An online video multiplier workpiece detector

A workpiece detection and video technology, used in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problem that precision workpieces cannot be detected online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

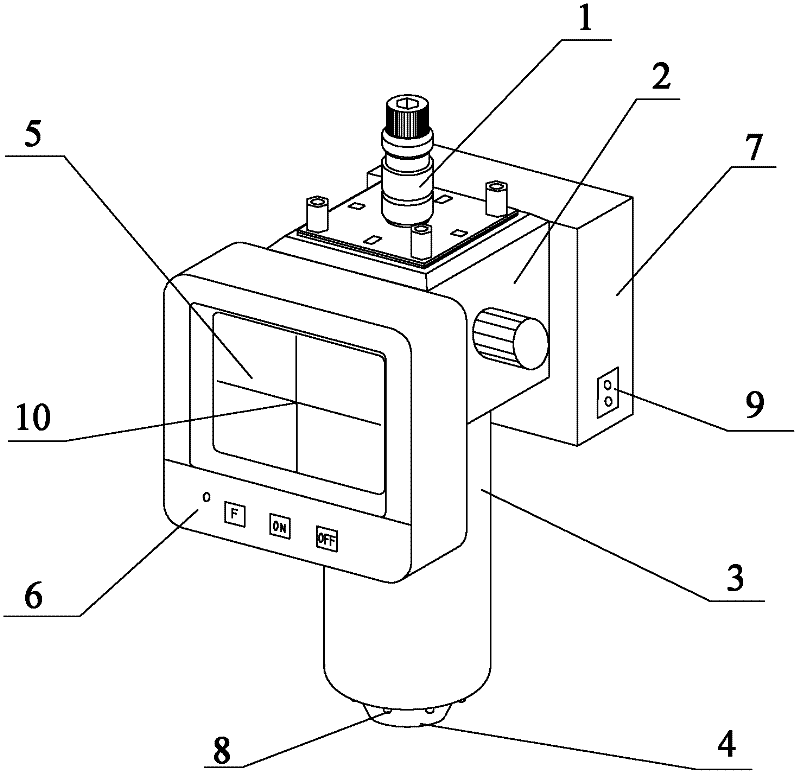

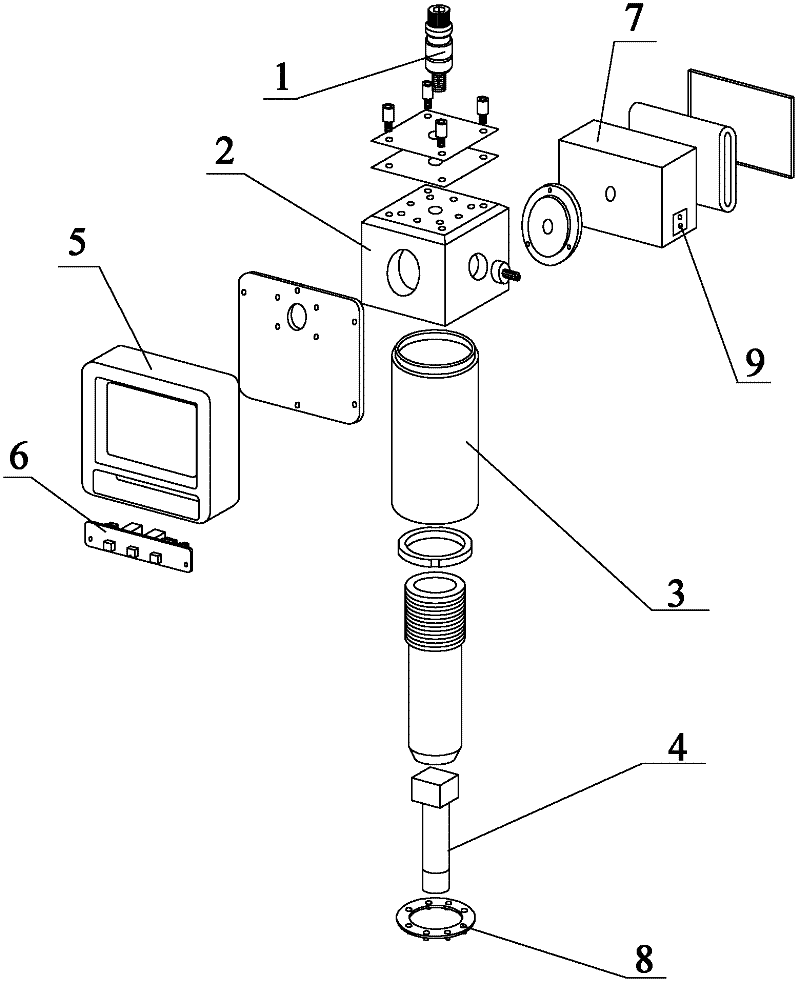

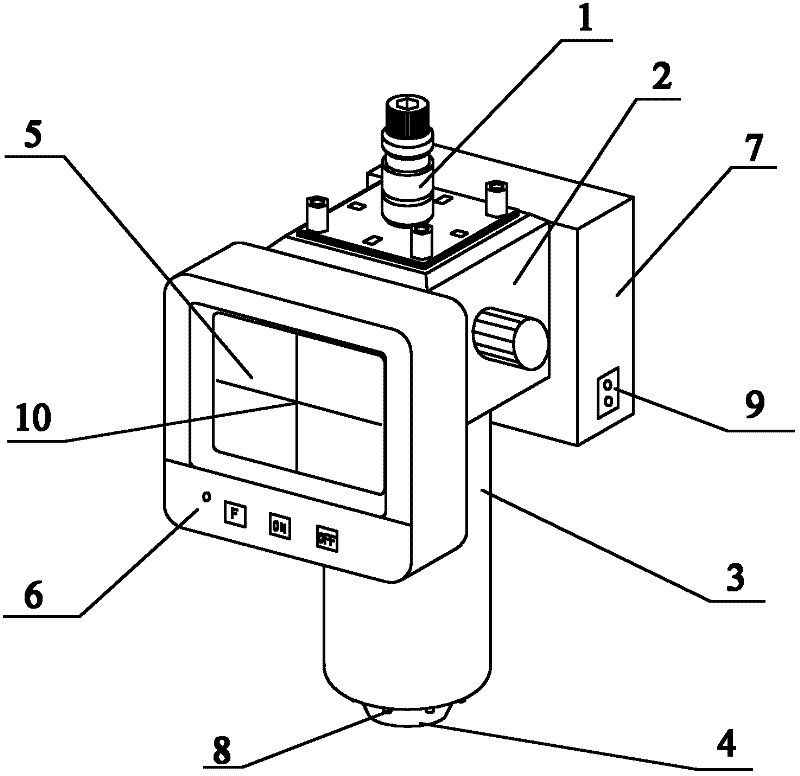

[0015] An online video multiplier workpiece detector, comprising an instrument main frame 1 and an internal circuit, a quick positioning mandrel 2 is connected above the instrument main frame 1, a camera mounting body 3 is installed under the instrument main frame 1, and the camera A CCD industrial camera 4 with a magnification lens is housed in the installation body 3. The display screen 5 of the CCD industrial camera 4 is installed in front of the instrument main frame 1, and a control keyboard 6 is arranged below the display screen 5. Connect the power supply box 7 that lithium battery is housed; The rapid positioning mandrel 2 on the top of the main frame 1 of the instrument and the CCD industrial camera 4 magnification lens that are housed in the camera mounting body 3 are coaxially and concentrically arranged, and the CCD industrial came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com