Roadbed reinforcement structure of oblique anchor cable cement earth pile

A technology for cement-soil piles and reinforcement structures, which is applied in the directions of roads, roads, buildings, etc., can solve the problems of difficult construction of rotary jetted piles in rigid bars in mountainous areas, poor control effect of lateral deformation of subgrade bodies, and influence on the safety of optical cables, etc. The effect of convenient transportation and construction, good promotion and application effect, and strong terrain adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the drawings and examples.

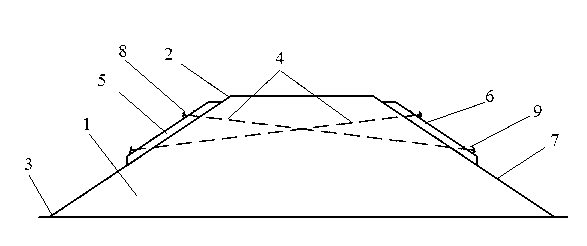

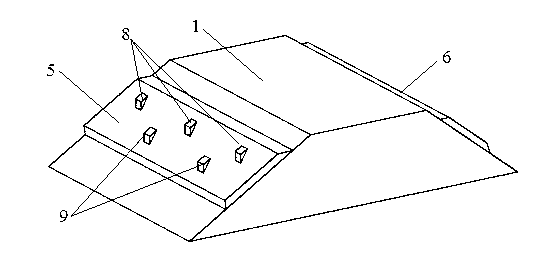

[0026] Such as Figure 1-4 As shown, an oblique anchor cable cement-soil pile subgrade reinforcement structure of the present invention includes a first reinforced concrete slab 5 and a second reinforced concrete slab 6 located on the subgrade slope 7, and several staggered slabs located inside the subgrade body 1 The arranged cement-soil pile 4 with the anchor cable is located at the upper anchor head 8 and the lower anchor head 9 at both ends of the cement-soil pile 4 .

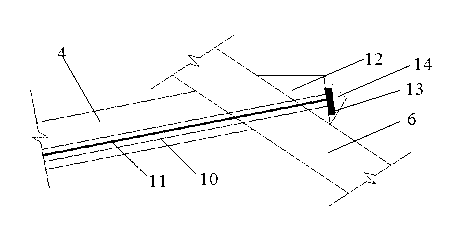

[0027] The lower part of the longitudinal section of the cement-soil pile 4 includes a PVC pipe 10 and a steel strand 11 , and the steel strand 11 is located inside the PVC pipe 10 .

[0028] The upper anchor head 8 and the lower anchor head 9 are respectively located on the first reinforced concrete slab 5 or the second reinforced concrete slab 6 on both sides of the roadbed slope 7, and the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com