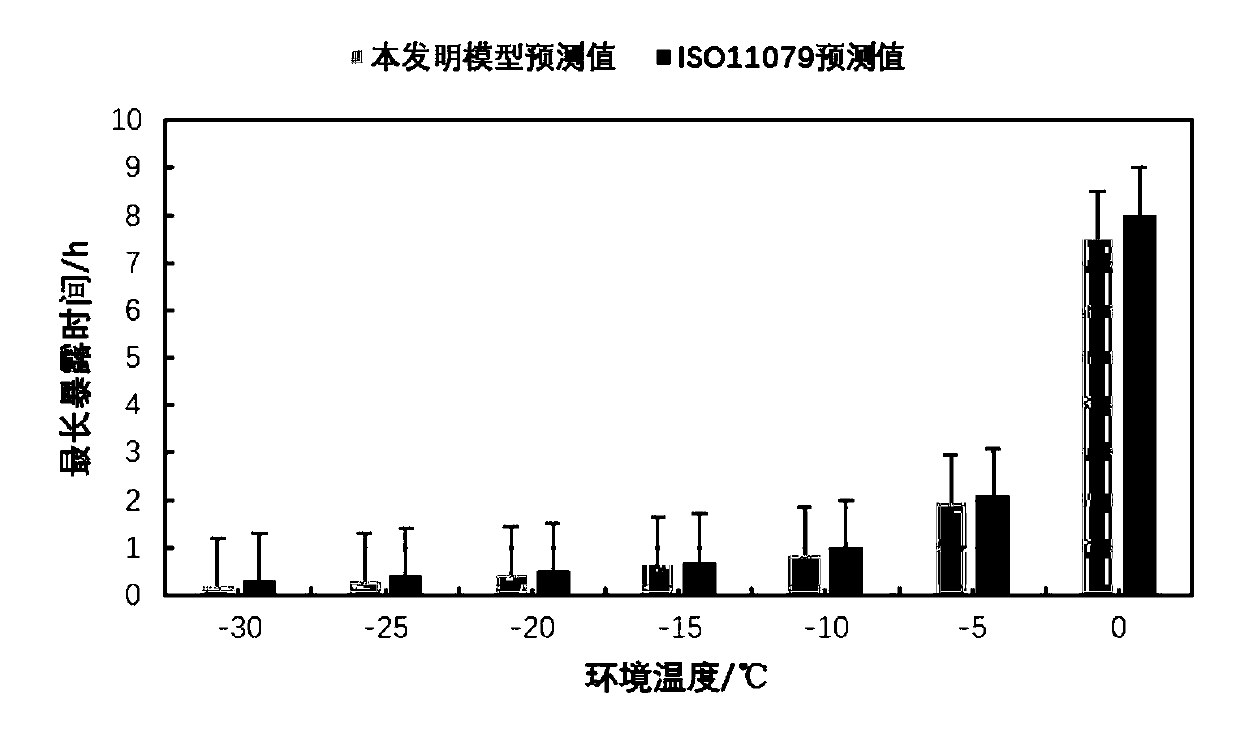

Human body cold stress fine grading evaluation system in low-temperature operation environment

ActiveCN110175732AThe measured value is accuratePredictableMaterial heat developmentResourcesSkin temperaturePhases of clinical research

The invention provides a human body cold stress fine grading evaluation system in a low-temperature operation environment. The system comprises the following steps of selecting metabolic rate values which accord with actual labor intensity and labor types of human bodies from an established metabolic rate database; selecting dynamic thermal resistance and moisture resistance values of clothes according with the actual environment from the established dynamic thermal and moisture resistance database of clothes and substituting the values into the system; calculating time-varying core temperature, local skin temperature and average skin temperature of human bodies in the low-temperature cold environment through the established human body cold stress partition fine prediction model. Comparedwith index thresholds of different cold stress stages, cold stress level of human bodies is evaluated. Therefore, acceptable longest exposure time for human bodies is determined, measured value is more accurate, predictability is good, guidance is provided for selecting appropriate emergency equipment according to the cold environment and reasonably arranging organization and production strategiesin the cold environment. Theoretical basis and guidance are provided for reduction of occupational injuries in China, personnel cold stress risk is reduced, and personnel life safety is protected.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

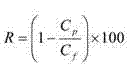

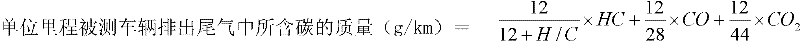

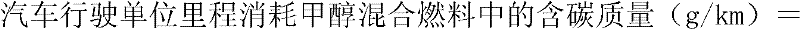

Method for measuring fuel consumption of methanol vehicle

ActiveCN102445247AEasy to analyzeConvenient researchRelative volume flow measurementsMethanolExhaust gas

The invention relates to a fuel consumption measurement method, in particular to a method for measuring mixed fuel consumption of a methanol vehicle. The method comprises the steps of: after preprocessing the vehicle, simulating a comprehensive working condition for detecting, collecting tail gas and then directly detecting consumption of a mixed fuel by using a law of indestructibility of matter. The method has the advantages of simple detection process, no influence of temperature and volume changes to a detection process, and accuracy in measurement values, and solves the technical programof incapability of effectively detecting the fuel consumption of the mixed fuel of the methanol vehicle in the prior art.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

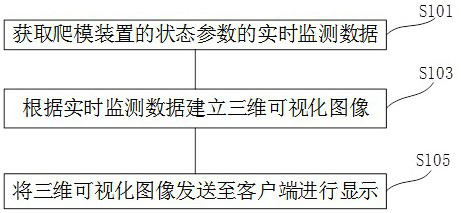

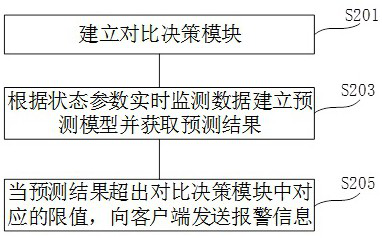

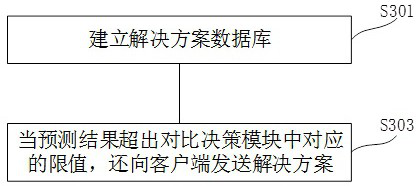

Creeping formwork construction monitoring method and system and computer readable storage medium

ActiveCN114547759ARespond quicklyReflect clearlyGeometric CADMeasurement devicesStructural deformation3d image

The invention provides a creeping formwork construction monitoring method and system and a computer readable storage medium. The safety monitoring method of the creeping formwork device comprises the following steps: acquiring real-time monitoring data of state parameters of the creeping formwork device, wherein the state parameters comprise structural stress, structural deformation, spatial three-dimensional position and dip angle change, wind load, live load and earthquake acceleration load; establishing a three-dimensional visual image according to the real-time monitoring data; and sending the three-dimensional visual image to a client for display. According to the safety monitoring method, the state parameters of the creeping formwork are obtained, three-dimensional modeling is conducted on the creeping formwork device, the monitoring result is fed back to the client side in a three-dimensional image mode, the construction state of the creeping formwork device can be rapidly and clearly reflected, and the monitoring process is more visual and efficient.

Owner:THE THIRD CONSTR CO LTD OF CTCE GRP +1

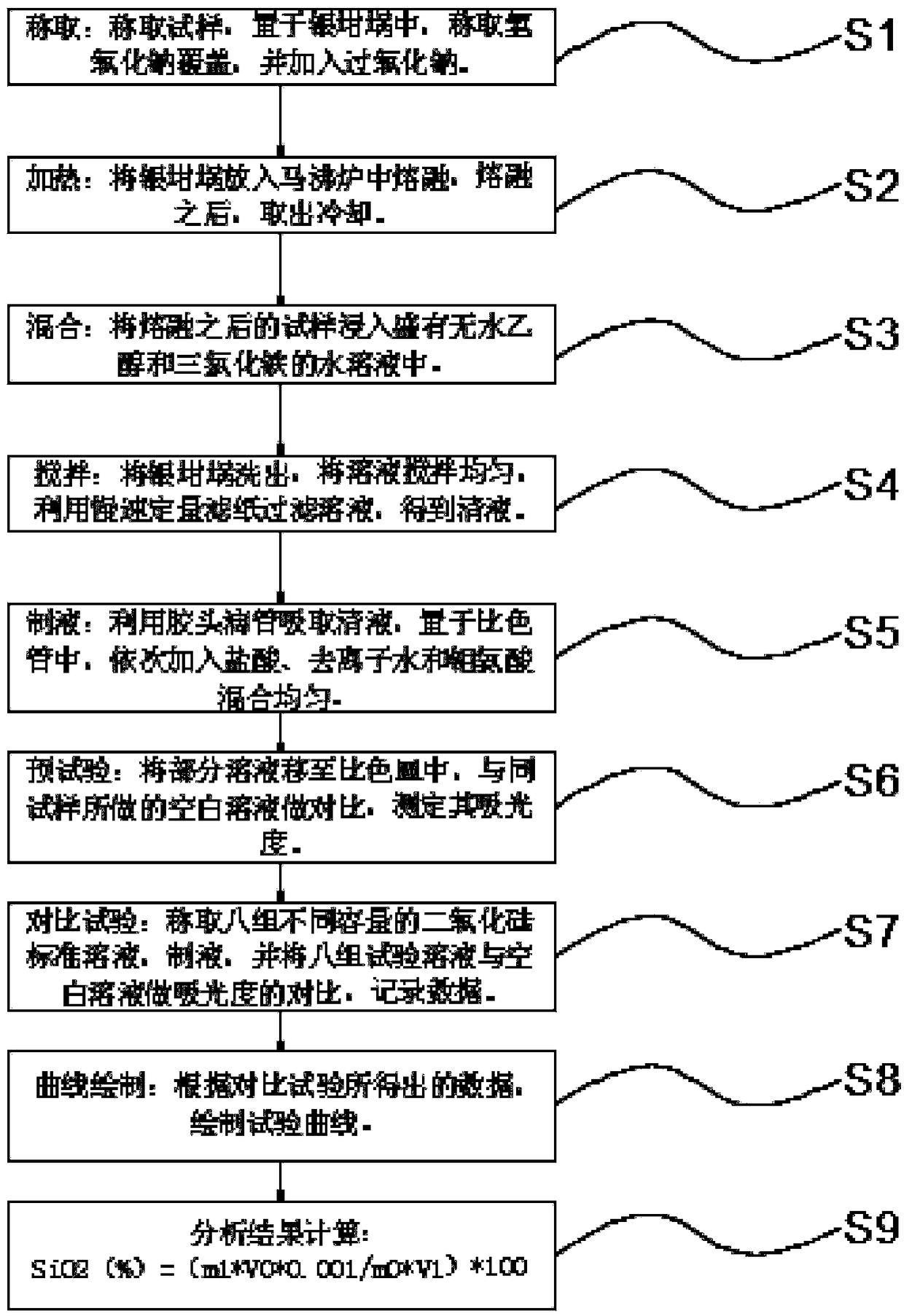

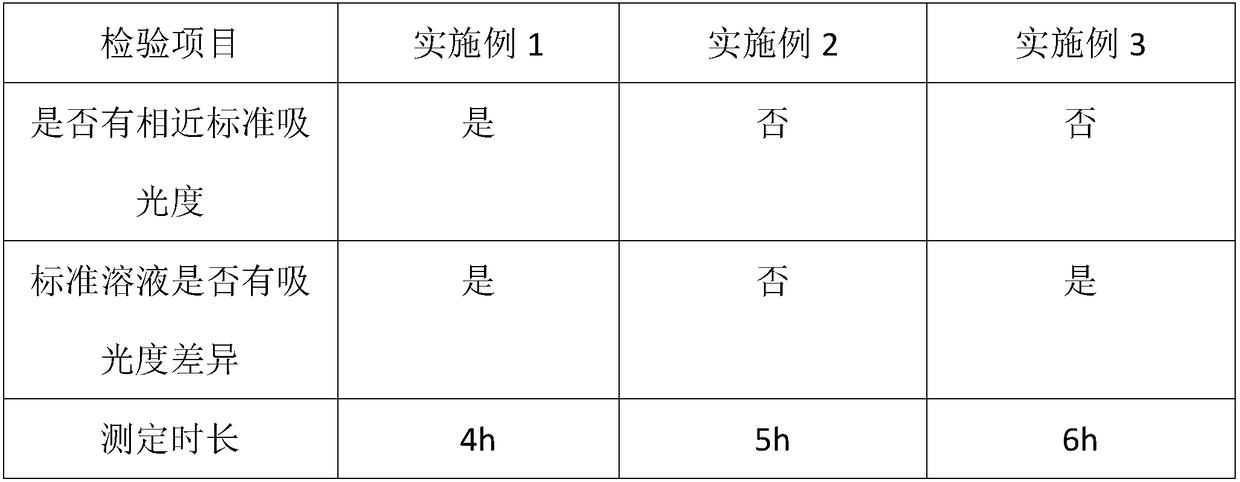

Method for measuring silicon dioxide amount

InactiveCN109115702AThe measured value is accurateBig errorColor/spectral properties measurementsSilicic acidPhysical chemistry

The invention discloses a method for measuring silicon dioxide amount. The method comprises the following steps: weighing, heating, mixing, stirring, liquid preparation, trial test, contrast test, curve plotting and analysis result calculation. The method disclosed by the invention is scientific and reasonable and safe and convenient to use; through high-temperature heating and melting of the silicon dioxide and by adopting sodium hydroxide and hydrogen peroxide solutions, the silicon dioxide is totally dissolved and converted into soluble silicic acid, then the measured value of the silicon dioxide is more accurate, and relatively great error is avoided; preheating at the furnace opening of a muffle furnace can effectively prevent sharp change of temperature in heating and vaporization of sodium hydroxide and silicon dioxide in the melting as well as difference in the final measured value and influence on the measurement result; during the measurement, a plastic container is adoptedfor the measurement, thus influence on the content of silicon dioxide can be effectively avoided, and the pollution caused by the silicon dioxide is eliminated.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Device for detecting pseudo soldering of power battery module and detection method thereof

PendingCN111856142AStable voltageThe measured value is accurateResistance/reactance/impedenceElectric connection testingPower batteryVoltage

The invention discloses a device for detecting pseudo soldering of a power battery module and a detection method thereof, and belongs to the technical field of battery module quality detection. A plurality of battery cells are connected in series, and a plurality of detection units are arranged, so that the resistances at the welding parts of the battery cells and connecting assemblies can be measured simultaneously, and the device is particularly suitable for measurement by methods such as a four-end method. Meanwhile, the plurality of battery cells are connected in series through the plurality of connecting assemblies and adapt to the use working conditions, and compared with a measurement mode only for the welding position of one battery cell and one connecting assembly, the method hasthe advantages of stable current and voltage during measurement and more accurate measurement numerical value.

Owner:XIAMEN HAICHEN NEW ENERGY TECH CO LTD

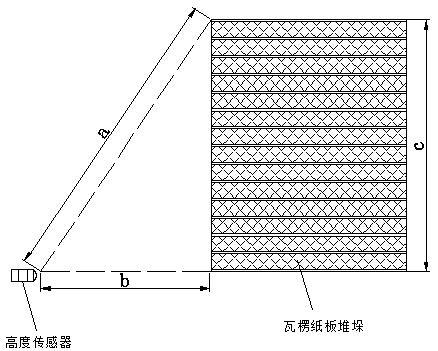

Paper height measurement system for corrugated board production

InactiveCN110360936AImprove efficiencyThe measured value is accurateUsing optical meansInformation repositoryCardboard

The invention discloses a paper height measurement system for corrugated board production. The system comprises a height measurement module, a corrugated board information database and a production management module. The height measurement module is used for measuring the stacking height of corrugated boards and transmitting the measurement result to the production management module; the corrugated board information database is used for storing basic information of the corrugated boards; and the production management module calculates stacking number of the corrugated boards. The invention relates to the paper height measurement system for corrugated board production. The system can automatically calculate the overall height of the corrugated board stack according to the data measured by aheight sensor, and meanwhile, the production management module can directly calculate the stacking number of the corrugated boards according to the measured stacking height information of the corrugated boards and the stored corrugated board thickness information, thereby changing the phenomenon that existing manual measurement wastes time and energy and is large in errors.

Owner:江苏通达纸业有限公司

Transformer station secondary side electric energy measuring system and method

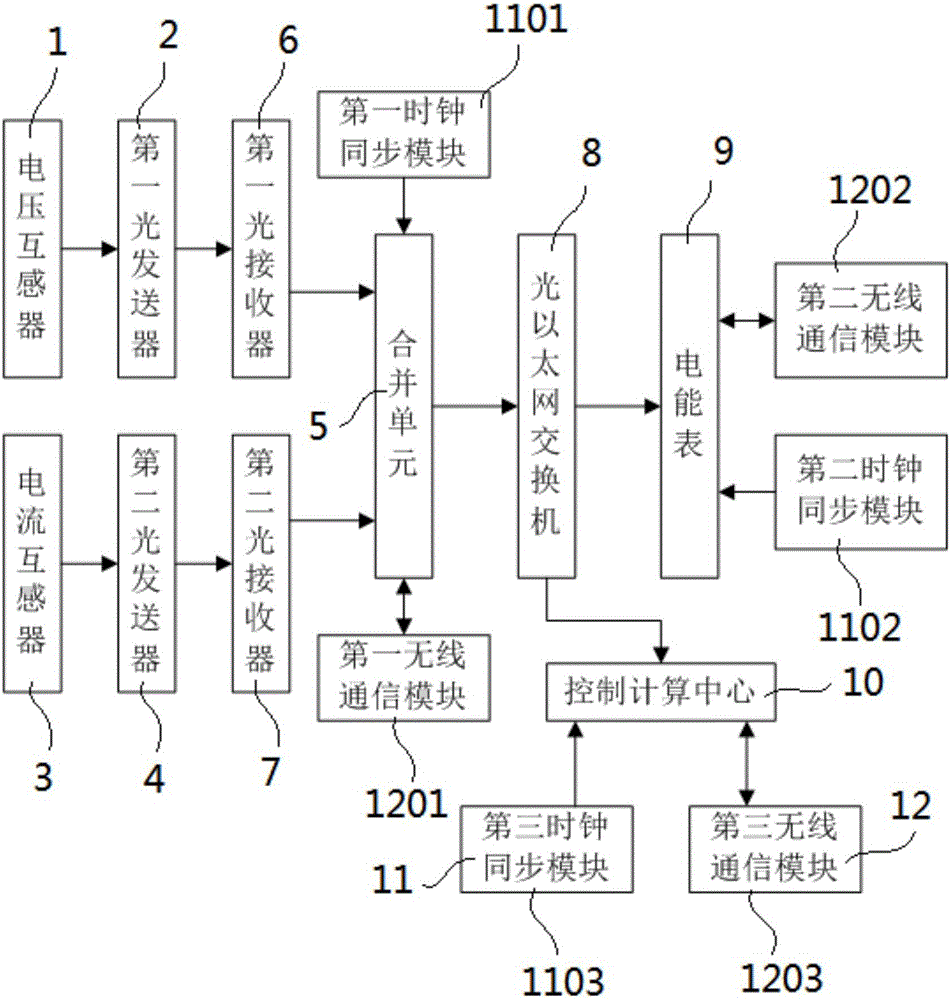

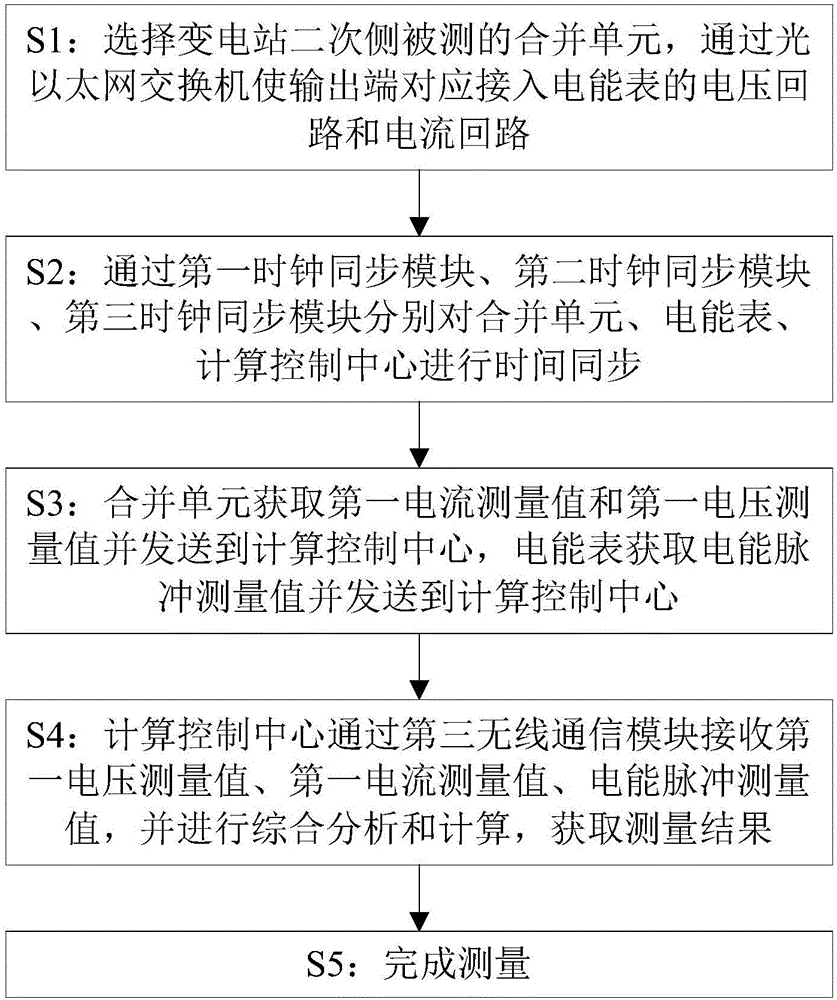

InactiveCN106093563AImprove accuracyImprove reliabilityNon-electrical signal transmission systemsElectrical measurementsElectricitySmart substation

The invention discloses a transformer station secondary side electric energy measuring system comprising a voltage transformer, a current transformer, a first optical transmitter, a second optical transmitter, a first optical receiver, a second optical receiver, a merging unit, an optical Ethernet switch, an electric energy meter, a computation control center, a clock synchronization module, and a wireless communication module. The transformer station secondary side electric energy measuring system solves a problem that an intelligent transformer station merging unit is long in distance and unsafe in field detection, may synchronously measure electric energy of merging units distributed at different sites and branch electric energy meters, achieves accurate measured values and maintains synchronization, enhances the electric energy metering accuracy and reliability of the transformer station, and is convenient, concise, efficient, and safe.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

PICC catheter length measuring method

PendingCN110051439ASimple and easy to operateThe measured value is accurateDiagnosticsSurgical needlesSacroiliac jointTip position

The invention relates to a PICC catheter length measuring method, and belongs to the clinical technical field of PICC. The method comprises the following steps that (1) a patient lies low lays the upper limbs out in parallel to form 90-degree angle with the side body, and the length A from the upper limb marking to the right sternoclavicular joint is measured; (2) after puncture, the length C between the upper limb marking and the PICC puncture point is measured to obtain the PICC catheter length = A+B-C, wherein B is the deviation distance. The method is simple and easy to operate. After puncture, the position of the PICC puncture point is determined, then the length between the upper limb marking to the length of the puncture point is measured, and the positioning is accurate. The upperlimb marking is the obvious feature position of the upper limb of the patient body, the positioning is accurate regardless of single or multiple measurement, no marking setting is required, and marking blur does not occur. Measured values are more accurate, and the measured values are more precise by means of calculation of the deviation distance B, so that the catheter tip position is more accurate.

Owner:隋君

Automatic detection device for honeycomb ceramic and detection method of device

PendingCN110426012AHigh feasibilityReasonable designUsing optical meansWeighing apparatus with automatic feed/dischargeMaterials scienceTesting equipment

The invention relates to an automatic detection device for honeycomb ceramic and a detection method of the device. The automatic detection device for detecting the height, outer diameter, perpendicularity, parallelism degree, weight and the like of the honeycomb ceramic and the method of the device are provided. The automatic detection device comprises a honeycomb ceramic supply conveying belt device, a first lifting conveying belt mechanism, a honeycomb ceramic boundary dimension parallelism degree and perpendicularity detection device, a weighing mechanism, a honeycomb ceramic detection conveying mechanism, a second lifting conveying belt mechanism and an automatic sorting device; the honeycomb ceramic boundary dimension parallelism degree and perpendicularity detection device is arranged on a rack, the honeycomb ceramic supply conveying belt device is arranged on the rear portion of the honeycomb ceramic boundary dimension parallelism degree and perpendicularity detection device, the first lifting conveying belt mechanism is arranged between the honeycomb ceramic supply conveying belt device and the honeycomb ceramic boundary dimension parallelism degree and perpendicularity detection device, the weighing mechanism is arranged on the front portion of the honeycomb ceramic boundary dimension parallelism degree and perpendicularity detection device, and the automatic sorting device is arranged on the front portion of the weighing mechanism.

Owner:常州市赫铭自动化科技有限公司

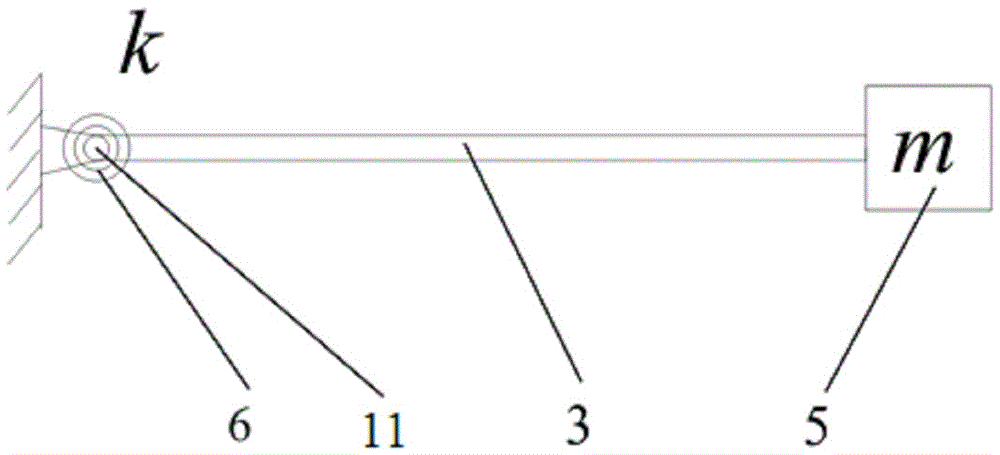

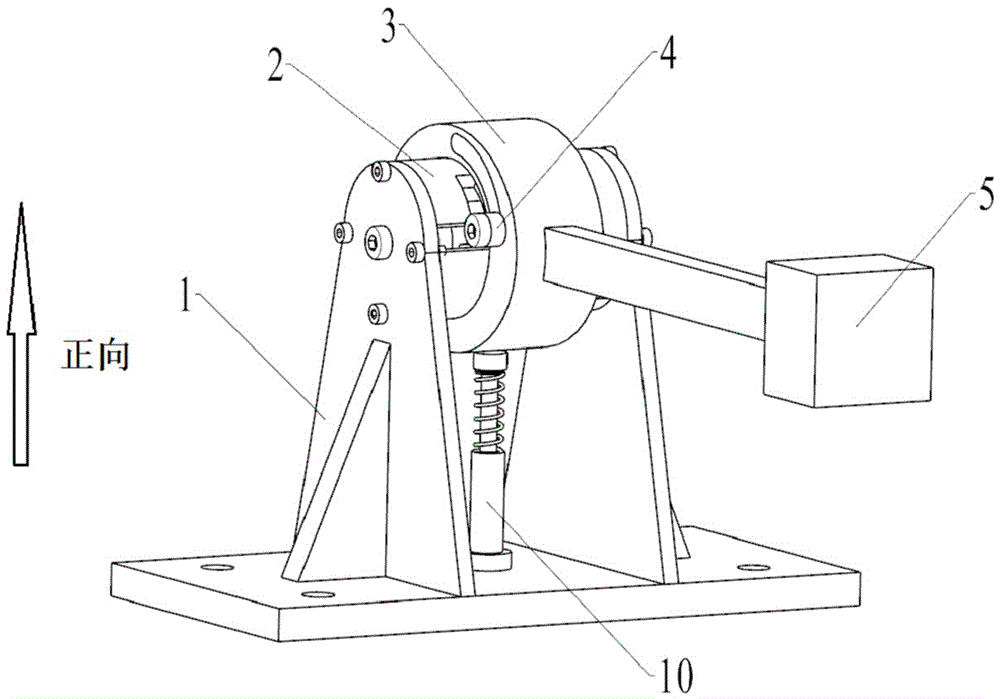

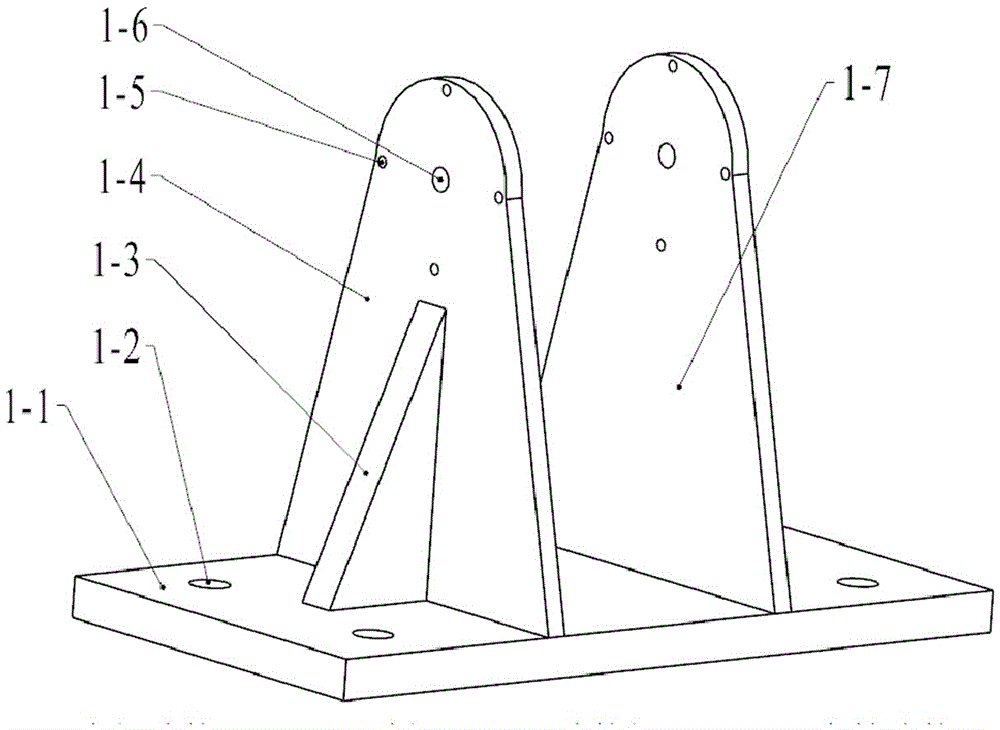

Torsional spring type measuring pendulum for low-and-medium-frequency shock spectrum

ActiveCN106768785AAvoid plastic deformationExtended service lifeShock testingMedium frequencyEngineering

A torsional spring type measuring pendulum for low-and-medium-frequency shock spectrum comprises a base, a torsional spring sleeve, a swing link, a shifting fork A, a mass block, a torsional spring, a supporting rod, a shifting fork B and two sliding pins. The two sliding pins include a sliding pin A and a sliding pin B. In terms of structure, the torsional pendulum structure of the torsional spring type measuring pendulum for shock spectrum has the advantages of reducing device mass and size and making the device portable as compared with the low-frequency vibrator structure for measuring low-frequency shock spectrum; as compared with a reed instrument, the torsional spring type measuring pendulum has the advantages that its hinge structure at the fixed end can prevent the swing link structure from plastic deformation so as to improve service life of the whole measuring device. In terms of function, the torsional spring type measuring pendulum for the shock spectrum can be used for measuring low-and-medium frequency shock spectrum directly and can substitute for the way of measuring the low-and-medium frequency shock spectrum by combination of the reed instrument and the low-frequency vibrator. In terms of measuring way, the torsional spring type measuring pendulum is of a cam structure of the swing link, which converts rotational measurement into linear displacement measurement; thus, compact structure and high measuring precision are achieved.

Owner:SHENYANG POLYTECHNIC UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com