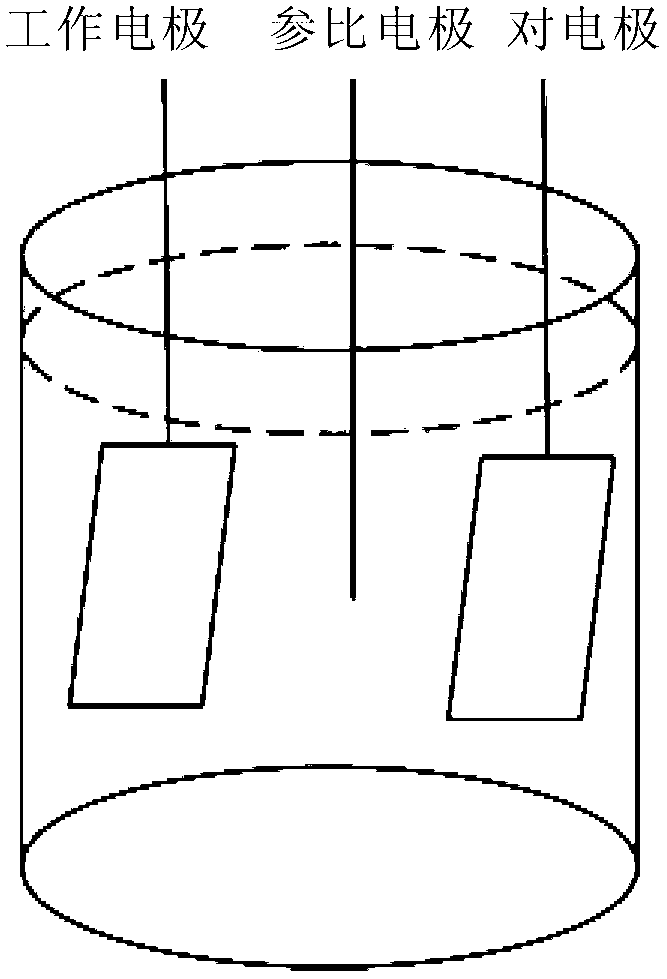

Electrolytic tank for detecting corrosion resistance of packing material

A technology of packaging materials and corrosion resistance, applied in the field of electrolytic cells, can solve problems such as large system errors, damage to metal packaging materials, and corrosion resistance of metal packaging materials that cannot simulate the actual use conditions of packaging materials, so as to improve detection accuracy, Reduce system error and reduce the effect of system error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

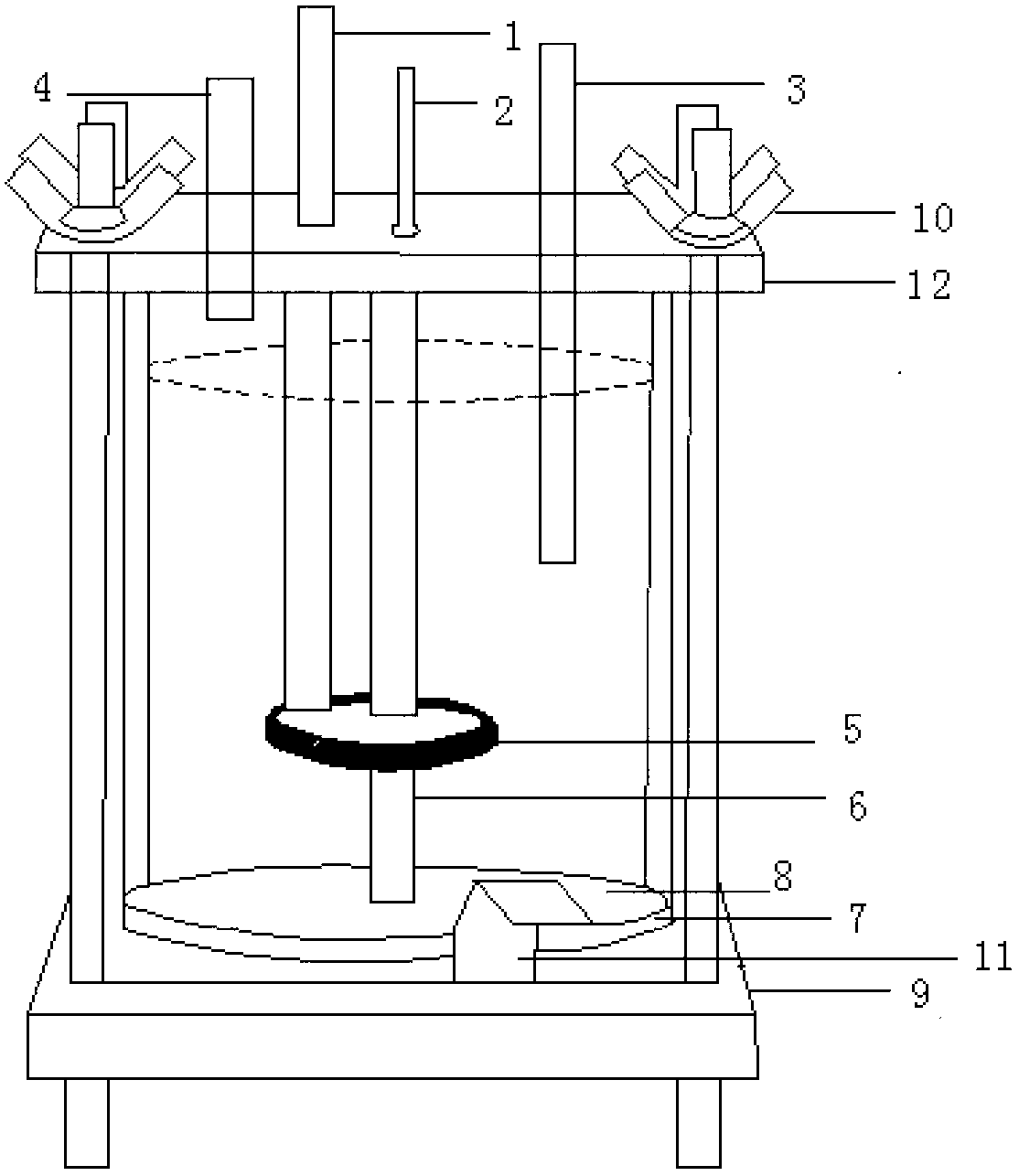

[0037] Embodiment 1 detects the corrosion resistance of the coated iron used for packing luncheon meat

[0038] Use a kind of device of the present invention to be used for detecting the corrosion resistance of packing material to detect, and this device comprises electrochemical workstation, nitrogen tank, air collecting device and figure 2 The electrolytic cell shown.

[0039] 1) Preparation of samples and standard sheets

[0040] Cut the coated iron into a sample whose outer peripheral edge coincides with the lower edge of the side wall, clean with alcohol to remove surface oil stains and sundries, then clean and dry with distilled water, and use it as a working electrode after welding the lead wire. The method may be, for example, to set a working electrode lead wire outlet on the base, so that the working electrode lead wire can be drawn out from the side of the coated iron sample to be detected that is not in contact with the electrolyte through the working electrode l...

Embodiment 2

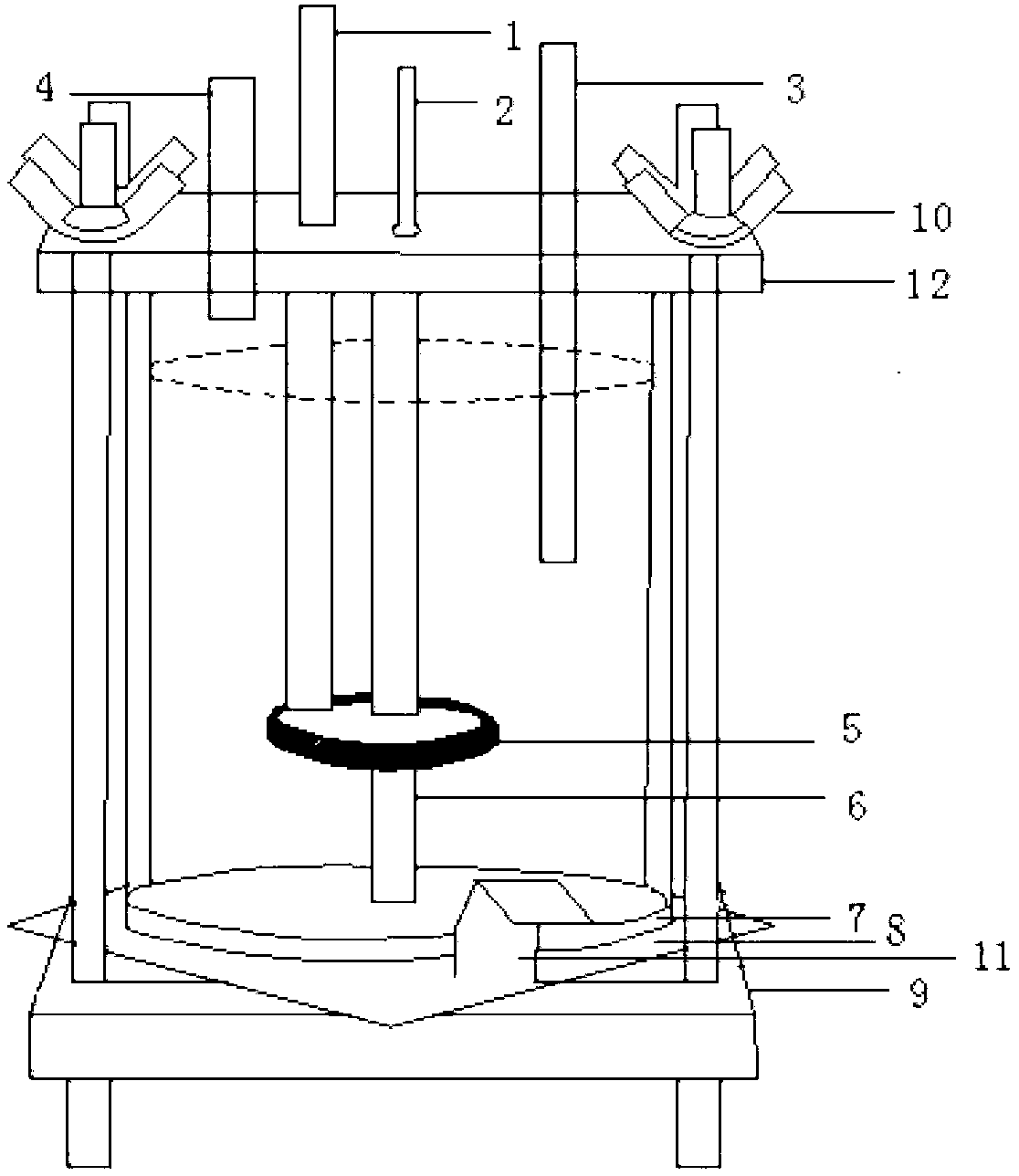

[0055] Example 2 Detection of corrosion resistance of coated iron for packaging black tea

[0056] Use a kind of device of the present invention to be used for detecting the corrosion resistance of packing material to detect, and this device comprises electrochemical workstation, nitrogen tank, air collecting device and image 3 The electrolytic cell shown.

[0057] 1) Preparation of samples and standard sheets

[0058] Cut the coated iron into a square plate as a sample. The outer peripheral edge of the sample exceeds the lower edge of the side wall, clean with alcohol to remove surface oil stains and sundries, then clean and dry with distilled water, and use it as a working electrode after welding the lead wire. The lead wire is drawn out through the part of the coated iron sample to be detected that is not in contact with the electrolyte;

[0059] Use a known corrosion resistance of 5 x 10 8 Ohm's coated iron sheet is used as a standard sheet, which is also cut into a sq...

Embodiment 3

[0074] Embodiment 3 detects the corrosion resistance of the coated iron used for packaging tomato paste

[0075] Use a kind of device of the present invention to be used for detecting the corrosion resistance of packaging material to detect, and this device comprises electrochemical workstation, argon tank, air collecting device and image 3 The electrolytic cell shown.

[0076] 1) Preparation of samples and standard sheets

[0077] Cut the coated iron into a square plate as a sample. The outer peripheral edge of the sample exceeds the lower edge of the side wall, clean with alcohol to remove surface oil and sundries, then clean and dry with distilled water, and use it as a working electrode after welding the lead wire. The lead wire is drawn out through the part of the coated iron sample to be detected that is not in contact with the electrolyte;

[0078] Use a known corrosion resistance of 1×10 9 Ohm's coated iron (self-enamel paint) standard sheet, also cut into a square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com