Device for testing antifouling property of hollow-fibre membrane

A test device and fiber membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems that there is no standard for analysis and testing equipment, and there is no commercial equipment for the anti-pollution performance of hollow fiber membranes. The measurement process is convenient, the operation process is simple, and the measurement value is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

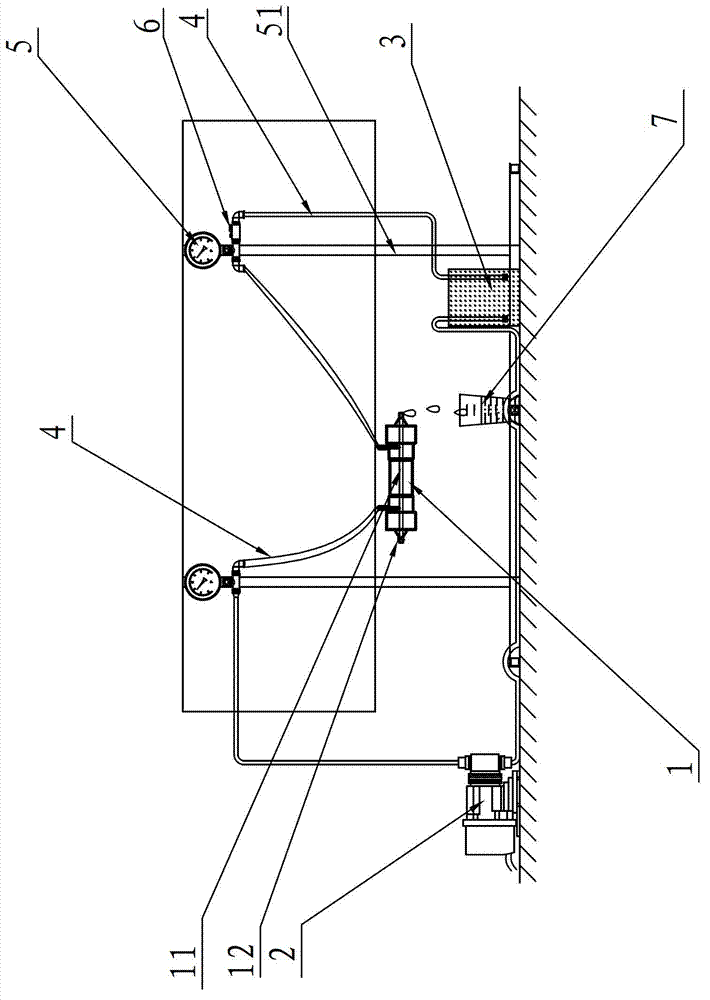

[0015] refer to figure 1 , the present invention is a hollow fiber membrane anti-pollution performance testing device, comprising a plug 1 and a hollow hole 11 arranged in the plug 1, connected to the two ends of the hollow hole 11, a feed pump 2 and a circulating circuit are arranged. The material-liquid circulation barrel 3, the two ends of the hollow hole 11 and the feed pump 2 and the material-liquid circulation barrel 3 are provided with a number of connecting pipes 4, the connecting pipes 4 are equipped with a pressure gauge 5, and the plug 1 is connected to the hollow hole 11. Valves 12 are also provided at both ends.

[0016] During the testing process of this hollow fiber membrane anti-pollution performance testing device, the fiber membrane to be tested is placed in the hollow hole 11, and the liquid in the material-liquid circulation barrel 3 is driven by the feed pump 2 to circulate, and the control device as a whole The internal pressure can simulate the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com