Method for measuring silicon dioxide amount

A silicon dioxide and sodium hydroxide technology, which is applied in the measurement of color/spectral characteristics, etc., can solve problems such as the vaporization of silicon dioxide and sodium hydroxide, the rapid temperature change of silicon dioxide and sodium hydroxide, and the influence of measurement results. Achieve the effect of accurate measurement value, safe and convenient use, and avoid influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

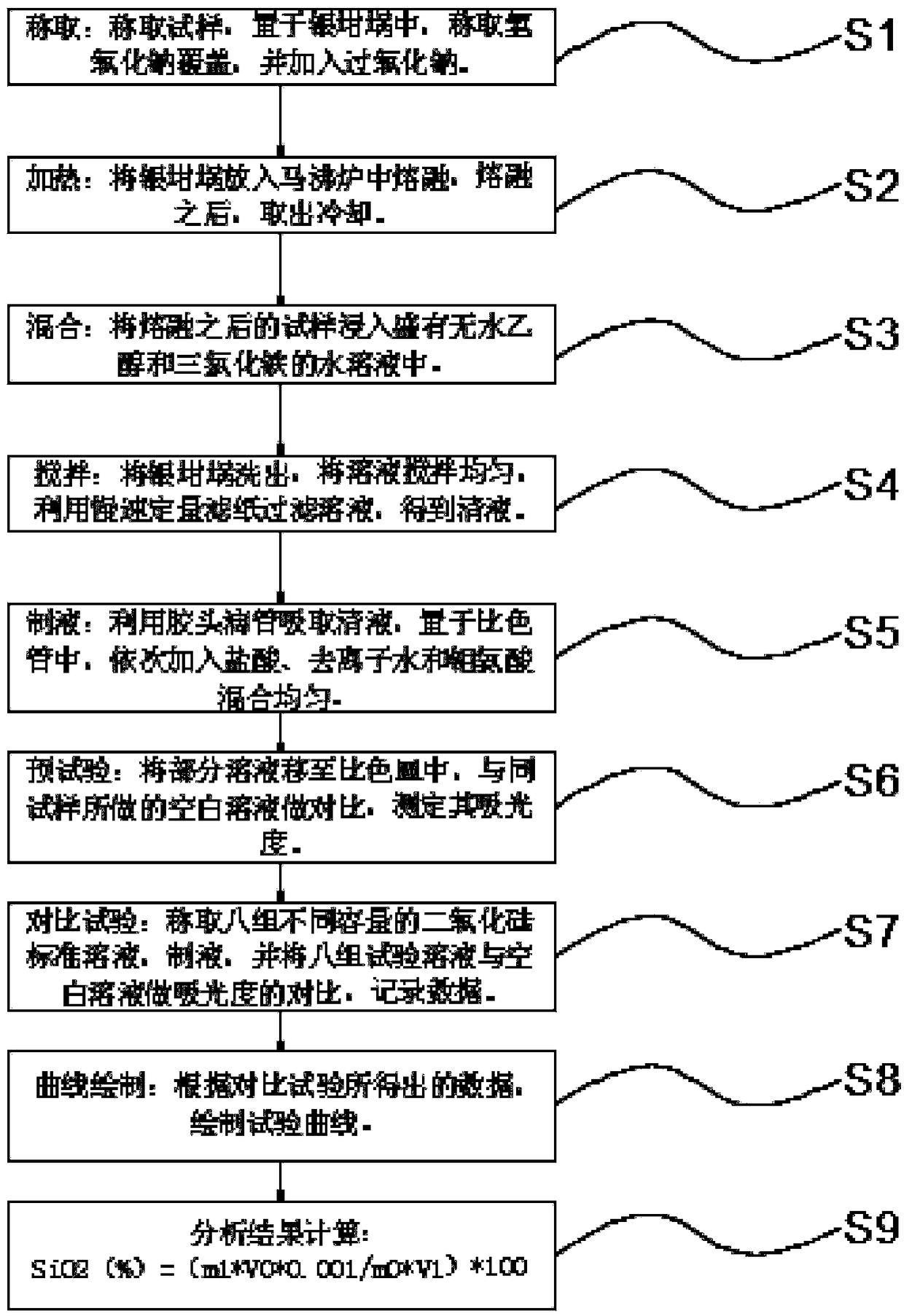

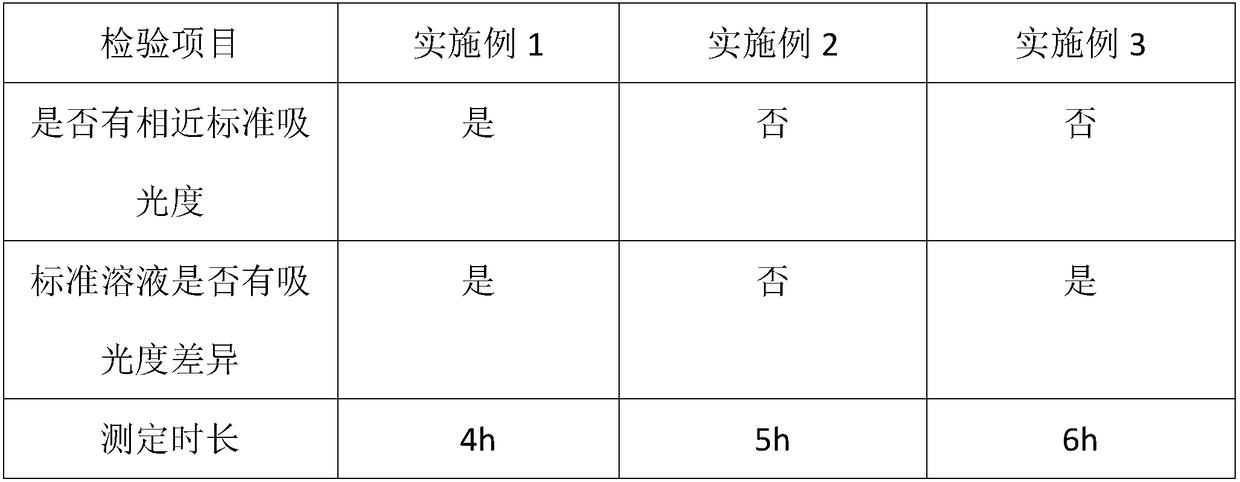

[0031] Embodiment 1: as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of method for measuring silicon dioxide amount, comprises the steps:

[0032] S1. Weighing: Weigh the sample, place it in a silver crucible, cover it with sodium hydroxide, and add sodium peroxide;

[0033] S2, heating: put the silver crucible into the muffle furnace for melting, after melting, take it out and cool it;

[0034] S3, mixing: immerse the molten sample in an aqueous solution filled with absolute ethanol and ferric chloride;

[0035] S4, stirring: wash out the silver crucible, stir the solution evenly, and filter the solution with slow quantitative filter paper to obtain clear liquid;

[0036] S5, liquid preparation: use the rubber dropper to absorb the clear liquid, put it in the colorimetric tube, add hydrochloric acid, deionized water and molybdenum acid in sequence and mix evenly;

[0037] S6. Pre-test: Move part of the solution to a cuvette, compare ...

Embodiment 2

[0053] Embodiment 2: as figure 1 Shown, a kind of method for measuring silicon dioxide amount comprises the steps:

[0054] S1. Weighing: Weigh the sample, place it in a silver crucible, cover it with sodium hydroxide, and add sodium peroxide;

[0055] S2, heating: put the silver crucible into the muffle furnace for melting, after melting, take it out and cool it;

[0056] S3, mixing: immerse the molten sample in an aqueous solution filled with absolute ethanol and ferric chloride;

[0057] S4, stirring: wash out the silver crucible, stir the solution evenly, and filter the solution with slow quantitative filter paper to obtain clear liquid;

[0058] S5, liquid preparation: use the rubber dropper to absorb the clear liquid, put it in the colorimetric tube, add hydrochloric acid, deionized water and molybdenum acid in sequence and mix evenly;

[0059] S6. Pre-test: Move part of the solution to a cuvette, compare it with the blank solution made with the same sample, and measu...

Embodiment 3

[0075] Embodiment 3: as figure 1 Shown, a kind of method for measuring silicon dioxide amount comprises the steps:

[0076] S1. Weighing: Weigh the sample, place it in a silver crucible, cover it with sodium hydroxide, and add sodium peroxide;

[0077] S2, heating: put the silver crucible into the muffle furnace for melting, after melting, take it out and cool it;

[0078] S3, mixing: immerse the molten sample in an aqueous solution filled with absolute ethanol and ferric chloride;

[0079] S4, stirring: wash out the silver crucible, stir the solution evenly, and filter the solution with slow quantitative filter paper to obtain clear liquid;

[0080] S5, liquid preparation: use the rubber dropper to absorb the clear liquid, put it in the colorimetric tube, add hydrochloric acid, deionized water and molybdenum acid in sequence and mix evenly;

[0081] S6. Pre-test: Move part of the solution to a cuvette, compare it with the blank solution made with the same sample, and measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com