Mounting clearance measuring device of reactor coolant pump thrust plate

A technology of a coolant pump and a measuring device, which is applied in the field of a clearance measuring device for a thrust plate of a reactor coolant pump, can solve the problems of inability to guarantee the accuracy of measurement values, complicated and complicated processes, large superposition errors, etc. Accurate numerical value and short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

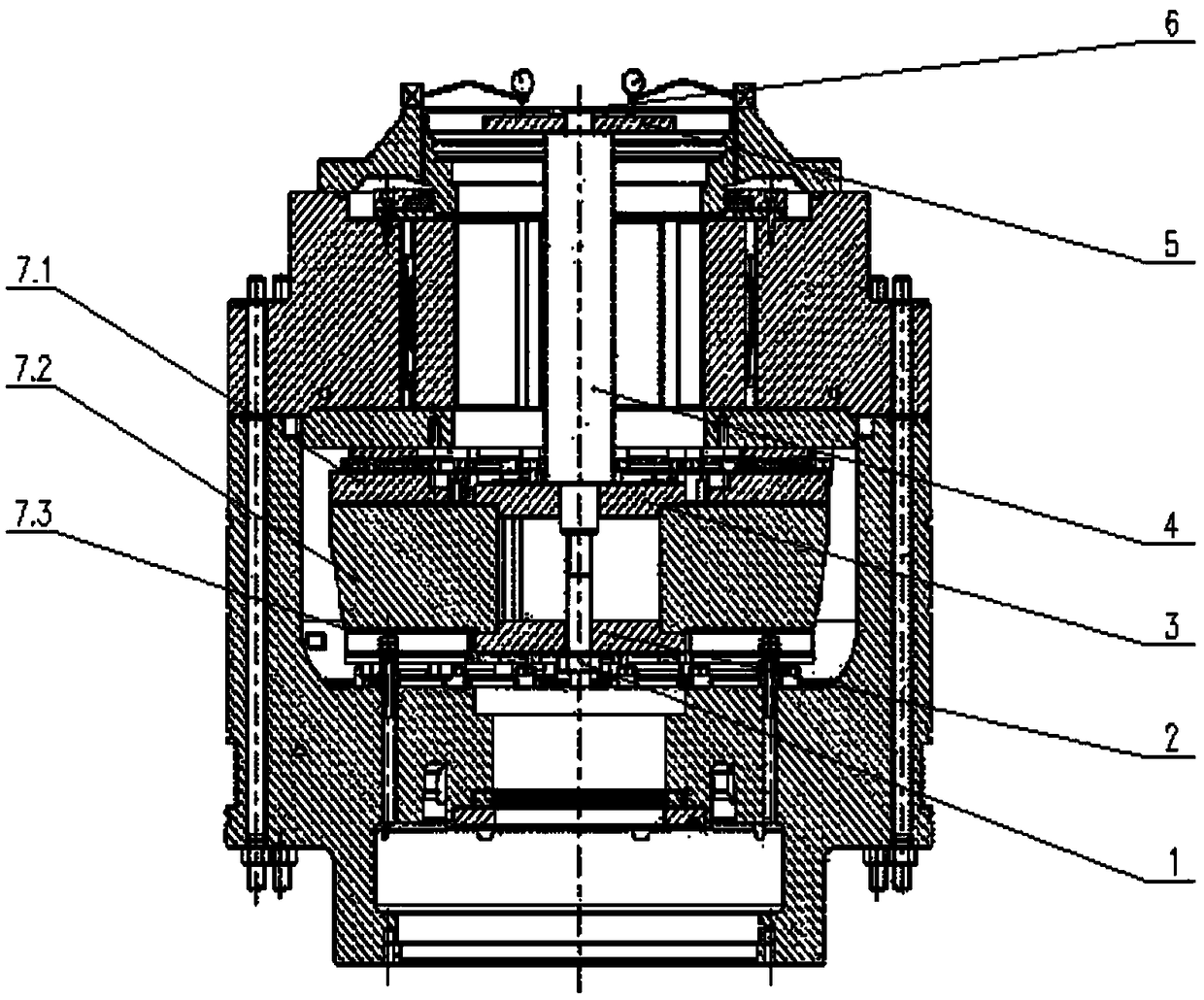

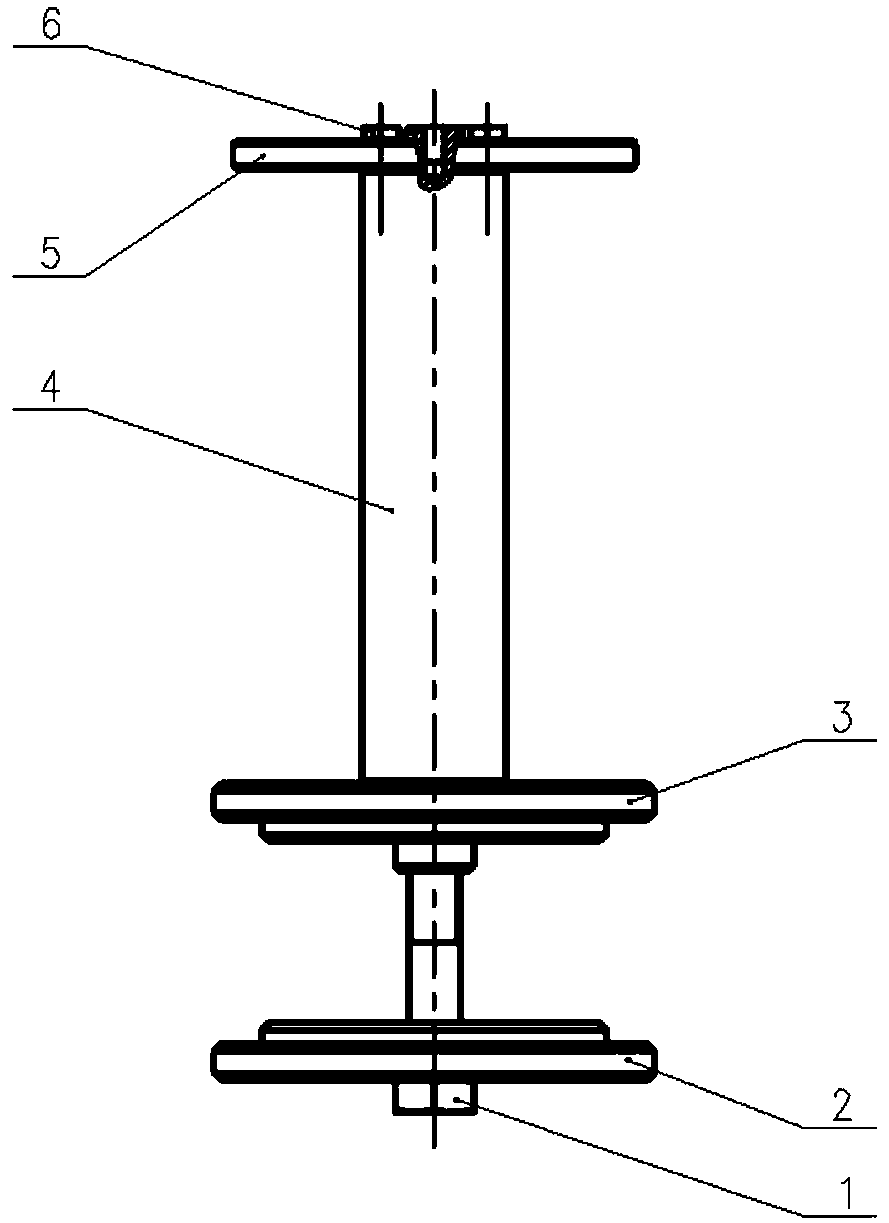

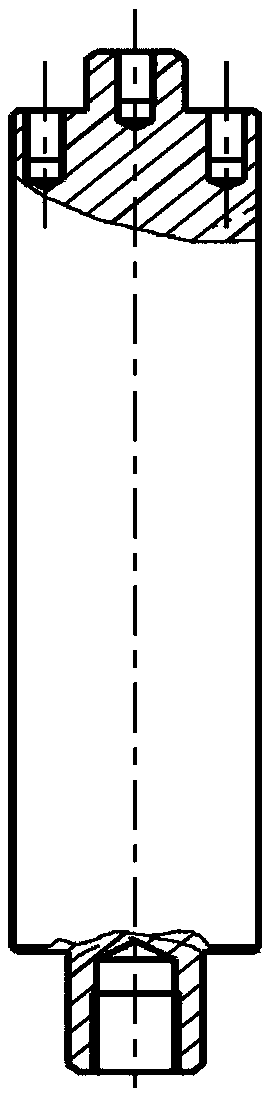

[0014] Such as figure 1 Shown is a reactor coolant pump thrust plate installation gap measurement device, which is characterized in that: the device is a vertical structure, the upper pressure plate 3 is installed on the tool shaft 4, and the bolt 1 penetrates the lower pressure plate 2 and the tool shaft 4 The lower threaded hole is fitted, the thrust plate 7.2 is installed between the upper pressure plate 3 and the lower pressure plate 2; the axial clearance plate 5 is installed by the hexagon head screw 6 above the tool shaft 4, and the threaded hole above the tool shaft 4 is installed. The ears and the dial indicator are installed on the plane of the axial clearance ring 5, and there is an increase or decrease gasket 7.3 between the thrust plate 7.2 and the main thrust pad 7.1.

[0015] In the trial assembly stage before the formal installation of the thrust bearing, the installation gap between the thrust plate 7.2 and the main thrust pad 7.1 needs to be measured, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com