Fully-graded concrete stress-free strain measuring device and measuring method

A strain measurement and stress-free technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of the influence of the measured value, the small gauge length of the strain gauge, and the loss of the stress-free environment of the barrel, so as to achieve accurate measured values and reduce the stress. The effect of small external stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

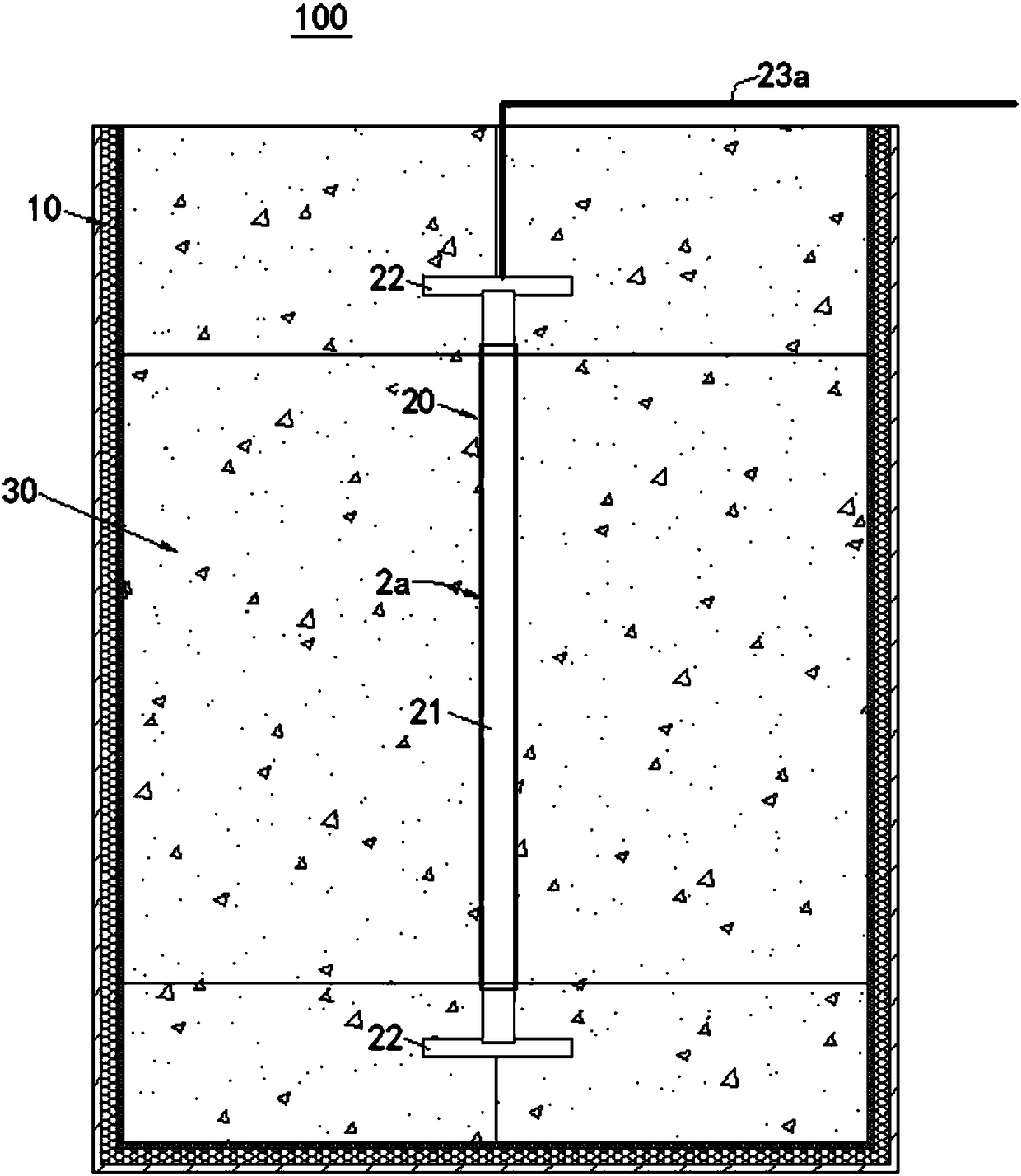

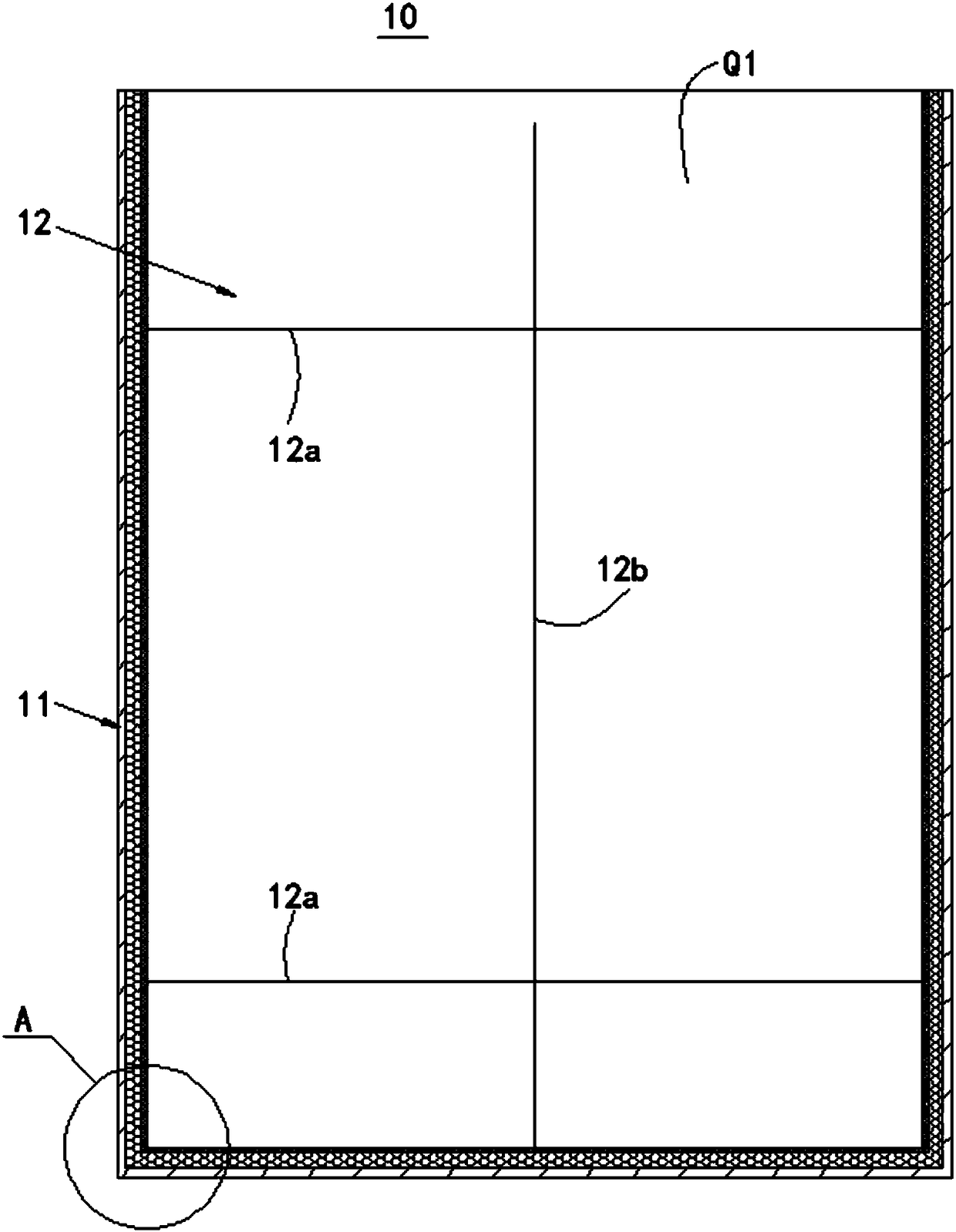

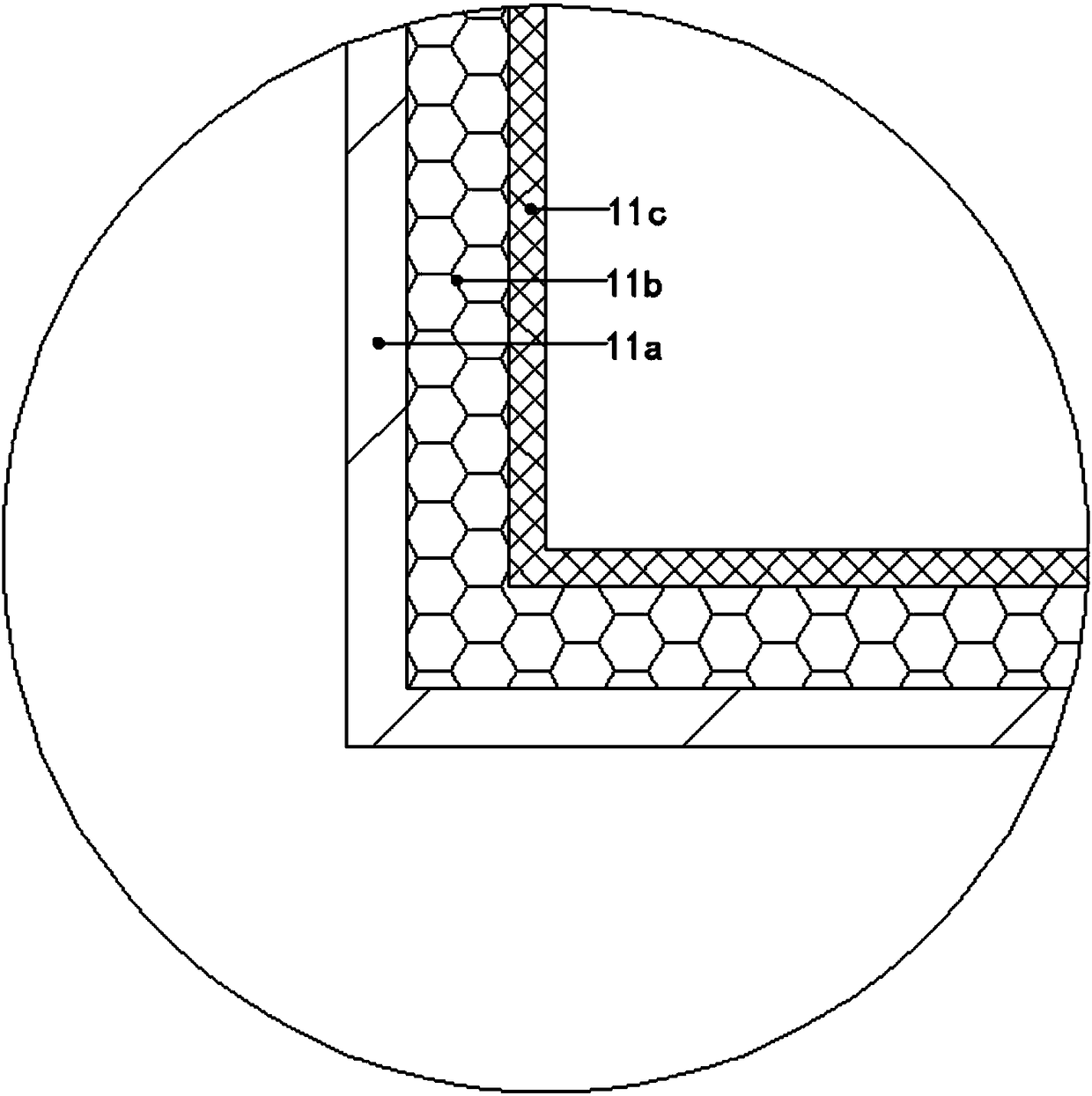

[0052] figure 1 It is a structural schematic diagram of a fully graded concrete stress-free strain measuring device 100 in an embodiment of the present invention; figure 2 Yes figure 1 The structural schematic diagram of the stress-free bucket 10 in; image 3 for figure 2 Enlarged view of A; Figure 4 for figure 1 Schematic diagram of the structure of the strain gauge 20 in .

[0053] Cooperate see figure 2 , image 3 , the barrel wall 11 of the stress-free barrel 10 in this embodiment is a solid barrel wall, and the barrel wall 11 defines the inner cavity Q1 of the stress-free barrel 10; The barrel wall 11 of the stress-free barrel 10 includes a metal outer barrel wall 11a and an inner barrel wall 11b attached to the inner side of the metal outer barrel wall 11a; the inner barrel wall 11b is a foam material layer structure capable of being compressed and concave, and the inner barrel wall 11b An asphalt layer 11c is attached to the side. Optionally, the inner cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com