Method for preparing multi-layer ridge optical waveguide

An optical waveguide and ridge-type technology, which is applied in the field of preparation of multilayer ridge-type optical waveguides, can solve the problems of affecting the optical performance of silicon ridge planar optical waveguides, increasing optical scattering loss, error or offset, and reducing optical scattering loss , solve the rough problem, reduce the effect of the initial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

[0036] The present application discloses a method for preparing a multilayer ridge optical waveguide 10, comprising a silicon ridge 31, which contains a tapered front end portion 50, such as Figure 13 shown.

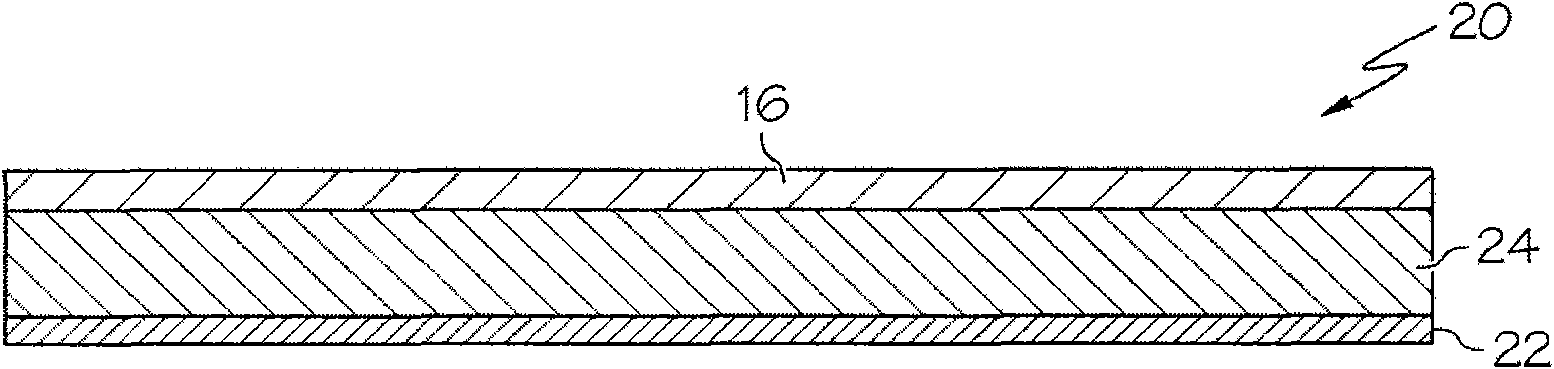

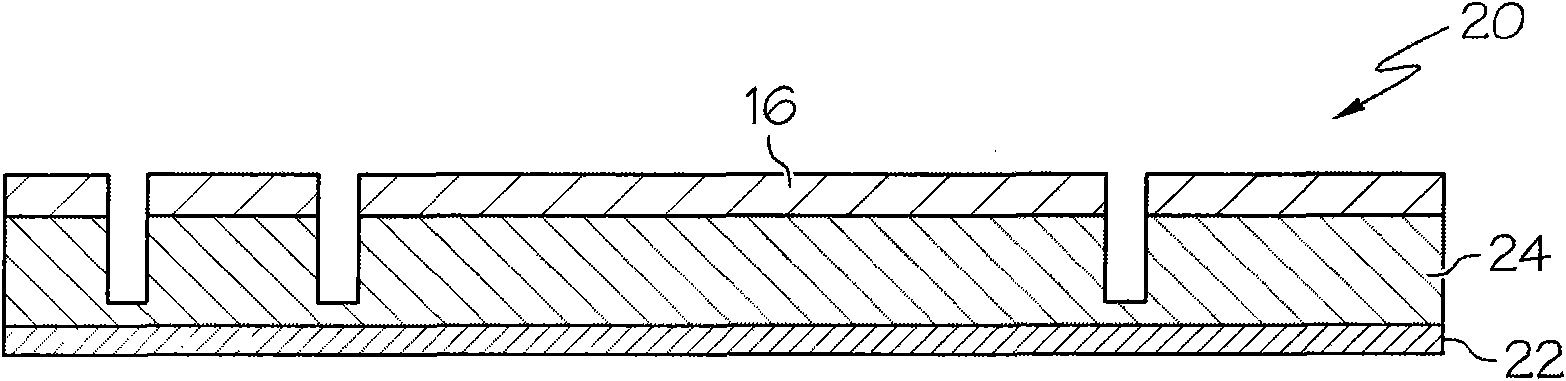

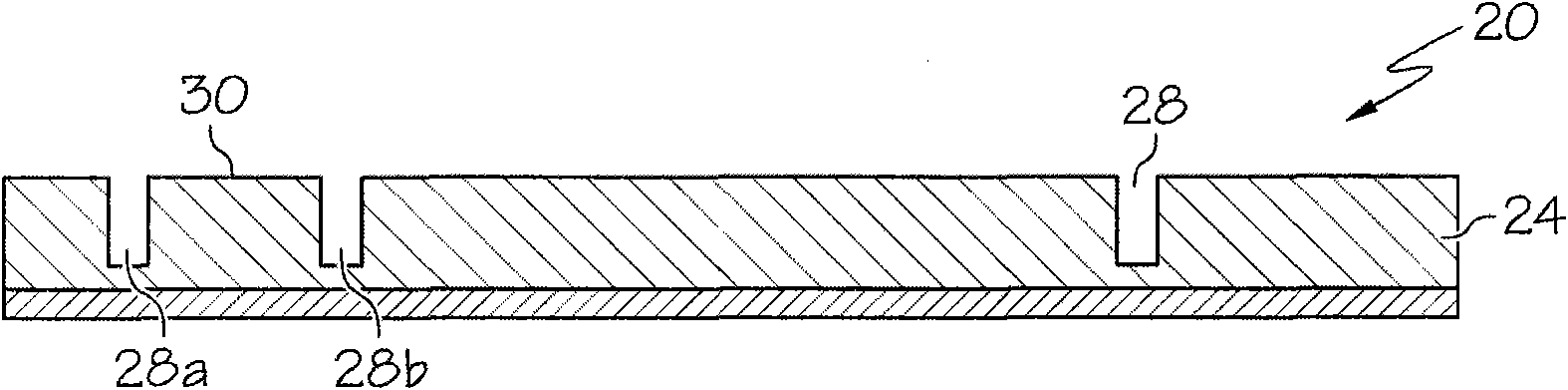

[0037] figure 1 It is a schematic diagram of the silicon wafer 20 used to prepare the optical waveguide 10 . Such as figure 1 As shown, the silicon wafer 20 is an SOI silicon wafer including a buried oxide layer 22 and a top silicon layer 24 .

[0038] Although the following descriptions are all about preparing optical waveguides on SOI silicon wafers, the present invention can also be applied to other substrates, such as silicon-based silicon dioxide, silicon quartz, NiNbO 3 and InP wafers and similar substrates.

[0039] Silicon wafer 20 may be fabricated by any suitable method, such as depositing a top silicon layer 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com