Digging machine structural element coating method

A coating method and technology for structural parts, which are applied to devices for coating liquid on surfaces, coatings, pre-treatment surfaces, etc., can solve the problems of lack of elasticity of the putty layer, low efficiency of scratching and fine grinding, and easy cracking. Improve scratches and scale, save working time, and solve roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

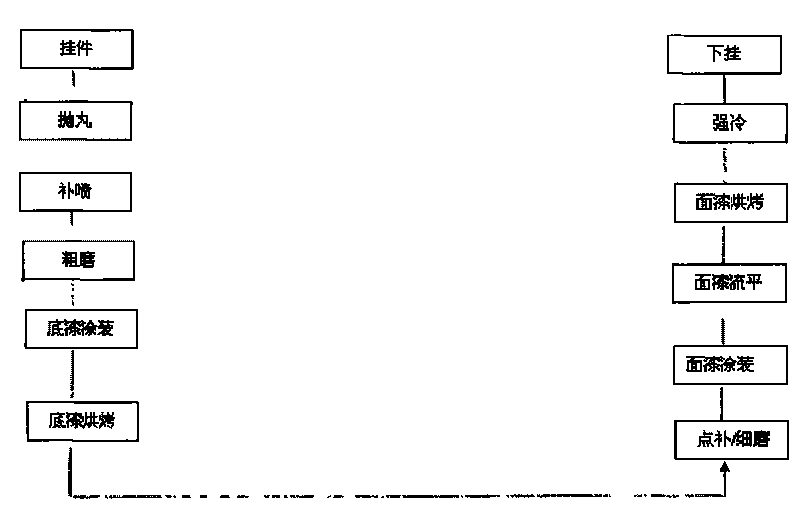

[0015] Such as figure 1 As shown, it is a flow chart of a coating method for excavator structural parts provided by the present invention, and its steps are:

[0016] Step 1. Hang up the structural parts of the excavator and perform shot blasting on them;

[0017] Step 2. Carry out respray treatment on the surface of the excavator structural parts after shot blasting;

[0018] Step 3, roughly grinding the surface of the excavator structural parts that have undergone respraying treatment;

[0019] Step 4, apply the primer, then scrape and bake the primer, and grind it finely after completion;

[0020] Step 5. Apply the topcoat, level off the topcoat and bake it, then force cool it, and finally remove the structural parts of the excavator from the shelf.

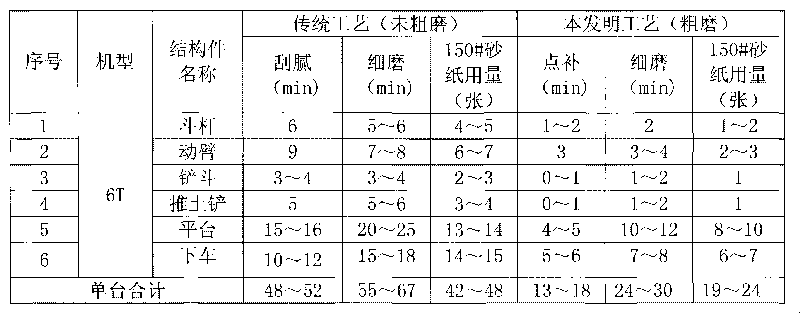

[0021] The parameter contrast before and after implementing a kind of excavator structural part coating method provided by the present invention is shown in the table below:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com