Cable marker printing and threading machine

A number tube, threading machine technology, applied in electrical components, circuits, marking conductors/cables, etc., can solve problems such as inability to accurately clamp and thread wires, shaping and fixed-point output, etc., to ensure accuracy and good correction. The effect of shaping and stable conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

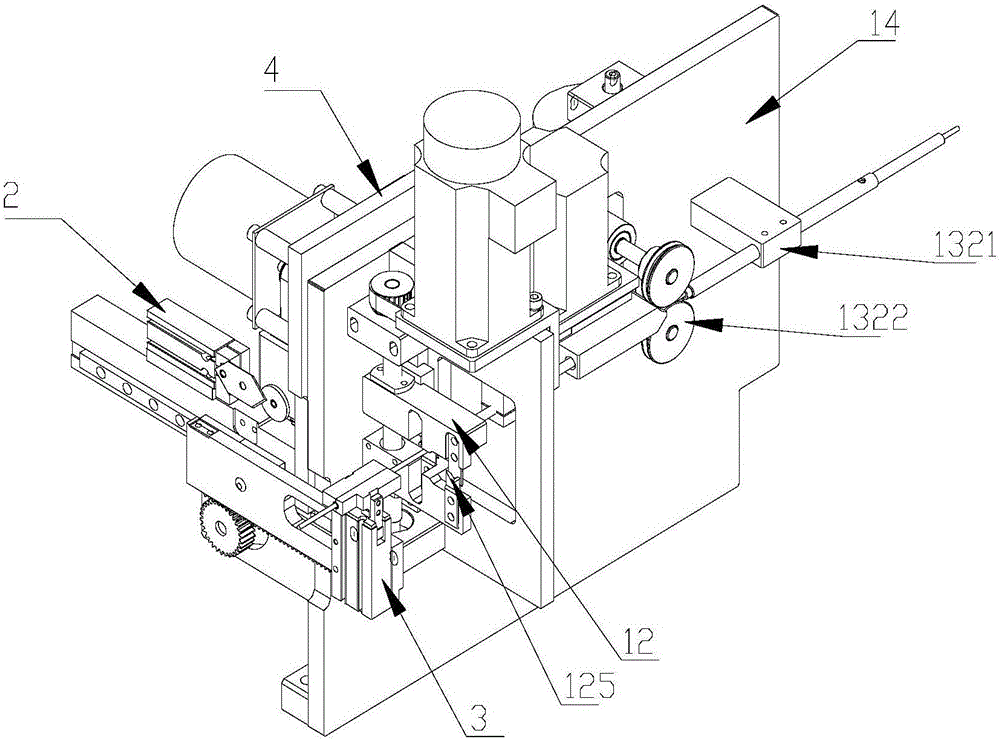

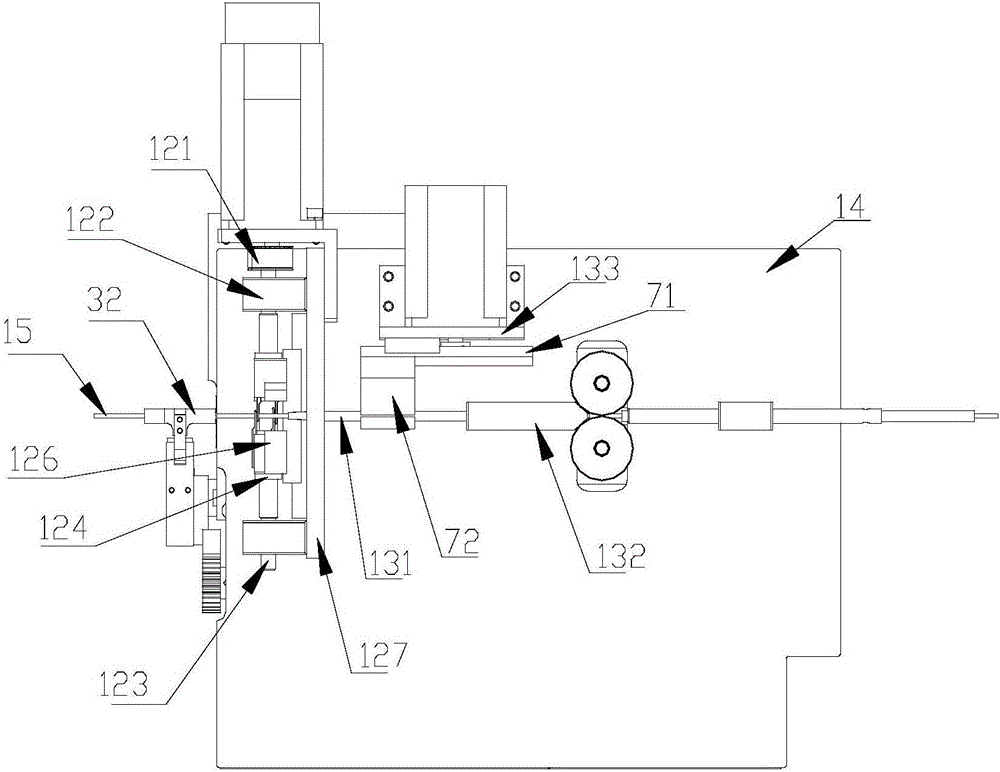

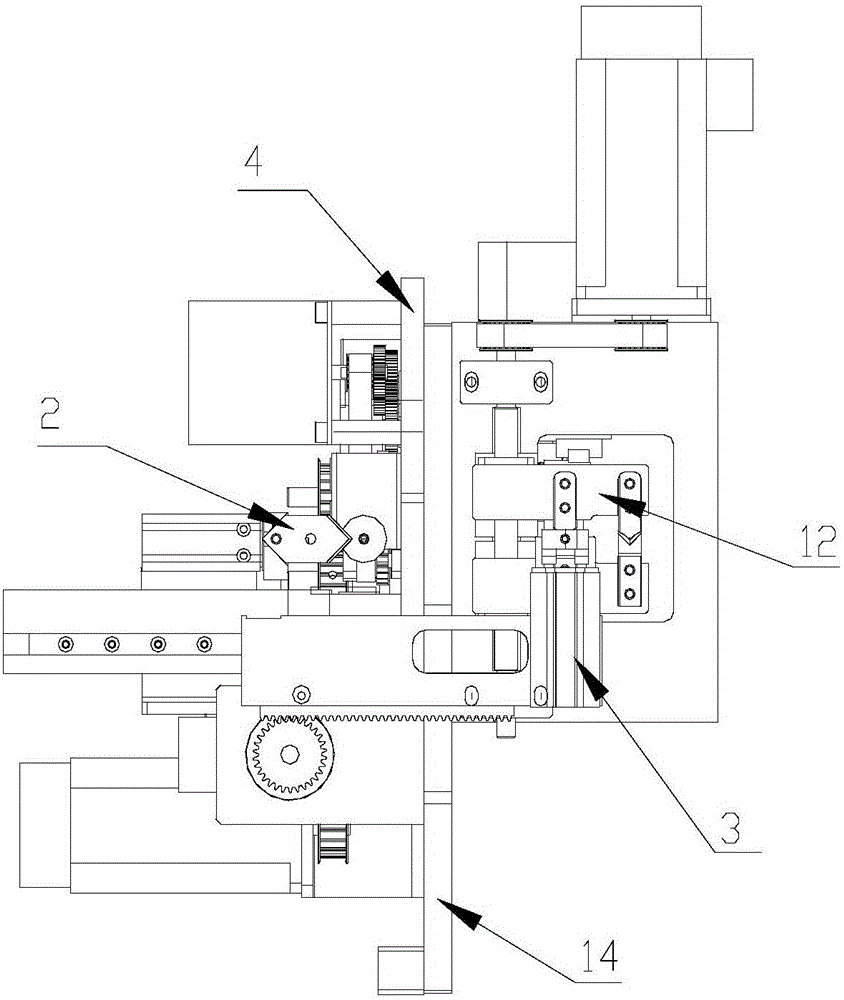

[0052] Such as Figure 1 to 6 As shown, a number tube printing and threading machine includes a printing assembly 1, a gear box assembly 9, a printing motor 10, a number tube cutting assembly 2, a clamping and moving assembly 3, a first mounting plate 14, a printing main panel 4, and a second Mounting plate 6, wire cutting assembly 12 and threading assembly 13. The printing main panel 4 is installed on the first mounting plate 14. The second mounting plate 6 is installed horizontally and vertically at the lower part of the printing main panel 4. The printing main panel 4 is installed with the printing assembly 1 and the gear box assembly 9, and the first mounting plate 14 is installed The threading assembly 13 and the wire cutting assembly 12, the numbering tube cutting assembly 2 and the clamping moving assembly 3 are installed on the second mounting plate 6. The numbering pipe cutting assembly 2 is located at the numbering tube outlet of the clamping moving assembly 3 and the ...

Embodiment 2

[0066] Such as Figure 12 to Figure 17 As shown, a number tube printing and threading machine includes a printing assembly 1, a gear box assembly 9, a printing motor 10, a number tube cutting assembly 2, a clamping and moving assembly 3, a guide pin assembly 8, a first mounting plate 14, and a printing main Panel 4, second mounting plate 6, wire cutting assembly 12 and threading assembly 13. The printing main panel 4 is installed on the first mounting plate 14, the second mounting plate 6 is installed horizontally and vertically at the lower part of the printing main panel 4. The printing main panel 4 is installed with the printing assembly 1 and the gear box assembly 9, and the first mounting plate 14 is installed The threading assembly 13 and the wire cutting assembly 12, the numbering tube cutting assembly 2 and the clamping moving assembly 3 are installed on the second mounting plate 6, and the numbering pipe cutting assembly 2 is located at the numbering tube outlet of the ...

Embodiment 3

[0074] A number tube printing and threading machine, including a printing assembly 1, a gear box assembly 9, a printing motor 10, a number tube cutting assembly 2, a clamping and moving assembly 3, a guide pin assembly 8, a first mounting plate 14, a printing main panel 4. The second mounting plate 6, the wire cutting assembly 12 and the threading assembly 13. The printing main panel 4 is installed on the first mounting plate 14, the second mounting plate 6 is installed horizontally and vertically at the lower part of the printing main panel 4. The printing main panel 4 is installed with the printing assembly 1 and the gear box assembly 9, and the first mounting plate 14 is installed The threading assembly 13 and the wire cutting assembly 12, the numbering tube cutting assembly 2 and the clamping moving assembly 3 are installed on the second mounting plate 6, and the numbering pipe cutting assembly 2 is located at the numbering tube outlet of the clamping moving assembly 3 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com