Method for detecting total iron content of steel slag

A detection method and technology for iron content, which are applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problems of inaccurate detection of total iron content and high detection cost, and achieve The effect of reducing human and environmental hazards, low detection cost, and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

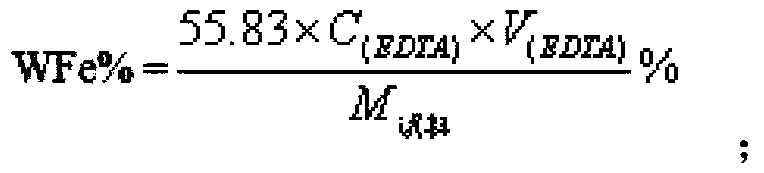

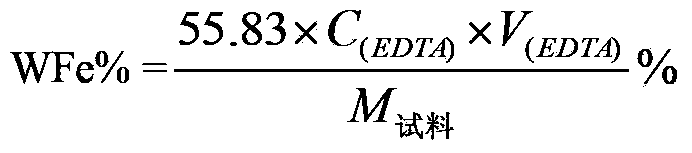

Method used

Image

Examples

Embodiment 1

[0036] ①Sampling and sample preparation: Take about 5kg of slag steel powder mixed sample (grain size 0-8mm) on site. The sample is wet, and the sample is dried at 105℃±2℃. Mix the dried sample thoroughly, and use a dividing device to divide into two parts, each about 100g, and mark them as M 1 Sample and M 2 Sample. The two samples were crushed several times by the crushing sample preparation machine, and all the samples passed through a 0.075mm standard sieve, and were bagged for use.

[0037] ②Weigh 0.5g sample accurately with analytical balance, accurate to 0.0001g, where M 1 Sample 0.5038g, M 2 The sample is 0.5011g. ③Analysis method: Put the samples in a 400ml beaker, add a little water to moisten, add 30ml of concentrated hydrochloric acid and then add 2ml of nitric acid dropwise, heat at high temperature until all the samples are dissolved, if there is a little undissolved sample, add 1g of fluorine Sodium sulfide, after the sample is completely dissolved, remove the run...

Embodiment 2

[0052] ①Sampling and sample preparation: Take about 1.5kg of slag steel powder mixed sample (grain size 0-8mm) on site, and the sample is wet, and the sample is dried at a temperature of 105℃±2℃. Mix the dried sample thoroughly,

[0053] ②Accurately weigh 0.5g sample with analytical balance, accurate to 0.0001g, M 1 The actual weight of the sample is 0.5085 g.

[0054] ③Analysis method: Put the samples in a 400ml beaker, add a little water to moisten, add 30ml of concentrated hydrochloric acid and then add 2ml of nitric acid dropwise, heat at high temperature until all the samples are dissolved, if there is a little undissolved sample, add 1g of fluorine Sodium sulfide, after the sample is completely dissolved, remove the running water and cool to room temperature, and dilute to a 250ml volumetric flask. Draw 25ml of the solution into a 300ml beaker, add water to dilute to about 100ml, adjust the pH of the solution between 1.8 and 2.0 with ammonia (1+1) and hydrochloric acid (1+1)...

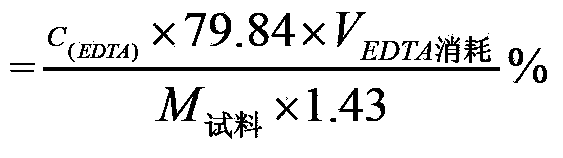

Embodiment 3

[0066] ①Sampling and sample preparation: Take about 1.385kg of slag steel powder mixed sample (grain size 0-8mm) on site. The sample is wet, and the sample is dried at 105℃±2℃. The dried samples are mixed thoroughly, all crushed and passed through a 1.25mm sieve. The magnetic iron weighing 0.455kg is absorbed by a magnetic block of +1.25mm (the upper part of the 1.25mm sieve), and the magnetic iron is calculated to account for 32.85%.

[0067] ②Use the above method to obtain -1.25mm (1.25mm under the sieve) sample: use an analytical balance to accurately weigh 0.5g sample, accurate to 0.0001g, M 2 The actual weight of the sample is 0.5013g.

[0068] ③Analysis method: Put the samples in a 400ml beaker, add a little water to moisten, add 30ml of concentrated hydrochloric acid and then add 2ml of nitric acid dropwise, heat at high temperature until all the samples are dissolved, if there is a little undissolved sample, add 1g of fluorine Sodium sulfide, after the sample is completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com