Open mesh leno fabric, bag made from the same, and method of making the leno fabric

A leno fabric, open-ended technology, applied in the direction of leno fabric, leno fabric, fabric, etc., can solve problems such as roughness, damage to perishable agricultural products, and inability to maintain shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

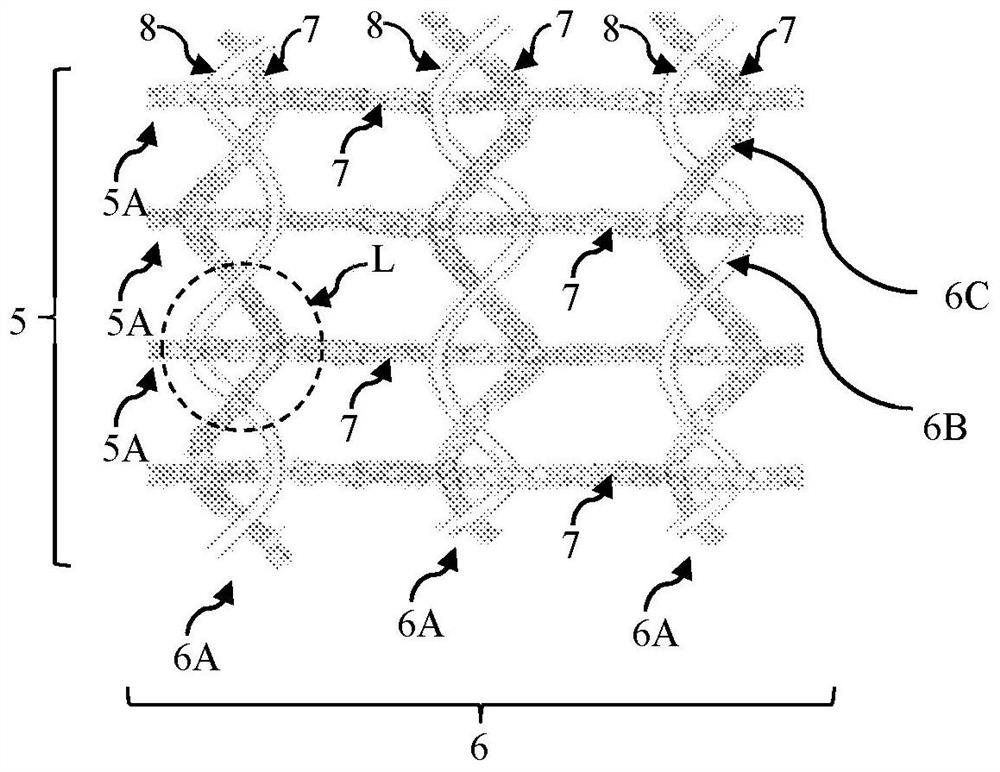

[0027] Woven fabrics generally include a warp structure and a weft structure formed using warp threads and weft threads, respectively. Woven tape fabrics typically include two sets of threads arranged in a warp structure and a weft structure. Yarns are typically made from multiple narrow film strips. The yarns of any one group (warp structure or weft structure) are arranged parallel to each other and interweaved with the yarns of the second group (weft structure or warp structure). The yarns of one set are generally oriented at right angles to the yarns of the other set. For a simple plain weave, the warp threads pass over and under the weft threads in an alternating pattern. Specifically, for a given warp thread to pass over a particular weft thread, an adjacent warp thread will pass under that particular weft thread, thereby locking the weft thread in place. A limitation of plain weave is the lack of porosity or openness.

[0028] A typical leno weave is different from a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com