Device for testing pipe resistance coefficient of water supply pipe network

A pipeline resistance and water supply network technology, applied in the field of environmental engineering, can solve problems such as test errors, difficult test site conditions, and complicated test processes, so as to reduce manpower, quickly and accurately record and process data efficiently, and avoid pipeline excavation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

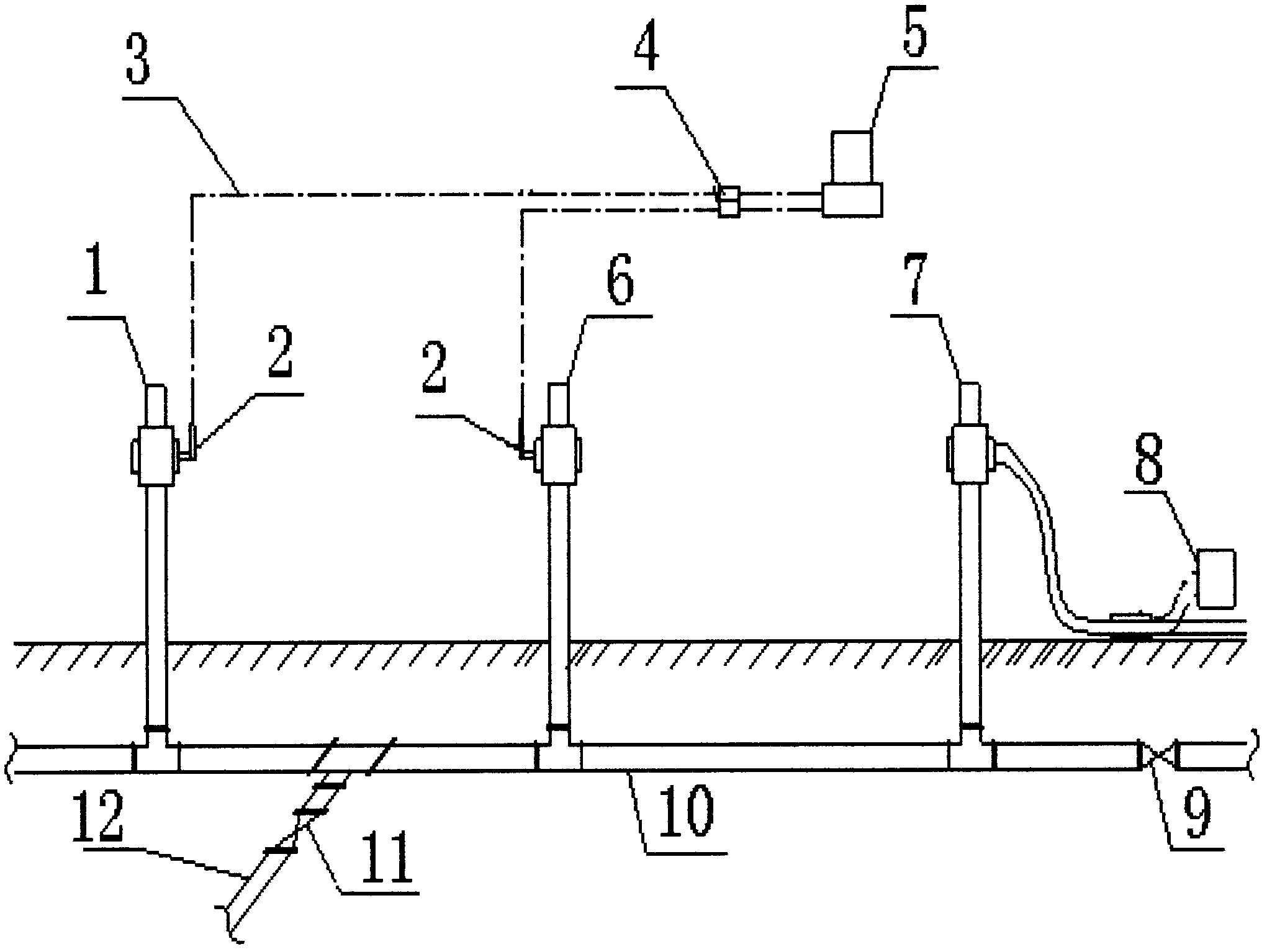

[0056] Referring to the accompanying drawings, the present invention includes a pipeline system, a pressure test module, a main pipe section 10, a flow test module and a control system 5, and a branch pipe section 12 is provided on the main pipe section 10, and a front control section 12 is provided on the branch pipe section 12. Valve 11, after the system is installed and debugged, the present invention can carry out resistance coefficient test, pressure test and flow test, pressure test and flow test need to be measured at the same time, the test method is:

[0057] (1) Stress test

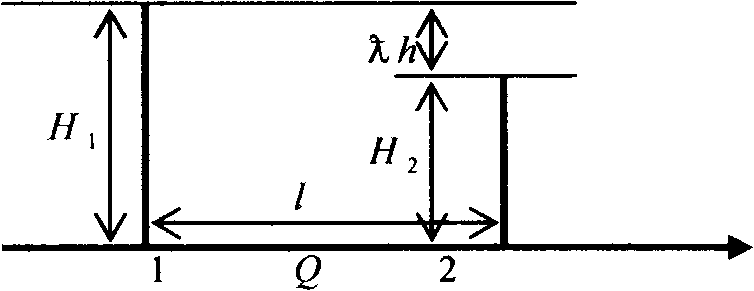

[0058] The pressure test module uses the pressure sensor 2 for absolute pressure test, which can output 4-20mA or 0-10V signal, and the analog value of the measured value is transmitted to the control system 5 through the 4-core shielded signal line 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com