Printing and dyeing wastewater recovery equipment

A technology for recycling equipment and printing and dyeing wastewater, applied in the field of dyeing, dyeing and finishing, can solve the problems of increased sewage discharge, waste of water resources, increased production costs of factories, etc., and achieve the effect of recycling, saving water resources, and facilitating manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

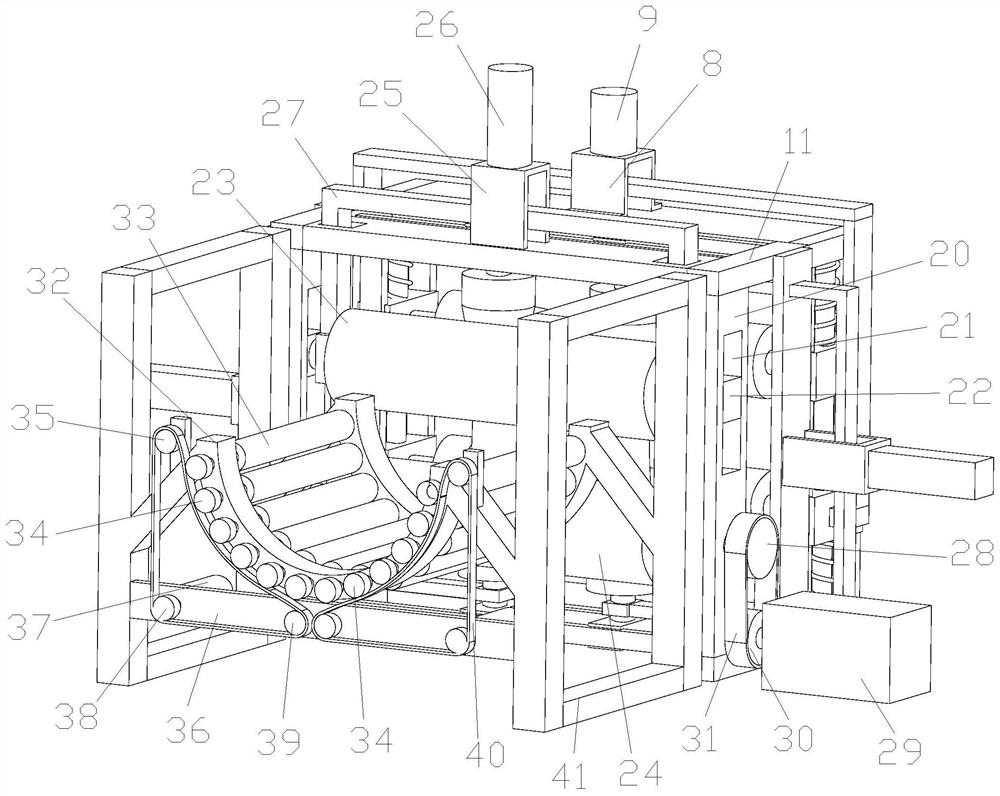

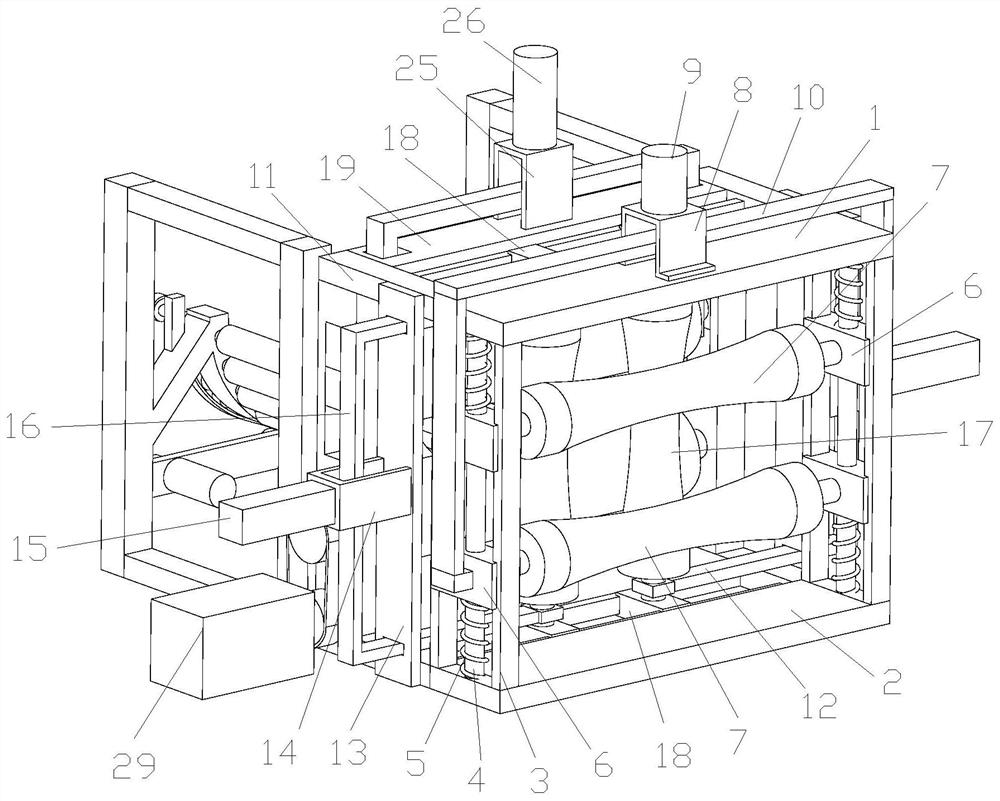

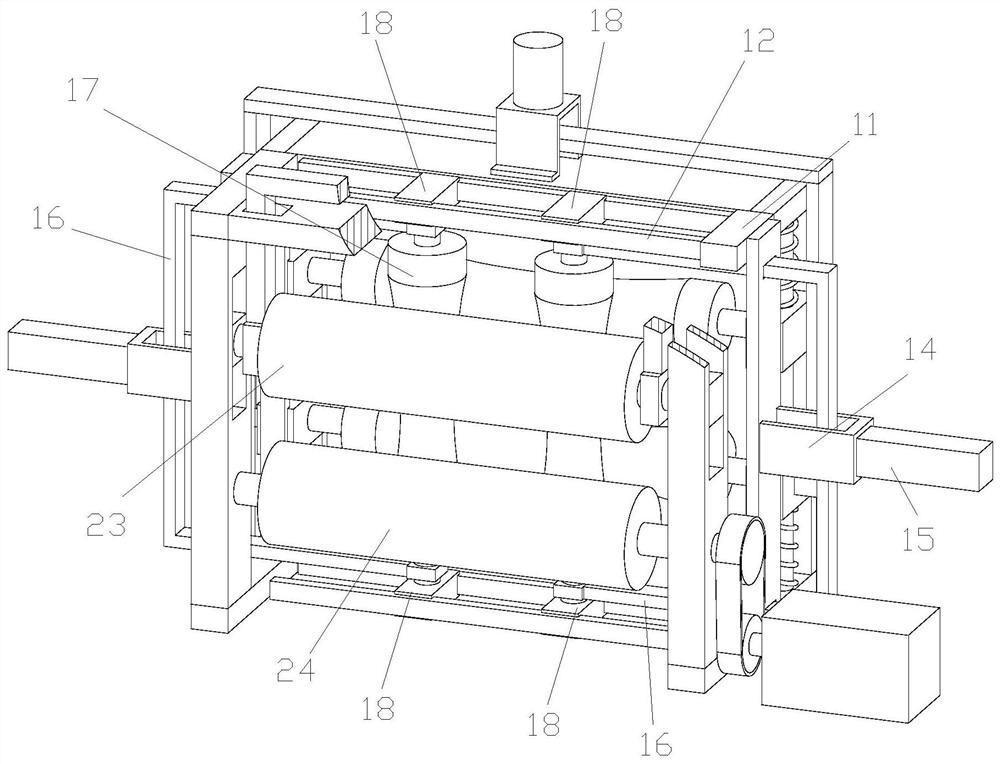

[0016] Embodiment: a kind of printing and dyeing wastewater recovery equipment, such as Figure 1-Figure 3 As shown, it includes a wringing device and a spreading device. The wringing device includes a horizontal wringing mechanism and a vertical wringing mechanism. The horizontal wringing mechanism includes an upper plate 1 and a lower plate 2. The upper plate 1 and the The left and right sides of the lower plate 2 are respectively provided with a set of sliding groups, and the sliding groups are provided with two first slide rails 3 parallel to each other, the upper ends of the first slide rails 3 are fixed on the upper plate 1, and the first The lower end of a slide rail 3 is fixed on the lower plate 2, and a guide rail 4 is vertically arranged between the two first slide rails 3, and a spring 5 is respectively set on the upper and lower ends of the guide rail 4, and the upper and lower ends of the guide rail 4 are each covered with a spring 5. The upper end of the spring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com