Paper height measurement system for corrugated board production

A corrugated cardboard and height measurement technology, which is applied to measuring devices, instruments, and optical devices, can solve the problems of easy errors, low efficiency, labor and time-consuming, etc., and achieve large error changes, high efficiency, and accurate measurement values Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

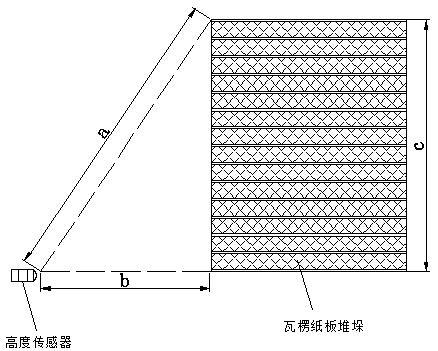

[0023] Embodiment 1, with reference to figure 1 , a paper height measurement system for corrugated cardboard production, including a height measurement module, a corrugated cardboard information library and a production management module, the height measurement module is used to measure the stacking height of corrugated cardboard, and transmit the measurement results to the production management module;

[0024] The corrugated cardboard information library is used to store the basic information of corrugated cardboard;

[0025] Sheet count information for calculating stacks of corrugated cardboard.

[0026] The height measurement module includes a height sensor and a PLC chip. The height sensor uses a laser scanner, which is set on one side of the corrugated cardboard stack to be measured, and its bottom is on the same level as the bottom of the corrugated cardboard stack to be measured. The height sensor is used for sensing The distance between the laser scanner and the bott...

Embodiment 2

[0032] Embodiment 2, with reference to figure 1 , the present invention also discloses a paper height measuring system for corrugated cardboard production, the specific measuring steps are as follows:

[0033] (S1), importing the corrugated cardboard information database into the corrugated cardboard information database, the corrugated cardboard information includes the material of the corrugated cardboard, the corrugated cardboard type and the thickness of the corrugated cardboard;

[0034] (S2), the height sensor senses the distance between the laser scanner and the bottom of the corrugated cardboard stack to be tested and the distance between the laser scanner and the top of the corrugated cardboard stack to be tested, and transmits the sensing information to the PLC chip, the PLC chip Calculate the stacking height of corrugated cardboard according to the induction information, and transmit the calculation result to the production management module;

[0035] (S3), the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com