Patents

Literature

185 results about "Lateral extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

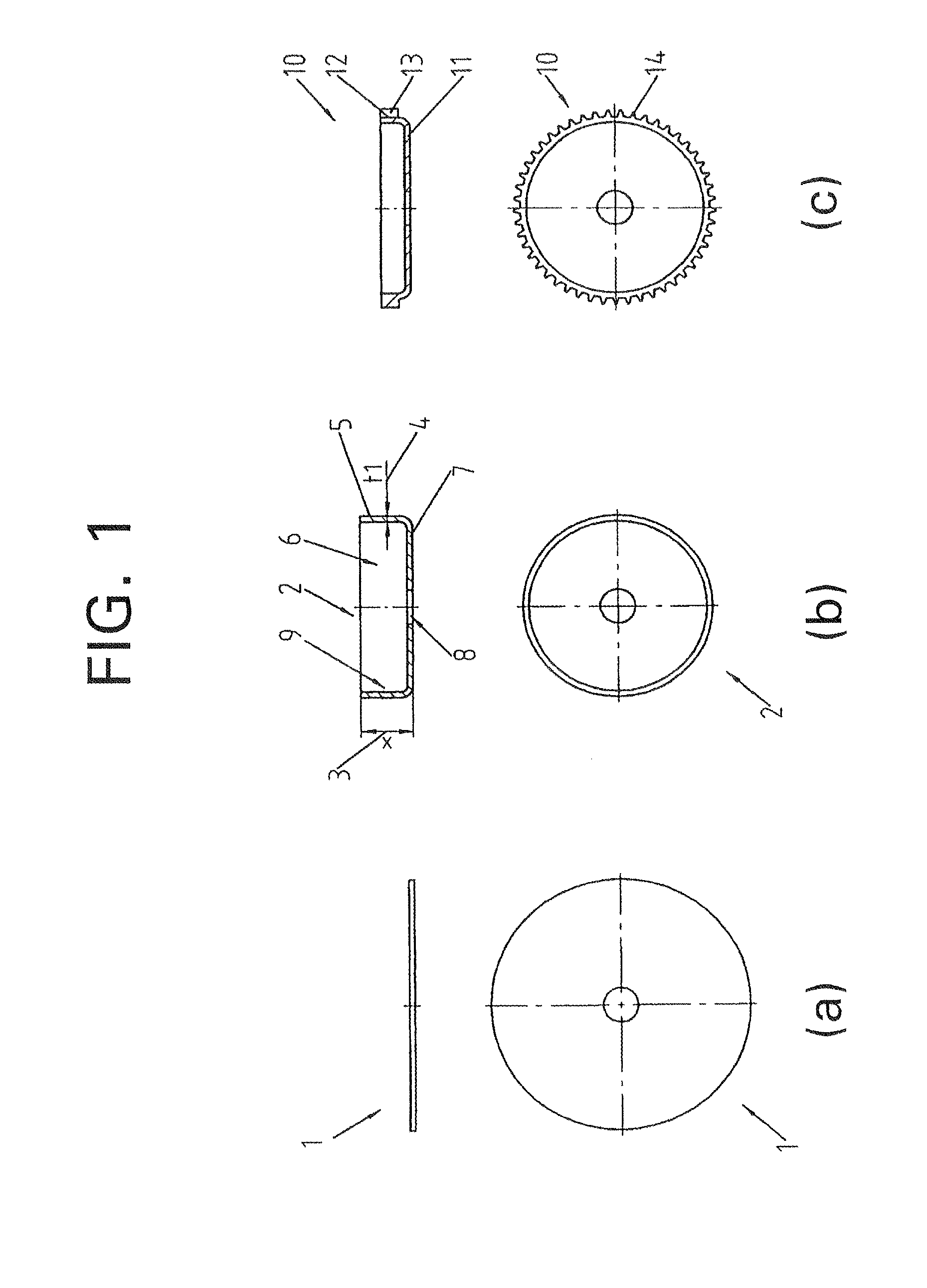

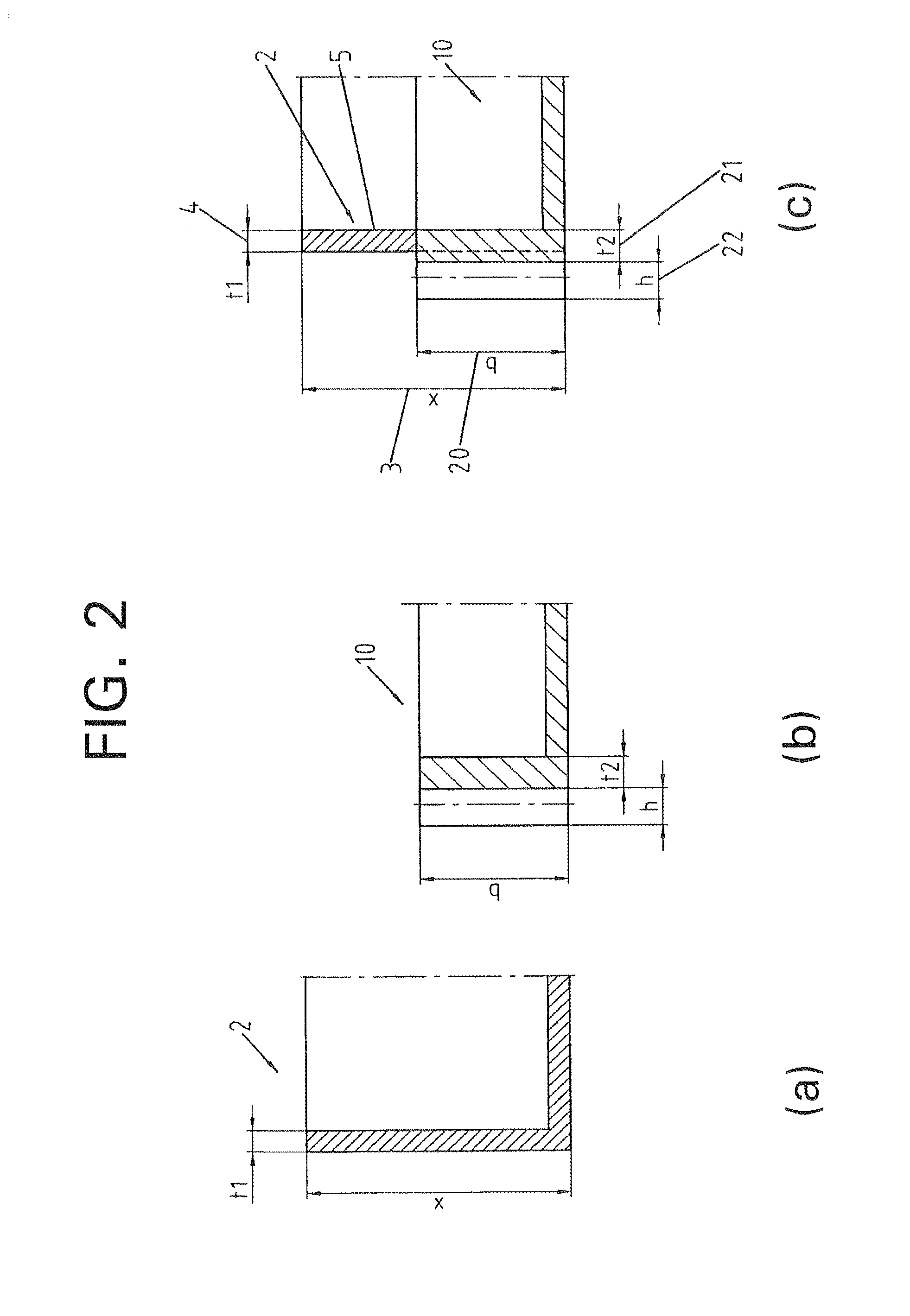

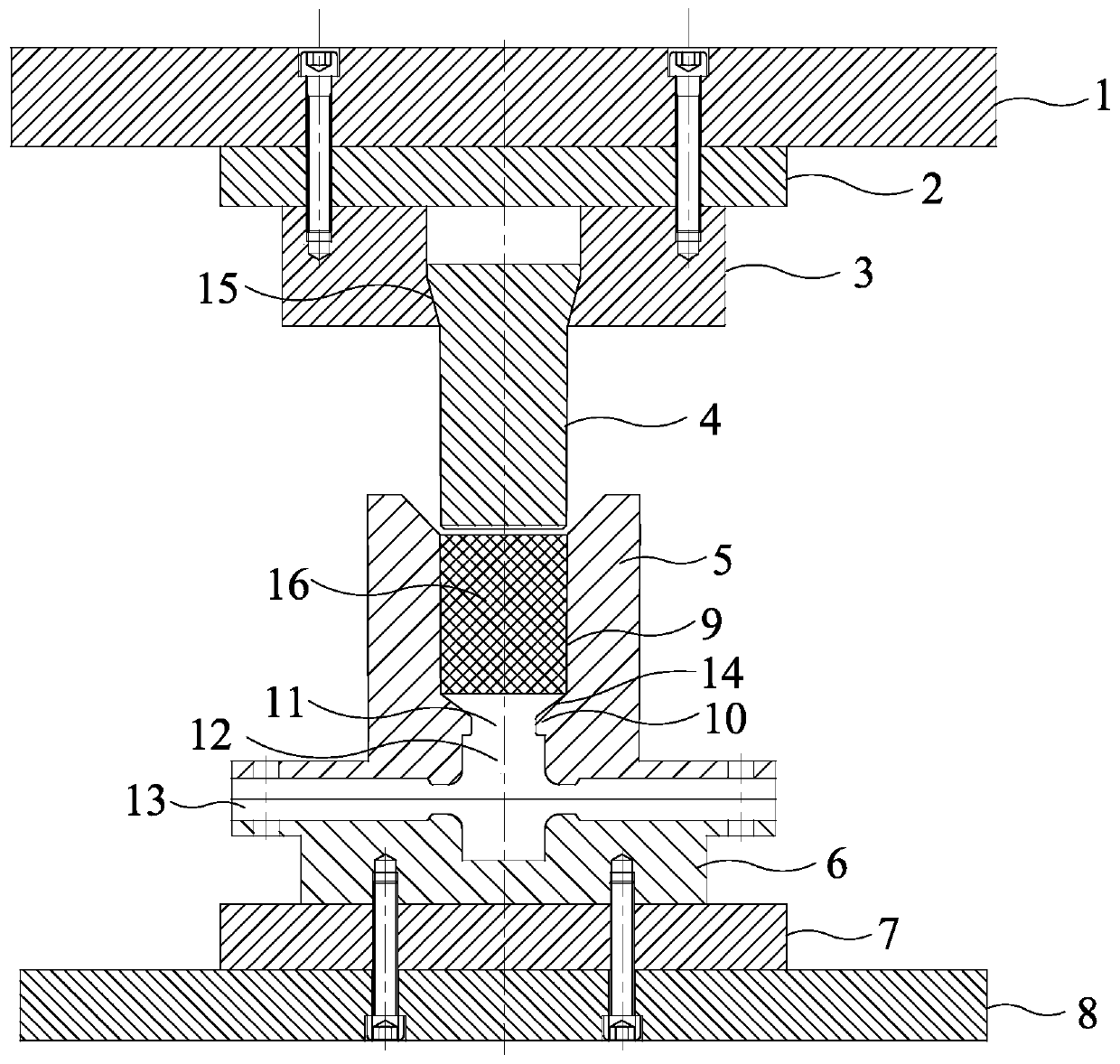

Method and tool for producing a component and a component produced by forming

The invention relates to a component, a method, and a tool for forming, in particular for the lateral extrusion or upsetting of thin-walled preforms to form components having a structure formed thereon, in particular having a toothing, wherein, by carrying out the method according to the invention and by using the tool according to the invention, buckling of the wall of the preform during the forming process to form the component according to the invention is prevented.

Owner:SCHULER CARTEC

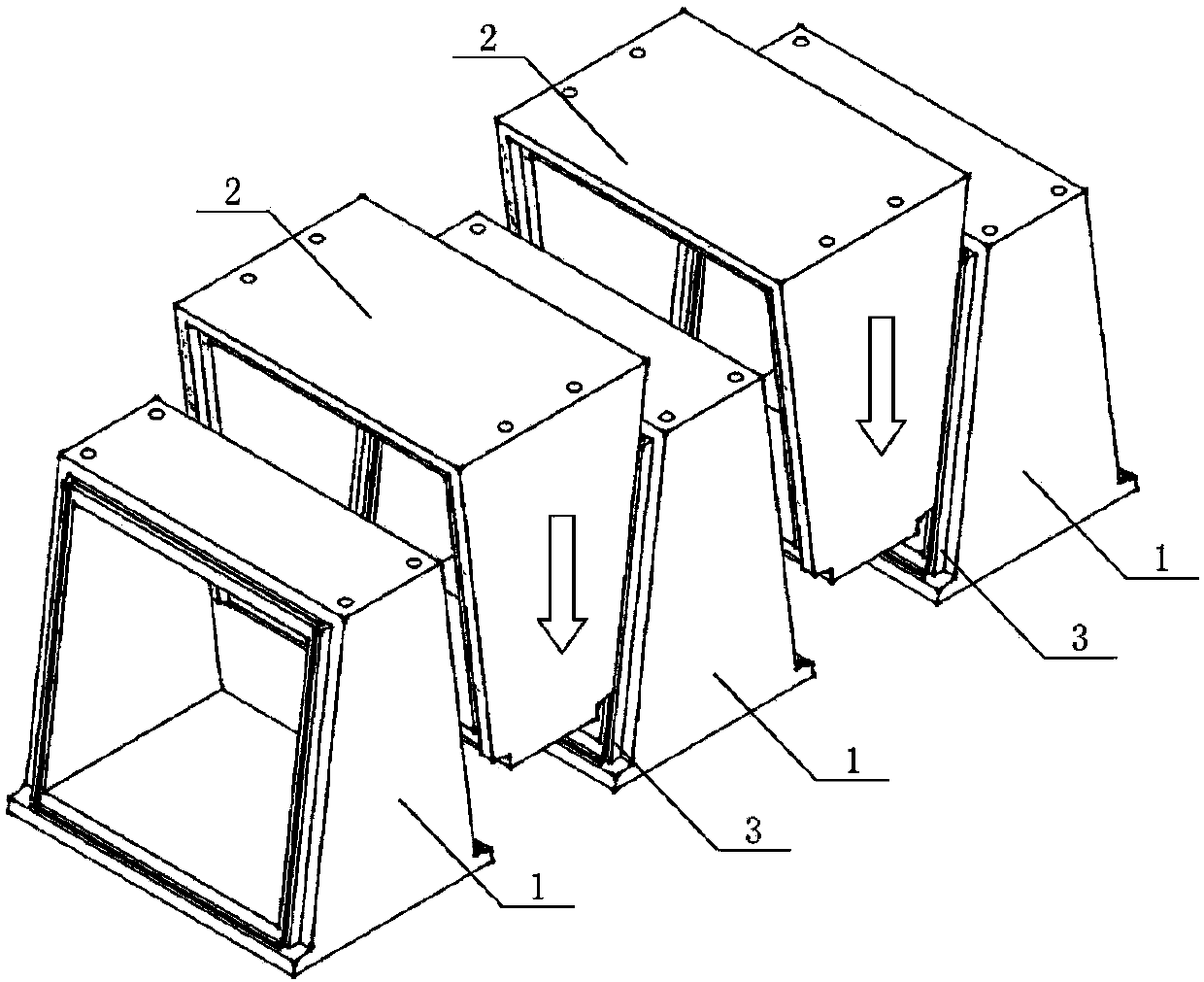

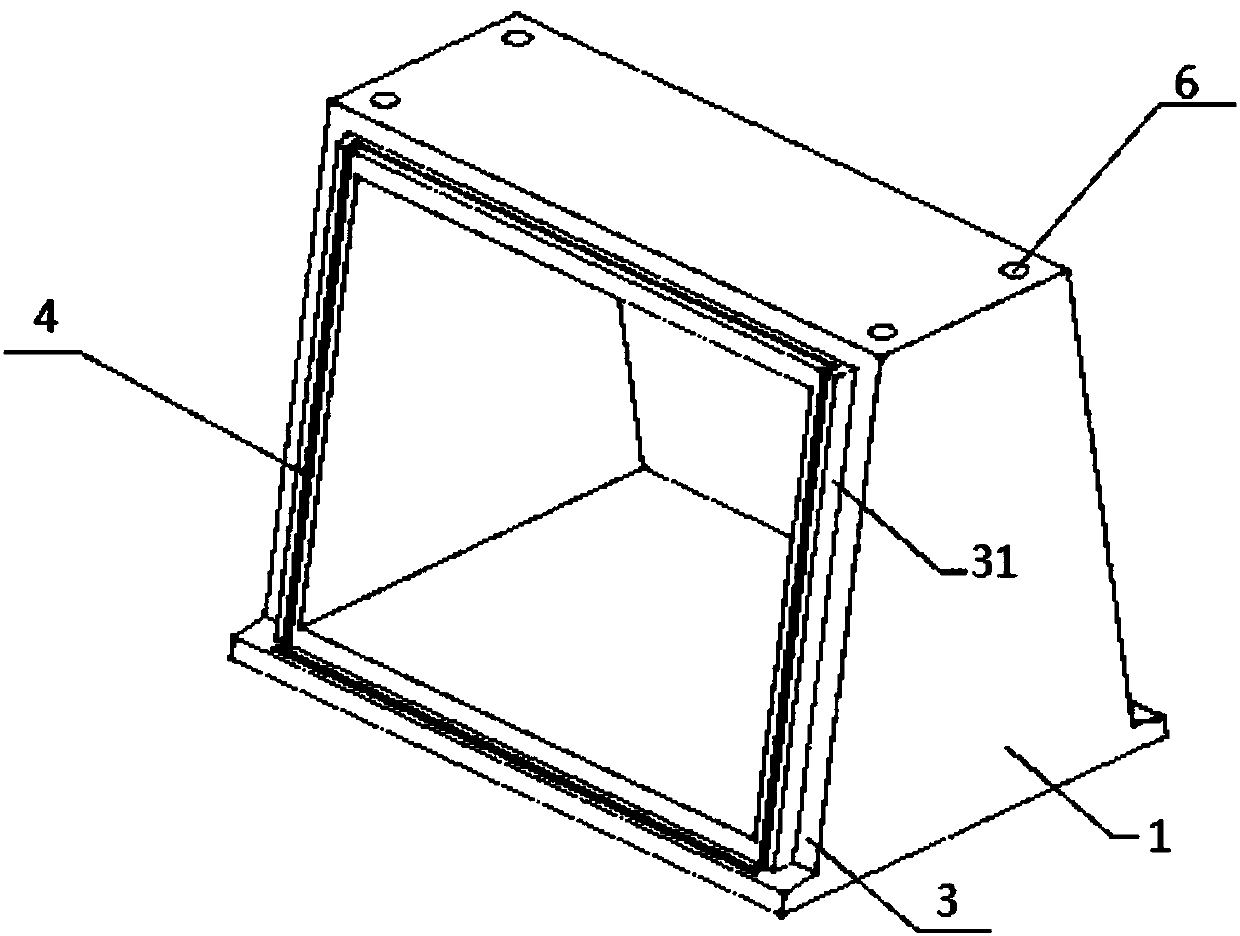

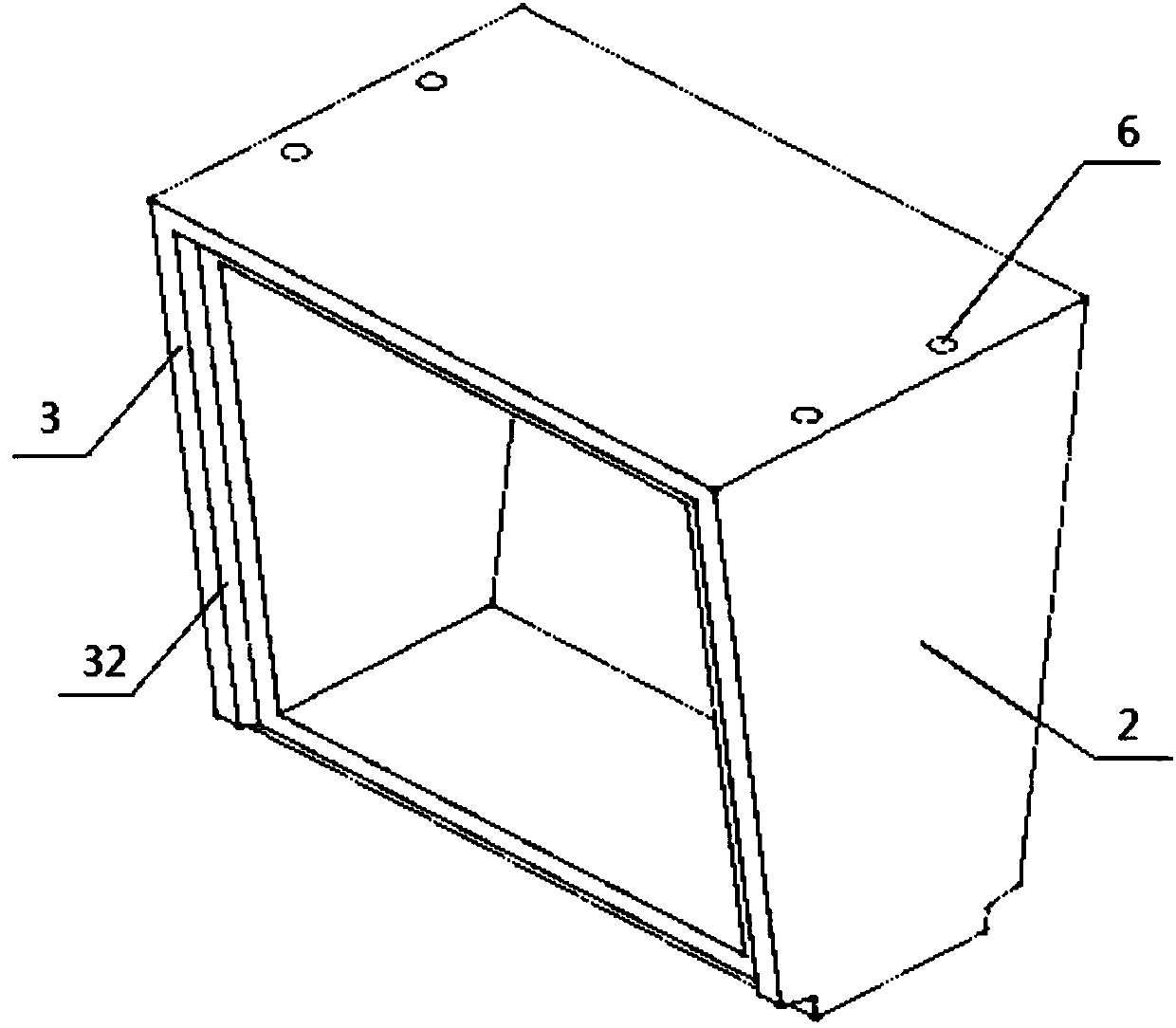

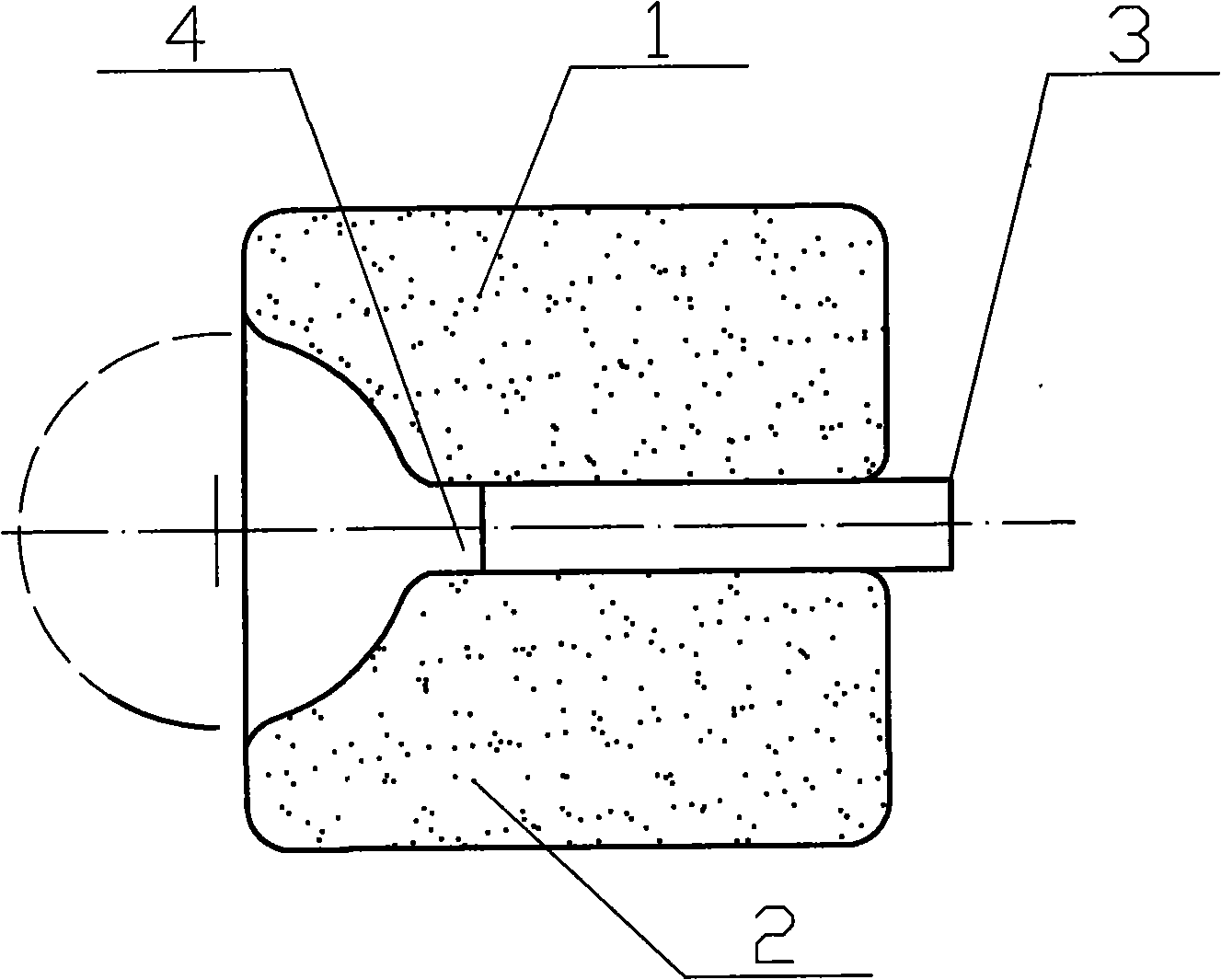

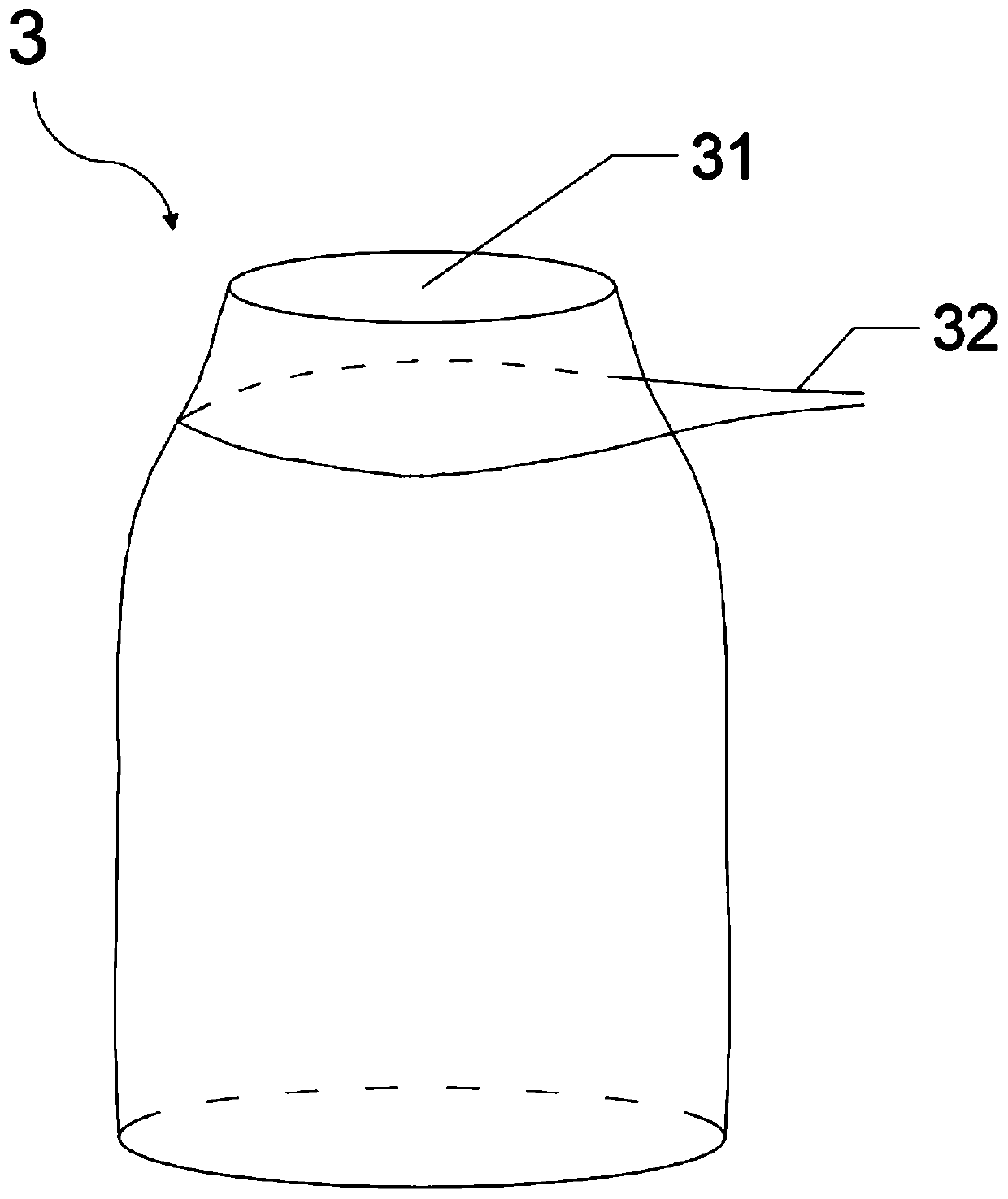

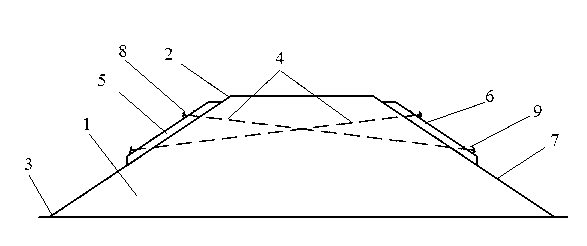

Prefabricated type pipe joint of comprehensive pipe gallery

PendingCN107780437AReach water stopAchieve water resistanceArtificial islandsUnderwater structuresTongue and grooveEngineering

A prefabricated type pipe joint of a comprehensive pipe gallery comprises erected trapezoidal segment structures and inverted trapezoidal segment structures. Convex openings are made around fracturesof the erected trapezoidal segment structures; waterproof rubber strip mounting grooves are made around the convex openings; the mounting grooves on the two sides are located in the front faces of theconvex openings, and the upper and lower mounting grooves are located in the top faces of the convex openings; hoisting bolt holes are reserved in the tops of the side walls of the two sides of the erected trapezoidal segment structures; notches are formed around the inverted trapezoidal segment structures; and the convex openings of the erected trapezoidal segment structures and the notches of the inverted trapezoidal segment structures are in Z-shaped tongue-and-groove connection in the mounting process. Lateral extrusion force and vertical extrusion force are generated directly through theshapes and the weights of the structures in the vertical mounting process to extrude waterproof rubber strips, so that the water-stopping and waterproof purposes are achieved. Meanwhile, the waterproof rubber strips can be mounted immediately after engineering prefabricating, accordingly, the mounting efficiency is improved, the on-site mounting procedures are reduced, and the construction cost is reduced.

Owner:MCC TIANGONG GROUP

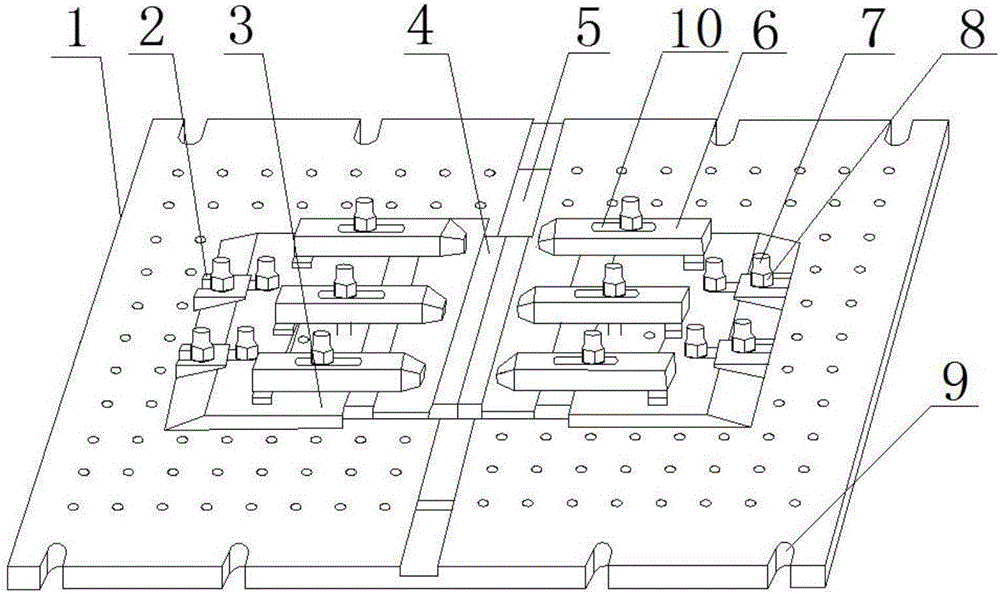

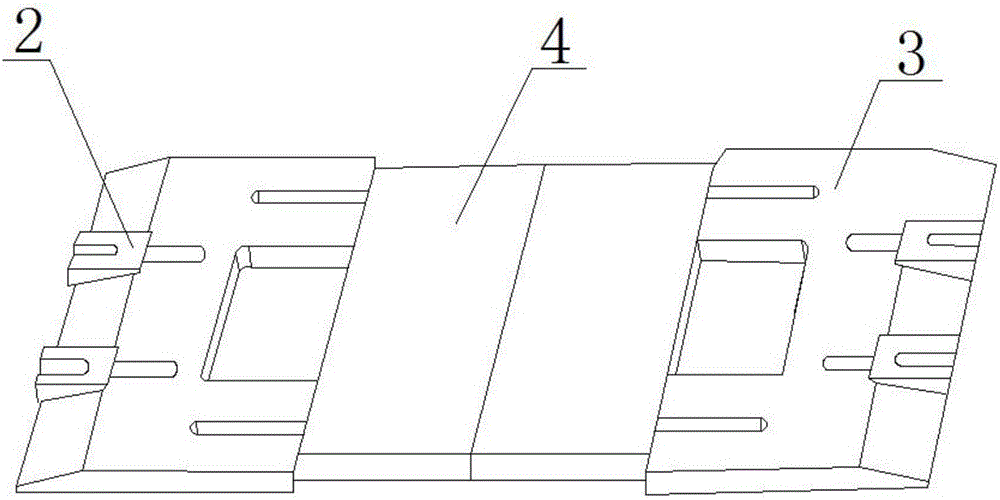

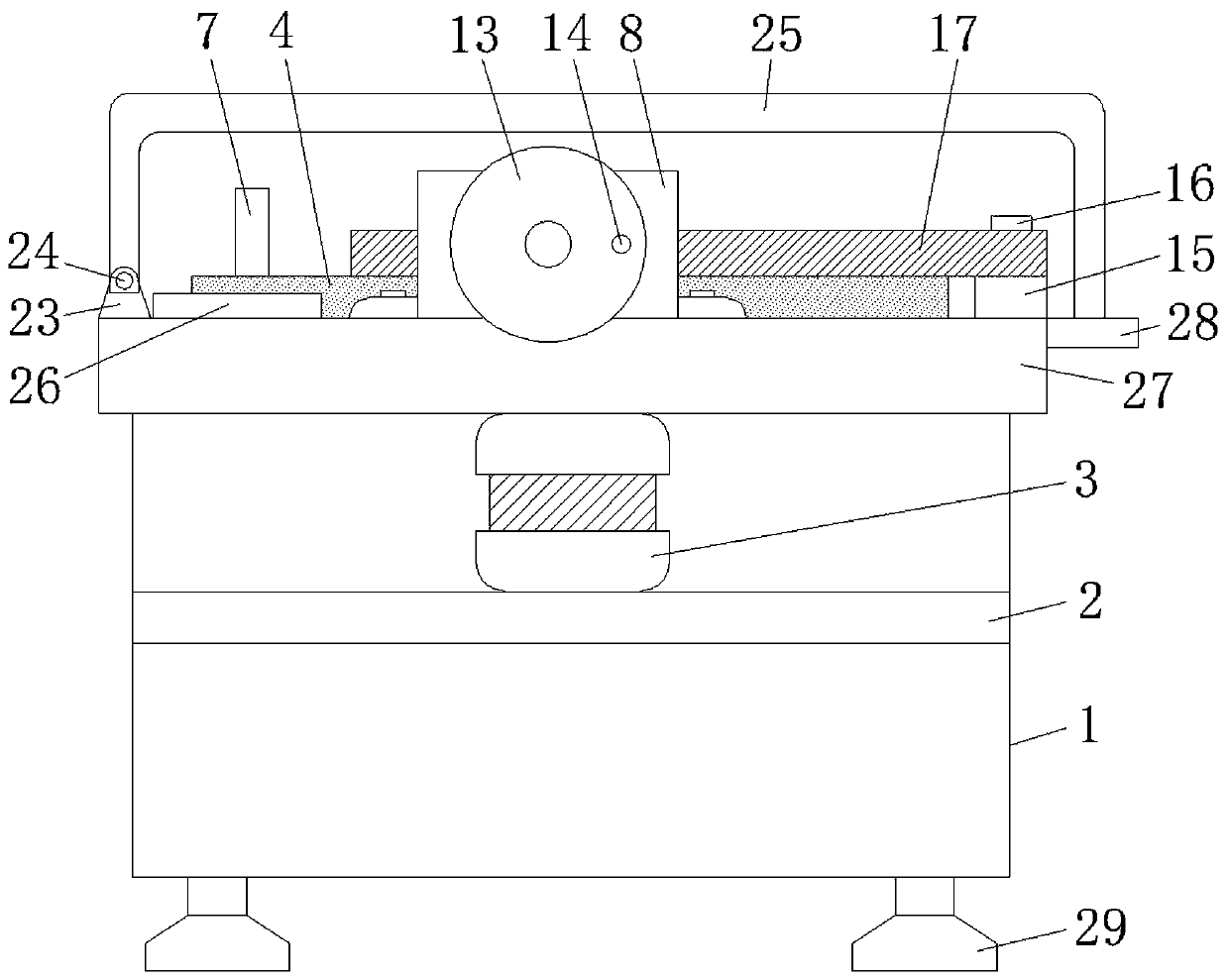

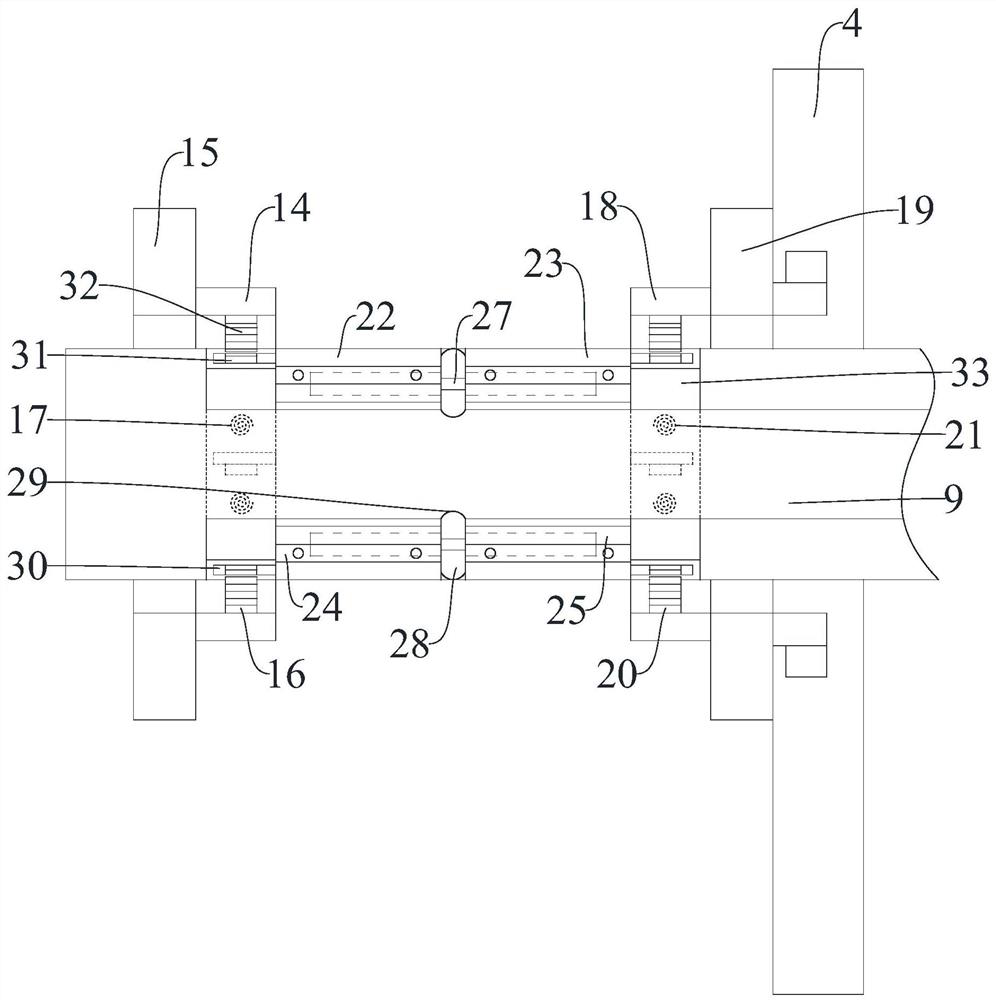

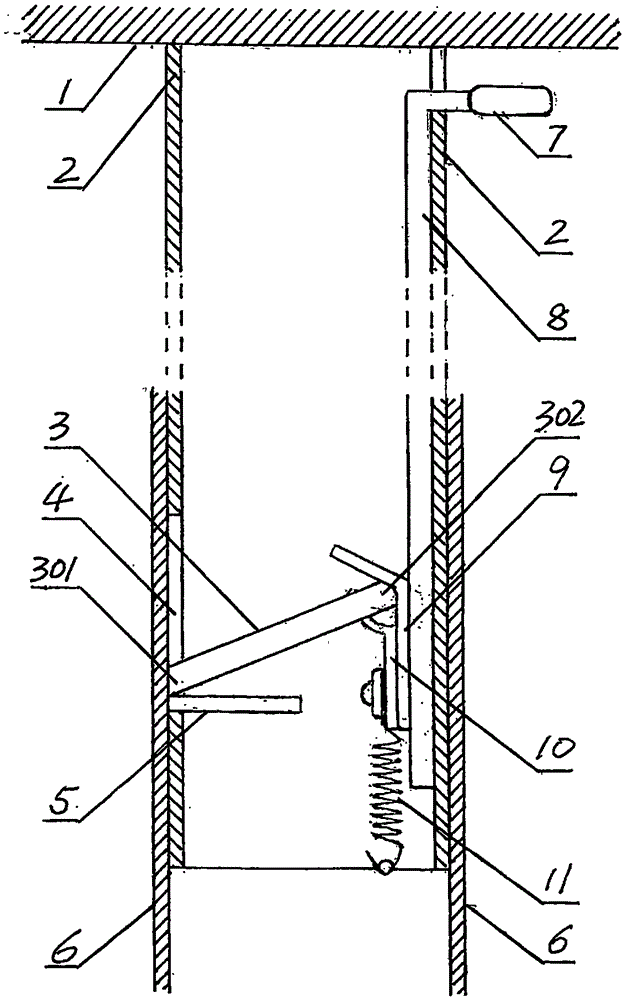

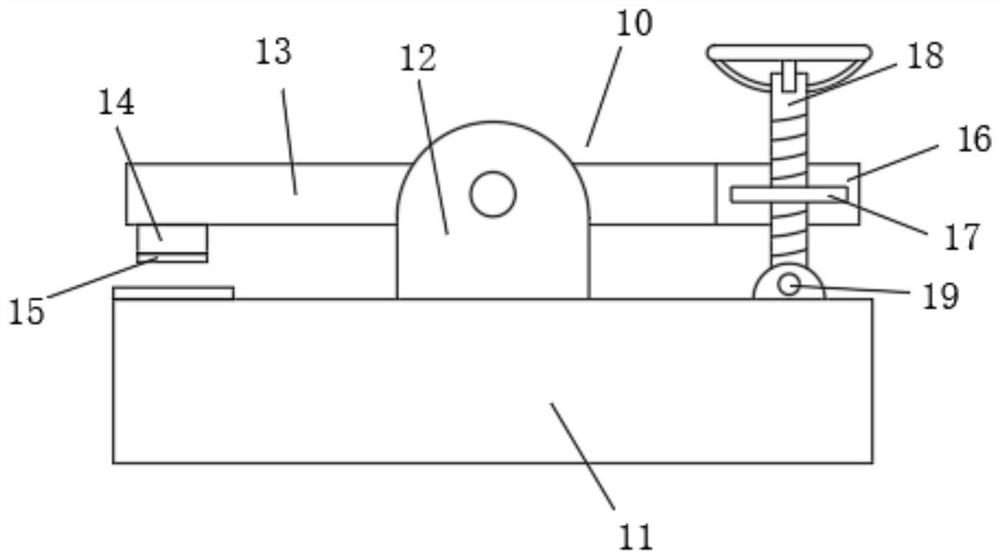

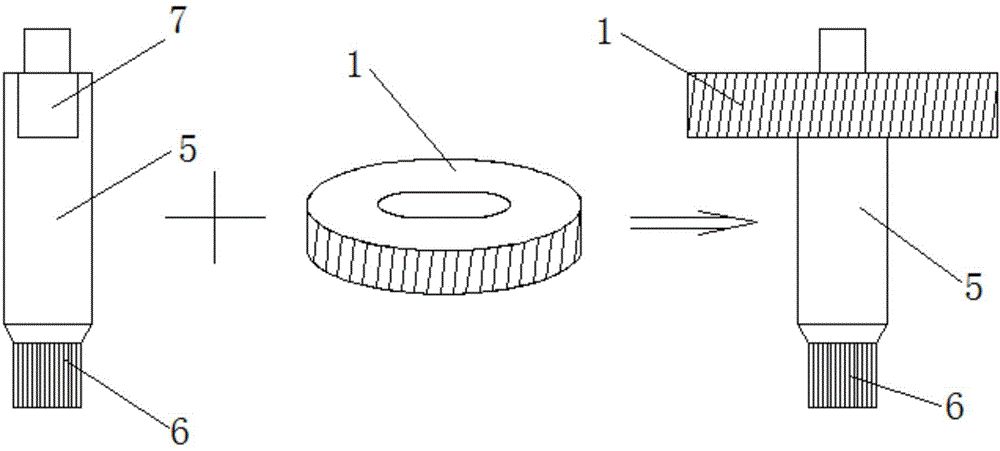

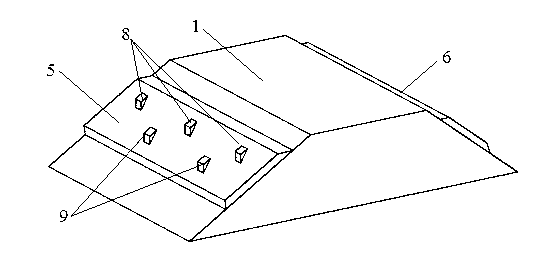

Lateral extrusion tool used for stirring friction butt welding of plate

ActiveCN105689886ARelieves the need for surface compactionReduce indentationNon-electric welding apparatusButt weldingCombined use

The invention proposes a lateral extrusion tool used for stirring friction butt welding of a plate. The tool comprises a threaded bottom plate, a welding compaction structure, fasteners and a backboard. The tool has the technical key points that the welding compaction structure is arranged on the upper sides of an extrusion block and a welded plate; a lateral compaction structure and the welding compaction structure are used for compacting the threaded bottom plate through the fasteners; and each of the lateral compaction structure and the welding compaction structure is provided with a long strip hole matched with the corresponding fastener. The tool is simple in structure, easy to mount and wide in applicability, and can adapt to effective clamping and limiting of relatively wide and thick welded plates, enable a butting surface to be always in a close-fit state and ensure that a high-quality stirring friction butt weld joint with stable performance is formed. Due to the addition of lateral extrusion force, the demand on surface compaction force of the welded plate can be relieved, and through the combined use of the backboard, the pressing marks of the welded plate can be reduced and even completely prevented.

Owner:山东新蓝海装饰材料有限公司

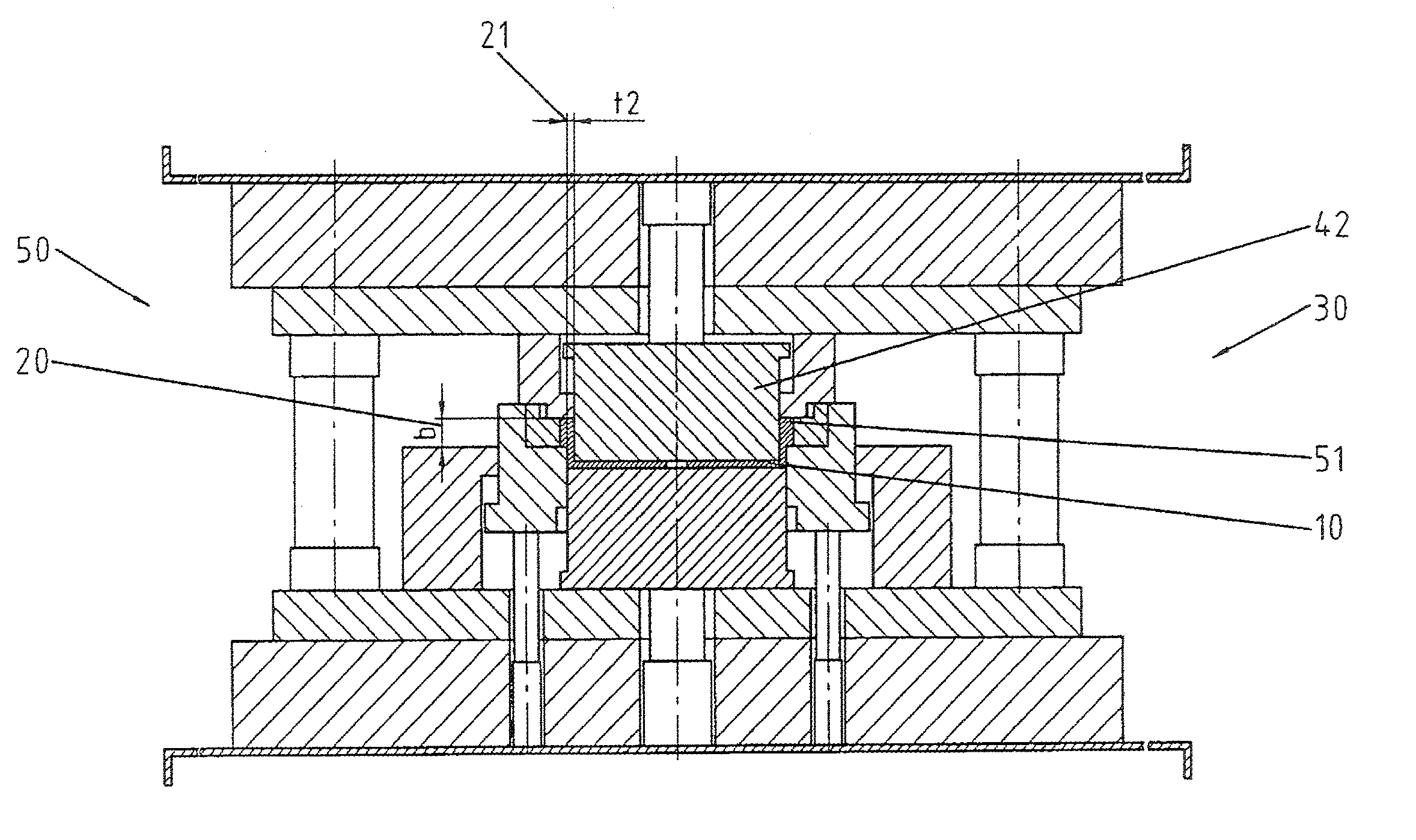

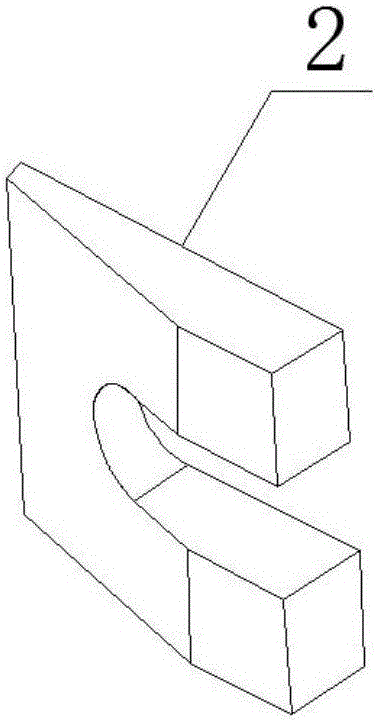

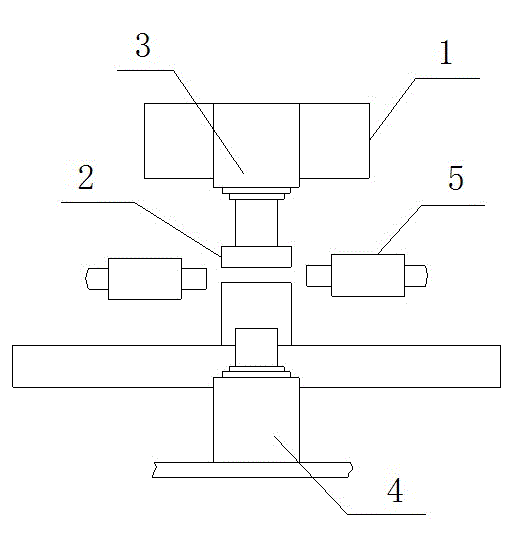

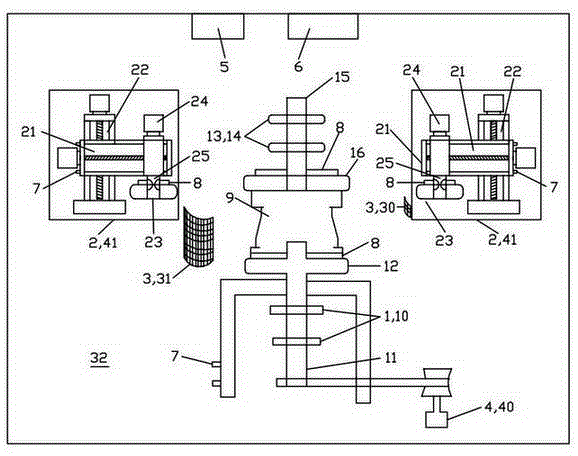

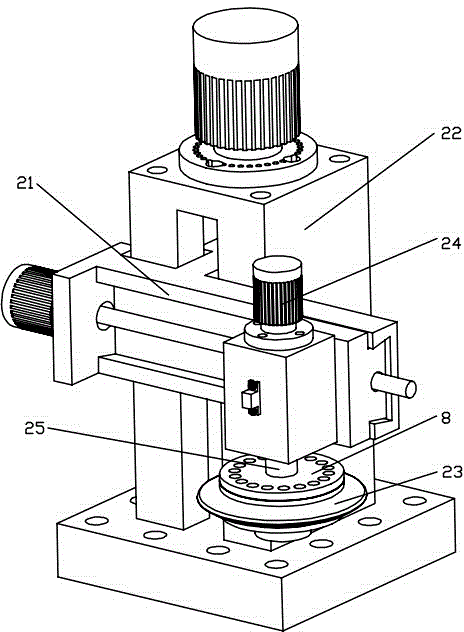

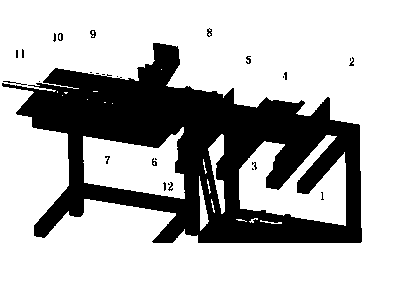

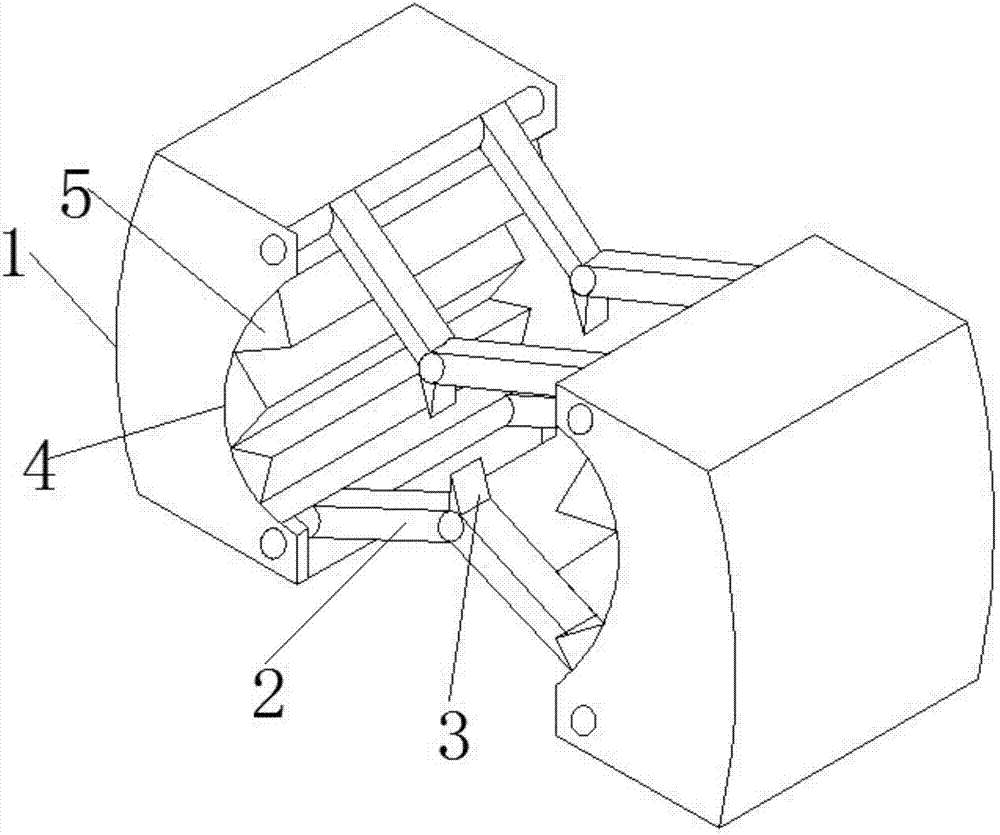

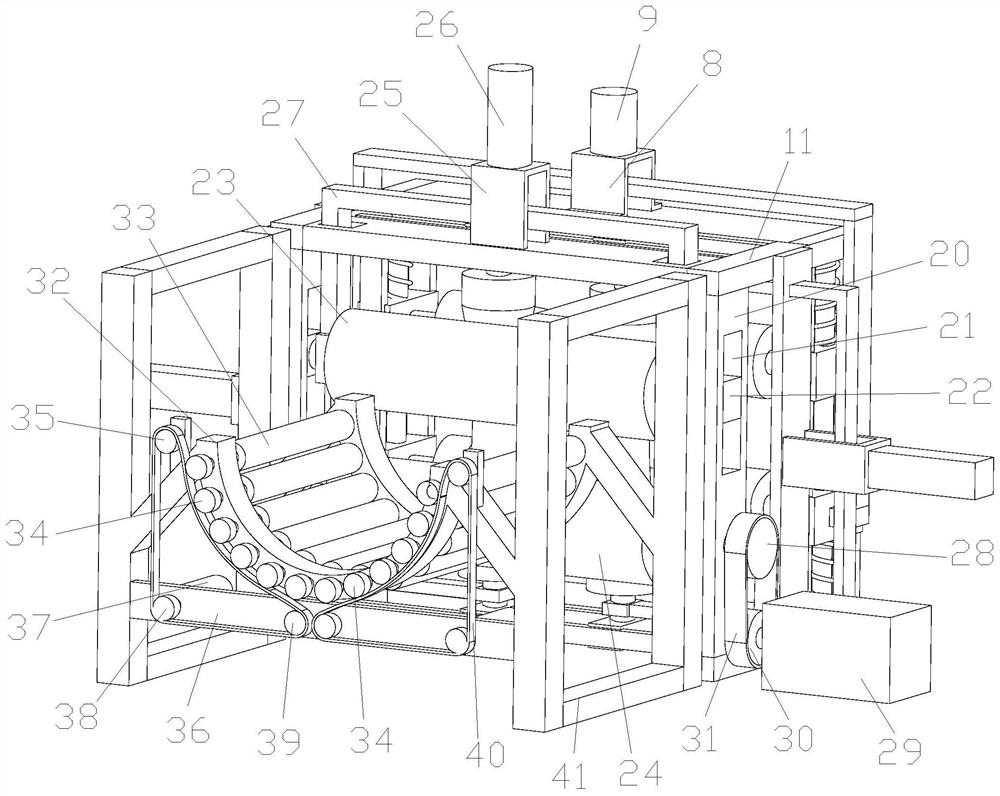

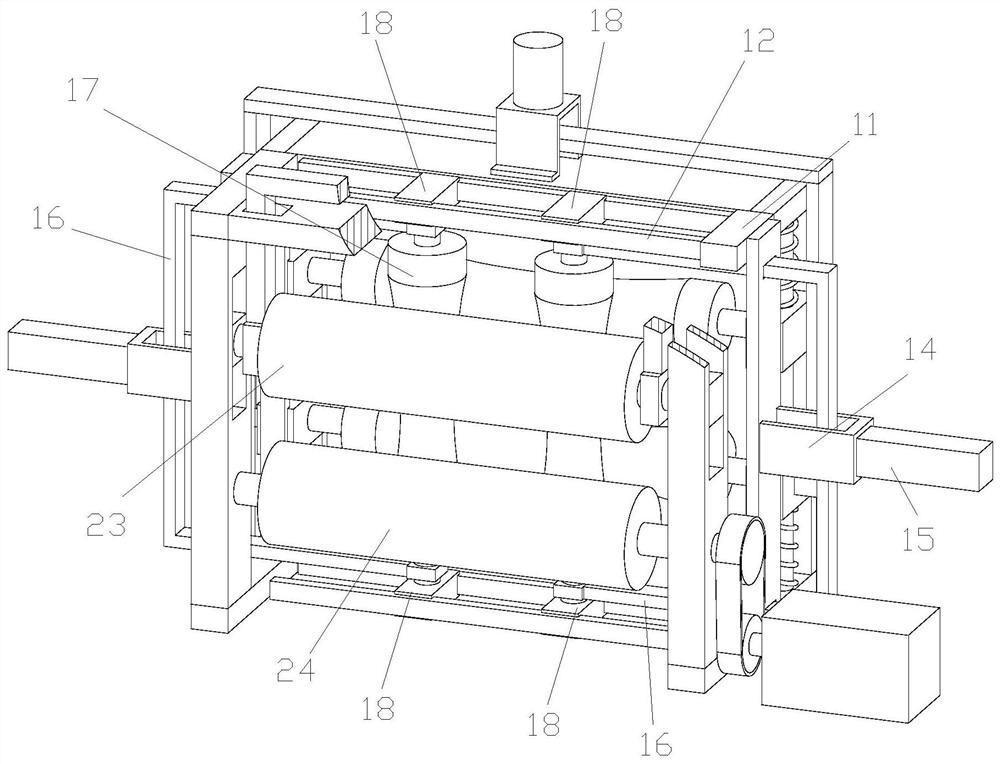

Block type multidirectional forging device

ActiveCN102794380AForce balanceReduce or avoid the generation ofForging/hammering/pressing machinesForging press detailsEngineeringBlock type

The invention discloses a block type multidirectional forging device, which comprises a frame, a die for forming a product and a hydraulic transmission device. The hydraulic transmission device comprises a main cylinder, a jacking cylinder and at least two lateral extrusion cylinders, wherein a movable element is arranged at the rear end of each lateral extrusion cylinder; and the frame comprisesa bracket and fasteners in wrapped connection with the outer sides of the movable elements and used for fixedly connecting a plurality of movable elements sequentially, and each fastener has a closedannular structure. According to the device, the movable elements are arranged at the rear ends of the lateral extrusion cylinders and fixedly connected with the fasteners, and when each lateral extrusion cylinder extrudes a workpiece, a force reacting on the frame can directly act on the fasteners; and because the fasteners have the closed annular structures, stress balance at each position of the fasteners is ensured, the forging precision is effectively ensured, degraded products are reduced or avoided, the working efficiency is improved, and the production cost is reduced.

Owner:山东格新精工有限公司

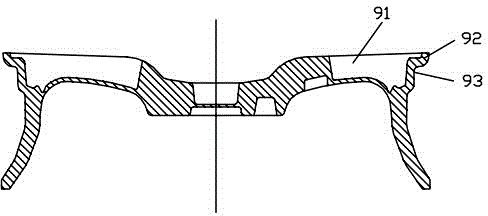

Magnesium alloy vehicle hub molding device and molding process

The invention discloses a magnesium alloy vehicle hub molding device and a molding process. The molding process comprises the following steps: (A) semi-finished hub blanks are put on a mold core and a pressure bearing tray; a pressurizing disc with corresponding diameter is adjusted to apply axial force on the semi-finished hub blanks; and the pressure is 0.5-10 T; (B) a heating system is adopted to heat a rolling disc, the mold core, the pressure bearing tray and the pressurizing disc of a mold bearing mechanism and the semi-finished hub blanks; and the heating temperature is 250-450 DEG C; and (C) roller discs corresponding to the semi-finished hub blank structures in outer edge arc are selected in sequence to perform the lateral and axial rolling of thinning, extrusion, extension and flanging for the semi-finished hub blanks; the transverse extrusion pressure of the roller discs is 0.5-10 T; and the axial pressure is 1-10 T. The process effectively overcomes the problems of multiple steps, multiple molds and single material flowing direction caused by repeated machining re-extrusion in a traditional process, optimizes the material mechanical performance of hubs, reduces the manufacturing cost, and effectively widens the application prospect of magnetism alloy materials on the manufacturing of vehicle hubs.

Owner:刘兴军

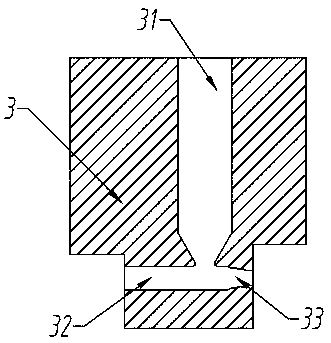

Large-deformation composite extrusion preparation method for magnesium alloy profile for vertical hydraulic machine

ActiveCN111438213AIncrease profitSpeed up the flowExtrusion diesLarge deformationUltimate tensile strength

The invention discloses a large-deformation composite extrusion preparation method for a magnesium alloy profile for a vertical hydraulic machine. The large-deformation composite extrusion preparationmethod comprises the steps that (1) blanking is conducted; (2) homogenization treatment is conducted; (3) a blank and a die are heated and subjected to heat preservation; (4) a lubricant is smeared,and the blank is placed into a forward extrusion cavity; (5) the blank is forwards extruded into a storage cavity through a calibrating straight; (6) the blank continuously bears pressure to flow tillmaking contact with the bottom of the storage cavity, the blank radially flows, the space in the storage cavity is gradually and fully filled with the blank, and in the process, the blank is subjected to upsetting deformation; (7) under the downward pressing effect of the male die, blank metal starts to flow towards a radial cavity extrusion opening communicating with the two sides of the storagecavity to be subjected to lateral extrusion deformation, and when the stroke of the male die is completed, the lateral extrusion process is also completed; and (8) die release is conducted. Accordingto the large-deformation composite extrusion preparation method, one-time forming of large plastic deformation of forward extrusion, upsetting and lateral extrusion is achieved, thus the strain amount is increased, the stress strain state is enriched, the structure is improved, the structure strength is weakened, production processes are effectively reduced, and the large-deformation composite extrusion preparation method adapts to market economic prospects in China.

Owner:ZHONGBEI UNIV

Silage compaction method

InactiveCN102113638AAccelerate the progress of silage storageSpeed up the storage processAnimal fodder preservationEngineeringHorizontal and vertical

The invention relates to a silage compaction method, and the method performs rapid stratification, landfill, and compaction of silages by a wheel loader. The method comprises the following steps: (1) rapidly stratifying silage after pit entry with 20-30 cm per layer, compacting the silage alternately in horizontal and vertical direction to ensure that air in gaps of each silage layer is discharged; (2) compacting edges and corners of the silage by using a lateral extrusion method and through the reaction force generated by the wheel loader and a wall body; (3) compacting and planishing the plane of the upper layer of the silage and performing manual flattening again before pit sealing, after film sealing, compacting the silage by waste and old tyres to ensure that air is discharged as much as possible during film sealing; (4) spading and flattening the bottom silage at the end of pit sealing, adjusting the inclination angle to facilitate the draining and the placement of the compacting tyres. The invention can accelerate the progress of silage storage, reduce labor cost, and increase labor efficiency; and the technique has simple operation, is easy to learn and understand, can completely ensure the silage preparation quality, and is easy for popularization.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Process and die for stamping girdle-free conical spheres

InactiveCN101513665AIncrease profitExtended service lifeForging/hammering/pressing machinesEngine componentsTissue densityEngineering

The invention discloses a process and a die for stamping girdle-free conical spheres. The process comprises the following steps that: a light process with one-off transverse extrusion is adopted to enable a material to have transverse deformation in the transverse direction so as to increase the tissue density of the material before being cut and forged; the cut-off length of the lightly pulled material is determined in a feeding structure; the lightly pulled material is cut off; and the cut material is sent into a tapering die cavity at an angle between 90 and 120 degrees and stamped so as to form sphere billets and manufacture the girdle-free conical spheres. The research and development of a novel girdle-free conical sphere die and a forging process increase the life span of the die and the utilization rate of the material, reduce the impact force of stamping, and ensure that the sphere billets can be knocked out more smoothly.

Owner:JIANGSU LIXING GENERAL STEEL BALL

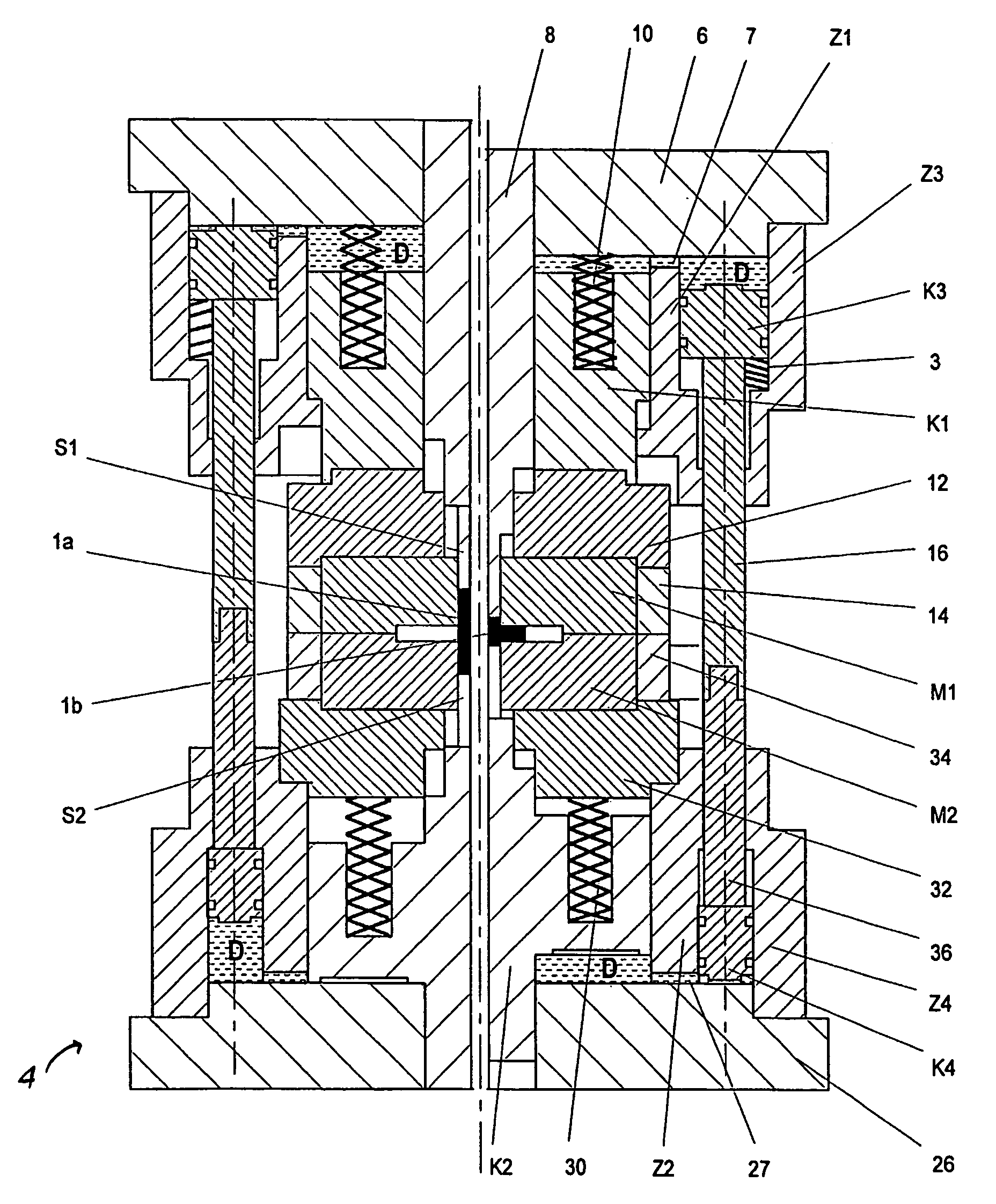

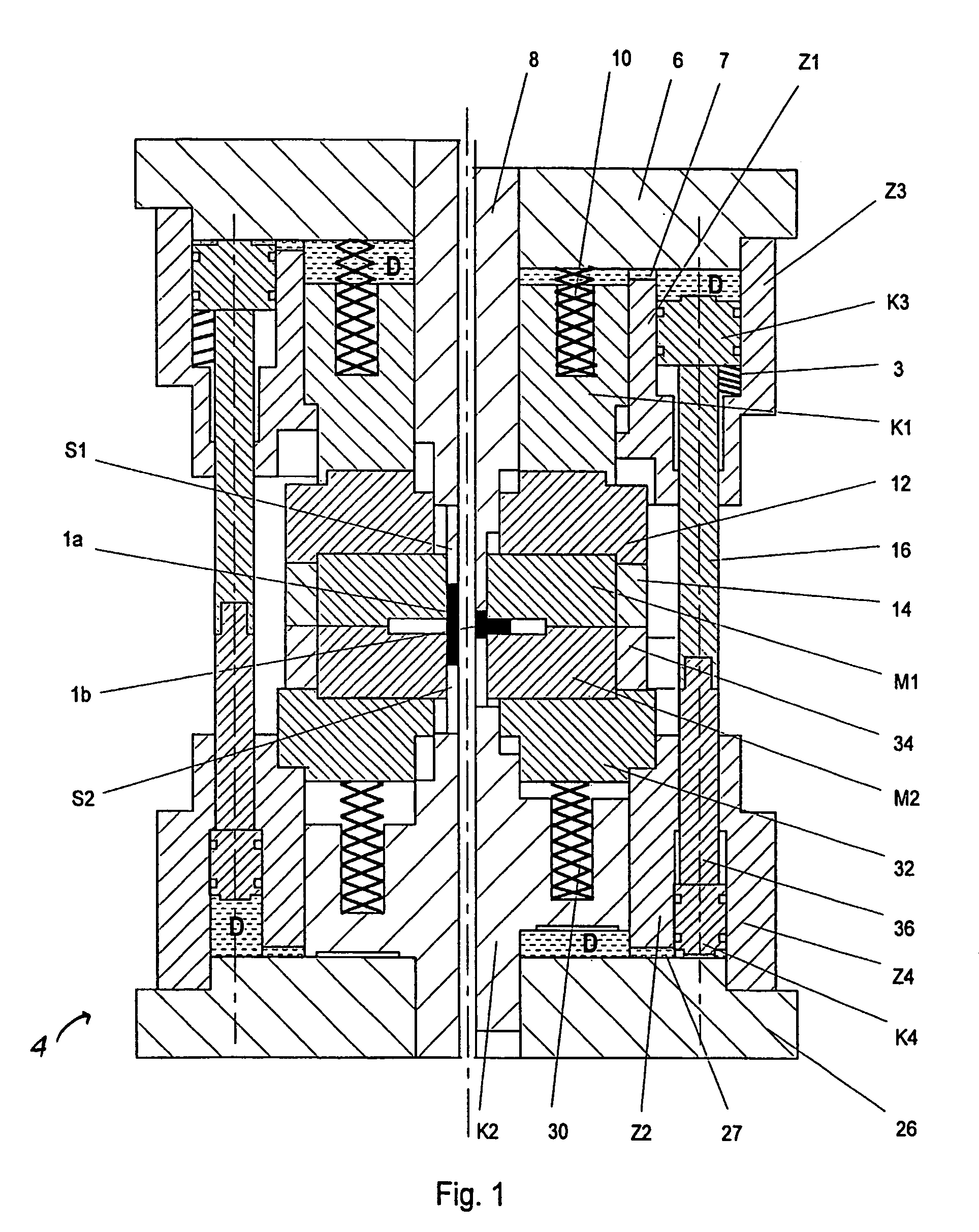

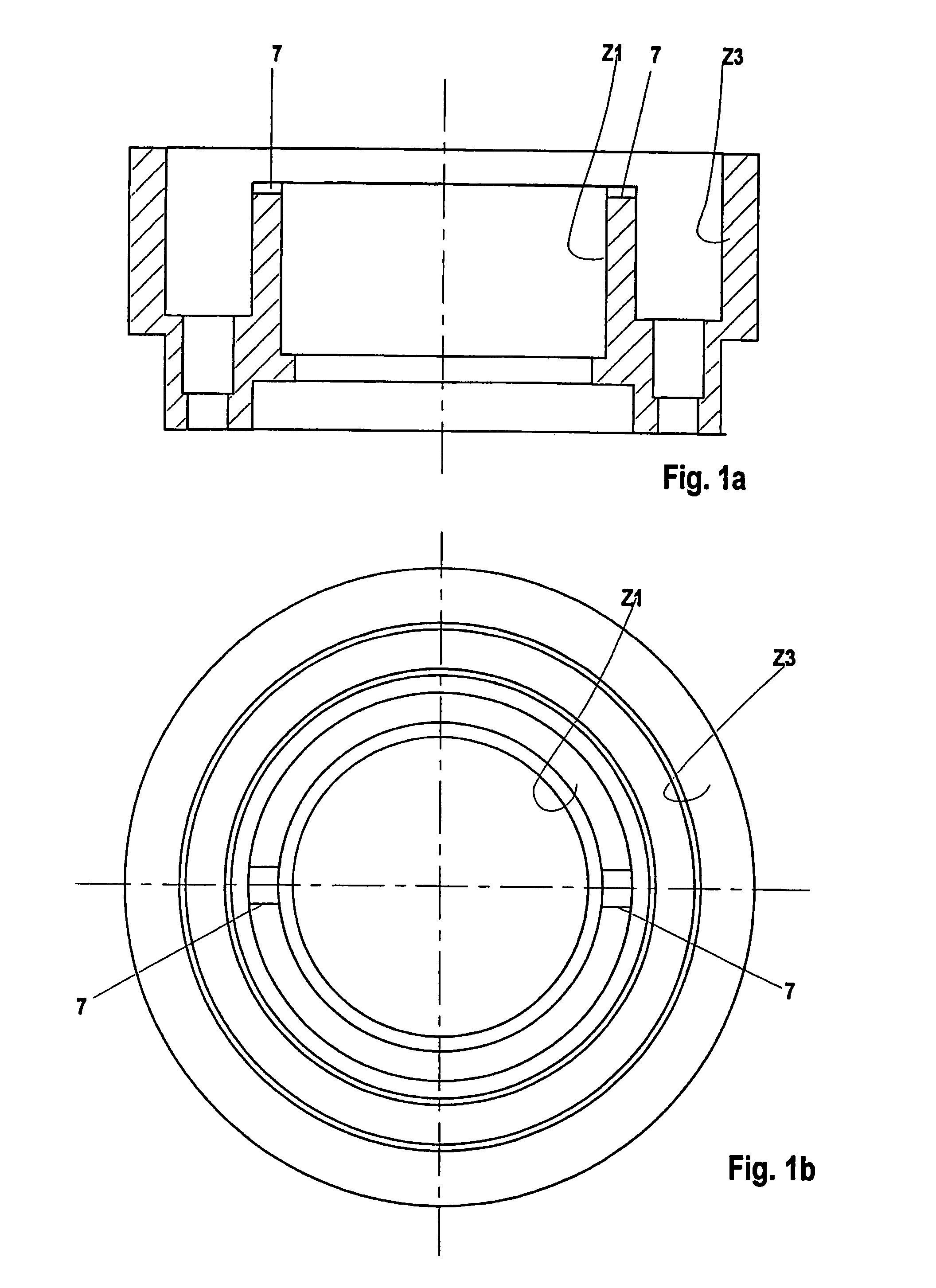

Hydromechanical closing device, in particular for lateral extrusion

InactiveUS7059165B2Simple and compact structureIncrease pressureForging/hammering/pressing machinesForging press drivesHydraulic cylinderHydraulic machinery

The invention relates to a hydromechanical clamping device having two movable die halves and two punches, a first hydraulic piston, and a second hydraulic piston. The second die half is fixed to the frame and the second punch is arranged on the second hydraulic piston. The first hydraulic cylinder is connected to a third hydraulic cylinder. The latter acts on a fourth hydraulic piston. The first hydraulic cylinder is connected to the third hydraulic cylinder, so that the pressure medium displaced from the first hydraulic cylinder during a feed movement flows into the third hydraulic cylinder and the third hydraulic piston moves the fourth hydraulic piston in the feed direction, so that pressure medium is displaced into the second hydraulic cylinder, and the requisite forming pressure can be applied to the second hydraulic piston and the punches move toward one another.

Owner:HATEBUR UMFORMMASCHEN

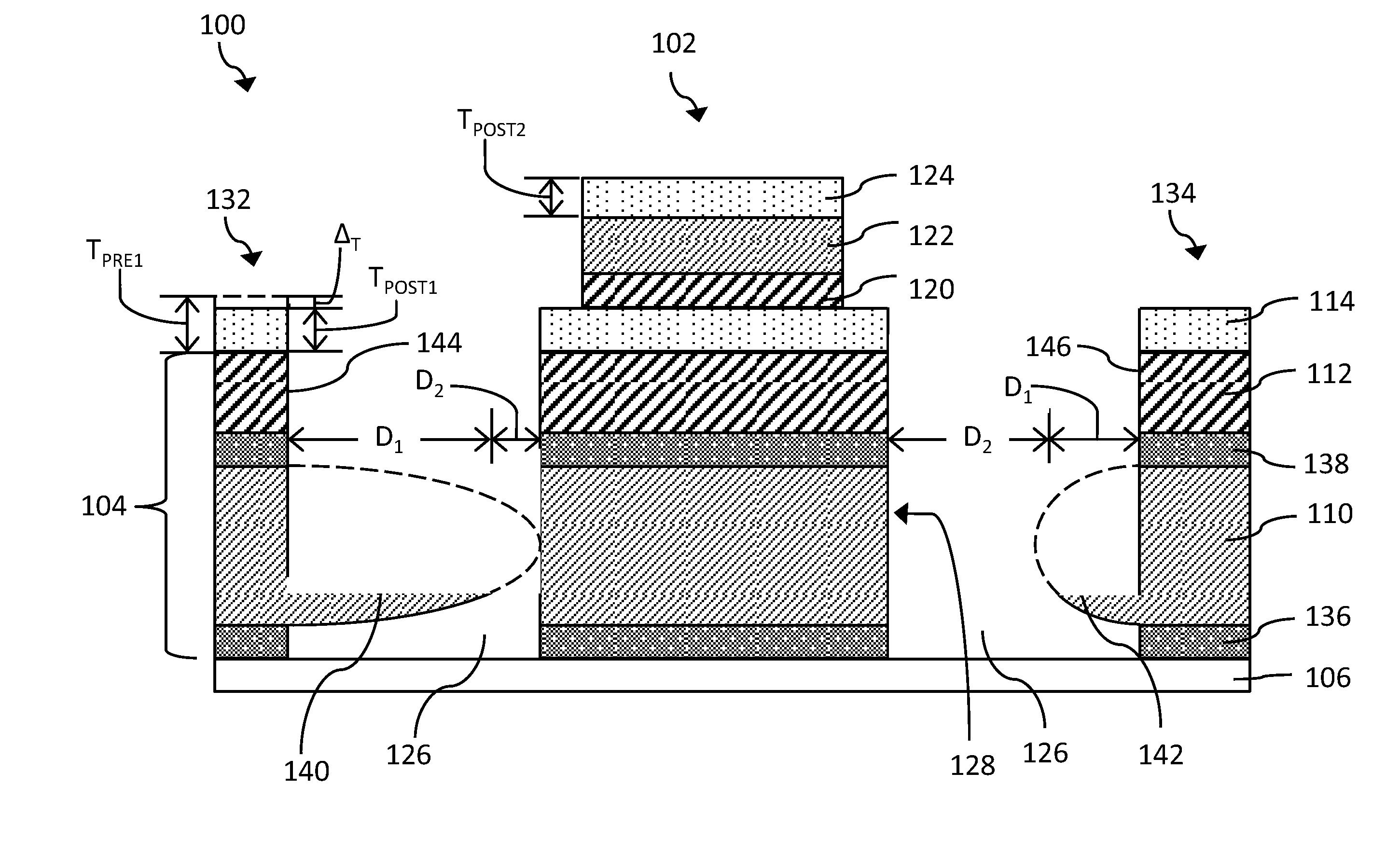

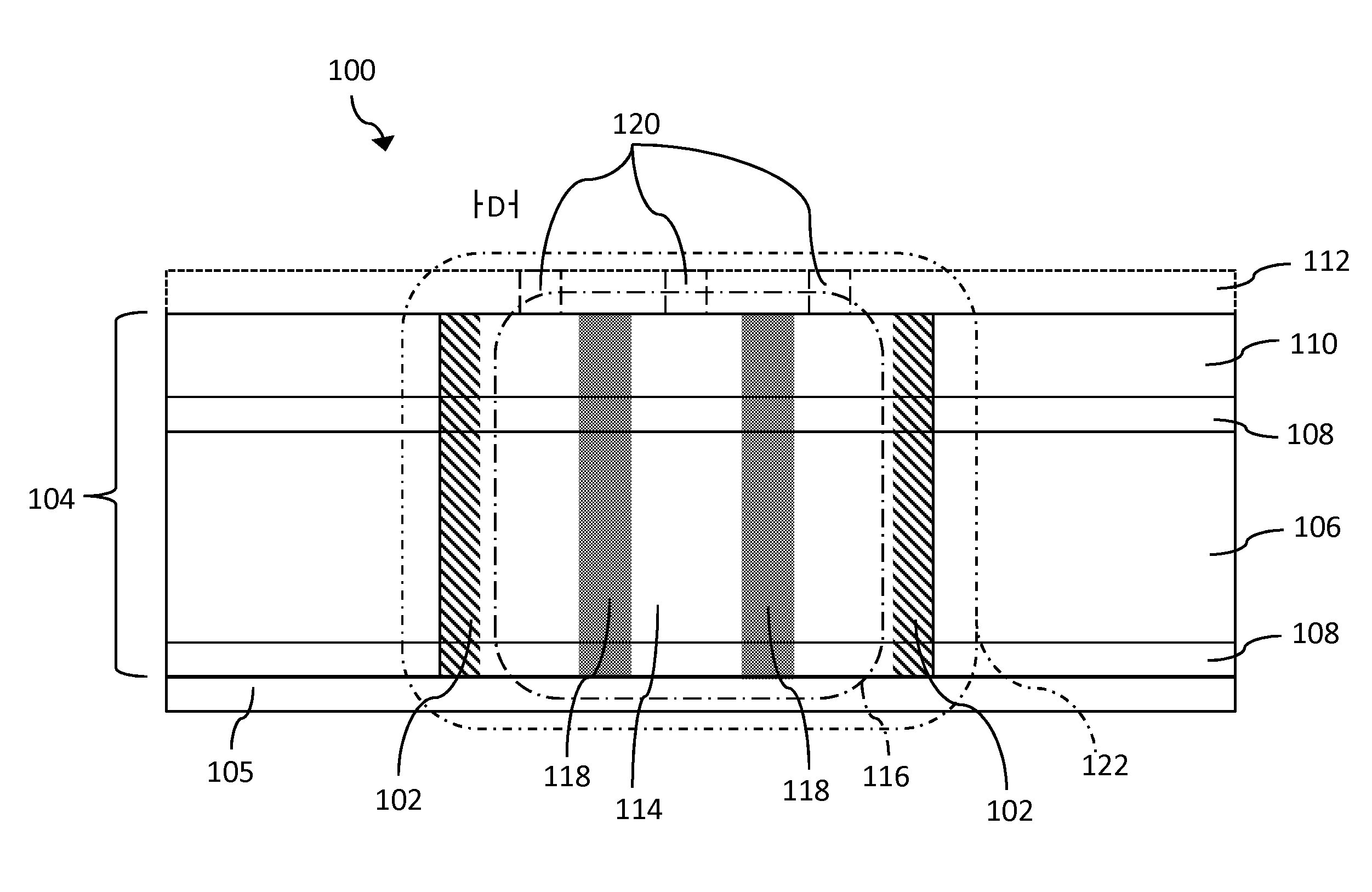

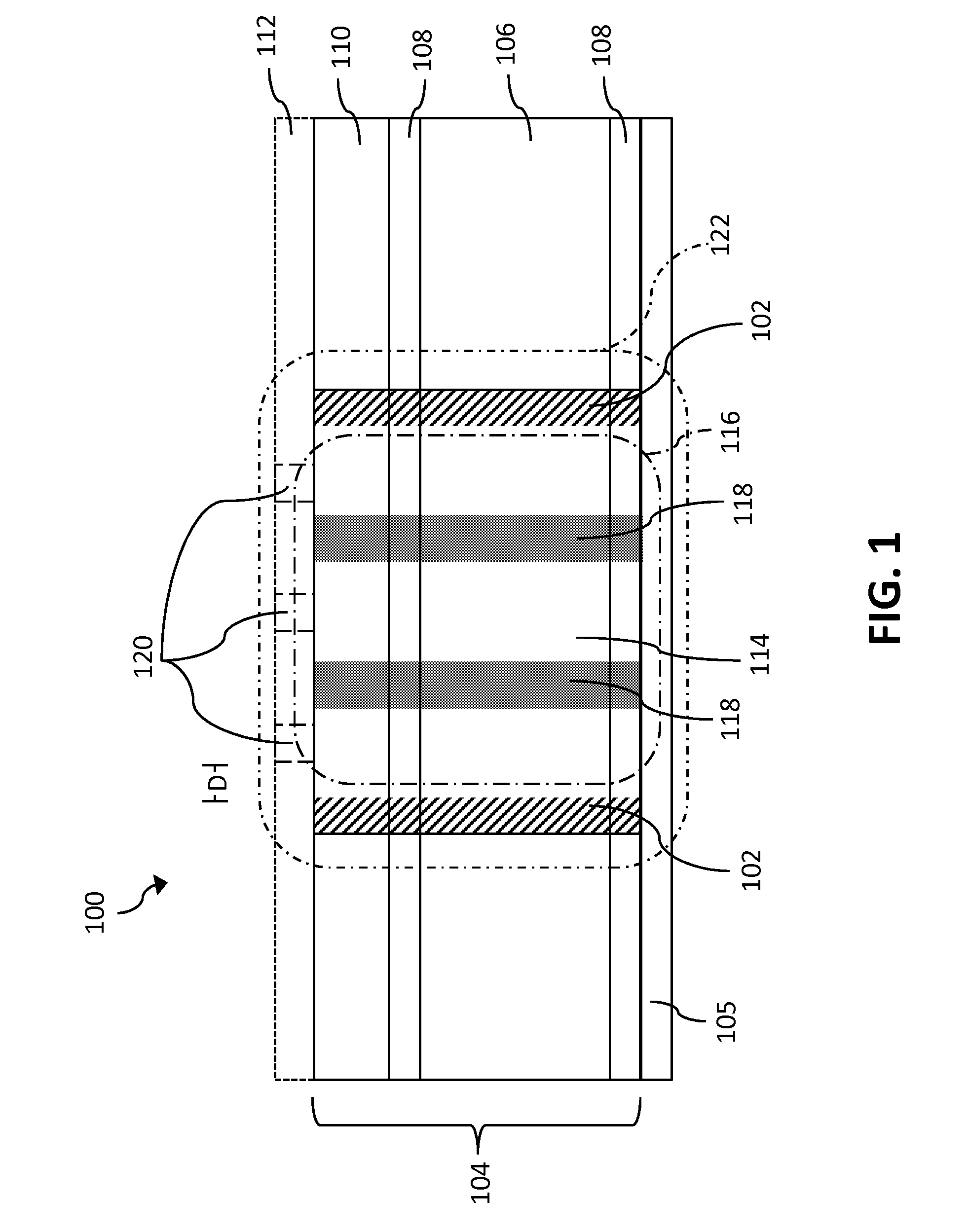

Method for reducing lateral extrusion formed in semiconductor structures and semiconductor structures formed thereof

InactiveUS20150035117A1Less squeezeSemiconductor/solid-state device testing/measurementSolid-state devicesSemiconductor structureEngineering

Owner:GLOBALFOUNDRIES INC

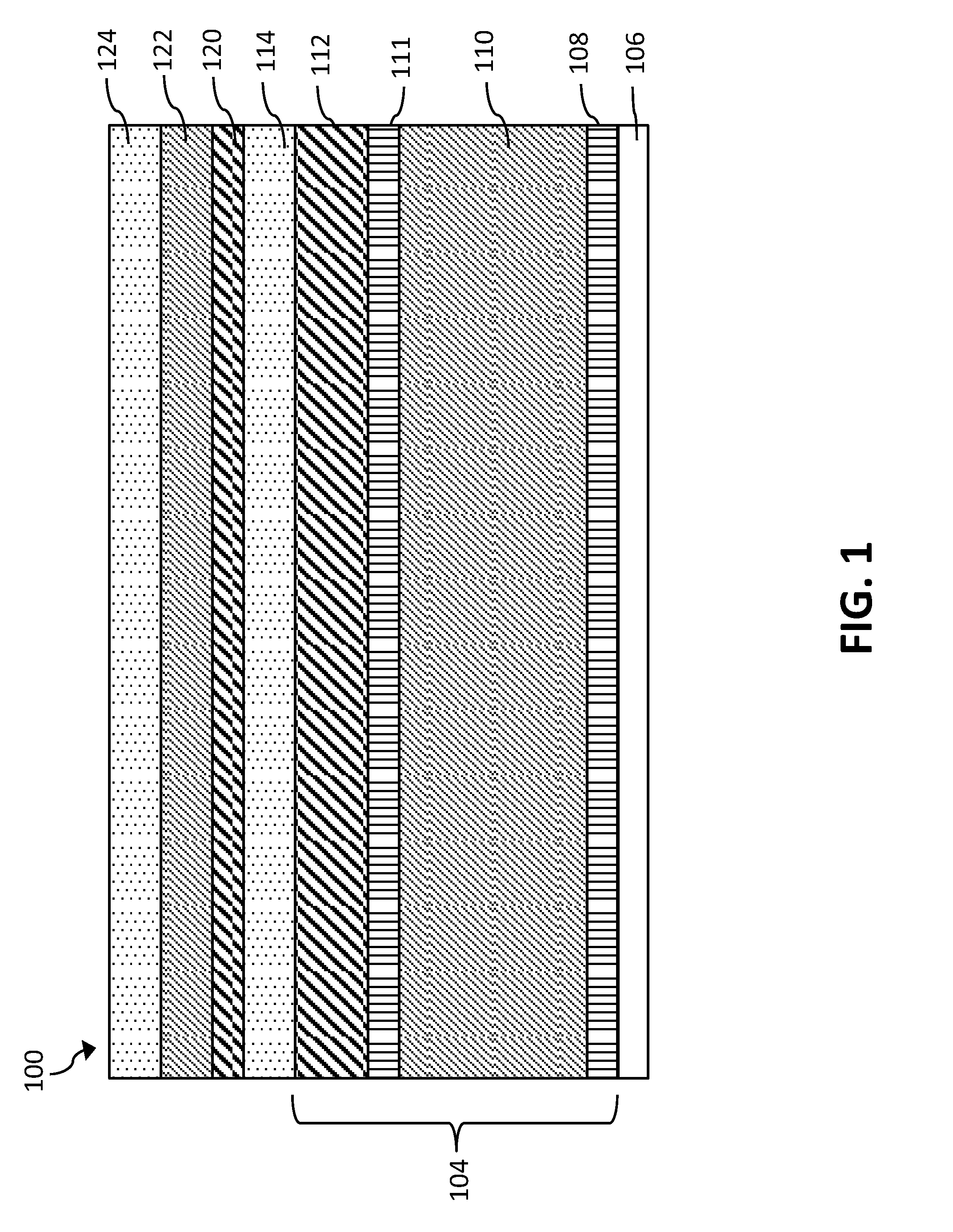

Controlled metal extrusion opening in semiconductor structure and method of forming

InactiveUS20140246777A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor structureComposite material

Aspects of the present invention relate to a controlled metal extrusion opening in a semiconductor structure. Various embodiments include a semiconductor structure. The structure includes an aluminum layer. The aluminum layer includes an aluminum island within the aluminum layer, and a lateral extrusion receiving opening extending through the aluminum layer adjacent the aluminum island. The opening includes a lateral extrusion of the aluminum layer of the semiconductor structure. Additional embodiments include a method of forming a semiconductor structure. The method can include forming an aluminum layer over a titanium layer. The aluminum layer includes an aluminum island within the aluminum layer. The method can also include forming an opening extending through the aluminum layer adjacent the aluminum island within the aluminum layer. The opening includes a lateral extrusion of the aluminum layer of the semiconductor layer.

Owner:ALSEPHINA INNOVATIONS INC

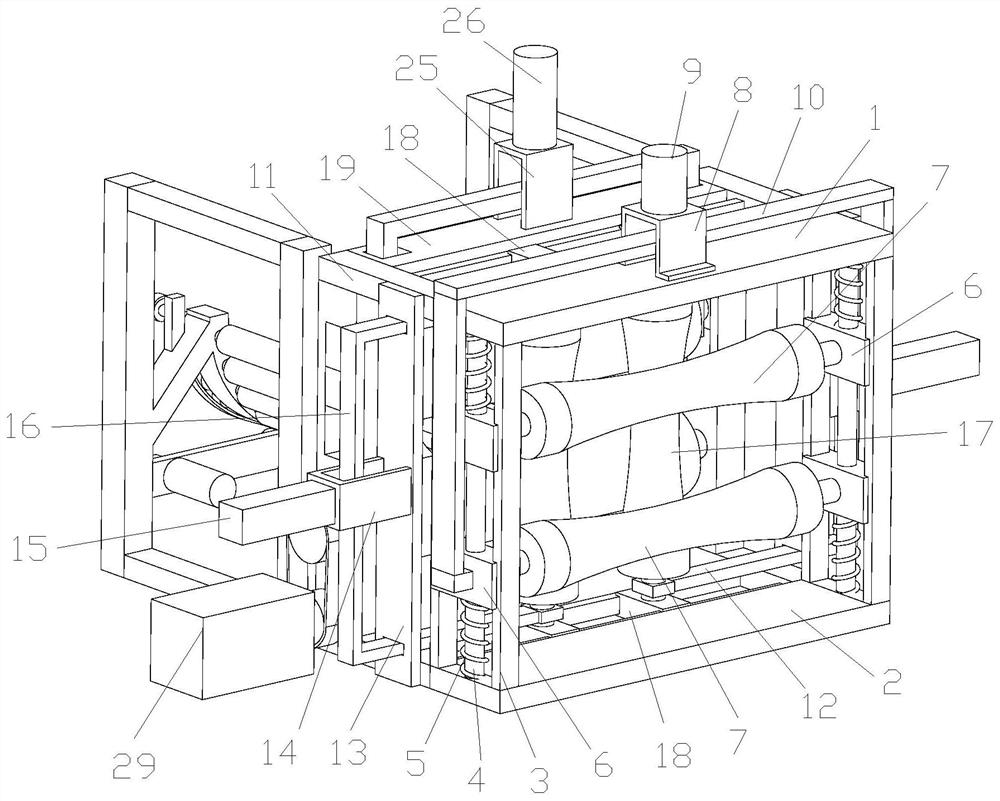

Hot extrusion device and method for molybdenum and molybdenum alloy

The invention discloses a hot extrusion device for molybdenum and molybdenum alloy. The hot extrusion device comprises an extrusion die, the extrusion die is internally provided with an extrusion channel, and the middle of the extrusion channel retracts; the extrusion die is sleeved with a heat-preservation preheating device; the hot extrusion device further comprises a vertical hydraulic press and a pair of overturn extrusion devices, the overturn extrusion devices are used for turning over and laterally extruding the extrusion die, and the vertical hydraulic press is used for longitudinallyextruding and heating the molybdenum or molybdenum alloy in the extrusion channel. The invention further discloses a hot extrusion method for the molybdenum and molybdenum alloy. The method comprisesthe steps of preheating of the extrusion die, die combination and preheating, extrusion molding and 2-5 times of repeated extrusion molding. The hot extrusion device can unevenly extrude the molybdenum and molybdenum alloy in three phases, and large-sized even grain-refined molybdenum and molybdenum alloy are obtained; by means of the hot extrusion method, obtained finished materials of molybdenumand molybdenum alloy can be even in structure and refinement degree.

Owner:JINDUICHENG MOLYBDENUM CO LTD

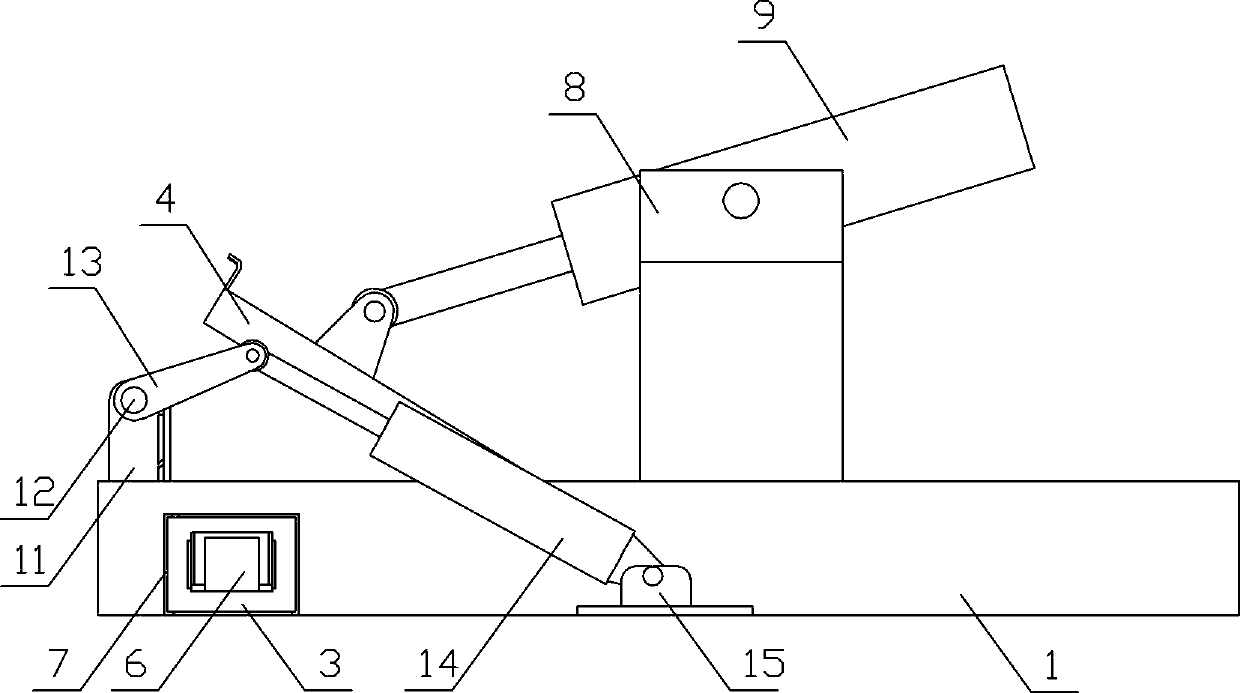

Reinforcing steel bar bending strength detection device

PendingCN110806355ANo displacementAvoid accidental injuryMaterial strength using steady bending forcesRebarScrew thread

The invention discloses a reinforcing steel bar bending strength detection device which comprises a supporting part. A workbench is fixedly connected to the top of the supporting part; a first connecting rod is fixedly connected to the interior of the supporting part; and a servo motor is fixedly connected to the top of the first connecting rod. According to the invention, the bending resistance of the reinforcing steel bar is tested in a lateral extrusion bending manner; with a fixation device, the reinforcing steel bar body is protected from being clamped into a push plate in testing and oneside of the reinforcing steel bar body can be limited; after setting of first limiting holes and second limiting holes in different positions, adaptability to reinforcing steel bar bodies with different lengths can be improved; the push plate is prevented from displacement in the testing process because of mutual limiting between a fixed thread sleeve and a pushing device, so that the high detection accuracy is ensured; and with a set sealing cover, the reinforcing steel bar is prevented from being broken effectively in testing and thus the operation is protected from being injured by any mistake.

Owner:阜阳市路兴公路工程检测有限公司 +1

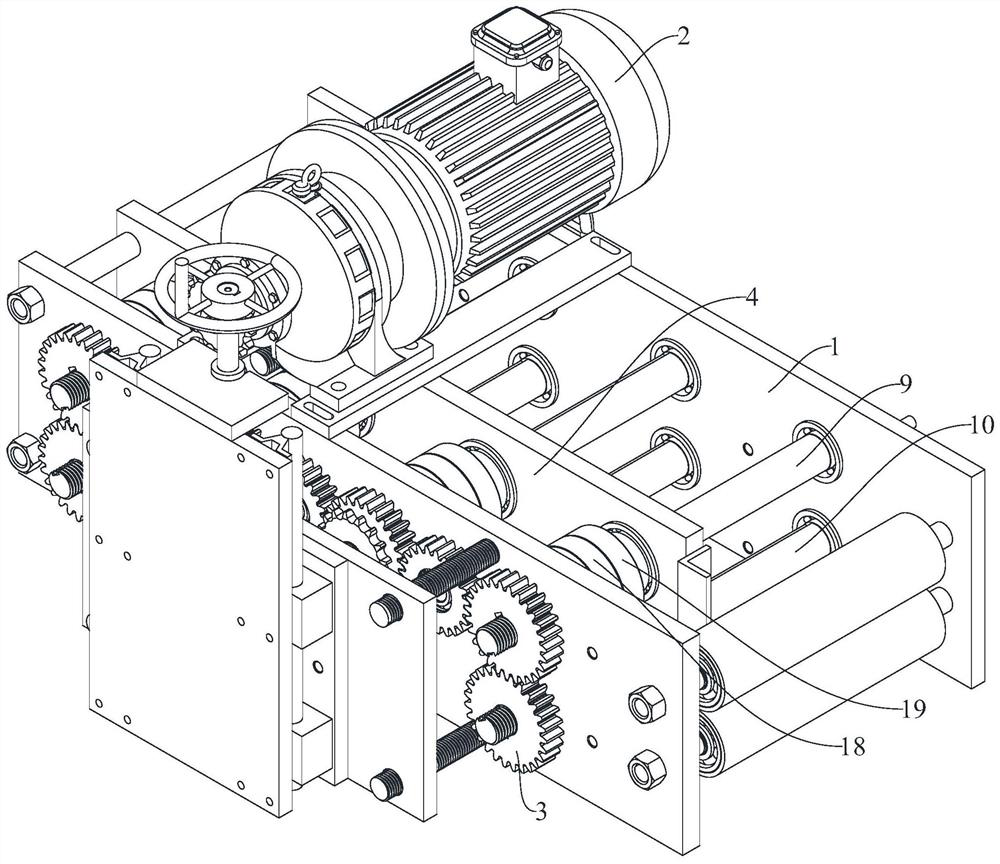

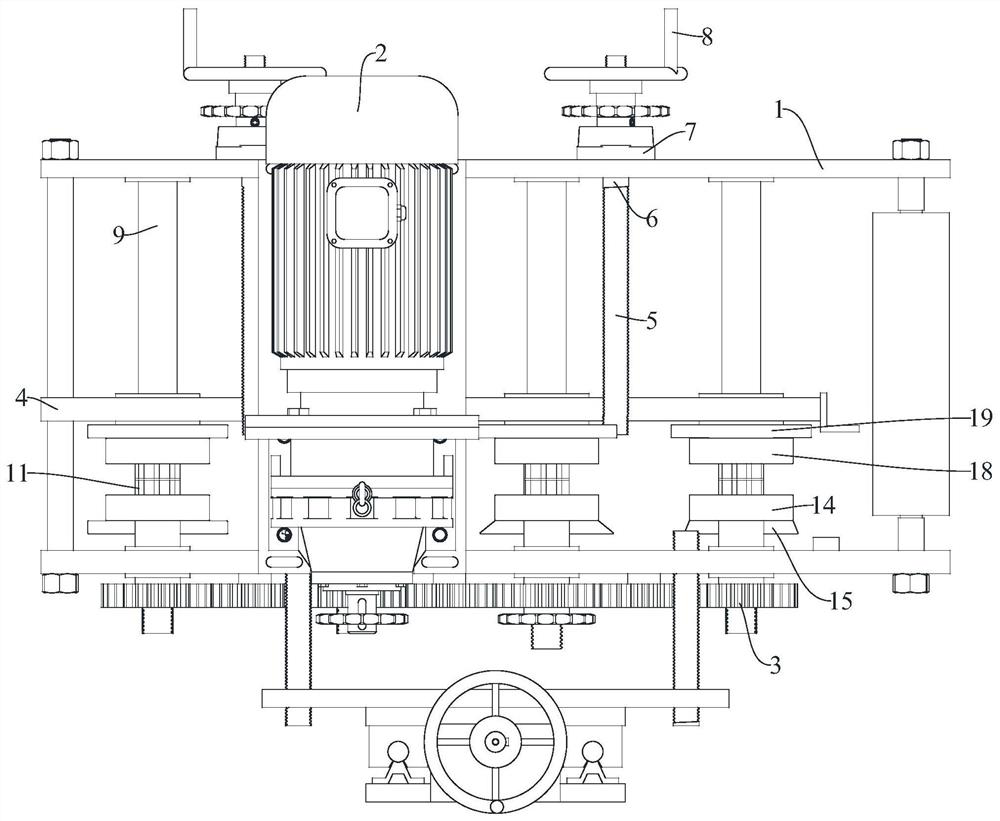

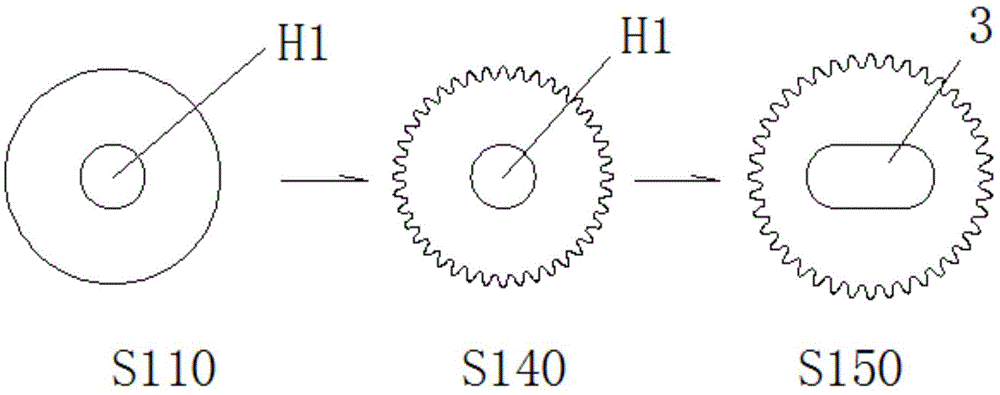

Transmission device for composite board sleeve-free edge sealing machine

PendingCN113059649AStable supportHigh precisionWood working apparatusDomestic articlesGear driveGear wheel

The invention relates to the technical field of sleeve-free edge sealing equipment matching, and particularly relates to a transmission device for a composite board sleeve-free edge sealing machine. The transmission device comprises an external main rack, an overhead driving motor and a side gear transmission set. According to the transmission device for the composite board sleeve-free edge sealing machine, an external guide roller set of an external lateral extrusion forming mechanism and a lateral linkage mechanism is movably assembled in the external main rack, the lateral linkage mechanism is synchronously controlled to turn over by pressing the lateral extrusion forming mechanism through the two ends of a composite board, and therefore the supporting performance of the bottom of the composite board is improved, and the extrusion forming precision of the two ends of the edge sealing machine is improved; and the lateral linkage mechanism is in transmission connection with a guide rod through a lateral transmission rod, an arc-shaped assembling plate is driven to turn over through stretching and retracting of the guide rod, an arc-shaped anti-skid cover makes contact with the surface of the composite board, and therefore the surface friction force is improved, the composite board is prevented from slipping in the conveying and extruding process, and the transmission and extrusion forming efficiency is improved.

Owner:江苏孜俊自动化科技有限公司

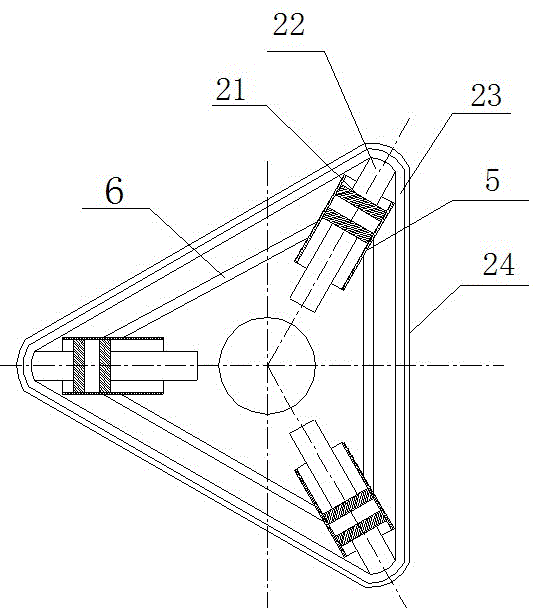

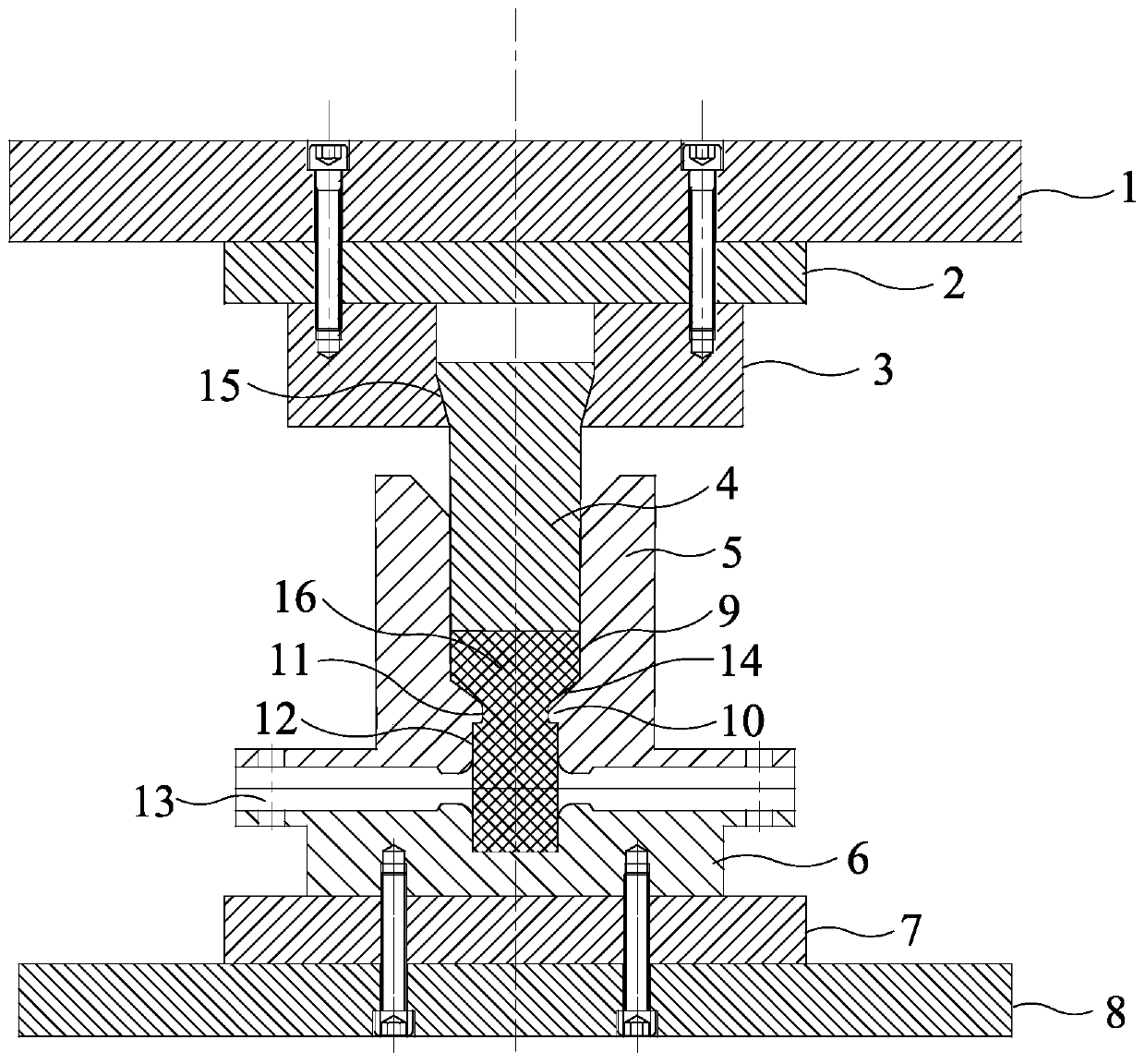

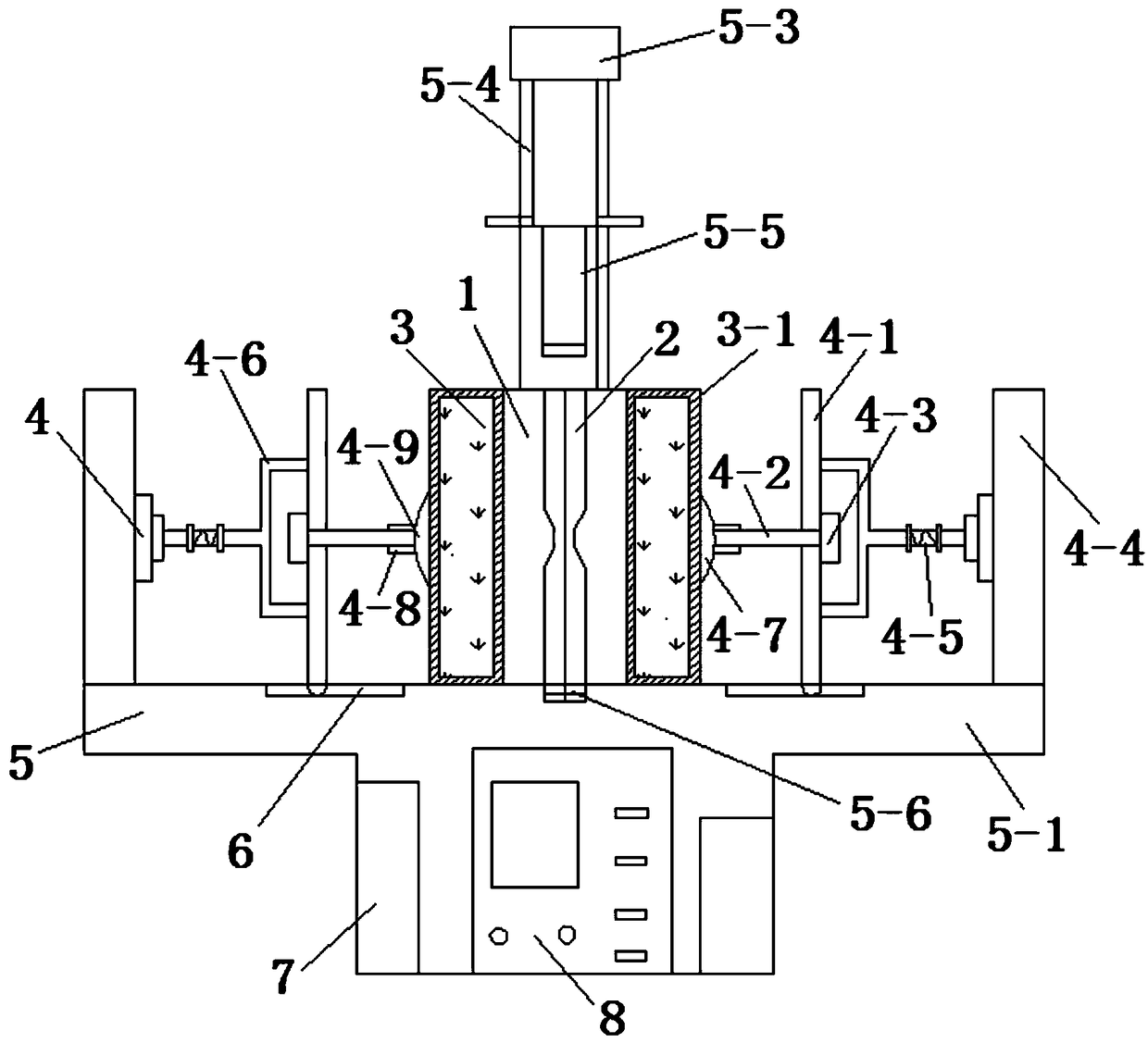

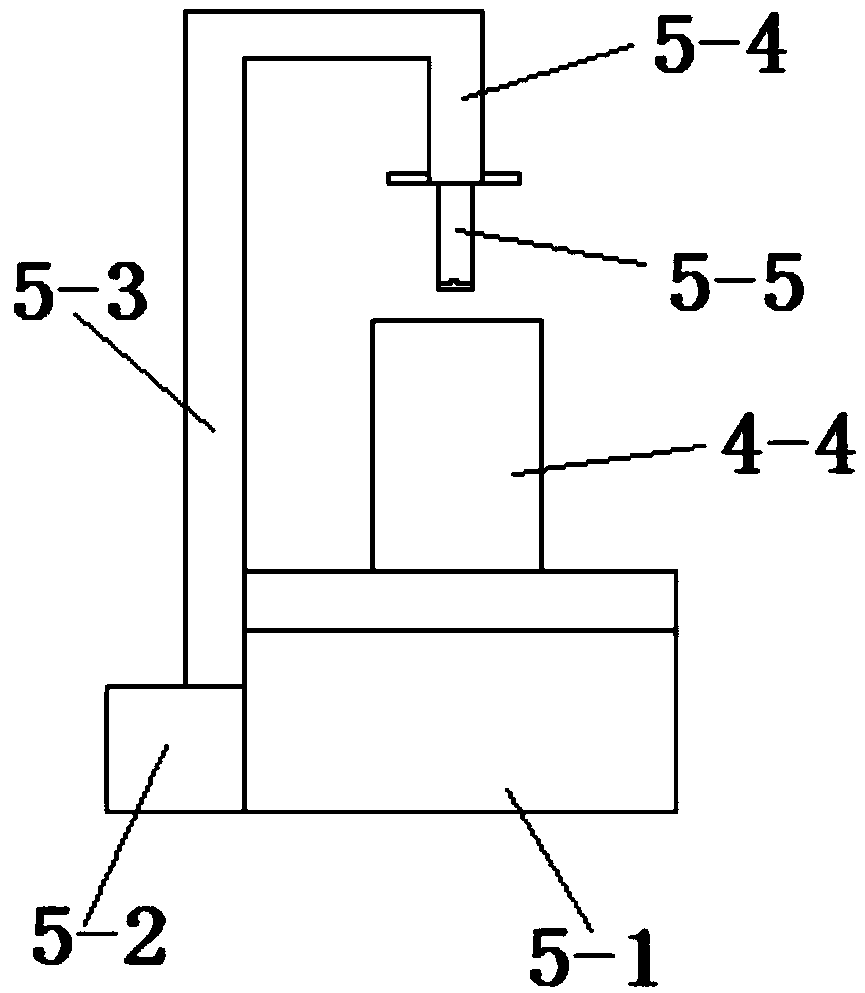

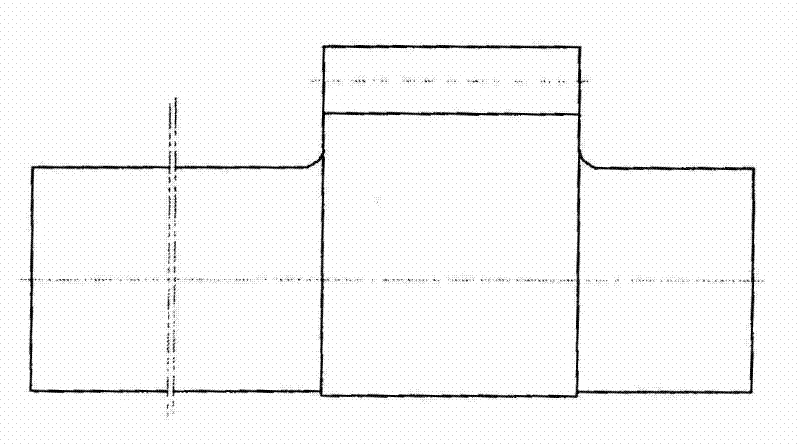

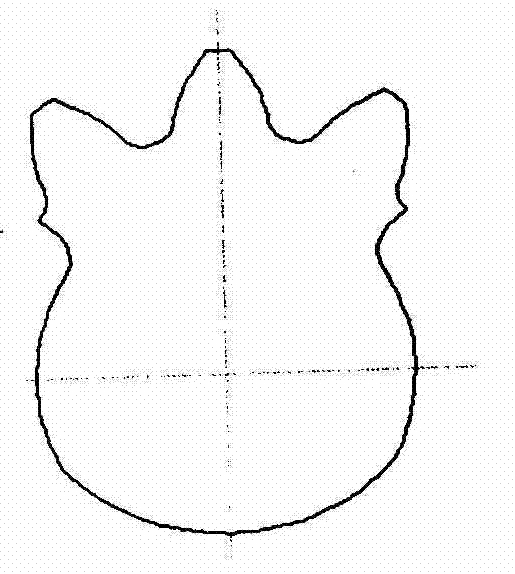

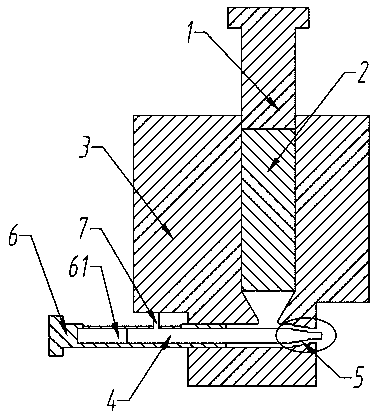

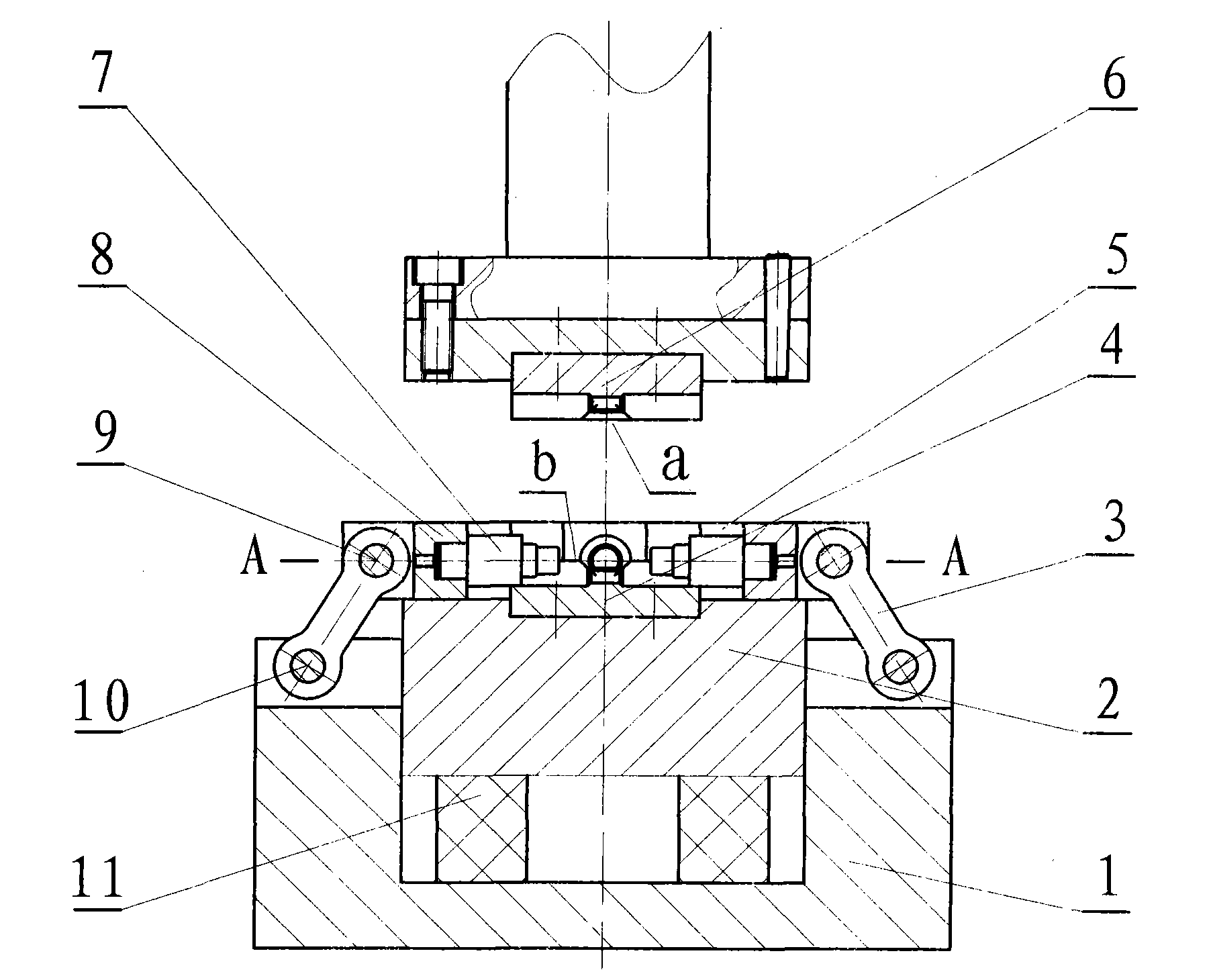

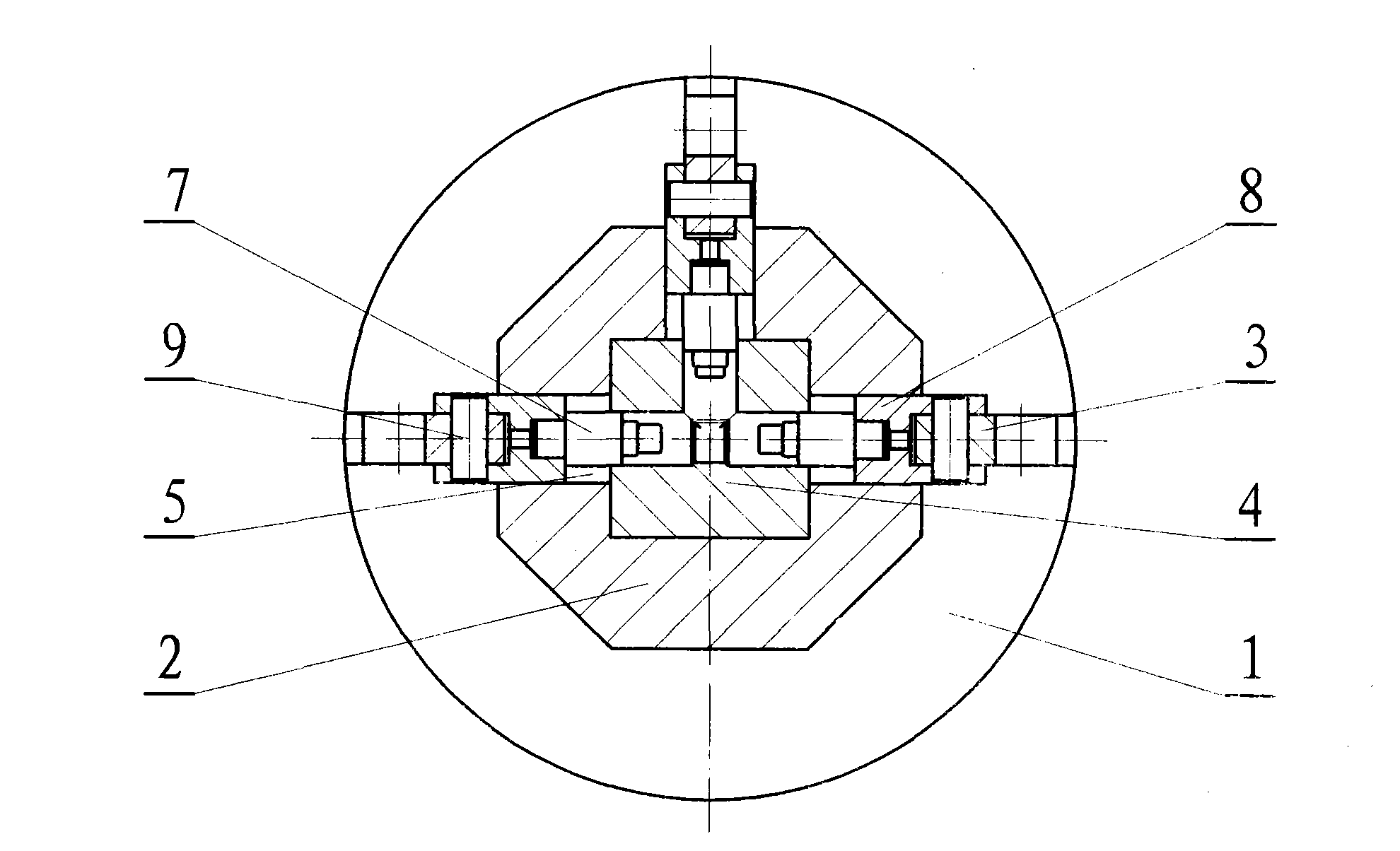

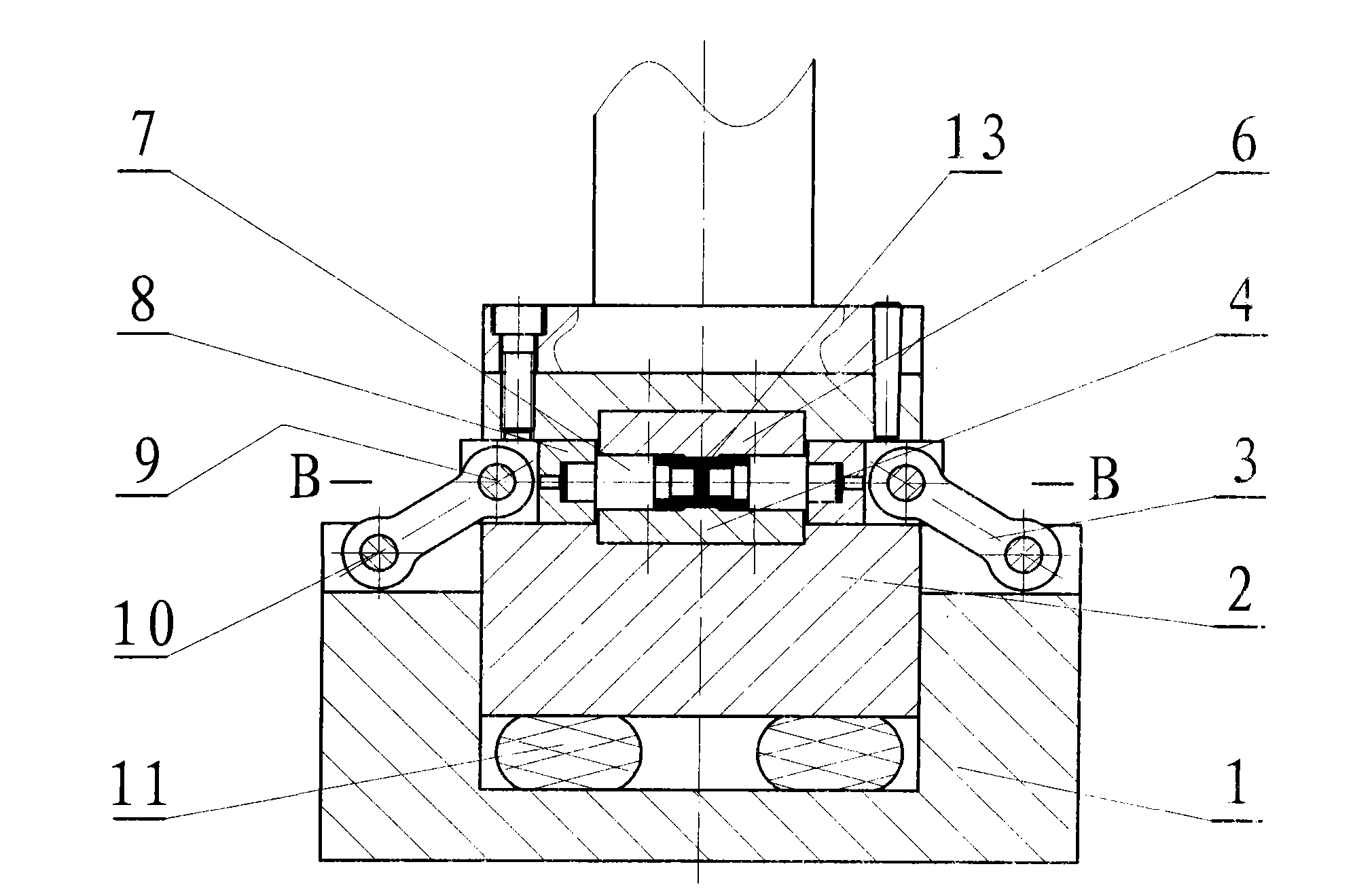

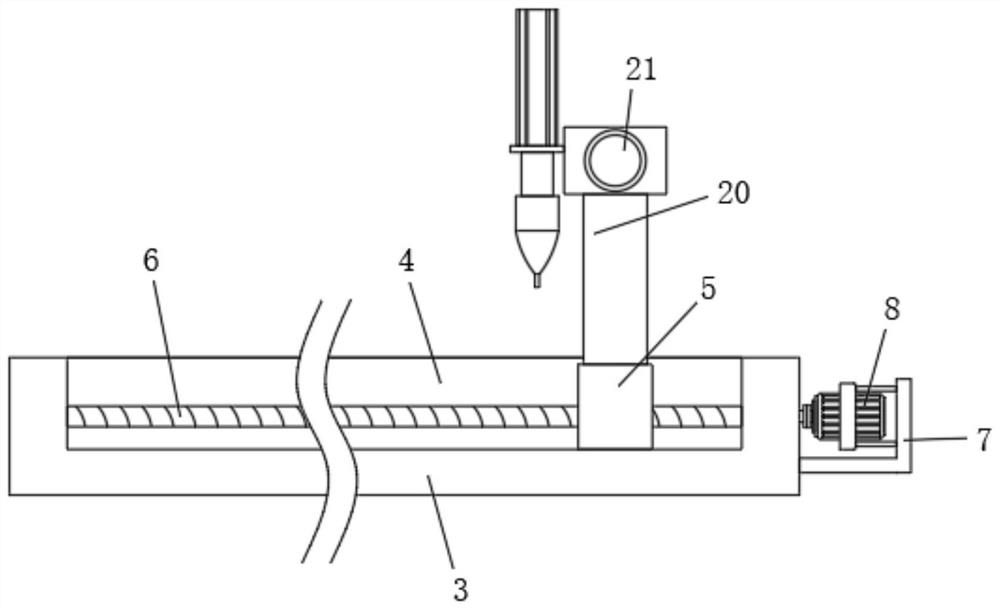

Thermal precise forming method and device for toothed steering rocker arm shaft

ActiveCN102228948ASimple processShort processUpsetting pressesSwagging pressesHydraulic cylinderEngineering

The invention discloses a thermal precise forming method and a thermal precise forming device for a toothed steering rocker arm shaft. The method is characterized in that: a toothed steering rocker arm shaft precision forging is formed by a one-step method in a forming mode of positive extrusion upsetting and lateral extrusion; and the method comprises the following steps that: a metal blank is put into a female die and an extrusion upsetting sleeve, a sliding block of a hydraulic press starts descending, an upper punch head starts contacting and extruding the metal blank, the metal blank flows into the fan-shaped cavity of the female die under the extrusion of the upper punch head, a lateral hydraulic cylinder starts pressing when the fan-shaped cavity is full of the metal blank so as to drive a lateral toothed punch head to extrude the metal blank flowing into the fan-shaped cavity, the pressure and the stroke of the sliding block of the hydraulic press and the lateral hydraulic cylinder are numerically controlled, and the toothed steering rocker arm shaft precision forging is extruded under the combined action of the upper punch head and the toothed punch head. The method has the characteristics of one-step formation, simple process and short flow, and fulfills the purposes of high efficiency, energy conservation and material economization of precise forming.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

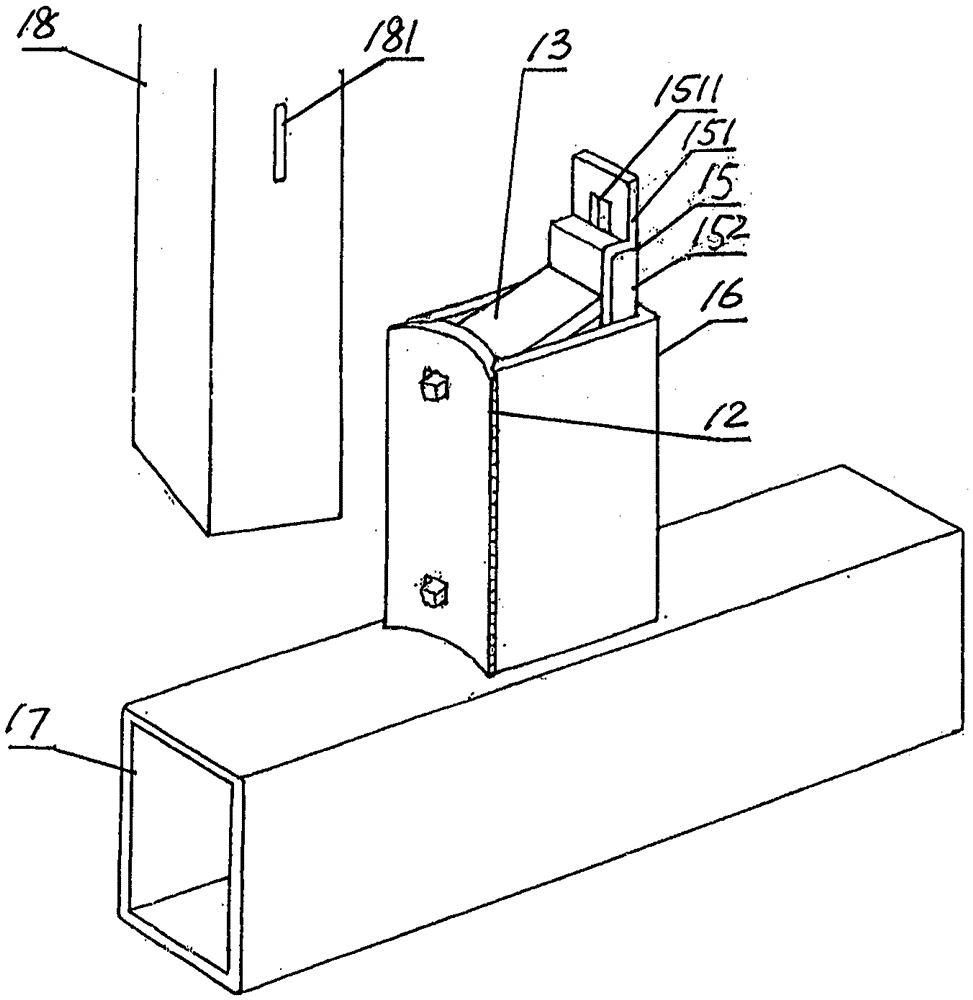

Inclined plate and application thereof

The invention provides an inclined plate and an application thereof. The inclined plate is an inclined rectangular flat plate, and two ends of the plate are attached to two planes which are perpendicular to each other; the two ends of the inclined plate can slide on the two planes; when pushing force is applied to one end of the inclined plate in the direction parallel to the corresponding plane and perpendicular to the other plane, pushing force parallel to the corresponding plane and perpendicular to the other plane is generated at the other end of the inclined plate. The former pushing force drives the inclined plate to slide, and the later pushing force acts on a corresponding work object through the other end. In the process, the pushing force is increased, and the direction is turned for 90 degrees. When the inclined plate is taken as a locating part for a lifting table or a temporary connecting piece of a rectangular pipe, longitudinal force is increased to extrude inner and outer pipe walls transversely, and locating is realized. The structure is simple and the operation is convenient. Adjustment of the lifting table is finished instantly, connection of the rectangular pipe is realized within 5 s, and dismounting only needs 2 s. The inclined plate is driven through conversion of the longitudinal force, is abutted from the lateral back surface and can only advance without retreating, so that the locating is firm and free of shock influence, and the anti-shock and anti-fatigue performance is not inferior to that of welding. The inclined plate is quite simple, thereby being taken as a basic machine to be applied to extensive fields.

Owner:饶弘剑

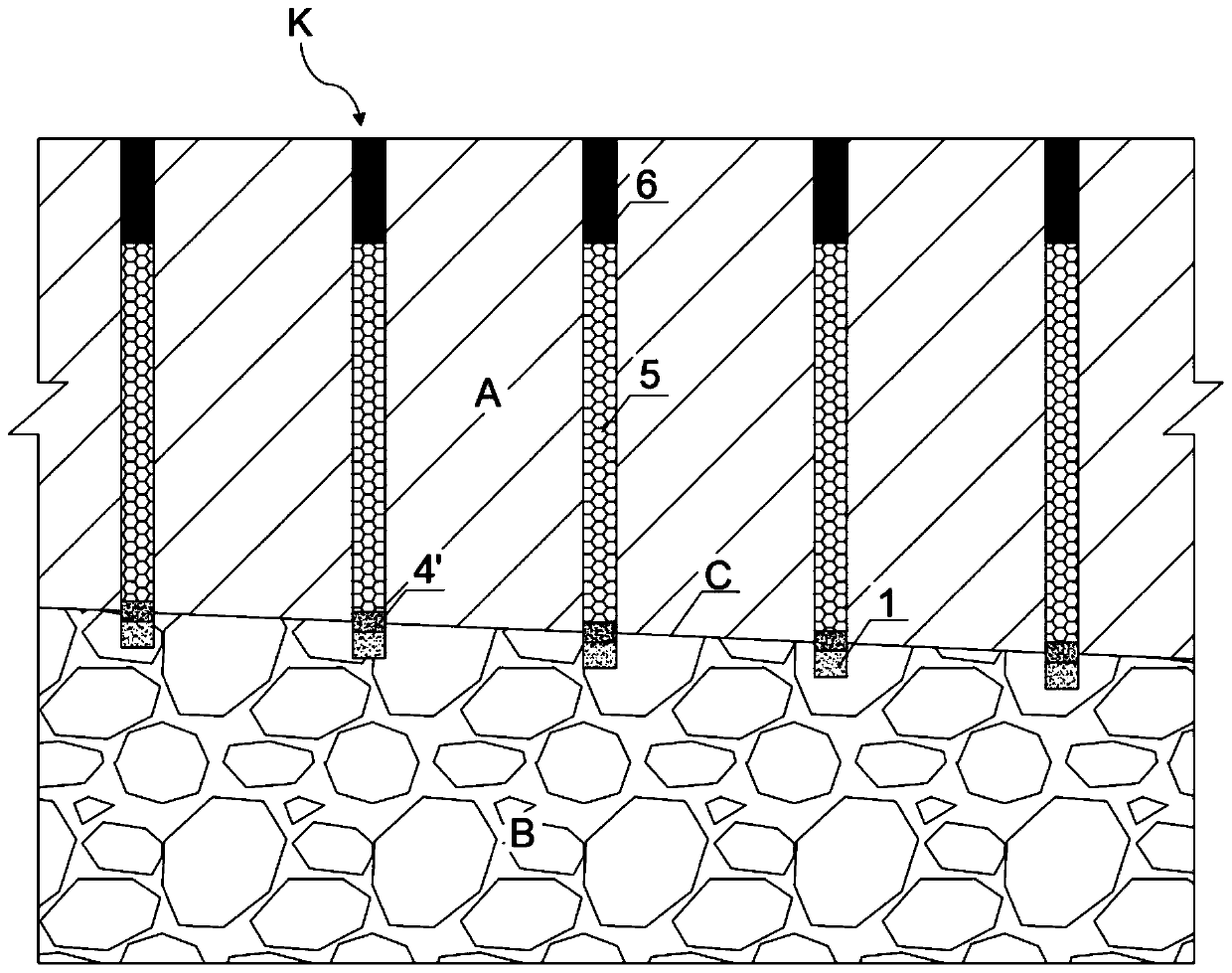

Non-destructive blasting excavation method without integrated rock interface foundation

The invention discloses a non-destructive blasting excavation method without integrated rock interface foundation. The method can effectively eliminate energy, separate gas and isolate vibration, therock body damage depth at the bottom of blast holes is reduced, and the blasting effect is enhanced; the method is characterized by comprising the following steps that 1, vertical blast holes which are arranged in rows are drilled in the surface of a to-be-excavated rock body; 2, a buffer layer is laid at the bottoms of the blast holes; 3, a packaging bag with certain deformability is adopted forwrapping quick-setting high-wave impedance concrete with the expansibility so as to obtain a bagged flexible energy dissipation body, and the bagged flexible energy dissipation body is enabled to freely fall to the upper part of the buffer layer through dead weight; 4, a lifting hammer is adopted to apply lateral extrusion force to the bagged flexible energy dissipation body through hammering, sothat the bagged flexible energy dissipation body and the walls of the blast holes are preliminarily attached, after the quick-setting high-wave impedance concrete in the bag is expanded and solidified, the blast holes can be filled, and high-wave impedance concrete cushion blocks which are tightly blocked at the hole bottoms are formed; and 5, explosive are loaded and blocked in the blast holes, the explosive bag is detonated through a detonator, and rock blasting is carried out.

Owner:WUHAN UNIV

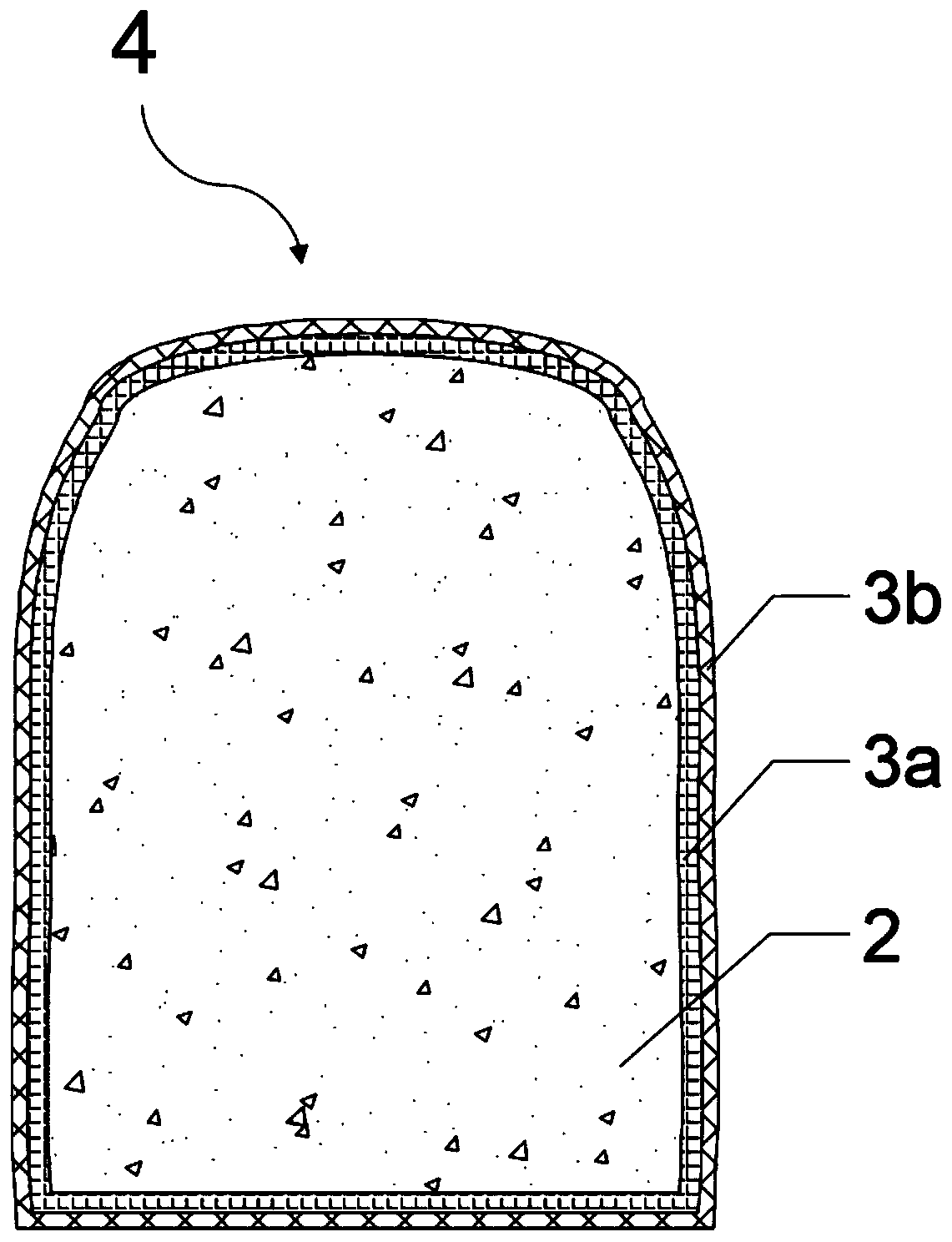

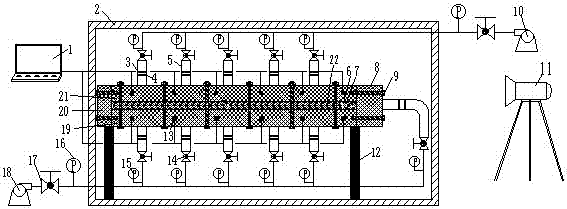

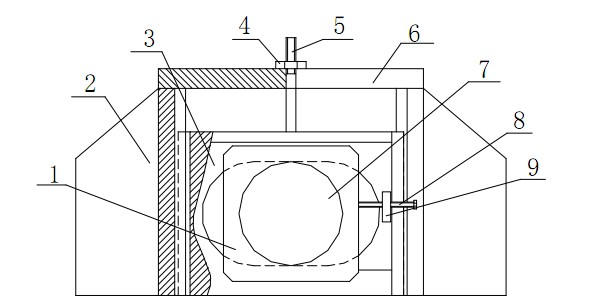

Experiment device used for simulating influences of various cause conditions on low-amplitude structural configuration

InactiveCN106896215AEasy to operateGet real-time pressure changesEarth material testingEngineeringAir compressor

The invention relates to an experiment device used for simulating the influences of various cause conditions on low-amplitude structural configuration in the technical field of geologic structures. The experiment device mainly comprises a computer system, a case body, a piston ring, a piston, a pressure pipe, sandstone particles, mudstone particles, a pressure feed ring, a bolt, an air compressor A, a high-speed camera, an iron prop, a pressure sensor, a small ball valve, a small pressure gauge, a large pressure gauge, a large ball valve, an air compressor B, a lower ground layer, a lateral substrate, an upper ground layer, and a reservoir stratum. The core of the technical scheme is that the actual condition of the underground stratum and the stress effects of differential compaction, basement uplift and lateral extrusion on the stratum in the formation of the low-amplitude structure are relatively truly simulated in the case body. The experiment device is simple in operation, and can well simulate the process of the influences of various cause conditions on the low-amplitude structural configuration.

Owner:SOUTHWEST PETROLEUM UNIV

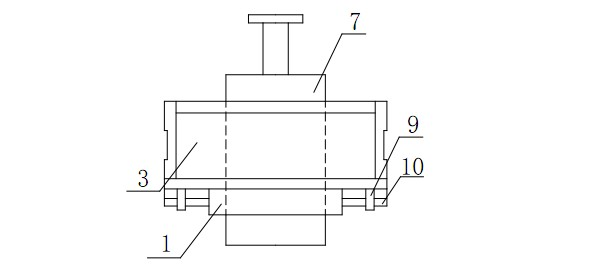

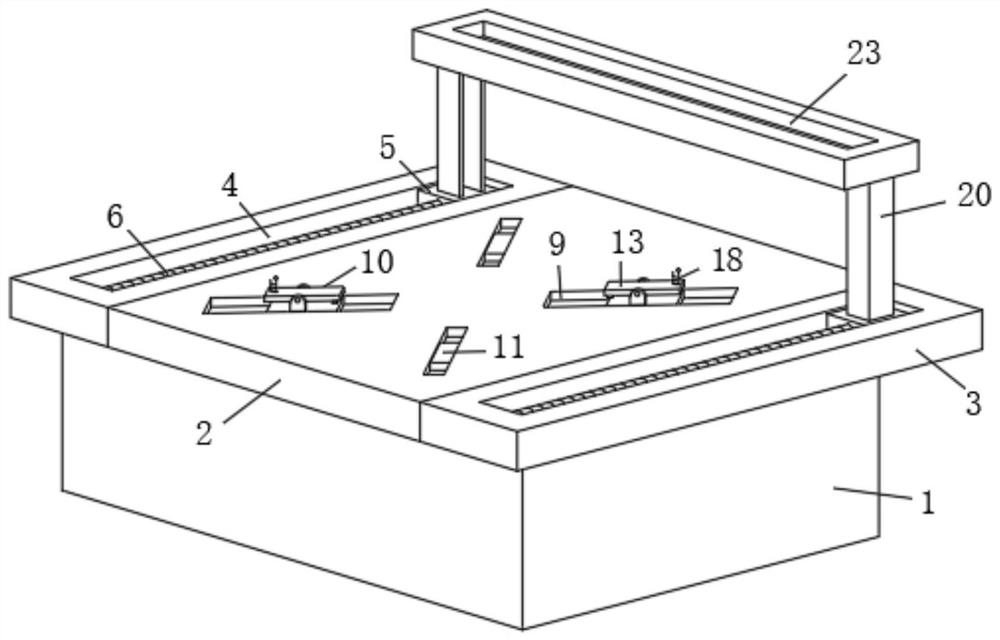

Lateral extrusion casting mechanism for multidirectional die casting machine

The invention discloses a lateral extrusion casting mechanism for a multidirectional die casting machine. The lateral extrusion casting mechanism is arranged on a foundation of the multidirectional die casting machine and comprises a supporting plate and an extrusion cylinder which are fixed on the foundation; the supporting plate is provided with a slide block which can drive the extrusion cylinder to move up and down; the slide block is provided with a sliding chute; the extrusion cylinder can be movably arranged in the sliding chute along the sliding chute; and the extrusion cylinder is connected with a hydraulic system which controls the extrusion cylinder to extend and return. The lateral extrusion casting mechanism has the advantages that: (1) the horizontal feeding for a casting isfinished; and when the casting has high dimensional accuracy requirement on the horizontal direction, the local feeding for the casting can be finished by controlling the displacement of all movementdirections of the lateral extrusion casting mechanism; and (2) a piston rod of the extrusion cylinder can finish vertical, horizontal and longitudinal three-freedom-degree movement to meet the requirements of certain castings with asymmetric structures on the feeding positions.

Owner:重庆市明鑫机械制造有限公司

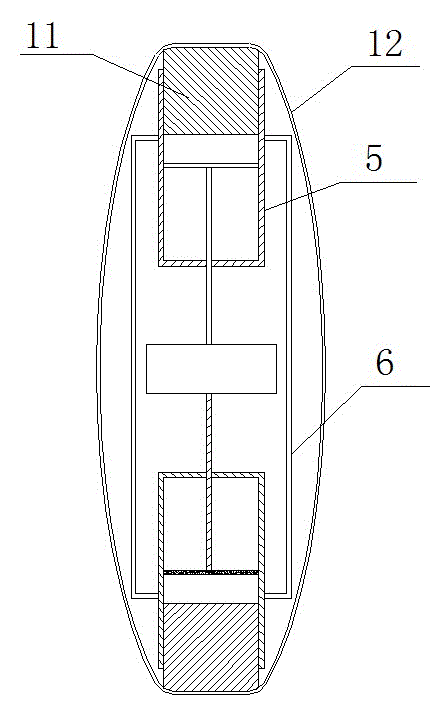

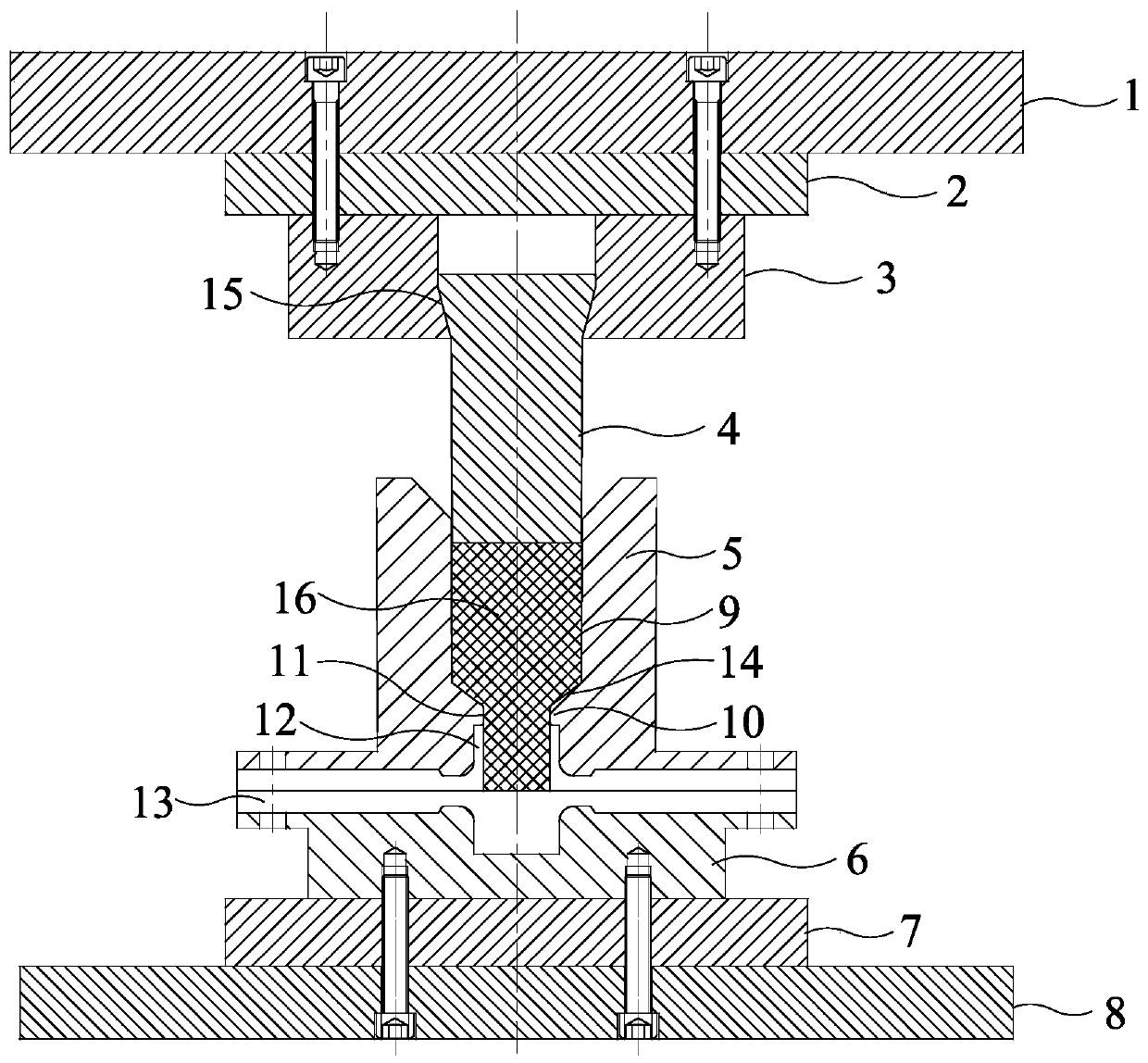

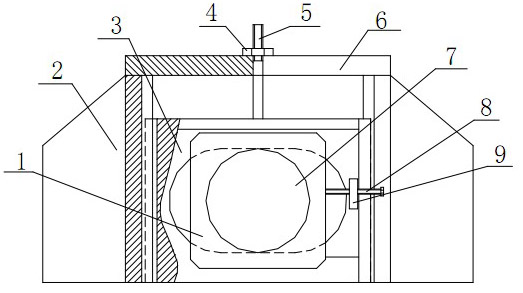

Magnesium alloy thin wall pipe bidirectional extrusion forming mold and forming method of magnesium alloy thin wall pipe

ActiveCN110576070AKnow the temperature in real timePrecise control of extrusion temperatureExtrusion diesExtrusion control devicesToughnessThin walled

The invention discloses a magnesium alloy thin wall pipe bidirectional extrusion molding mold and a molding method of a magnesium alloy thin wall pipe. The mold comprises a concave mold, an extrusionrod and an extrusion needle, a forward extrusion cavity, a lateral extrusion cavity and a concave mode cavity which communicate with one another are arranged in the concave mold; the extrusion rod comprises a forward extrusion rod and a lateral extrusion rod, the upper end of the forward extrusion rod is connected with a main cylinder of the hydraulic machine, the lower end the forward extrusion rod is matched with the forward extrusion cavity, one end of the lateral extrusion rod is connected with the side cylinder of the hydraulic machine, and the other end of the lateral extrusion rod is arranged in the lateral extrusion cavity and is in clearance fit with the extrusion needle; the shape of one end of the extrusion needle close to the concave mode cavity corresponds to the shape of theconcave mode cavity, and a pipe forming cavity is formed between the extrusion needle and the concave mode cavity; and after a blank is extruded in the forward direction by the forward extrusion rod,the blank is extruded in the direction of the pipe forming cavity by the lateral extrusion rod. The magnesium alloy thin wall pipe bidirectional extrusion molding mold and the molding method of the magnesium alloy thin wall pipe can effectively improve the strength and toughness of the magnesium alloy thin wall pipe after forming.

Owner:CHONGQING UNIV OF TECH

Novel movement recoil type hot extrusion forming and processing method

InactiveCN102632176ASimple structureReasonable power distributionExtrusion diesForging/hammering/pressing machinesElastomerForge

The invention relates to a novel movement recoil type hot extrusion finish forge forming and processing method and belongs to the technical field of hot (warm) extrusion forging. According to the invention, a used hot extrusion finish forge die comprises a lower concave die, a transverse convex die base, a transverse convex die, an upper concave die, a connecting rod and an elastomer. The method comprises the step of carrying out whole downward movement on the upper concave die and the lower concave die which are closed as well as a lower die base, wherein in the downward movement process, the lower die base and a support plate are supported and connected by the elastomer; and carrying out lateral extrusion and feed of a blank on a die head through a fixed hinge formed by a support base plate and the connecting rod, and a moveable hinge formed by the connecting rod and the transverse convex die. The method disclosed by the invention has the obvious advantages that die structure is simple, dynamic distribution is reasonable, work efficiency is high, and energy is saved.

Owner:JIANGSU HAIDA PIPE FITTINGS GROUP

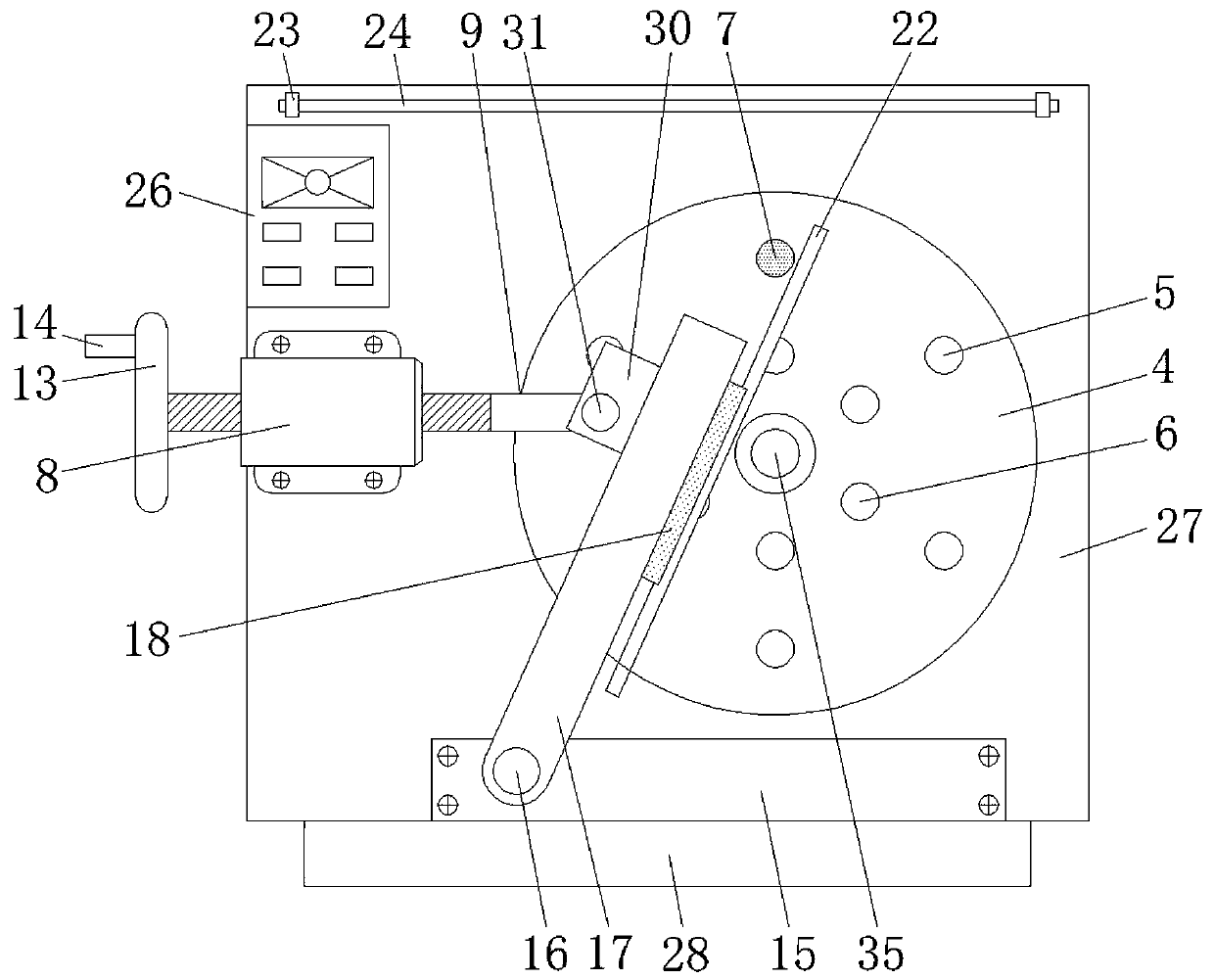

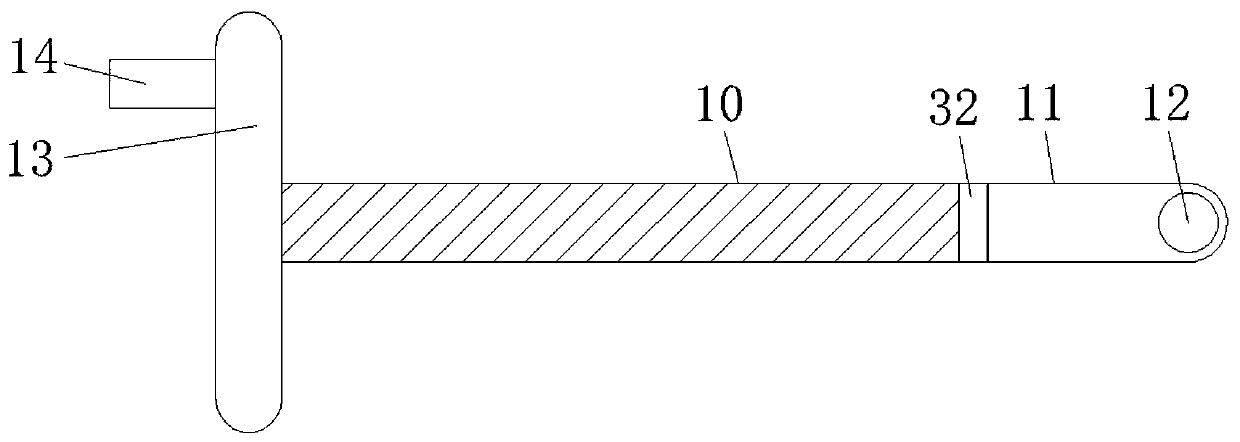

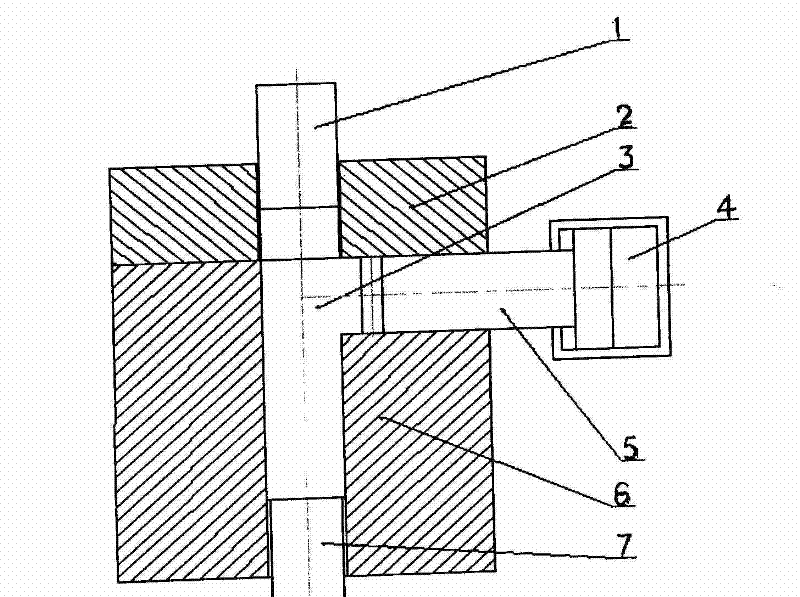

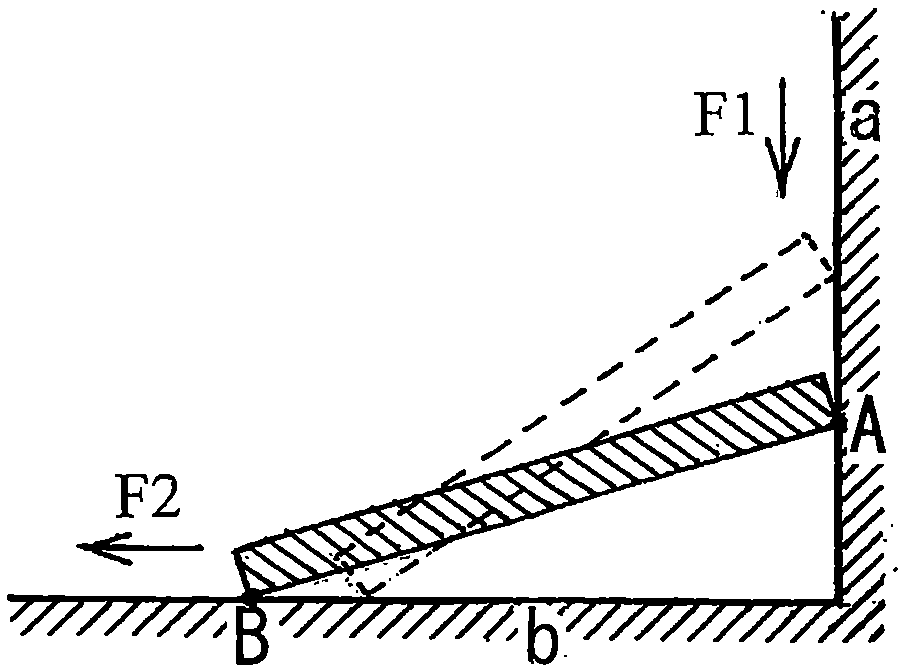

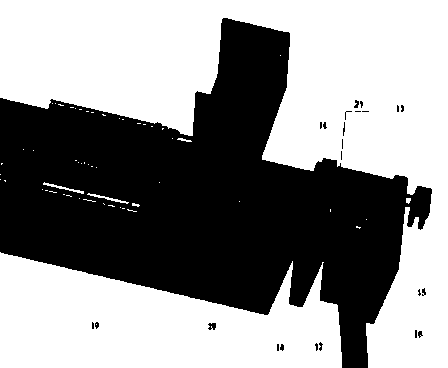

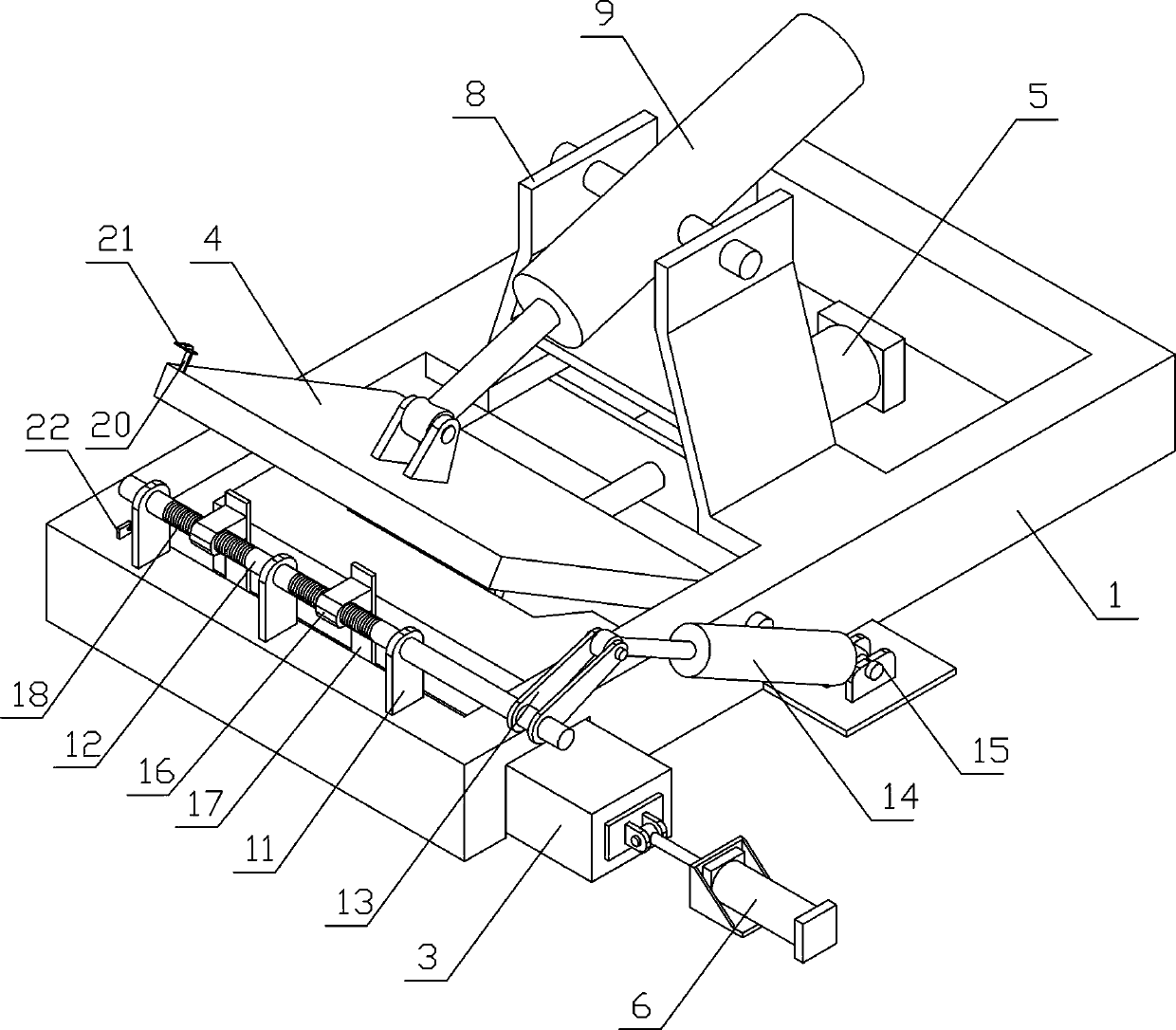

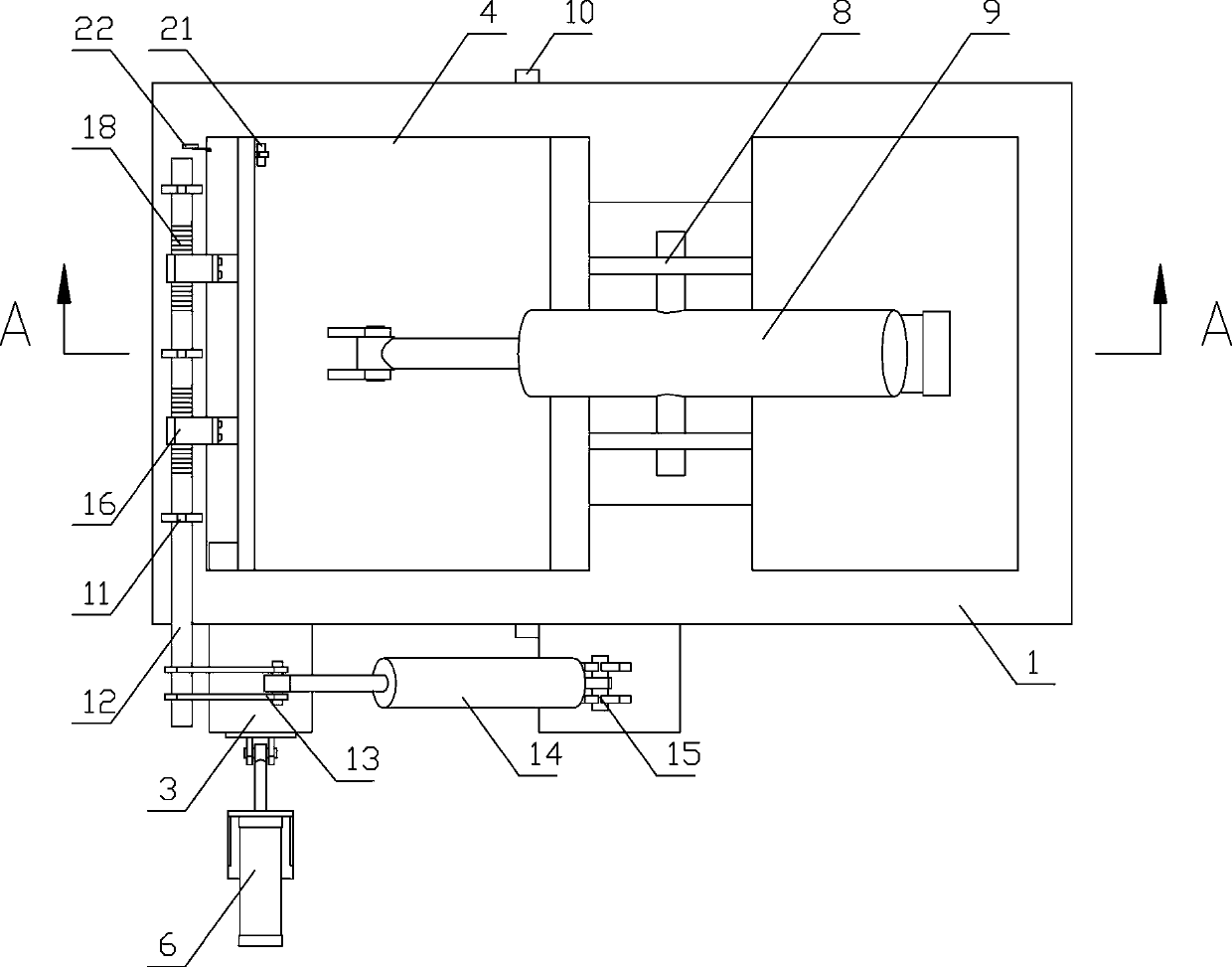

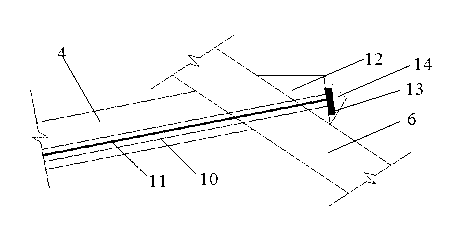

Horizontal detonator full-automatic bayonet machine

InactiveCN103664428ASuccessfully realize bayonet operationGuarantee the safety of lifeDetonatorsDetonatorEngineering

The invention relates to a horizontal detonator full-automatic bayonet machine. The horizontal detonator full-automatic bayonet machine is composed of 10 independent bayonet units and a stepping mould conveyer. One bayonet action comprises following steps: a detonator shell is delivered into a detonator shell guide groove 14; a detonator shell push-out cylinder 10 is pushed by a shell pushing cylinder 11, so that the detonator shell is delivered to a preset bayonet position; at the same time a detonator explosive head on an explosive head mould 4 is delivered into the detonator shell by an explosive head delivering cylinder 5; a connecting rod 3 is driven by piston telescoping of a bayonet action cylinder 1, a reciprocating seat 15 is driven to move for lateral extrusion of a collet chuck 21, and so that detonator bayonet is completed; the detonator shell push-out cylinder 10 is protruded so as to push the detonator treated via detonator bayonet out of the collet chuck 21, and convey the detonator into the explosive head mould 4; at the same time, a mould blocking cylinder 12 is protruded so as to block the explosive head mould 4; a positioning plate of the mould blocking cylinder 12 is driven by a stepping cylinder so as to convey the explosive head mould 4 to a next station; and then the cylinders are all driven back to initial positions. According to the horizontal detonator full-automatic bayonet machine, pipeline operation is completed via motions of the stepping mould conveyer.

Owner:HUNAN SHENFU GRP XIANGHONG MACHINERY CHEM

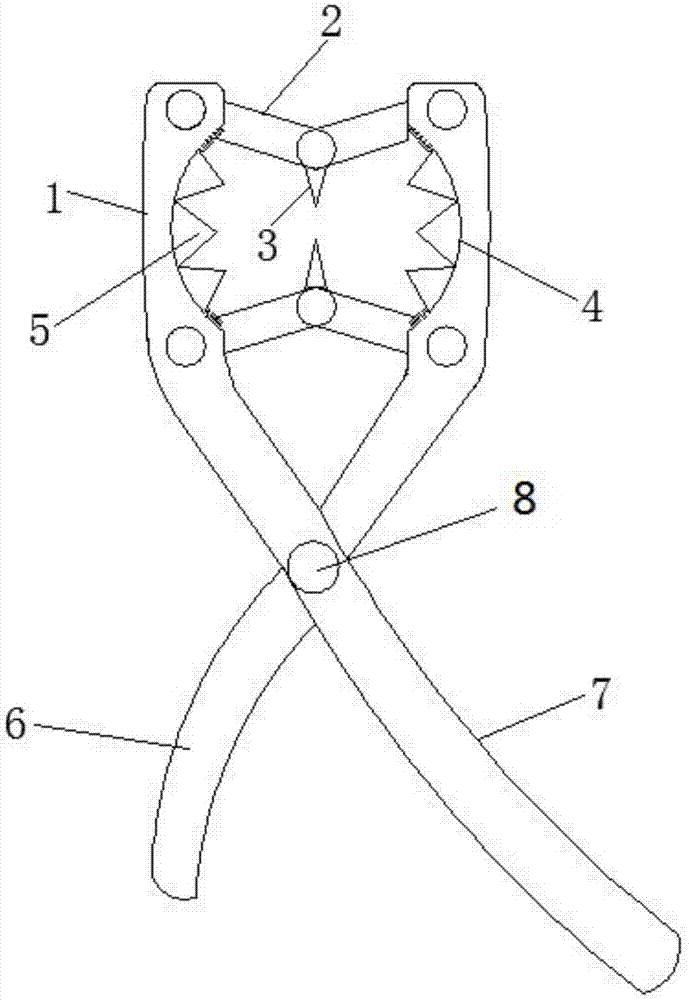

Nutshell flying preventive cracker

The invention relates to a nutshell flying preventive cracker. The nutshell flying preventive cracker comprises two clamping handles. The clamping handles are hinged to each other through a pin. One end of each clamping handle is an extrusion end, and the other end of each clamping handle is a hand holding end. The extrusion ends comprise extrusion blocks arranged at the ends of the clamping handles. The nutshell flying preventive cracker is characterized in that a vertical extrusion device hinged to the extrusion blocks is arranged between the two extrusion blocks. The nutshell flying preventive cracker has the advantages that the structure is simple, nuts are extruded transversely and vertically, and accordingly, nut shells can be cracked without large force during operation; the transverse extrusion blocks and the vertical extrusion device are connected in a hinged mode and can apply force to the nuts at the same time, good blocking effect in the transverse and vertical directions is achieved, the nut shells are prevented from being stressed to splash around, and high practicability and promotional value are achieved.

Owner:SUZHOU VOCATIONAL UNIV

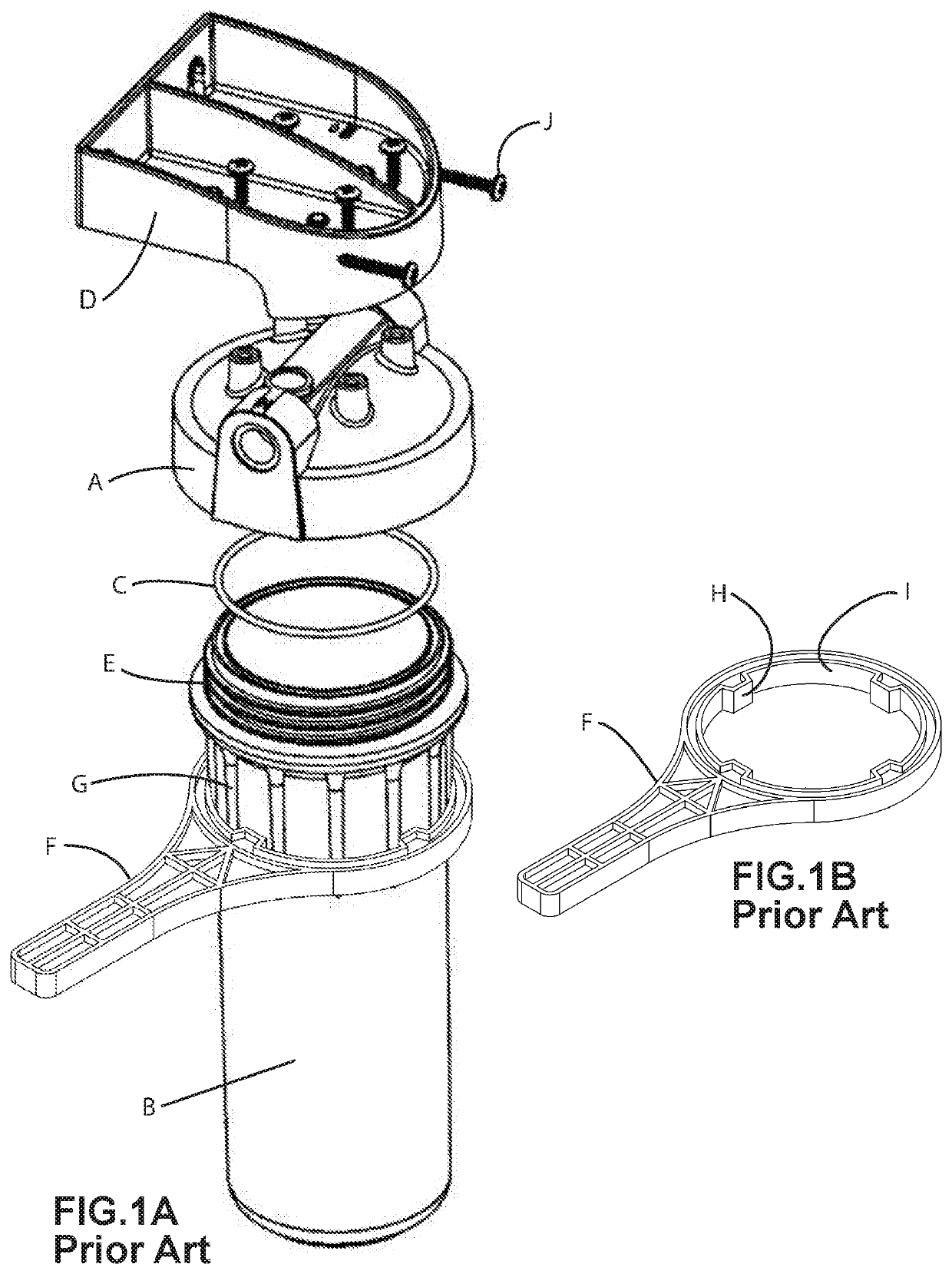

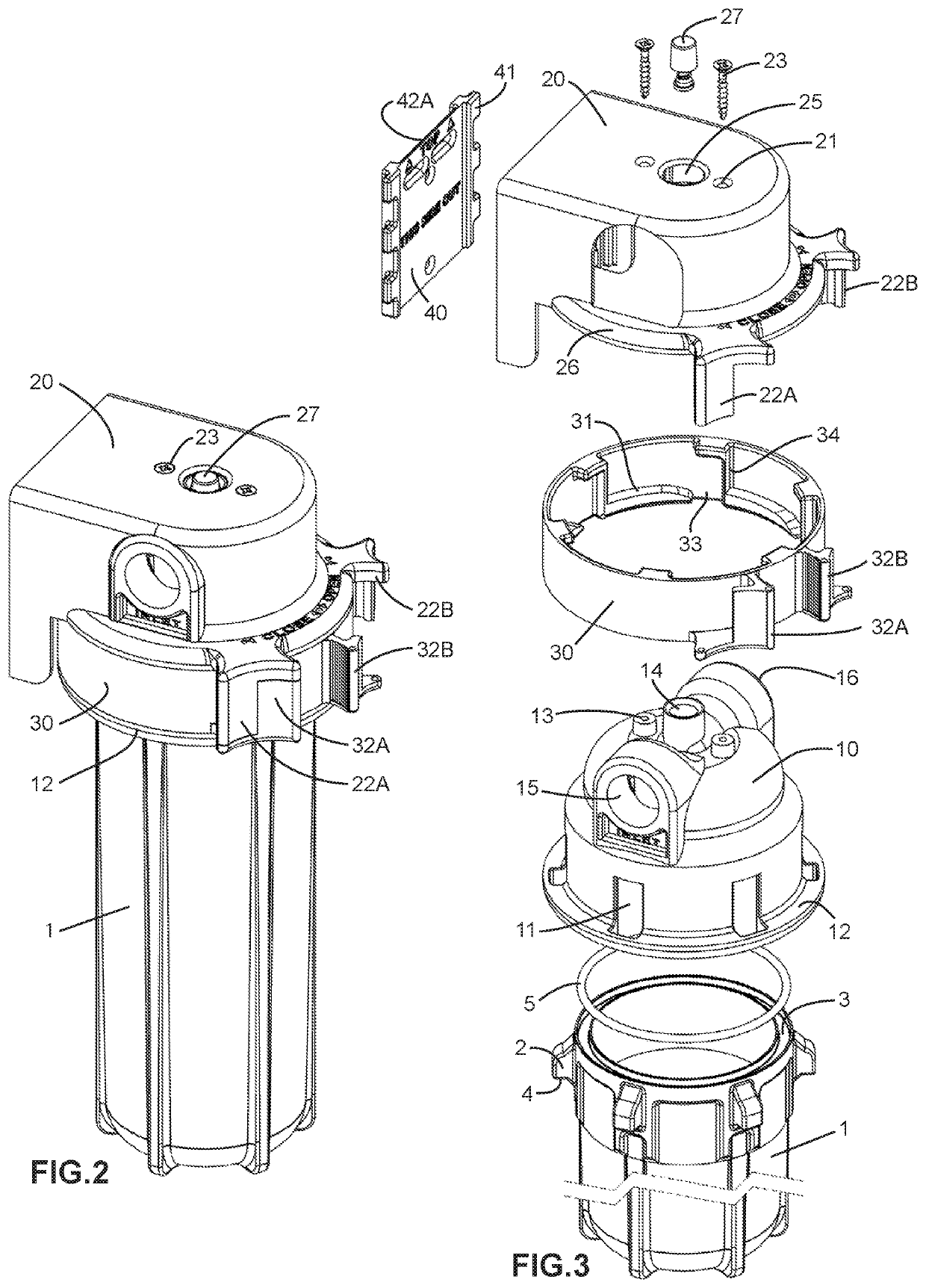

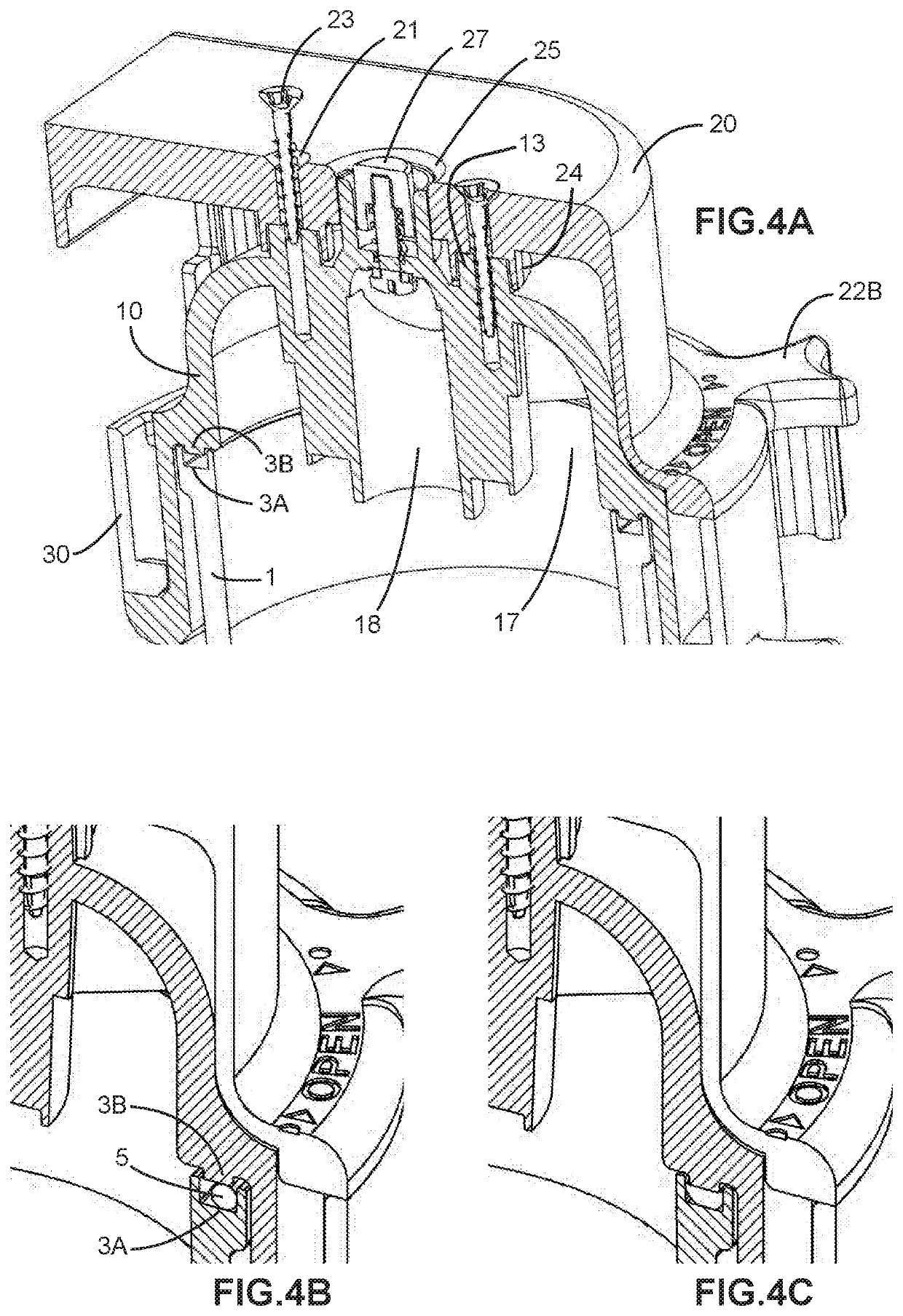

Manually detachable enclosure for replaceable filter elements and the like

ActiveUS10918982B1Quickly and easily attachedQuickly and easily and detachedMembrane filtersStationary filtering element filtersEngineeringMechanical engineering

An apparatus and method for using a detachable sealed enclosure for containing and quickly accessing filter elements and the like without the use of tools and without the possibility of initial or subsequent over tightening. A first set of paired protrusions receive lateral pinch forces which draw the enclosure into a sealed connection with a lid while selectively compressing a seal between these components. A second set of paired protrusions receive lateral pinch forces which release the sealed connection, providing access to the enclosure content.

Owner:SUTTON JEPSON

Prism glass cutting machine

PendingCN111875245AAvoid displacementHigh precisionGlass severing apparatusMetal working apparatusClassical mechanicsStructural engineering

The invention discloses a prism glass cutting machine, which comprises an equipment base; a placing plate is fixedly connected to the top of the equipment base, four second sliding grooves are formedin the top of the placing plate in a digging mode, clamping mechanisms are arranged in the second sliding grooves, sliding ways are fixedly connected to the two sides of the placing plate, and first sliding grooves are formed in the tops of the two sliding ways in a digging mode; first sliding blocks are slidably connected to the interiors of the two first sliding grooves correspondingly, and a connecting frame is connected to the tops of the two first sliding blocks. According to the glass cutting device, a clamping mechanism is arranged, a glass plate needing to be cut can be clamped and limited, glass displacement caused by lateral extrusion force when the glass plate is cut is prevented, and the glass cutting precision is improved; besides, the clamping mechanism drives the clamping plate and the extrusion block to get close to the second sliding block through rotation of the second threaded rod so as to achieve the clamping effect, the clamping tightness degree can be freely adjusted, and the situation that the glass is broken due to large extrusion force is avoided.

Owner:深圳市圭华智能科技有限公司

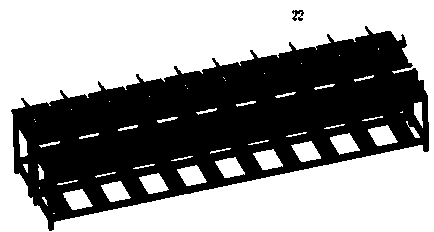

Metal turn-milling scrap packing device

The invention provides a metal turn-milling scrap packing device. The device comprises a rectangular molding groove, wherein a molding station is formed on the left side of the molding groove, and a transverse extrusion block, a longitudinal extrusion block and an overturning press block corresponding to the molding station are arranged cooperatively; the transverse extrusion block is connected with a transverse main-pushing hydraulic cylinder; the longitudinal extrusion block is connected with a longitudinal lateral-pushing hydraulic cylinder; a vertical bracket is arranged on the upper sideof the molding groove and hinged with an overturning oil cylinder in the radial direction, the telescopic end of the overturning oil cylinder is hinged with the back side of the overturning press block, and the non-overturning end of the overturning press block is hinged with the front side wall and the back side wall of the molding groove through a longitudinal shaft; a plurality of bearing seatswhich are distributed side by side are arranged at the left end of the molding groove, deflection rods driven by a deflection oil cylinder to perform deflection motion are assembled in the bearing seats, and L-shaped turning hooks are mounted on the deflection rods. According to the device, bulk metal turn-milling scraps are pressed into a rectangular square structure, so that occupation of sitespace is greatly reduced, feeding and discharging are convenient, and industrial injury accidents are avoided.

Owner:黄石市瑞通机械有限公司

Printing and dyeing wastewater recovery equipment

ActiveCN112941780AEasy to pass throughAchieve recyclingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsElectric machineryProcess engineering

The invention provides printing and dyeing wastewater recovery equipment, and belongs to the technical field of dyeing and finishing. Two spreading motors are arranged, a spreading belt is used for driving a plurality of spreading rollers to rotate, the two spreading motors operate in opposite directions, the spreading rollers are divided into two parts, the two parts correspondingly rotate outwards in the opposite directions, extruded cloth is spread again, the size of a gap between two transverse extrusion rollers is changed through downward stretching of a first push cylinder, so that the extrusion dehydration effect on the cloth with different thicknesses is realized, and the universality of the device is improved; meanwhile, the transverse extrusion roller on the lower side is controlled to move downwards, before the device works, the cloth can conveniently penetrate through the extrusion gap, and manual operation is facilitated; and dye water attached to the cloth is extruded out and guided back to a dye vat through a flow guide hopper by controlling a second push cylinder to stretch out and utilizing the extrusion dewatering effect of a vertical extrusion roller on the cloth, recycling of the dye water is achieved, so that water resources are saved, the sewage discharge amount is reduced, and the production cost of a factory is greatly reduced.

Owner:绍兴国泰印染有限公司

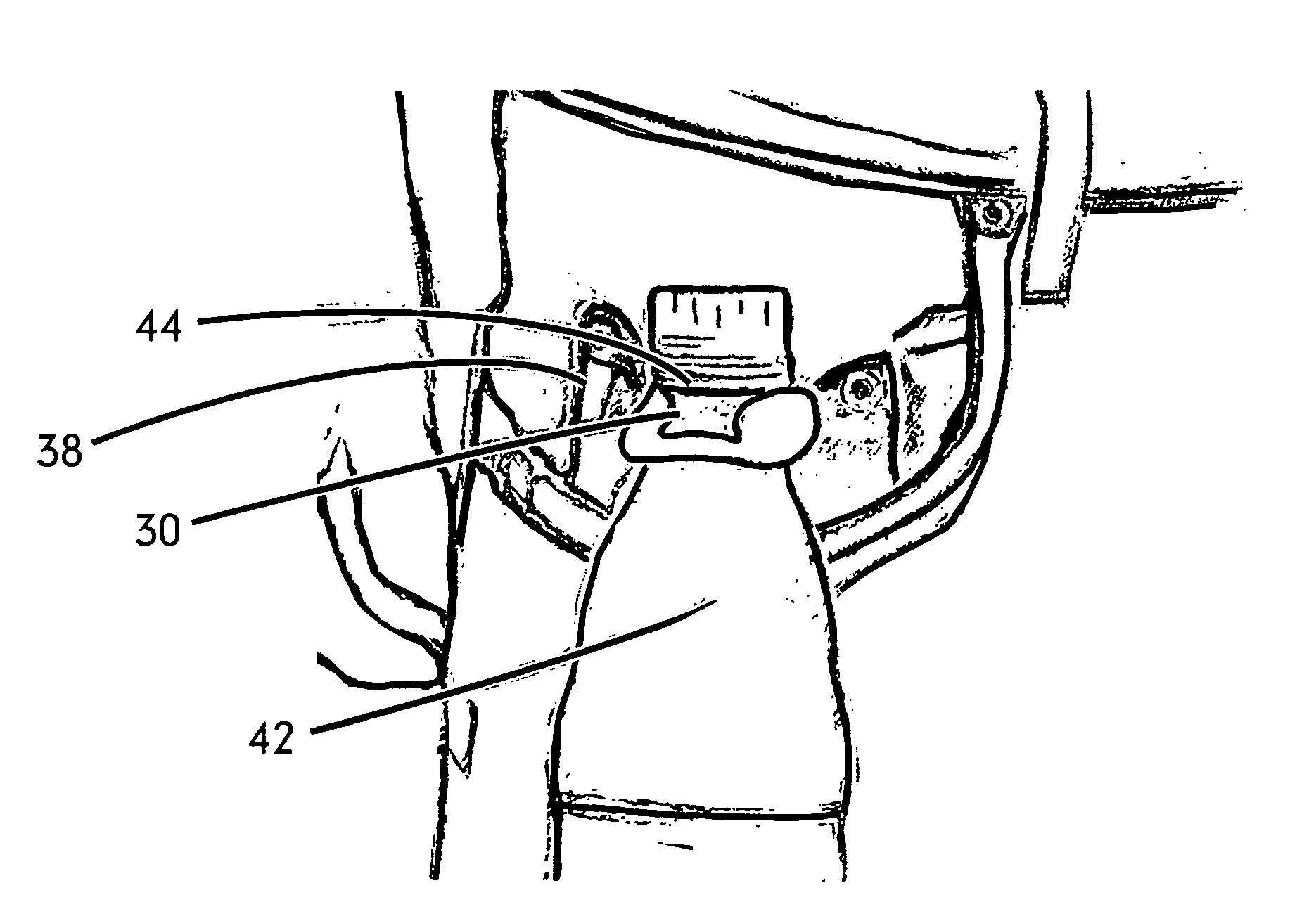

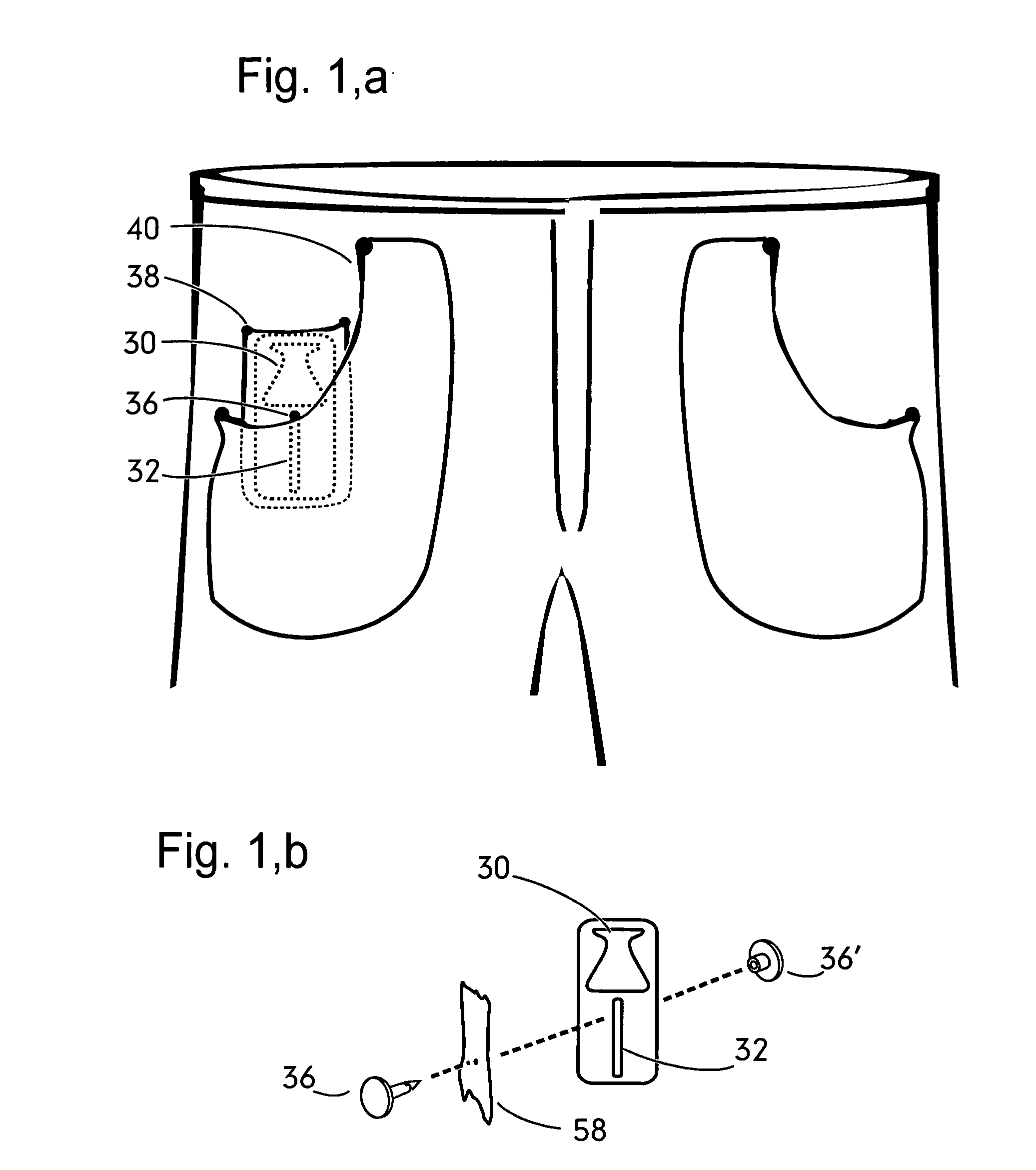

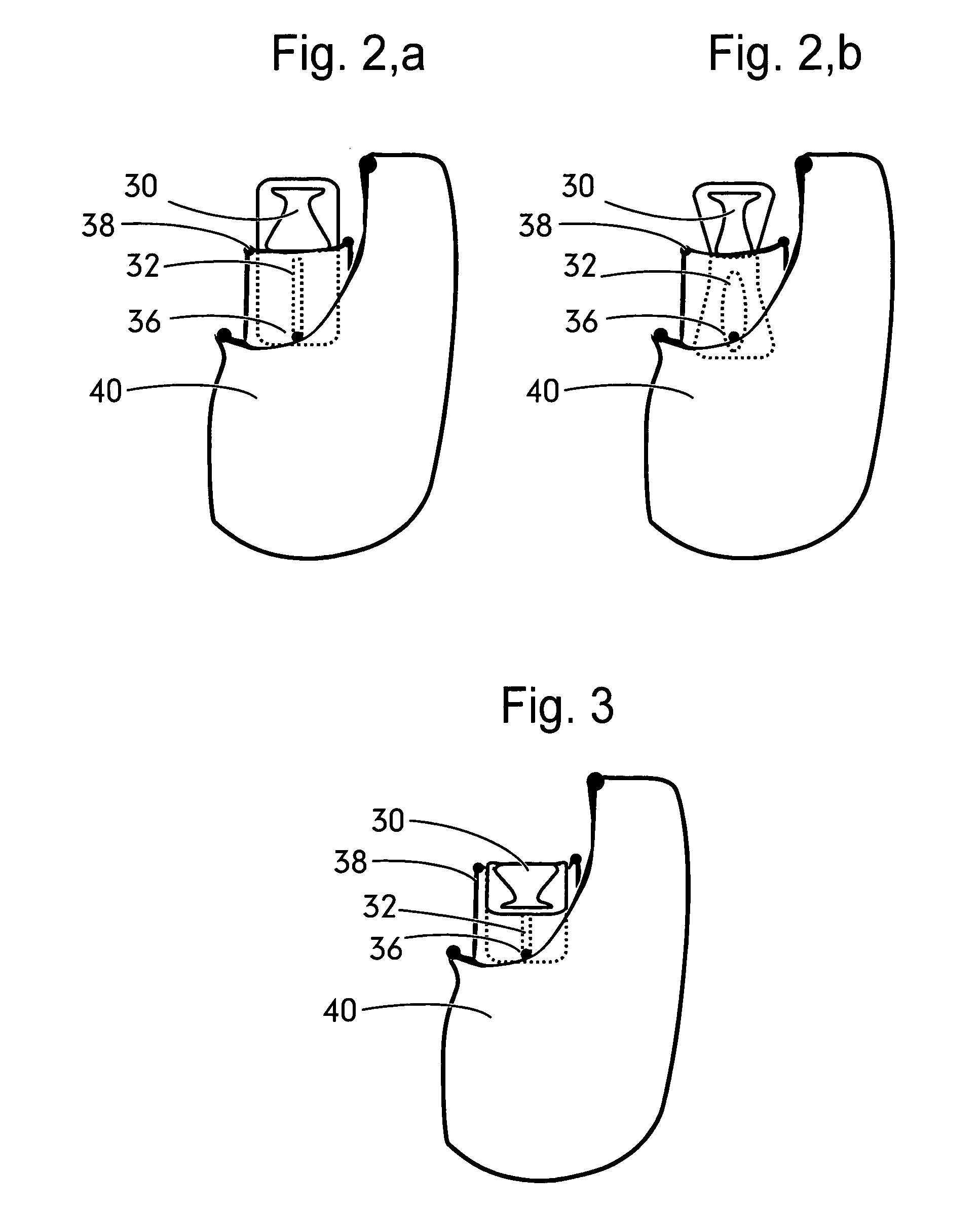

Coin pocket bottle carrier

A removable bottle carrying attachment for a human user's trousers retains a beverage bottle adjacent an exterior surface of a small coin or watch pocket's opening. The tightly confined space within the almost inaccessible pocket defines a retaining sleeve which secures the planar structural integrity of the carrier's thin substrate as it slides vertically and limitedly upwards to sufficiently expose its bottle gripping aperture to surround a bottle's cap stop rim. A preferred embodiment's planar, elongate, flexible polymer substrate body parallels an elongate slot located centeredly near one distal end, and with a bottle gripping aperture located near an uppermost and opposite end. A preferred means for fastening the carrier to an interior area of the pocket is a cloth piercing two part dungaree button which extends through the pocket's exterior cloth and the elongate slot to allow application by a user. The attachment is concealed within the pocket until accessed by a users fingernail, and is removed by laterally squeezing two edges to distort the elongate slot into a more circular shape for removal past the fastening means.

Owner:WAGENKNECHT TERRY LEE +3

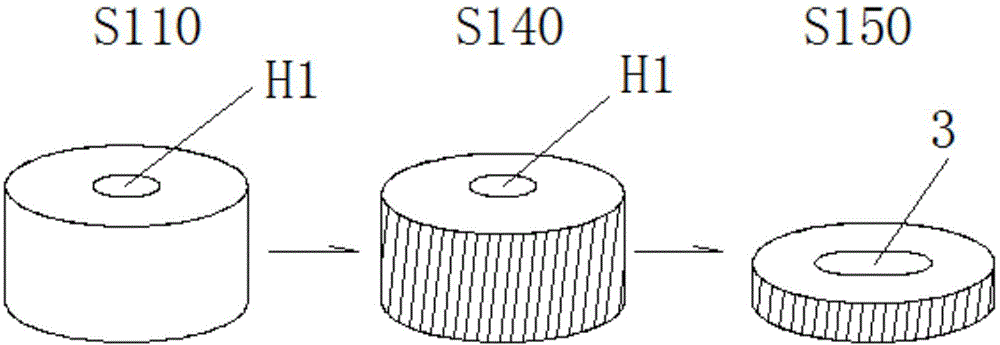

Manufacturing method of spiral bearing frame for electronic parking brake system, produced by lateral extrusion cold forging process

InactiveCN104308458AHigh hardnessHigh strengthForging/hammering/pressing machinesWheelsProduction rateHardness

The invention relates to a manufacturing method of a spiral bearing frame for an electronic parking brake system, produced by a lateral extrusion cold forging process. The method comprises the following steps: manufacturing a bevel gear, namely forming a hollow assembly groove and manufacturing the bevel gear with spiral wheel teeth at the periphery; manufacturing a bearing frame shaft, namely manufacturing the bearing frame shaft with a spline part formed on one side and an assembly staggered layer part corresponding to the hollow assembly groove, formed on the other side; finally, assembling, namely pressing and assembling the bearing frame shaft in the bevel gear, and enabling the assembly staggered layer part of the bearing frame shaft to be positioned in the hollow assembly groove of the bevel gear. According to the method, the spiral bearing frame with high quality in the aspects of cost performance, productivity, durability, hardness and strength can be produced by the cold forging process.

Owner:SERIM T & D

Roadbed reinforcement structure of oblique anchor cable cement earth pile

ActiveCN103290751ALimit lateral extrusion deformationReduced chance of flex crackingRoadwaysRebarSedimentation

The invention discloses a roadbed reinforcement structure of an oblique anchor cable cement earth pile. The roadbed reinforcement structure comprises a first reinforced concrete slab, a second reinforced concrete slab, a plurality of cement earth piles, an upper anchor head and a lower anchor head, wherein the first reinforced concrete slab and the second reinforced concrete slab are positioned on roadbed side slopes; the plurality of cement earth piles with anchor cables are distributed in a staggered way and positioned inside a roadbed body; the upper anchor head and the lower anchor head are positioned at two ends of each cement earth pile. By arranging the first reinforced concrete slab and the second reinforced concrete slab on the roadbed side slopes on two sides, the roadbed reinforcement structure effectively limits lateral extrusion deformation of the roadbed side slopes, and improves the function of controlling the sedimentation of the roadbed body; by applying the cement earth piles to the parts above the toes of the roadbed side slopes, the roadbed reinforcement structure has an obvious reinforcement effect on the upper middle part of the roadbed body, and the disturbance on optical cables at the lower part by construction is small; by applying prestress to steel strands, the bending rigidity of cement earth piles is enhanced, and the probability of bending cracking of the cement earth piles is reduced, so that the roadbed reinforcement structure has high topographical adaptive capacity during construction and has good popularization and application effects.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com